Port and Polish by Comiittee thread (Cool pics throughout)

#181

Rennlist Member

Thread Starter

At the same time, I had the port area by the seats cleaned up as I was starting. He simply finished it. He also cleaned up the transition from the chamber to the seat.

But your previously offered suggestions are still appreciated. If the heads were machined properly, I would not have brought them to the shop and continued to do the porting myself. I am sure others are in the same boat.

#182

Those Honda heads look real nice, any idea on what they flow? I was always jealous of those heads, I asked what those polished chambers are worth in terms of power and they said from what they have learned and been told, it is about 1 hp per cylinder. So not a lot but maybe they are done for marketing reasons?

While I have my guys finalising my 2V heads I had the run a flow test on my 4V head that I have developed, it wasn't a huge effort, I just wanted to get an idea on how things were going because I would also change the intake valves to 6 mm stems for weight saving and better flow still. I tried 2 different sizes as far as the valve head goes. One was 39 mm the other was 41 mm.

Tests were run at 28" of water, we ran them up to 0.700'. The cam I would use would be the same profile as the current GT3, that lift being 500 thou or 12.7 mm. First the exhaust, it flowed 245 cfm at 500 thou. That is not bad but we can improve it a bit maybe another 10 to 20 cfm or so withou too much trouble. The intake was pretty exciting, so much so that the bench operator called the owner to query the result. The bore size used was 101 mm. In fact you would use a 104 mm bore in practice and this would flow better than 101 mm due to the shrouding.

Flow at max cam lift for GT or 10 mm was almost 700 hp!!! It was just a touch under 340 cfm and at 0.500' or 12.7 mm it was over 350 cfm or 722 hp. We discussed ways to improve this, improving the valve seat, throating and different valve seat. He believed that 750 hp would be possible. When the valves were opened up to 700 thou the flow peaked at 770 hp, this confirms the various thoughts we had about getting to 750 hp with the lower lifts.

That would be one killer engine, spin it up to 8000 rpm and there would be much that you couldn't pass down a straight assuming that you could get a gearbox to take that power.

What I deduced from all of this is that Porsche never wanted the 928 to be that

powerful as the changes I have made are minor, but Porsche putting in low lift cams i.e 9 mm for the S4 and small valves 35 mm for the S3 and 37 mm for the S4. It goes to show how tame these engines are and despite this their architecture is still excellent and capable of very big upgrades but they are expensive none the less, I estimated my cost to build the top end would be just under $10K.

Brendan, how did you find that the exhaust valves were too tight from Motorsport? Is that Motorsport SLC? You can hone out the guides, I don't personally do this work but from my knowledge it is the same guide but there is greater clearance in the exhaust side due to the fact that the valve stem is slightly smaller in diameter. It is needed because it obviously gets hotter than the intake.

Greg

While I have my guys finalising my 2V heads I had the run a flow test on my 4V head that I have developed, it wasn't a huge effort, I just wanted to get an idea on how things were going because I would also change the intake valves to 6 mm stems for weight saving and better flow still. I tried 2 different sizes as far as the valve head goes. One was 39 mm the other was 41 mm.

Tests were run at 28" of water, we ran them up to 0.700'. The cam I would use would be the same profile as the current GT3, that lift being 500 thou or 12.7 mm. First the exhaust, it flowed 245 cfm at 500 thou. That is not bad but we can improve it a bit maybe another 10 to 20 cfm or so withou too much trouble. The intake was pretty exciting, so much so that the bench operator called the owner to query the result. The bore size used was 101 mm. In fact you would use a 104 mm bore in practice and this would flow better than 101 mm due to the shrouding.

Flow at max cam lift for GT or 10 mm was almost 700 hp!!! It was just a touch under 340 cfm and at 0.500' or 12.7 mm it was over 350 cfm or 722 hp. We discussed ways to improve this, improving the valve seat, throating and different valve seat. He believed that 750 hp would be possible. When the valves were opened up to 700 thou the flow peaked at 770 hp, this confirms the various thoughts we had about getting to 750 hp with the lower lifts.

That would be one killer engine, spin it up to 8000 rpm and there would be much that you couldn't pass down a straight assuming that you could get a gearbox to take that power.

