Phenolic S3 Intake spacer?

#1

Inventor

Rennlist Member

Rennlist Member

Thread Starter

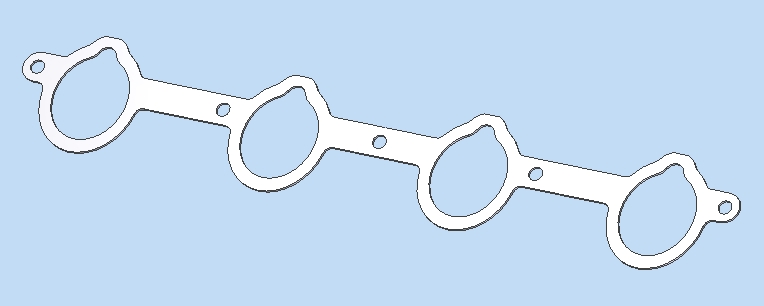

Anyone have access to phenolic and a CNC/waterjet?

Free when made @ work?

Free when made @ work?

Last edited by PorKen; 08-31-2008 at 09:34 PM.

#3

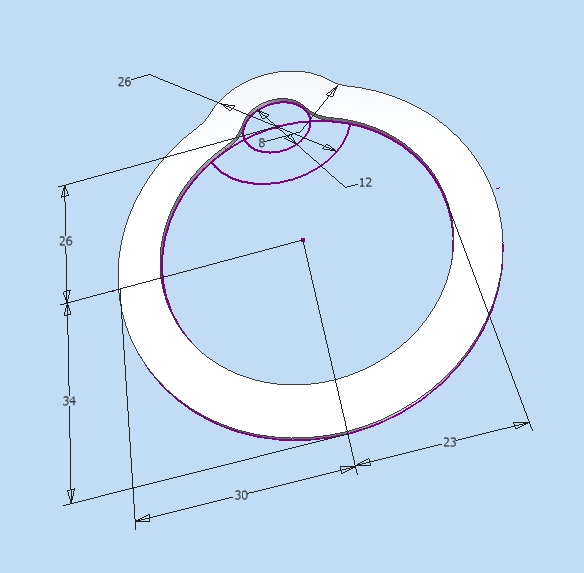

Is that exactly the measurements of the S3 port?

#4

Inventor

Rennlist Member

Rennlist Member

Thread Starter

It's exactly the size of the paper and metal gaskets. The ID is about 1mm larger all round than the head ports. The intake legs vary in ID, some are 2-3mm smaller in places than the gasket and are not oval.

I don't think I gasket matched the intake legs as much as I could have. Next time I have the intake off I will.

I don't think I gasket matched the intake legs as much as I could have. Next time I have the intake off I will.

#6

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I found I can't get over 300 rwhp/tq with airbox/MAF/plenum temps over 90░F. Back in December when I made 312+, it was stuck around 280 until I managed to cool the intake down from >130░F to ambient, 70-80░F. Once the intake cooled, the numbers just kept going up and up.

I'm going to

isolate the intake with a phenolic spacer

use studs for the intake, and isolate the nuts

use a bilge fan to blow cool air on the MAF, and into the valley

cover the top rear of the engine fan so it doesn't blow up over the engine

I'm going to

isolate the intake with a phenolic spacer

use studs for the intake, and isolate the nuts

use a bilge fan to blow cool air on the MAF, and into the valley

cover the top rear of the engine fan so it doesn't blow up over the engine

#7

928 Collector

Rennlist Member

Rennlist Member

cooling the top of the engine while the bottom is hot may not be healthy?

what about radiant heat?

why not use incoming, directed airflow ... via the hood

dig a hole in your hood ...

what about radiant heat?

why not use incoming, directed airflow ... via the hood

dig a hole in your hood ...

Trending Topics

#8

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Is it going to catch a cold?

I don't think you'll be able to make it super cool, anyway.

Hot engine + cold air = good. Back in December, my thermostat was stuck(?), and my temps were near the upper white line (never higher). With a 75C, they were just above the first line, and with the 83C I have now, it's just below the tween of the lines. That's with the (superior) belt driven fan on all.

I already have the rear hood seal out, and that helps somewhat, but it's at city speeds that there's not enough airflow into the V. Cruisin', the internal airflow keeps it cool.

I have a spare hood which I've considered going (931) on, but probably won't...

I don't think you'll be able to make it super cool, anyway.

Hot engine + cold air = good. Back in December, my thermostat was stuck(?), and my temps were near the upper white line (never higher). With a 75C, they were just above the first line, and with the 83C I have now, it's just below the tween of the lines. That's with the (superior) belt driven fan on all.

I already have the rear hood seal out, and that helps somewhat, but it's at city speeds that there's not enough airflow into the V. Cruisin', the internal airflow keeps it cool.

I have a spare hood which I've considered going (931) on, but probably won't...

#9

Burning Brakes

Ken, I should be able to machine your parts. I don't have much time to talk today (swamped at work) but am happy to make them for you on a weekend. Send me an e-mail and we can figure it out if you're interested. I might, might have some material, but you'll probably have to send it to me.

although this probalby isn't what you had in mind with your hood, a picture of what I'm working on to alleviate underhood temps. No testing involved, just fun.

Ben

although this probalby isn't what you had in mind with your hood, a picture of what I'm working on to alleviate underhood temps. No testing involved, just fun.

Ben

#11

Ben - do you have access to a CNC machine as well?

#13

Did you by chance see my "Screw it: Sheet metal intake" thread?

#15

Thanks!