Rebuilding 1988 manual transaxle after wasting $2710 at local shop

#61

Instructor

Thread Starter

Join Date: Nov 2006

Location: Fort Lauderdale, FL USA

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

See attached pic:

Interesting notes on the lapping procedure.

The procedure in "c" makes no sense to me at all.

I think it is a poor translation from the original Japanese.

argh....

Bruce Toski

Interesting notes on the lapping procedure.

The procedure in "c" makes no sense to me at all.

I think it is a poor translation from the original Japanese.

argh....

Bruce Toski

#62

Instructor

Thread Starter

Join Date: Nov 2006

Location: Fort Lauderdale, FL USA

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

The factory manual for my 1972 Audi says they used the Porsche type synchros. No mention there of lapping in that type of synchro.

On the other hand the factory manual for my 1974 Mazda Rotary Engine Pickup does mention lapping the synchros. The synchros appear to be the same design as that used in the 88 928.

The REPU procedure:

"2. Inspect the synchronizer for wear. Standard clearance between the side faces of the synchronizer and the gear is 1.5mm or .059" "

The 928 manual states the standard gap is .9 to 1.5mm and states that the wear limit is .6 to .7mm

"3. Inspect the contact between the inner surface of the synchronizer ring and the cone surface of the gear. To inspect, apply a thin coat of prussian blue on the cone surface of the gear and fit it into the ring. If the contact pattern is poor, correct this by applying compound and lapping the surfaces together.

No mention of a molybdenum coating on the Mazda synchros and no mention of the one way action talked about in the Camry manual.

argh....

BT

On the other hand the factory manual for my 1974 Mazda Rotary Engine Pickup does mention lapping the synchros. The synchros appear to be the same design as that used in the 88 928.

The REPU procedure:

"2. Inspect the synchronizer for wear. Standard clearance between the side faces of the synchronizer and the gear is 1.5mm or .059" "

The 928 manual states the standard gap is .9 to 1.5mm and states that the wear limit is .6 to .7mm

"3. Inspect the contact between the inner surface of the synchronizer ring and the cone surface of the gear. To inspect, apply a thin coat of prussian blue on the cone surface of the gear and fit it into the ring. If the contact pattern is poor, correct this by applying compound and lapping the surfaces together.

No mention of a molybdenum coating on the Mazda synchros and no mention of the one way action talked about in the Camry manual.

argh....

BT

#63

Instructor

Thread Starter

Join Date: Nov 2006

Location: Fort Lauderdale, FL USA

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Bill Ball

It's easier to work the exhaust slip joints apart by twisting the rear exhaust section clockwise then counter clockwise 4 or 5 times. They will work themselves off. Same when putting them back together.

Did not work for me. Rawhide mallet worked well in an instant.

BT

#64

Instructor

Thread Starter

Join Date: Nov 2006

Location: Fort Lauderdale, FL USA

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

http://www.pmgsinter.com/downloads/m...0_krehlrau.pdf

plasma welding combined with molybdenum coatings etc...

Looks like the molybdenum coating is far harder and more wear resistant than a simple brass or steel synchro. I might need to find some diamond dust in order to do the lapping !?

Bruce Toski

plasma welding combined with molybdenum coatings etc...

Looks like the molybdenum coating is far harder and more wear resistant than a simple brass or steel synchro. I might need to find some diamond dust in order to do the lapping !?

Bruce Toski

#65

Instructor

Thread Starter

Join Date: Nov 2006

Location: Fort Lauderdale, FL USA

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

Would it be logical and correct to assume that all shift forks, when properly adjusted and locked down, would be "centered" between their respective synchro sets ?

To me this would seem to be one of the main objectives during setup but I am not finding any mention of it in the factory manual or the training doc I mentioned earlier.

Oh, BTW, if anyone wants a copy of the training doc just shoot me an email.

Bruce Toski

To me this would seem to be one of the main objectives during setup but I am not finding any mention of it in the factory manual or the training doc I mentioned earlier.