What I deduced from all of this is that Porsche never wanted the 928 to be that

powerful as the changes I have made are minor, but Porsche putting in low lift cams i.e 9 mm for the S4 and small valves 35 mm for the S3 and 37 mm for the S4. It goes to show how tame these engines are and despite this their architecture is still excellent and capable of very big upgrades but they are expensive none the less, I estimated my cost to build the top end would be just under $10K.

Brendan, how did you find that the exhaust valves were too tight from Motorsport? Is that Motorsport SLC? You can hone out the guides, I don't personally do this work but from my knowledge it is the same guide but there is greater clearance in the exhaust side due to the fact that the valve stem is slightly smaller in diameter. It is needed because it obviously gets hotter than the intake.

Greg

#183

Drifting

Ahhh yes, and here we go...

Shall we play Brendan?

Chapman Racing Heads http://www.chapmanracingheads.com/p_home.asp did the head work on Brendan's heads, the same company we have used for years and years without any problems at all in fact one of the premier headwork companies in the US. It took us quite a while to get any time from them at all with their NASCAR connections, Mopar, Edelbrock and Harley performance work. Even after two years (we do have a 90 day warrenty) of sitting on his shelf we were willing to take them back to Chapman to have any problems corrected on our dime. This was not acceptable to Brendan, he wanted us to refund him blindly based on some ****ty pics that didn't show squadouche. He complained about a brown sludge that was red lubricant when the heads were fresh...our fault. I personally will not take the word of anyone else, Brendan's percieved "professional" or not without seeing the problems for myself. If there were any problems we would have insured they were repaired with no charge to Brendan. Without seeing them ourselves, we had no proof that they were even the same heads.

He made some real choice comments about our workmanship and character even knowing that we didn't do the headwork ourselves. He was full of insults from minute one, even before we refused his request of a blind blackmail/refund.

Brendan was his normal classy self in all the correspondence, all documented and available should anyone want to see some of his true colors. He was a true joy to work with and I should not have given him all the help I have over the years. I have refrained from speaking bad of him while he still likes to get in his little digs on occaision but I am pretty tired of it. You might say that he has brought me down to his level by posting this but if you read the e-mails from him you would know that I am still very restrained in my comments in comparison.

Dave

Shall we play Brendan?

Chapman Racing Heads http://www.chapmanracingheads.com/p_home.asp did the head work on Brendan's heads, the same company we have used for years and years without any problems at all in fact one of the premier headwork companies in the US. It took us quite a while to get any time from them at all with their NASCAR connections, Mopar, Edelbrock and Harley performance work. Even after two years (we do have a 90 day warrenty) of sitting on his shelf we were willing to take them back to Chapman to have any problems corrected on our dime. This was not acceptable to Brendan, he wanted us to refund him blindly based on some ****ty pics that didn't show squadouche. He complained about a brown sludge that was red lubricant when the heads were fresh...our fault. I personally will not take the word of anyone else, Brendan's percieved "professional" or not without seeing the problems for myself. If there were any problems we would have insured they were repaired with no charge to Brendan. Without seeing them ourselves, we had no proof that they were even the same heads.

He made some real choice comments about our workmanship and character even knowing that we didn't do the headwork ourselves. He was full of insults from minute one, even before we refused his request of a blind blackmail/refund.

Brendan was his normal classy self in all the correspondence, all documented and available should anyone want to see some of his true colors. He was a true joy to work with and I should not have given him all the help I have over the years. I have refrained from speaking bad of him while he still likes to get in his little digs on occaision but I am pretty tired of it. You might say that he has brought me down to his level by posting this but if you read the e-mails from him you would know that I am still very restrained in my comments in comparison.

Dave

#184

Rennlist Member

Thread Starter

You have no reading skills or you didn't look at the pics. I have yet to post them. I now have the info from the shop that fixed them as well. Stuff that was more sinister came about from the pre-re-re-rebuild inspection.

I don't understand why this is continually brought up as if its not your fault: It doesn't matter who did them. You took responsibility when you took the heads as the contractor.

This is laughable, but the attitude that you both exuded from the beginning. Mostly you simply said I was wrong, and didn't know what I was talking about.

