TB PorKensioner

#61

Rennlist Member

Ken,

Just FYI,

I ran across a reference to a "place" called http://www.emachineshop.com/ in a recent thread.

<https://rennlist.com/forums/928-forum/278544-you-lose-abs-when-you-do-big-brakes-on-82-86-a-printthread.html >

I have no idea about prices/quality/service.

Just FYI,

I ran across a reference to a "place" called http://www.emachineshop.com/ in a recent thread.

<https://rennlist.com/forums/928-forum/278544-you-lose-abs-when-you-do-big-brakes-on-82-86-a-printthread.html >

I have no idea about prices/quality/service.

#62

Inventor

Rennlist Member

Rennlist Member

Thread Starter

I have read this before, about the factory tension gauge reading high on the Kempf tool.

So far when the car has been driven for a while the tension is just above the high mark on my Kempf tool, briefly. The tensioner quickly releases belt when the belt is twisted for the test! So the auto tensioner maintains a tight belt, but has more travel than the bi-metal Belleville washer powered factory tensioner, so it won't have spikes of overtension.

I too wonder why the engineeers didn't bother to upgrade the GTS's.

I don't know the actual internal design of the auto tensioner, but it appears to have two pistons inside. The tensioner will extend all the way out at full strength immediately. When retracting, however, there are two modes. There is the fast piston, which can be pushed down about 5mm under light load (resonance control). The fast piston is countered by a slow piston, which takes considerable force to move, and moves at a very slow rate (block expansion).

The one small inconvenience with this conversion is that you cannot reach the allen head hole in the tensioner pulley, which is used for slowly retracting the tensioner so you can insert the pin, without removing the balancer. You have to remove two of the three bolts which hold the tensioner, then release the third, and the tensioner rotates out. Then you have to put the tensioner in a vice, and slowly push the piston(s) in, and then lock it with the pin.

So far when the car has been driven for a while the tension is just above the high mark on my Kempf tool, briefly. The tensioner quickly releases belt when the belt is twisted for the test! So the auto tensioner maintains a tight belt, but has more travel than the bi-metal Belleville washer powered factory tensioner, so it won't have spikes of overtension.

Originally Posted by Hughett

If I only had one gauge, I'd use the P9201...but have it calibrated to the proper setting using someone's P9201. On my Kempf gauge (I've had two because I questioned the setting on the first one) I used a file to permantly mark the gauge setting for my car. It's about 1/16" of an inch above the window notch. Great tool.

The good thing about PorKen's new idea for a tensioner is that you'd not need to use a ension gauge very often since it's auto tensioning to the right tension all the time, year in and year out, until the tensioner wears out. Great development. Don't know why Porsche didn't use this on the 928 since they had the autotensioner on the 968 in 1992 and the S2 also (I think). Cost savings to not retool to the better system I guess.

The good thing about PorKen's new idea for a tensioner is that you'd not need to use a ension gauge very often since it's auto tensioning to the right tension all the time, year in and year out, until the tensioner wears out. Great development. Don't know why Porsche didn't use this on the 928 since they had the autotensioner on the 968 in 1992 and the S2 also (I think). Cost savings to not retool to the better system I guess.

I don't know the actual internal design of the auto tensioner, but it appears to have two pistons inside. The tensioner will extend all the way out at full strength immediately. When retracting, however, there are two modes. There is the fast piston, which can be pushed down about 5mm under light load (resonance control). The fast piston is countered by a slow piston, which takes considerable force to move, and moves at a very slow rate (block expansion).

The one small inconvenience with this conversion is that you cannot reach the allen head hole in the tensioner pulley, which is used for slowly retracting the tensioner so you can insert the pin, without removing the balancer. You have to remove two of the three bolts which hold the tensioner, then release the third, and the tensioner rotates out. Then you have to put the tensioner in a vice, and slowly push the piston(s) in, and then lock it with the pin.

#63

Inventor

Rennlist Member

Rennlist Member

Thread Starter

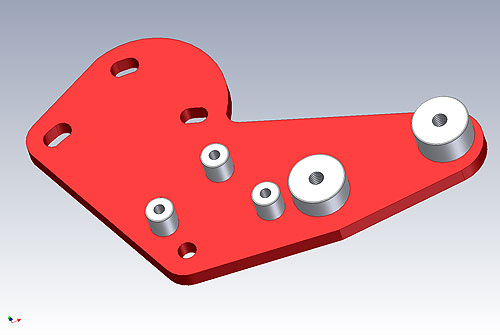

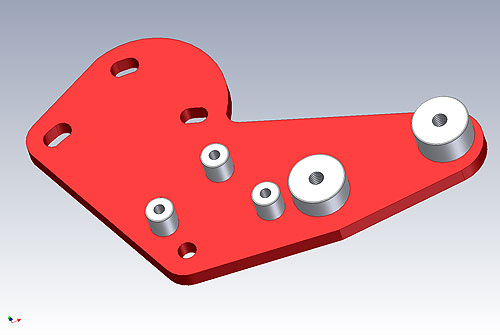

Something like this should work, I think:

So far I'm still going with laser cut steel. The posts will actually be separate parts. The plate has holes to only just fit them, and the machined posts will be driven in and welded on the back side.

