Water pump failure, may have ruined block!

#1

Rest in Peace

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2006

Location: Bird lover in Sharpsburg

Posts: 9,903

Likes: 0

Received 2 Likes

on

2 Posts

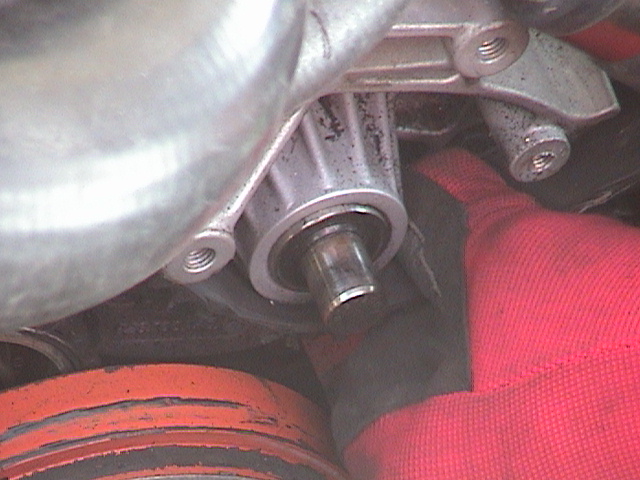

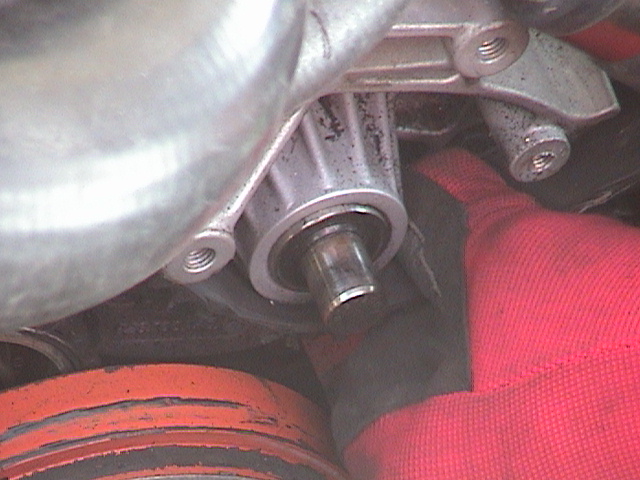

A bad day for the owner of this 928, me.

How far can this go before you have to replace the block?

When I got the car I knew very little about 928's, so I called my regular parts folks and they sold me a Laso pump.

Less than 5 thousand miles on this pump, bearings are fine but the impeller has moved back on the shaft into the block.

Does any body know if this can be saved?

Will it run hot now if I put a good pump on it?

You can see where the metal impeller has rusted against the block, this really sucks.

I am not having a very good day, I think I is time for a beer and some goodies..

How far can this go before you have to replace the block?

When I got the car I knew very little about 928's, so I called my regular parts folks and they sold me a Laso pump.

Less than 5 thousand miles on this pump, bearings are fine but the impeller has moved back on the shaft into the block.

Does any body know if this can be saved?

Will it run hot now if I put a good pump on it?

You can see where the metal impeller has rusted against the block, this really sucks.

I am not having a very good day, I think I is time for a beer and some goodies..

#2

Captain Obvious

Super User

Super User

I don’t think it will matter one bit. The pump is spinning so fast that even with the increased clearance it will pump just fine. But if for some strange reason the gap is extremely large and the pump can not push enough coolant, you can always mill a little off the pump to close the gap.

#6

Supercharged

Rennlist Member

Rennlist Member

Join Date: May 2002

Location: Back in Michigan - Full time!

Posts: 18,925

Likes: 0

Received 60 Likes

on

34 Posts

This is precisely why I am not replacing my pump. Several of the rebuilt pumps have failed in these strange unpredictable ways. IMHO as long as you're doing the work, if the pump seems fine, leave it be. If you're paying to have teh TB replaced, then it's a no brainer.

-Andrew

-Andrew

#7

Three Wheelin'

It's still probably a better fit than alot of domestic crap, a pump can still be efficient even with a gap. I bet the flow loss would be a trace amount.

Put down those goodies!