Let me put in plainly:

The heads, as delivered, even if I could have taken them apart and cleaned them properly of all the machining shavings and brass guides shavings everywhere, and reassembled them, would have not even lasted 1000 miles.

1) The guides were hammered in with no regard to proper procedure of heating the head and cooling the guide. Aluminum obviously transferred to the guide and fell into the port behind the valve. You said I was obviously supposed to clean them before I assembled the engine with them. Then why assemble the heads if I have to take them apart again and clean up monkey-slop work?

Because the guides were hammered in, the tops were mushroomed. This made it difficult to put the seals on for whomever assembled them. But they did anyway, probably knowing of the error - so the seals were ripped and deformed upon installation, with green rubber shavings throughout the heads. The inside lips were also ripped because its obvious no care was used with the valve tip going through the seals.

2) More on the guides - other than the mushrooming issue from hammering them in, they were never properly honed for the valves. The exhaust valves were so tight as to probably be in danger of seizing upon the first heat cycle. They barely moved up and down with hand pressure. To get the valves out, I had to gently sand the keeper grooves of these horrible little knicks and scrapes that seem to have been made from pointy tangs used to assemble the keepers into the grooves. You know, there is a better way to do this.

Moving on,

3) The heads were decked wrong. A separate machinist that we all know and trust found that the heads were cocked at an angle the long way and the short way. The welds that had to be done because of the coolant corrosion had to be REDONE because they were porous.

4) The spring pressures were incorrect to the point of being negligent. The springs were 944S2, you knew this, it was communicated. The open and closed pressures that were allowed by the cut spring seats were so high was to again, probably not have allowed the cams to last very long at all. This is not a few thousands. This is more in the area of 1/8 of an inch off in height on the spring seat.

5) The valve seats. They were done as rough as anyone who as seen the pictures have seen in years. There was noticeable burning on the seats themselves from the stone cutting, and from the new cutting that had to happen (the second time around), it seems that they were not even at the proper angles in the proper areas. The valves were not sealing on most chambers, as the cutting was so uneven and rough, that there would have been serious issues upon run in.

Now, if you think you will be able to publish emails from me to you, which show my aggravation, irritation, and anger about the situation, - and have that somehow stand in place of a substantive argument on why these units were so screwed up, then feel free - but what I said or how I said it makes no difference. What it amounts to is me saying that its appalling the lack of concern with right and wrong your shop produced, as well as being ridiculous the caliber of mistakes made - and you saying that I was mean when I informed you.

Now, to the aforementioned dirt, crap, shavings, etc which you would like to explain away as "I should have cleaned everything" - I am going to post them. The brown stuff was never an issue - its obviously assembly grease. What I take issue with, and what I WAS taking issue with was the aparent lack of any sort of program of proper assembly technique, and cleanliness. Little did I know the machining was even done wrong.

So, following this last thought, I will post the pics. You obviously somehow relish this argument as is made clear in your post, and have again repeated your threat of posting my emails to show how wronged you were by my "attitude". I don't see how that affects my point that the work MOTORSPORTS SLC oversaw, contracted, and is distinctly responsible for is so utterly fvcked up and monkey-sloppy.

Now, for the pics - obviously I cannot show in pictures the ballooning of the guides, improper honing of the guides, a crooked deck job, etc - but some of the pics go to provide a visual account of how the heads were delivered and put them in a clean bag. Indeed, time passed. Quite a bit of time. But the outcome from the shoddy workmanship, overseen by Motorsports SLC, which they are duty bound and responsible for, is time-independent. People can make their own conclusions from the pics. But they don't do the ridiculousness of the state of them justice. You can stand proud, I guess, that I will not get my 1800 back unless I sue you from this far away, nor will you need to take responsibility for this shop that "did the work"

