TB PorKensioner

#32

Three Wheelin'

Joined: Nov 2004

Posts: 1,372

Likes: 1

From: Gatineau/Ottawa Canada 84 928S triple black

Originally Posted by G Man

...Any chance of getting a diagram of the bracket and a part# of the tensioner for us DIY'rs out here?..

#34

Originally Posted by FlyingDog

You don't need to worry about it. You aren't using the water pump for any of your mounting points and you've replaced the tensioner and arm.

#35

I cut ground, and welded some reinforcements to the bracket (looks pretty ratty  ), and went for a test drive. The tensioner worked fine. (Oops, I put the belt over the left cam one tooth advanced, so it sound quite odd, and pinged if I got on it.)

), and went for a test drive. The tensioner worked fine. (Oops, I put the belt over the left cam one tooth advanced, so it sound quite odd, and pinged if I got on it.)

Randomly checking when hot, without turning to TDC, the tension was just past the high side of the Kempf tool.

This morning I checked again, and realized that you have to take the measurement quickly, as the T/D adapts to twisting the belt, and shows less and less tension, each time it's checked.

...

Jim,

It's probably going to require at least a couple of laser cut test brackets to get the measurements right (>$150 each), plus all the time putting it into a CAD drawing. Then I will sell maybe 30-40 of them.

If it all works out, I will probably offer the bracket, plus the required hardware, and people can get the Audi parts from their local vendor.

...

Dave,

I have to dig in the basement and try and find the center cover. I think mine might be broken though!

), and went for a test drive. The tensioner worked fine. (Oops, I put the belt over the left cam one tooth advanced, so it sound quite odd, and pinged if I got on it.)

), and went for a test drive. The tensioner worked fine. (Oops, I put the belt over the left cam one tooth advanced, so it sound quite odd, and pinged if I got on it.)Randomly checking when hot, without turning to TDC, the tension was just past the high side of the Kempf tool.

This morning I checked again, and realized that you have to take the measurement quickly, as the T/D adapts to twisting the belt, and shows less and less tension, each time it's checked.

...

Jim,

It's probably going to require at least a couple of laser cut test brackets to get the measurements right (>$150 each), plus all the time putting it into a CAD drawing. Then I will sell maybe 30-40 of them.

If it all works out, I will probably offer the bracket, plus the required hardware, and people can get the Audi parts from their local vendor.

...

Dave,

I have to dig in the basement and try and find the center cover. I think mine might be broken though!

#38

Originally Posted by PorKen

It's probably going to require at least a couple of laser cut test brackets to get the measurements right (>$150 each), plus all the time putting it into a CAD drawing. Then I will sell maybe 30-40 of them.

PM me if I can help.

Michael

#40

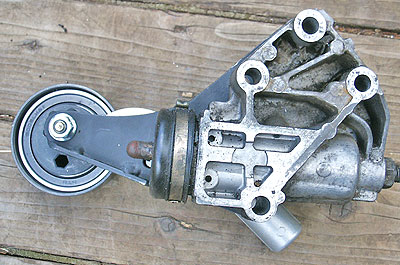

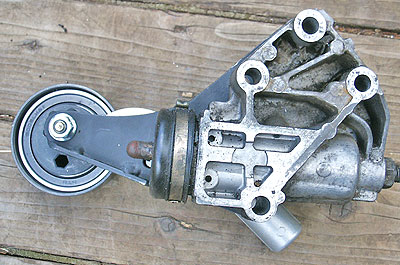

I don't think the cover will be much of a problem:

Look at those clunky 70's parts!

All three T/D parts sit on different height spacers, so I either have to have some made, and weld them on a steel bracket, or have it CNC'ed out of aluminum. The CNC bracket would surely look much better, and be lighter...

Look at those clunky 70's parts!

All three T/D parts sit on different height spacers, so I either have to have some made, and weld them on a steel bracket, or have it CNC'ed out of aluminum. The CNC bracket would surely look much better, and be lighter...

#43

I've been driving around normally with no problems. Highway, acceleration, no issues, yet.

...

Dave - forget the air pump bracket! I'm going straight for the bracket to hold the variable valve timing pulleys.

...

Dave - forget the air pump bracket! I'm going straight for the bracket to hold the variable valve timing pulleys.