Oh, BTW, if anyone wants a copy of the training doc just shoot me an email.

Bruce Toski

#66

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Originally Posted by 72Audi

I tried that many times and pulled with all my mighty mouse might.

Did not work for me. Rawhide mallet worked well in an instant.

BT

Did not work for me. Rawhide mallet worked well in an instant.

BT

Sorry, this is so completely incidental to what you are doing. Eh, get on with the main task at hand. Good luck with the rebuild!

#67

Addict

Rennlist Member

Rennlist Member

There are few different combinations of '85-95 syncro rings IIRR. '85-86 all six are same part. '87+ have different reverse, 1st-3rd and 4th-5th rings. These are not Porsche patented syncros. Those where used in '78-84 MY gearboxes.

These are much better Borg Warner patent design. I know at least few gearboxes where any lapping were not done and syncros worked fine. I thing ring fitting to gear too well is not ever desired as some amount of oiling between syncro and gear is integral part of the design.

I have set forks to be in center between two gears on 2-3 and 4-5 sets where it is somewhat adjustable. So far have only experience of one '85 MY and it worked fine. Currenty working on '88 where 4-5 needed to be set again as it had to be moved out of the way to replace broken side to side spring. The one which almost always breaks and seems to be hard to get nowdays.

These are much better Borg Warner patent design. I know at least few gearboxes where any lapping were not done and syncros worked fine. I thing ring fitting to gear too well is not ever desired as some amount of oiling between syncro and gear is integral part of the design.

I have set forks to be in center between two gears on 2-3 and 4-5 sets where it is somewhat adjustable. So far have only experience of one '85 MY and it worked fine. Currenty working on '88 where 4-5 needed to be set again as it had to be moved out of the way to replace broken side to side spring. The one which almost always breaks and seems to be hard to get nowdays.

#68

Former Vendor

The moly coating comes off at an alarming rate when you try to lap the syncro into the hub. You will need to use a really very fine compound (not the "fine" valve grinding compound at the auto supply store) and be super carefull about pressure and duration....good luck with this. You might want to practice with a used piece, as the stock syncros are getting really expensive. The syncros break in rather quickly when the correct gearoil is used.....unless the hubs were really bad. Like I said, super slippery gear oils are not desirable for break-in.

This looks like it is going to be a bunch of fun.....I think I'll sit back and watch from here on out.

gb

This looks like it is going to be a bunch of fun.....I think I'll sit back and watch from here on out.

gb

#69

Addict

Rennlist Member

Rennlist Member

Originally Posted by 72Audi

All manual transmission models / years have a spigot bearing in the rear of the crank right ?

Should be easy to change once clutch is out, correct ?

Unfortunately ..... for my 88 model, the manual says that the exhaust manifolds have to be unbolted. For real? This is a definite bummer on a clutch job that in previous years appears to be very easy !

BT

Should be easy to change once clutch is out, correct ?

Unfortunately ..... for my 88 model, the manual says that the exhaust manifolds have to be unbolted. For real? This is a definite bummer on a clutch job that in previous years appears to be very easy !

BT

Don't think I would be wrong in saying that apart from clutch hydraulics (which have there own set of 928 specific symptoms) impending failure of the spigot bearing is probably the most likely cause of hard shifting. Change this and check the hydraulic actuation - ensure it disengages fully before suspecting the gearbox.

For what it's worth my 90GT does not shift desperately well 1-2 or 2-3 but 3-4 and 4-5 is fine as is neutral to reverse even when going forwards at up to 10 mph !!!!!!! - some new shifter bushings required.

This doesn't help you much I know - I think you probably need to do enough dissasembly to prove that the local shop just cleaned the outside of the box and sprayed it silver, then charged you $a lot for the privilege. You should replace the preload spring. Then ebfore you put it back together change the spigot bearing and check for proper clutch operation. After that probably button it all back up and see what (hopefully) if anything has changed.