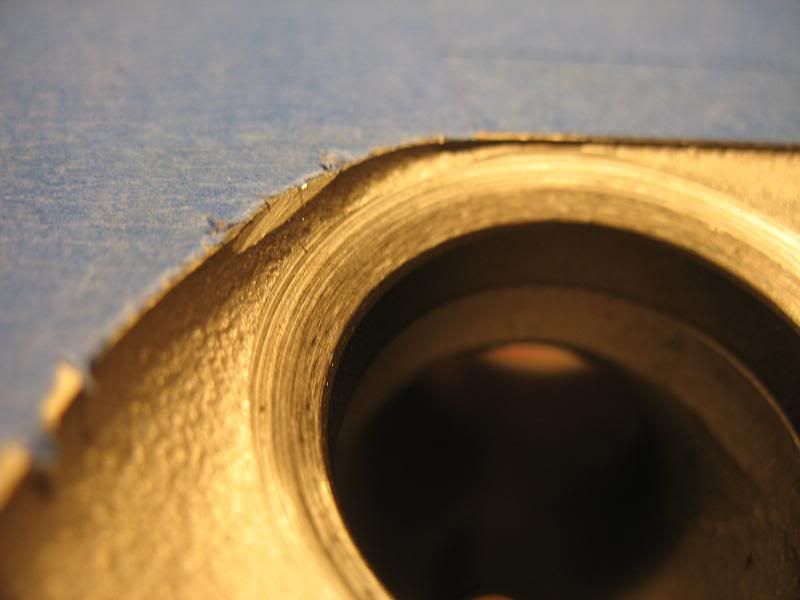

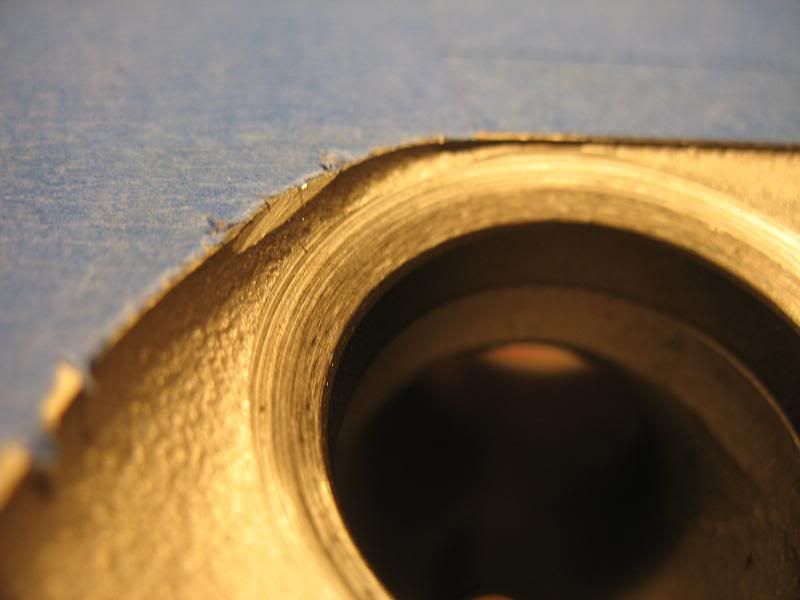

(See the guide shavings)

These were supposed to be "new" exhaust valves. I highly doubt it:

Improper seat cut surface:

I don't understand why this is continually brought up as if its not your fault: It doesn't matter who did them. You took responsibility when you took the heads as the contractor.

"Without seeing them ourselves we had no proof that they were even the same heads" -

Let me put in plainly:

The heads, as delivered, even if I could have taken them apart and cleaned them properly of all the machining shavings and brass guides shavings everywhere, and reassembled them, would have not even lasted 1000 miles.

1) The guides were hammered in with no regard to proper procedure of heating the head and cooling the guide. Aluminum obviously transferred to the guide and fell into the port behind the valve. You said I was obviously supposed to clean them before I assembled the engine with them. Then why assemble the heads if I have to take them apart again and clean up monkey-slop work?

Because the guides were hammered in, the tops were mushroomed. This made it difficult to put the seals on for whomever assembled them. But they did anyway, probably knowing of the error - so the seals were ripped and deformed upon installation, with green rubber shavings throughout the heads. The inside lips were also ripped because its obvious no care was used with the valve tip going through the seals.