Put down those goodies!

Trending Topics

#8

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Try test-fitting the new pump on there with the correct gasket, and use some little ***** of modeling clay on the block-to-impellor face to determine the installed clearance between the impellor and the block. I don't know what is considered excessive, maybe somebody with a good block can give you the new dimensions. One thing you can do is compare the locations of the two inpellors sitting on the bench. The old one obviously is zero clearance on the block, while the new one should be correctly placed with some clearance.

I guess if it happened to be mine, I'd measure three times, and maybe consider running the pump with a film of hylomar or gasket maker instead of the gasket if the clearance with the correct pump is excessive. Remember that there's an angle to consider there. A little math will help you convert impellor clearance to gasket thickness-- a little wear by the impellor may show up as a big clearance number when you measure with the clay.

Impellor clearance directly affects the performance of the pump. This is likely not a huge issue since there are variances in manufacturing both the block and the pump to consider. You'll know by mid-summer I guess.

I guess if it happened to be mine, I'd measure three times, and maybe consider running the pump with a film of hylomar or gasket maker instead of the gasket if the clearance with the correct pump is excessive. Remember that there's an angle to consider there. A little math will help you convert impellor clearance to gasket thickness-- a little wear by the impellor may show up as a big clearance number when you measure with the clay.

Impellor clearance directly affects the performance of the pump. This is likely not a huge issue since there are variances in manufacturing both the block and the pump to consider. You'll know by mid-summer I guess.

#9

Rest in Peace

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2006

Location: Bird lover in Sharpsburg

Posts: 9,903

Likes: 0

Received 2 Likes

on

2 Posts

I had all ready called home and told them to have cold beer and Percodan waiting for me, I guess it will just be beer tonight then.

#10

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

It looks worse than it is. I do not think that much material was worn away. It should work fine. The water pump spins at about crank speed that style pump works with pretty loose clearances ! It is submerged so it does not have to pump air / suck the water up into it.

#11

Rest in Peace

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2006

Location: Bird lover in Sharpsburg

Posts: 9,903

Likes: 0

Received 2 Likes

on

2 Posts

It looks worse than it is. I do not think that much material was worn away. It should work fine. The water pump spins at about crank speed that style pump works with pretty loose clearances ! It is submerged so it does not have to pump air / suck the water up into it.

I am going to call you in just a bit.

#12

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Just a bit of support for what others have said - Heinrich bought a car that we found to have just this problem when we tore into it. We knew there was a problem with the pump being partially seized. We found the impeller had worked its way back off the shaft and milled the block, as you show. It worked fine with a new pump.

#13

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

This is a similar failure mode to what happened with John Veninger's track car at Summit Point this year.

Did the impeller back off of the shaft into the motor or did the impeller and shaft come back toward the block away from the pulley?

Here's what happened to John (pulley walked off the front):

Did the impeller back off of the shaft into the motor or did the impeller and shaft come back toward the block away from the pulley?

Here's what happened to John (pulley walked off the front):

#14

Nordschleife Master

I disagree with andrew

The original engine from my car failed after the water pump seized up, causing the belt to overheat and snap. This was because the pump was not replaced when the timing belt was last changed.

Ask Jim B, he said something like 0.5% of their pumps come back as faulty. I cant argue with that.

The original engine from my car failed after the water pump seized up, causing the belt to overheat and snap. This was because the pump was not replaced when the timing belt was last changed.

Ask Jim B, he said something like 0.5% of their pumps come back as faulty. I cant argue with that.

#15

Rennlist Member

Hey, i have recent experience here. Scots did EXACTLY what yours did. messed up the block something fierce!! didnt make any noise, just was leaking so we narrowed it down to the pump and thats what we found when we pulled it. just bolted up a new pump and everything was just fine. as was mentioned, the gap is for efficiency, but there is a lot of water being moved ,and this probably only effects flow by a small amount. (maybe more at idle speeds)

There was some talk of JBwelding the rough areas and then taking the old pump and sanding it down with a drill attached to the pump or something. I dont think you need to do that.

mk

There was some talk of JBwelding the rough areas and then taking the old pump and sanding it down with a drill attached to the pump or something. I dont think you need to do that.

mk