So far I'm still going with laser cut steel. The posts will actually be separate parts. The plate has holes to only just fit them, and the machined posts will be driven in and welded on the back side.

#67

Inventor

Rennlist Member

Rennlist Member

Thread Starter

Dave,

I'm doing construction for a while, so all work has stopped. (See this thread.)

I have been driving around with the PorKensioner since I put it in without issue. The last few weeks have included the PKVVTS. (I admit the car has been parked during the 95+ days, and I drive the Merc with A/C. )

)

It may be a fluke, but I don't seem to get the same empty cam follower clatter after leaving the car parked for more than a few days.

I'm doing construction for a while, so all work has stopped. (See this thread.)

I have been driving around with the PorKensioner since I put it in without issue. The last few weeks have included the PKVVTS. (I admit the car has been parked during the 95+ days, and I drive the Merc with A/C.

)

)It may be a fluke, but I don't seem to get the same empty cam follower clatter after leaving the car parked for more than a few days.

#70

Instructor

Join Date: Mar 2006

Location: Morgan Hill, CA

Posts: 185

Likes: 0

Received 0 Likes

on

0 Posts

I'd love go get rid of my leaking tensioner.

Keep us posted.

My wife is starting to hint it is time to put down the wrench, pick up the hammer and start the front bathroom remodel.

Cheers,

John Fagerlund

Keep us posted.

My wife is starting to hint it is time to put down the wrench, pick up the hammer and start the front bathroom remodel.

Cheers,

John Fagerlund

#72

Rennlist Member

Originally Posted by DANdeMAN

Porken, is that thing coming along?

I will be doing my belt next srping.

Yould love to upgrade the tentionner...

Yes I'm preparing early.

I will be doing my belt next srping.

Yould love to upgrade the tentionner...

Yes I'm preparing early.

#73

Inventor

Rennlist Member

Rennlist Member

Thread Starter

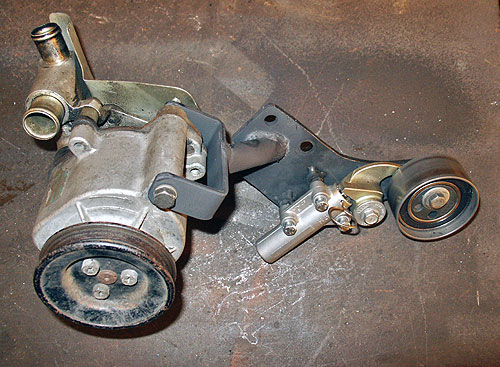

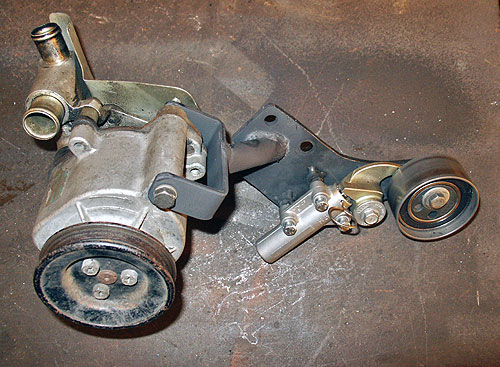

Still running without issue on the '81, now with air pump attached. 3 months, and a couple thousand miles.

I did a quick check of the system this afternoon. I used a screwdriver to keep the lever from moving while I checked the tension with the Kempf tool. It was as usual, just below max in the window. The belt rides in the center of the gears, and the tensioner pulley shows the belt riding dead center too, which makes me happy.

The 86.5 needs the timing belt, right now, so I want to install a PorKensioner on the valve bender and get some miles on it. I just need to double check the pattern I've made for the laser cutter shop, and send it off, but I've had no time.

I just need to double check the pattern I've made for the laser cutter shop, and send it off, but I've had no time.

I did a quick check of the system this afternoon. I used a screwdriver to keep the lever from moving while I checked the tension with the Kempf tool. It was as usual, just below max in the window. The belt rides in the center of the gears, and the tensioner pulley shows the belt riding dead center too, which makes me happy.

The 86.5 needs the timing belt, right now, so I want to install a PorKensioner on the valve bender and get some miles on it.

I just need to double check the pattern I've made for the laser cutter shop, and send it off, but I've had no time.

I just need to double check the pattern I've made for the laser cutter shop, and send it off, but I've had no time.

#75

Inventor

Rennlist Member

Rennlist Member

Thread Starter

You talkin' to me?

For the next few weeks, I'm still a 'stucco guy'.

Tired an inventor makes naught.

For the next few weeks, I'm still a 'stucco guy'.

Tired an inventor makes naught.