2) More on the guides - other than the mushrooming issue from hammering them in, they were never properly honed for the valves. The exhaust valves were so tight as to probably be in danger of seizing upon the first heat cycle. They barely moved up and down with hand pressure. To get the valves out, I had to gently sand the keeper grooves of these horrible little knicks and scrapes that seem to have been made from pointy tangs used to assemble the keepers into the grooves. You know, there is a better way to do this.

Moving on,

3) The heads were decked wrong. A separate machinist that we all know and trust found that the heads were cocked at an angle the long way and the short way. The welds that had to be done because of the coolant corrosion had to be REDONE because they were porous.

4) The spring pressures were incorrect to the point of being negligent. The springs were 944S2, you knew this, it was communicated. The open and closed pressures that were allowed by the cut spring seats were so high was to again, probably not have allowed the cams to last very long at all. This is not a few thousands. This is more in the area of 1/8 of an inch off in height on the spring seat.

5) The valve seats. They were done as rough as anyone who as seen the pictures have seen in years. There was noticeable burning on the seats themselves from the stone cutting, and from the new cutting that had to happen (the second time around), it seems that they were not even at the proper angles in the proper areas. The valves were not sealing on most chambers, as the cutting was so uneven and rough, that there would have been serious issues upon run in.

Now, if you think you will be able to publish emails from me to you, which show my aggravation, irritation, and anger about the situation, - and have that somehow stand in place of a substantive argument on why these units were so screwed up, then feel free - but what I said or how I said it makes no difference. What it amounts to is me saying that its appalling the lack of concern with right and wrong your shop produced, as well as being ridiculous the caliber of mistakes made - and you saying that I was mean when I informed you.

Now, to the aforementioned dirt, crap, shavings, etc which you would like to explain away as "I should have cleaned everything" - I am going to post them. The brown stuff was never an issue - its obviously assembly grease. What I take issue with, and what I WAS taking issue with was the aparent lack of any sort of program of proper assembly technique, and cleanliness. Little did I know the machining was even done wrong.

So, following this last thought, I will post the pics. You obviously somehow relish this argument as is made clear in your post, and have again repeated your threat of posting my emails to show how wronged you were by my "attitude". I don't see how that affects my point that the work MOTORSPORTS SLC oversaw, contracted, and is distinctly responsible for is so utterly fvcked up and monkey-sloppy.

Now, for the pics - obviously I cannot show in pictures the ballooning of the guides, improper honing of the guides, a crooked deck job, etc - but some of the pics go to provide a visual account of how the heads were delivered and put them in a clean bag. Indeed, time passed. Quite a bit of time. But the outcome from the shoddy workmanship, overseen by Motorsports SLC, which they are duty bound and responsible for, is time-independent. People can make their own conclusions from the pics. But they don't do the ridiculousness of the state of them justice. You can stand proud, I guess, that I will not get my 1800 back unless I sue you from this far away, nor will you need to take responsibility for this shop that "did the work"

(See the guide shavings)

These were supposed to be "new" exhaust valves. I highly doubt it:

Improper seat cut surface:

#185

Former Sponsor

Oops. Didn't know that re-opening this thread was going to turn into a battle. Perhaps I'll start a new thread about things regarding porting.

No input from me on the current impending discussion, other than Brendan's pictures are incredible. I can't get pictures anywhere like this! Look at that crap in the keepers and the scratches in the valve seat! That's amazing, for an "internet" picture! What are you using to take these outstanding pictures?

No input from me on the current impending discussion, other than Brendan's pictures are incredible. I can't get pictures anywhere like this! Look at that crap in the keepers and the scratches in the valve seat! That's amazing, for an "internet" picture! What are you using to take these outstanding pictures?

#186

Rennlist Member

Thread Starter

Its a nice Canon powershot 7MP (megapixel) with a good "macro" setting Greg, I think its called that. On a canon, its the icon with a "flower" which means you would need it for real close up shots. It cannot do it at certain aperture settings, but it works most of the time. Only about 250 now for like a 9mp

#187

I would echo what Greg said about the pics, I think will post my little bit on porting on his thread.

In regard to your seats, I have never seen seats cut like that and i make no judgements about who cut them but we went away from cutting seats with a stone decades ago, that is almost Fred Flintstone stuff. We at a minimum replicate the factory seat or use the performance cutter which gives a beautiful radius. This makes a big difference to flow on certain heads but not all, horses for courses so to speak.