#70

Instructor

Thread Starter

Join Date: Nov 2006

Location: Fort Lauderdale, FL USA

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

Thanks guy for all the responses.

I called Borg Warner on the synchro issue but ..... guess what?

They sold their manual tranmission facilities to Tremec in Mexico a few years ago. Great. Called their office in Ohio and left a message and sent an email.

The synchro issue is intriguing.

Below are parts and tool that I think I will need.

Checking here first in case anyone has spares they don't need.

Next I will email 928 Specialists. The local dealer Champion Porsche said they won't deliver to me anymore ..... so what is the point of dealing with them ?

They don't want my business .... I take it to another dealer.

+++++++++++++++++++++++++++++

928 102 111 02 spigot bearing, rear of crankshaft

928 424 017 05 bearing block just forward of shifter

or order just the bushings?

928 920 001 3

928 920 951 2

928 424 182 03 sound absorbing chamber around shifter

928 424 181 03 sleeve, rubber seal for shifter

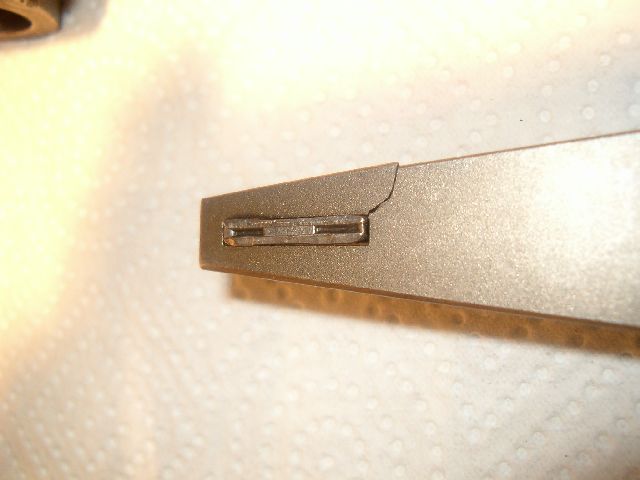

928 552 283 03 ABS mounting plate for shifter MT (pic attached)

928 552 017 00 frame for sound absorbing chamber ? needed ?

928 331 520 01, 02, 03, 04 washers, special, go under the tranny mounts

928 300 901 01 gasket set for transaxle overhaul

928 303 287 01 spring for reverse gear lockout

TOOLS:

9149 Plate to mount transaxle to engine stand, pg .34-214g

9155 Lever to help make shifts out of car, pg 34-217

9144 Bracket to turn bearing assy for drive pinion, pg 34-214h

VW 771 Slide puller, pg 34-214h

9140 Extractor, pg 34-214h

9148 Puller to remove input shaft?, pg 34-209

9321 Centering pins for drive pinion installation pg 34-214j

Thanks in advance,

Bruce Toski

I called Borg Warner on the synchro issue but ..... guess what?

They sold their manual tranmission facilities to Tremec in Mexico a few years ago. Great. Called their office in Ohio and left a message and sent an email.

The synchro issue is intriguing.

Below are parts and tool that I think I will need.

Checking here first in case anyone has spares they don't need.

Next I will email 928 Specialists. The local dealer Champion Porsche said they won't deliver to me anymore ..... so what is the point of dealing with them ?

They don't want my business .... I take it to another dealer.

+++++++++++++++++++++++++++++

928 102 111 02 spigot bearing, rear of crankshaft

928 424 017 05 bearing block just forward of shifter

or order just the bushings?

928 920 001 3

928 920 951 2

928 424 182 03 sound absorbing chamber around shifter

928 424 181 03 sleeve, rubber seal for shifter

928 552 283 03 ABS mounting plate for shifter MT (pic attached)

928 552 017 00 frame for sound absorbing chamber ? needed ?

