How to drill a 5L crank like a chevy?

#17

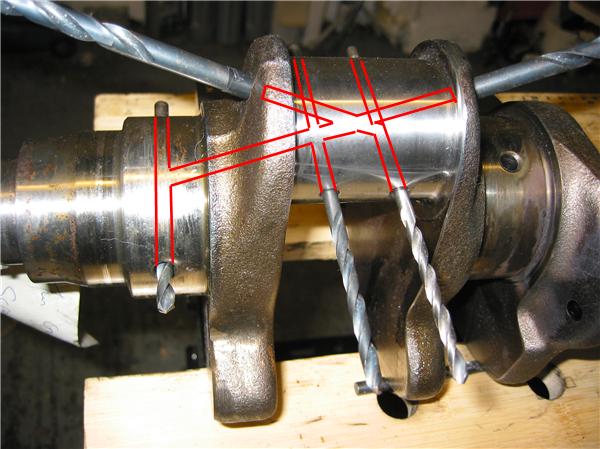

In this thread, we see a crank that was "drilled" but they added another hole to the rod journal. I don't know why.

https://rennlist.com/forums/showthre...crank+drilling

https://rennlist.com/forums/showthre...crank+drilling

#18

[QUOTE=atb;4612570]Those access points that have been filled are on both sides of the throw of each rod journal?[/QUOTE

Correct. Each one, each side, drilled down diagonally into where the oil hole/shaft is on the mains.

Correct. Each one, each side, drilled down diagonally into where the oil hole/shaft is on the mains.

#19

Rennlist Member

Thread Starter

So basically now the rod journal is receiving pressurized oil from the mains fore and aft of it, where the stock oiling has one main feeding one rod journal? Is this correct?

Last edited by atb; 09-26-2007 at 03:31 PM.

#20

#21

Addict

Rennlist Member

Rennlist Member

Brendan, your setup looks like stock Porsche thing on quick clance. AFAIK drilled like Chevy means one direct drilling from main to rod bearing. This is Moldex crank where center thrust bearing main feeds rods #6 and #3. Drill bits show direct drillings for #1 and #5.

#22

My stroker crank is drilled like that as well. But with a 5L crank, those journals are not hollow, so it is drilled from the side, which does the same connection. The journal holes are in a different place.

#23

In Your Face, Ace

Rennlist Member

Rennlist Member

I just got mine back from Taylor and it was a little under $700 for the service and shipping. I'm actually leaving in a few minutes to head to UPS and ship it to the shop doing the work in New Orleans. Picking the track car up on October 22 and heading to Rennsport Reunion.

I also had the crank drilled on the turbo engine

I'm thinking between the cross drilling, scraper set up, oil pan baffle from 928 Motorsports in addition to the Accusump, that the motor should oil well and be saved from starvation. Also including some crank case breathing to help with the oil foaming up.

I also had the crank drilled on the turbo engine

I'm thinking between the cross drilling, scraper set up, oil pan baffle from 928 Motorsports in addition to the Accusump, that the motor should oil well and be saved from starvation. Also including some crank case breathing to help with the oil foaming up.

#25

In Your Face, Ace

Rennlist Member

Rennlist Member

3 weeks +/- a day or two.

The crank WOULD have arrived at the shop last Friday had they shipped it to where I requested. They made an error and shipped it to my home in Georgia. They made good on their mistake and I am now sending it on their $$$$$ to the shop. The week of time we lost hurts, however we should be ok with having 3 weeks before the 22nd..

FYI~ crated weight is 67lbs

The crank WOULD have arrived at the shop last Friday had they shipped it to where I requested. They made an error and shipped it to my home in Georgia. They made good on their mistake and I am now sending it on their $$$$$ to the shop. The week of time we lost hurts, however we should be ok with having 3 weeks before the 22nd..

FYI~ crated weight is 67lbs

#26

Addict

Rennlist Member

Rennlist Member

One idea why oiling is problem in Porsche cranks is that when mains are drilled straight through oil which is meant for rod bearings is actually diverted out from other end of straight through drilling. Fix for this which is probably heading into one local engine is to have four lower halfs of main bearings grooved like stock upper half are grooved. Our theory is that this will prevent oil escaping from lower half when oil pressure is fed into crank main drilling from both ends simultaneusly instead of just end which is rotating on upper half bearing. There shouldn't be any bad side effects as 360 grooved bearings are commonly used on drilled like Chevy cranks. If this works it would provide cheap fix for rod bearing oiling problem. If it doesn't work trial cost isn't too bad.

#27

Addict

Rennlist Member

Rennlist Member

The journal holes are in a different place.

So Porsche opted for easy way which works on low revs but gets very problematic on 6k rpm. Drilling more holes to this structure doesn't necessarily fix anything. It might help on going against centrifucal force part of the problem but doesn't help on any other issue involved in this complex problem.

#28

OK - that's a good pic that explains a lot.

However Brendan I'm very curious about your plugged holes in the sides, can you find out what A) material they are of and B) that they are firmly welded in and not merely *****-punched in?

#29

So Porsche opted for easy way which works on low revs but gets very problematic on 6k rpm. Drilling more holes to this structure doesn't necessarily fix anything. It might help on going against centrifucal force part of the problem but doesn't help on any other issue involved in this complex problem.

Well, I guess we'll see. I will have a 7k shift point/rev limit on this engine, and hopefully everything will stay together. This, plus a accusump, and eventually a drysump will make sure it does.