We at a minimum replicate the factory seat or use the performance cutter which gives a beautiful radius. This makes a big difference to flow on certain heads but not all, horses for courses so to speak.

I save my other material for the new thread.

Greg

In regard to your seats, I have never seen seats cut like that and i make no judgements about who cut them but we went away from cutting seats with a stone decades ago, that is almost Fred Flintstone stuff.

We at a minimum replicate the factory seat or use the performance cutter which gives a beautiful radius. This makes a big difference to flow on certain heads but not all, horses for courses so to speak.

We at a minimum replicate the factory seat or use the performance cutter which gives a beautiful radius. This makes a big difference to flow on certain heads but not all, horses for courses so to speak.I save my other material for the new thread.

Greg

#188

Drifting

Once again I never said that there were no problems with the heads. We never got a chance to witness them ourselves or make them right if there were. Without being able to take the heads back to Chapman what recourse do we have? We offered multiple times to have any problems repaired on our dime but they would have to come back to Chapman, plain and simple.

I see one actual piece of grit inside the lock, one small sliver of seal material and the rest of what I see is assembly lube and associated crap from sitting around for a couple of years. The seat does not look good to me but you have to realize that we do not "oversee" any of their work. If you think we dismantle every head we have them do and go over it with a fine toothed comb, get real. We give them our specifications and requirements, they do the work. We have never had any problems with Chapmans work and to think that their valve heights were off by 1/8"? We have a couple of dozen sets just like this out there and many built to a rather extreme level and none of them have had any sort of problem or failure. Why would we question your diagnosis? Simply because we have had extensive work done by Chapman with great satisfaction. Yours is the first and still only problem we have heard of. Even knowing this, we did offer multiple times to have everything corrected on our dime if Chapman would not cover it after TWO YEARS!

It has been so long that I cannot remember if these heads got the new exhaust valves or the ones lost by UPS were the ones that did. Remember that? This is the second set we came up with for you after the first set disappeared. I'm sure that is our fault too, using UPS we should have "overseen" their delivery practices and made sure you got your heads.

Your attitude from minute one was ****ty to say the least. If you had approached us with the attitude of "I don't think this is right, what can we do about it" we still would have told you the same thing. Give us the heads and we will take care of everything. As bad as you have treated us we still offered to correct any and all problems on our dime but we simply have no recourse other than taking them back to the shop that did them for us. After two years we would have probably been laughed out of their office but they are the ones that need to see and correct the problem. Associating our work with theirs is just another little dig, Brendan style. Trying to associate Motorsport with "monkey-sloppy" work is quite a stretch there Brendan.

I see one actual piece of grit inside the lock, one small sliver of seal material and the rest of what I see is assembly lube and associated crap from sitting around for a couple of years. The seat does not look good to me but you have to realize that we do not "oversee" any of their work. If you think we dismantle every head we have them do and go over it with a fine toothed comb, get real. We give them our specifications and requirements, they do the work. We have never had any problems with Chapmans work and to think that their valve heights were off by 1/8"? We have a couple of dozen sets just like this out there and many built to a rather extreme level and none of them have had any sort of problem or failure. Why would we question your diagnosis? Simply because we have had extensive work done by Chapman with great satisfaction. Yours is the first and still only problem we have heard of. Even knowing this, we did offer multiple times to have everything corrected on our dime if Chapman would not cover it after TWO YEARS!

It has been so long that I cannot remember if these heads got the new exhaust valves or the ones lost by UPS were the ones that did. Remember that? This is the second set we came up with for you after the first set disappeared. I'm sure that is our fault too, using UPS we should have "overseen" their delivery practices and made sure you got your heads.

Your attitude from minute one was ****ty to say the least. If you had approached us with the attitude of "I don't think this is right, what can we do about it" we still would have told you the same thing. Give us the heads and we will take care of everything. As bad as you have treated us we still offered to correct any and all problems on our dime but we simply have no recourse other than taking them back to the shop that did them for us. After two years we would have probably been laughed out of their office but they are the ones that need to see and correct the problem. Associating our work with theirs is just another little dig, Brendan style. Trying to associate Motorsport with "monkey-sloppy" work is quite a stretch there Brendan.