928 331 520 01, 02, 03, 04 washers, special, go under the tranny mounts

928 300 901 01 gasket set for transaxle overhaul

928 303 287 01 spring for reverse gear lockout

TOOLS:

9149 Plate to mount transaxle to engine stand, pg .34-214g

9155 Lever to help make shifts out of car, pg 34-217

9144 Bracket to turn bearing assy for drive pinion, pg 34-214h

VW 771 Slide puller, pg 34-214h

9140 Extractor, pg 34-214h

9148 Puller to remove input shaft?, pg 34-209

9321 Centering pins for drive pinion installation pg 34-214j

Thanks in advance,

Bruce Toski

#71

Addict

Rennlist Member

Rennlist Member

Originally Posted by 72Audi

928 102 111 02 spigot bearing, rear of crankshaft

928 424 017 05 bearing block just forward of shifter

or order just the bushings?

928 920 001 3

928 920 951 2

928 920 001 3

928 920 951 2

I would add these to list:

928 424 005 01 Forward Shift Ball Socket

911 424 223 03 Shift Rod Coupler Bushing (need 2)

928 424 182 03 sound absorbing chamber around shifter

928 424 181 03 sleeve, rubber seal for shifter

928 552 283 03 ABS mounting plate for shifter MT (pic attached)

928 552 017 00 frame for sound absorbing chamber ? needed ?

928 552 283 03 ABS mounting plate for shifter MT (pic attached)

928 552 017 00 frame for sound absorbing chamber ? needed ?

928 331 520 01, 02, 03, 04 washers, special, go under the tranny mounts

928 300 901 01 gasket set for transaxle overhaul

928 303 287 01 spring for reverse gear lockout

Spring 928 303 034 09 is more important to check and replace if there is any sign of cracks at top end. Same as other spring, should be changed before it has time to break into two pieces. Top piece can fit out from front drain plug so can be totally gone from gearbox at some previous oil change. Selector will be extremely loose when this is broken. If there is luck involved top part will end up in magnet. If not, it will destroy entire gearbox.

I would change few bearings at least. For example two selector bushes, 999 203 003 00. These seem to loose ***** relatively easily.

Also if major bearings are changed shims can be needed for correct preload adjustment.

TOOLS:

9149 Plate to mount transaxle to engine stand, pg .34-214g

9149 Plate to mount transaxle to engine stand, pg .34-214g

9155 Lever to help make shifts out of car, pg 34-217

9144 Bracket to turn bearing assy for drive pinion, pg 34-214h

VW 771 Slide puller, pg 34-214h

9140 Extractor, pg 34-214h

https://rennlist.com/forums/928-forum/320873-5-speed-rebuild-post-process-pics-and-tips-g28-05-a.html

9148 Puller to remove input shaft?, pg 34-209

9321 Centering pins for drive pinion installation pg 34-214j

Really, only special tools needed to do entire gearbox rebuild is 9218 and 9219. Even those can be made locally. Below is custom version which works at least as well as factory tool.

#72

Instructor

Thread Starter

Join Date: Nov 2006

Location: Fort Lauderdale, FL USA

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

Erkka,

Thanks a million for the thorough response !

You said, "Really, only special tools needed to do entire gearbox rebuild is 9218 and 9219."

I agree .... I see those in the manual on page 35-211.

Interested in any or all of these tools in any case as I don't have time to waste trying to fab the little SOBs.

Still have not torn down case yet.

I just the gaps at the 1st and reverse synchro rings; 1st appears to be .76mm and reverse was only .6mm

Manual says wear limit is .6 to .7mm.

If the synchros were in fact replaced this seems to indicate that the tapered cone surface of the gear wheels that the synchros press against,... are worn ?

Thanks a million for the thorough response !

You said, "Really, only special tools needed to do entire gearbox rebuild is 9218 and 9219."

I agree .... I see those in the manual on page 35-211.

Interested in any or all of these tools in any case as I don't have time to waste trying to fab the little SOBs.

Still have not torn down case yet.