#189

Rennlist Member

What a stretch. This comes from a guy that takes money and doesn't send the product for a couple of months until we I have to issue a charge back with paypal? Come on man, this is ridiculous. You are an extortionist with regards to these heads. If there were any problems with them, why not just send them back with notes of the problem and have probably the WORLDS leading cylinder head shop take another look at them and "FIX any Mistakes". I don't buy it, Brendan. You have stooped to a new low here and only show your true self. Very disappointed by you. And who was the idiot that told you to install Moly lube on both ends of a fastener like stud. I am very suspect of your expert sources. I can give you my expert source at ARP fastners who makes fasteners all the time and everyday. I don't buy all the crap slinging.

Thanks and reconsider the way you handle this problem.

Thanks and reconsider the way you handle this problem.

#190

Rennlist Member

Thread Starter

It has been so long that I cannot remember if these heads got the new exhaust valves or the ones lost by UPS were the ones that did. Remember that? This is the second set we came up with for you after the first set disappeared. I'm sure that is our fault too, using UPS we should have "overseen" their delivery practices and made sure you got your heads.

I got my heads. I made the claim, and had you sign the form to let me do so. I followed up on everything.

#191

Rennlist Member

Thread Starter

What a stretch. This comes from a guy that takes money and doesn't send the product for a couple of months until we I have to issue a charge back with paypal? Come on man, this is ridiculous. You are an extortionist with regards to these heads. If there were any problems with them, why not just send them back with notes of the problem and have probably the WORLDS leading cylinder head shop take another look at them and "FIX any Mistakes". I don't buy it, Brendan. You have stooped to a new low here and only show your true self. Very disappointed by you. And who was the idiot that told you to install Moly lube on both ends of a fastener like stud. I am very suspect of your expert sources. I can give you my expert source at ARP fastners who makes fasteners all the time and everyday. I don't buy all the crap slinging.

Thanks and reconsider the way you handle this problem.

Thanks and reconsider the way you handle this problem.

I sent a fuel pump late. This has nothing to do with a nearly 2k botched job "That you didn't do". You disagree on how to install an ARP stud. What the hell does this have to do with how this work was done?

You don't want to take responsibility for the work done by a shop you contracted for the work. Thats clear.

Why the hell would I ever send them back? To do what? If you are saying this is a high class shop, then obviously this is their best work. Scary. But their best work.

The work that was done was second rate back street domestic engine production shop stuff. Stuff that happens when you bring in a Ford 302 head for a "R/R". Simply unacceptable.

#192

Rennlist Member

Thread Starter

As bad as you have treated us

we still offered to correct any and all problems on our dime but we simply have no recourse other than taking them back to the shop that did them for us. After two years we would have probably been laughed out of their office but they are the ones that need to see and correct the problem. Associating our work with theirs is just another little dig, Brendan style. Trying to associate Motorsport with "monkey-sloppy" work is quite a stretch there Brendan.

I don't care if you sent the heads to Ron Dennis's F1 palace itself, or the corner drug store with a drill press in the back for the work. I sent them to YOU. YOU are responsible for what happens from the moment they arrive to the moment they leave to come back to me. That's how this stuff works.

Why wouldn't I associate their work with yours? You two are the ones who took my money and made the promises.

And the work was truly monkey-****-sloppy.

#193

Rennlist Member

Thread Starter

There is very little else to really say. I'm really the one that is "disappointed" in this situation. I should have looked to a shop more locally and one that actually does their own work. That way there would be no "buck passing" and finger pointing as to who did what when and who can look at what to fix stuff.

Its unfortunate that a retailer on this board feels its okay to personally attack a customer who has a valid, supportable, documented complaint. Basically, its 1800 dollars down the drain. Thats a chunk of change to just spend, get basically nothing, and then have to spend another 2k to fix the damage done.

The heads have been fixed. The seats were recut, as I said, and they look 1000% better when I saw the work at the shop (I received assembled heads after they were done). The spring heights were documented and corrected. The guides were pin fitted properly with correct clearances. The valves now seal much better with the fluid test as well as the vac test. Before this, Todd actually was helpful enough to redo the welding and then use some special machine to fix the deck cut.

So the heads are on the engine, and I will move on.

I'm going to close the thread, as I basically went off topic in my own thread. I would still like to hear GregB's info on porting, etc. But I think it would be buried here, so hopefully he can open a new thread when he has a free moment.

I'm not closing the thread to have the last word - but to simply diffuse a non-helpful escalation between the parties. Nothing good will come of rehashing, but people who are interested are now aware. Or not.

Its unfortunate that a retailer on this board feels its okay to personally attack a customer who has a valid, supportable, documented complaint. Basically, its 1800 dollars down the drain. Thats a chunk of change to just spend, get basically nothing, and then have to spend another 2k to fix the damage done.

The heads have been fixed. The seats were recut, as I said, and they look 1000% better when I saw the work at the shop (I received assembled heads after they were done). The spring heights were documented and corrected. The guides were pin fitted properly with correct clearances. The valves now seal much better with the fluid test as well as the vac test. Before this, Todd actually was helpful enough to redo the welding and then use some special machine to fix the deck cut.

So the heads are on the engine, and I will move on.

I'm going to close the thread, as I basically went off topic in my own thread. I would still like to hear GregB's info on porting, etc. But I think it would be buried here, so hopefully he can open a new thread when he has a free moment.

I'm not closing the thread to have the last word - but to simply diffuse a non-helpful escalation between the parties. Nothing good will come of rehashing, but people who are interested are now aware. Or not.

#194

Rennlist Member

Thread Starter

Reopening this thread. There are some great sections of info previously posted by Greg Brown back in 2008 that I would like to copy to the end of this thread.

I have another set of heads for the rat motor that I would like to "clean up" with the advice that was given early in this thread.

Where I work there is a guy that is very into the idea that everything should first be done "in a computer" for testing purposes. His idea with the heads was to get a full 3D model and run through the changes that one would normally do to see what they mean for flow.

I am not sure this is the right set to do this on, because I need get the car going, but its an interesting idea.

Anyway....

I have another set of heads for the rat motor that I would like to "clean up" with the advice that was given early in this thread.

Where I work there is a guy that is very into the idea that everything should first be done "in a computer" for testing purposes. His idea with the heads was to get a full 3D model and run through the changes that one would normally do to see what they mean for flow.

I am not sure this is the right set to do this on, because I need get the car going, but its an interesting idea.

Anyway....

Last edited by BC; 02-24-2014 at 03:52 PM.

#195

Rennlist Member

Thread Starter

BC:

On the short wall, you need to be very careful not to lower the floor and reduce the radius of the turn to the seat. However, this radius needs to be as consistant as you can make it. If the air "breaks" off of this wall, at higher velocities, it simply crashes into the air that is trying to go down the center of the port and then slams into the long wall. This kills the airflow numbers. You can hear this happen on a flow bench...you don't even need to look at the flow meters to know that things just turned to crap. You will want to remove and blend the cut from the installation of the valve seats into the floor. You will need to gently cut this back and blend, all the time, trying to improve and make the radius consistant. Lowering the floor and making the radius tighter will help flow, right up to the point where it can't make the bend, so unless you are willing to guess at this, I'd just think a nice radius would do you well.

On the short wall, you need to be very careful not to lower the floor and reduce the radius of the turn to the seat. However, this radius needs to be as consistant as you can make it. If the air "breaks" off of this wall, at higher velocities, it simply crashes into the air that is trying to go down the center of the port and then slams into the long wall. This kills the airflow numbers. You can hear this happen on a flow bench...you don't even need to look at the flow meters to know that things just turned to crap. You will want to remove and blend the cut from the installation of the valve seats into the floor. You will need to gently cut this back and blend, all the time, trying to improve and make the radius consistant. Lowering the floor and making the radius tighter will help flow, right up to the point where it can't make the bend, so unless you are willing to guess at this, I'd just think a nice radius would do you well.

Greg- I am copying your post from.... almost 6 years ago.

I see a very sharp step in the short side radius on the exhaust ports at least. I will take pictures of them on the one head I have disassembled and cleaned.