I just the gaps at the 1st and reverse synchro rings; 1st appears to be .76mm and reverse was only .6mm

Manual says wear limit is .6 to .7mm.

If the synchros were in fact replaced this seems to indicate that the tapered cone surface of the gear wheels that the synchros press against,... are worn ?

#73

Instructor

Thread Starter

Join Date: Nov 2006

Location: Fort Lauderdale, FL USA

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

On this 88 transaxle the interior shift rod ( main shift rod coming in ) does not rest centered over the cut out in the 4/5 shift rod ( top of pic) while it is, in fact centered over the cut out for the 2/3 shift rod. Can't really see any way to correct this but have a hard time believing this is designed this way.

Any comments ?

Thanks,

Bruce Toski

Any comments ?

Thanks,

Bruce Toski

#74

Instructor

Thread Starter

Join Date: Nov 2006

Location: Fort Lauderdale, FL USA

Posts: 112

Likes: 0

Received 0 Likes

on

0 Posts

928 102 111 02 spigot bearing, rear of crankshaft $7.95

928 424 017 05 bearing block just forward of shifter $154.95

928 424 182 03 sound absorbing chamber around shifter $185

928 424 181 03 sleeve, rubber seal for shifter $13.95

928 552 283 03 ABS mounting plate for shifter MT supersedes to

928 552 017 00 $19.95

928 331 520 01, 02, 03, 04 washers, special, that go under the tranny mounts 01-$3.95, 02-$4.95, 03-$5.95, 04-$6.95

928 300 901 01 gasket set for transaxle overhaul $109.95

928 303 287 01 spring for reverse gear lockout $12.95

TOOLS:

9149 Plate mounts transaxle to engine stand $223.95

9155 Lever to help make shifts out of car, pg 34-217 $86.95

9144 Bracket to turn bearing assy for drive pinion $60.95

9140 Extractor, pg 34-214h $62.95

9148 Puller to remove input shaft?, pg 34-209 $116.95

9321 Centering pins for drive pinion installation $165.95

9218 $210.95

9219 $189.69

++++++++++++++++++++++++++++++++

He said no items in stock, and that tools must be ordered from Germany .... a few weeks wait for that if I go that route.

BToski

928 424 017 05 bearing block just forward of shifter $154.95

928 424 182 03 sound absorbing chamber around shifter $185

928 424 181 03 sleeve, rubber seal for shifter $13.95

928 552 283 03 ABS mounting plate for shifter MT supersedes to

928 552 017 00 $19.95

928 331 520 01, 02, 03, 04 washers, special, that go under the tranny mounts 01-$3.95, 02-$4.95, 03-$5.95, 04-$6.95

928 300 901 01 gasket set for transaxle overhaul $109.95

928 303 287 01 spring for reverse gear lockout $12.95

TOOLS:

9149 Plate mounts transaxle to engine stand $223.95

9155 Lever to help make shifts out of car, pg 34-217 $86.95

9144 Bracket to turn bearing assy for drive pinion $60.95

9140 Extractor, pg 34-214h $62.95

9148 Puller to remove input shaft?, pg 34-209 $116.95

9321 Centering pins for drive pinion installation $165.95

9218 $210.95

9219 $189.69

++++++++++++++++++++++++++++++++

He said no items in stock, and that tools must be ordered from Germany .... a few weeks wait for that if I go that route.

BToski

#75

Addict

Rennlist Member

Rennlist Member

Originally Posted by 72Audi

On this 88 transaxle the interior shift rod ( main shift rod coming in ) does not rest centered over the cut out in the 4/5 shift rod ( top of pic) while it is, in fact centered over the cut out for the 2/3 shift rod. Can't really see any way to correct this but have a hard time believing this is designed this way.

9218 and 9219 are surprisingly cheap. IIRR they were much more expensive few years ago and not really available at all. It was easier to have similar tools made. Especially as friend had gearbox parts on hand and they could be used as model.