Pre-oiling

#16

Former Vendor

Read through it several times and think I can do this by myself.

New FPR (found one from summit $97.00) should be here this week.

Dampeners are older but hold good vacuum.

only thing I need to fully understand is the timing and fuel mixture.

I used Pkr32 and timing is dead nut.

I am assuming timing may change a bit because of belt stretch and tensioner reaction? Stock tensioner.

on to read up on mixture adjustments.

Thanks again

John

New FPR (found one from summit $97.00) should be here this week.

Dampeners are older but hold good vacuum.

only thing I need to fully understand is the timing and fuel mixture.

I used Pkr32 and timing is dead nut.

I am assuming timing may change a bit because of belt stretch and tensioner reaction? Stock tensioner.

on to read up on mixture adjustments.

Thanks again

John

Other than injection components, the fuel mixture is not adjustable.

Since your dampers are not new, when you pressurize the fuel system, leave the vacuum connectors off and run the fuel pump for a few minutes (hopefully your injectors are good and not leaking fuel, into the combustion chambers.) Monitor the vacuum tube coming out of the dampers and make sure that there is no fuel leaking out....you can use a small allen wrench as a "dipstick", also. If there is any fuel leakage, buy new (replacement style) dampers from Mark Anderson at 928 International (there is another seller of dampers, but they know so little about fuel injection that they don't understand their basic design problem, yet..)

If everything looks good, hook up all the vacuum hoses and move on.

A good way to monitor fuel mixture would be to hook up the O2 sensor to the system and then monitor the output voltage from the sensor. You should be starting and running the engine with the O2 sensor hooked up and in good condition.

The output voltage from the sensor should be .5 volts...just sitting there, before you start the engine.

After a minute or two, the sensor will get enough heat and should begin constantly ranging from ~.2 to ~.8 volts.

This is the normal condition and tells you that the O2 sensor has enough range to correct the fuel mixtures to 14.7 to one. The engine will "love" this condition!

If the O2 sensor gets "stuck" at either end of the possible output voltage (0 to 1 volt), the engine is either too rich or too lean.

Hope all of this is helping, not confusing!

Last edited by GregBBRD; 03-10-2021 at 04:41 PM.

#17

Former Vendor

#18

Former Vendor

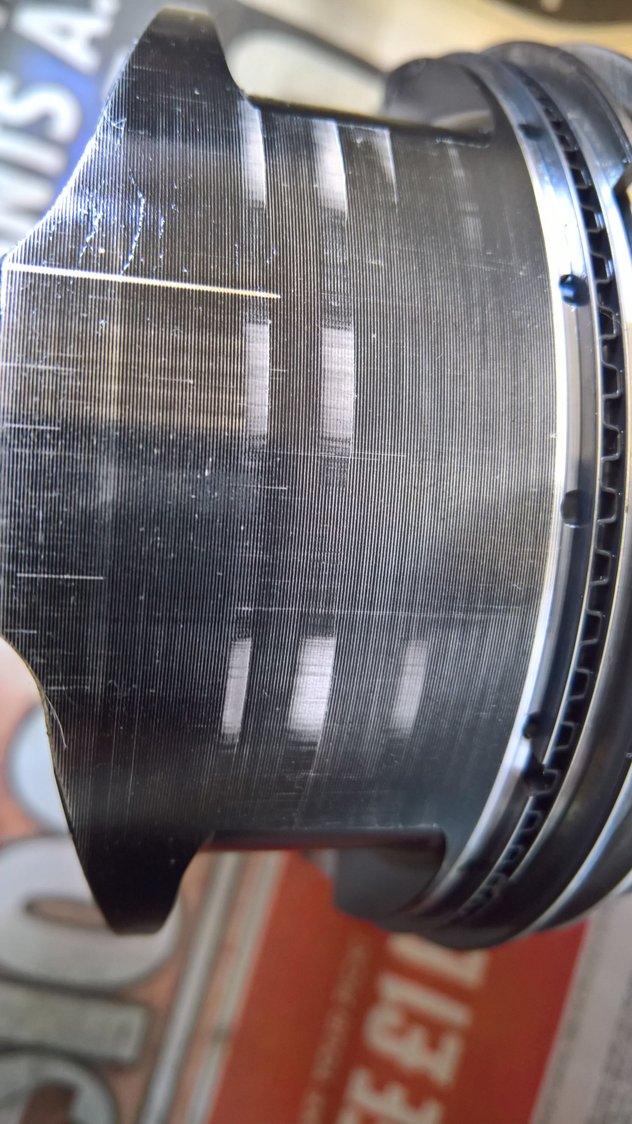

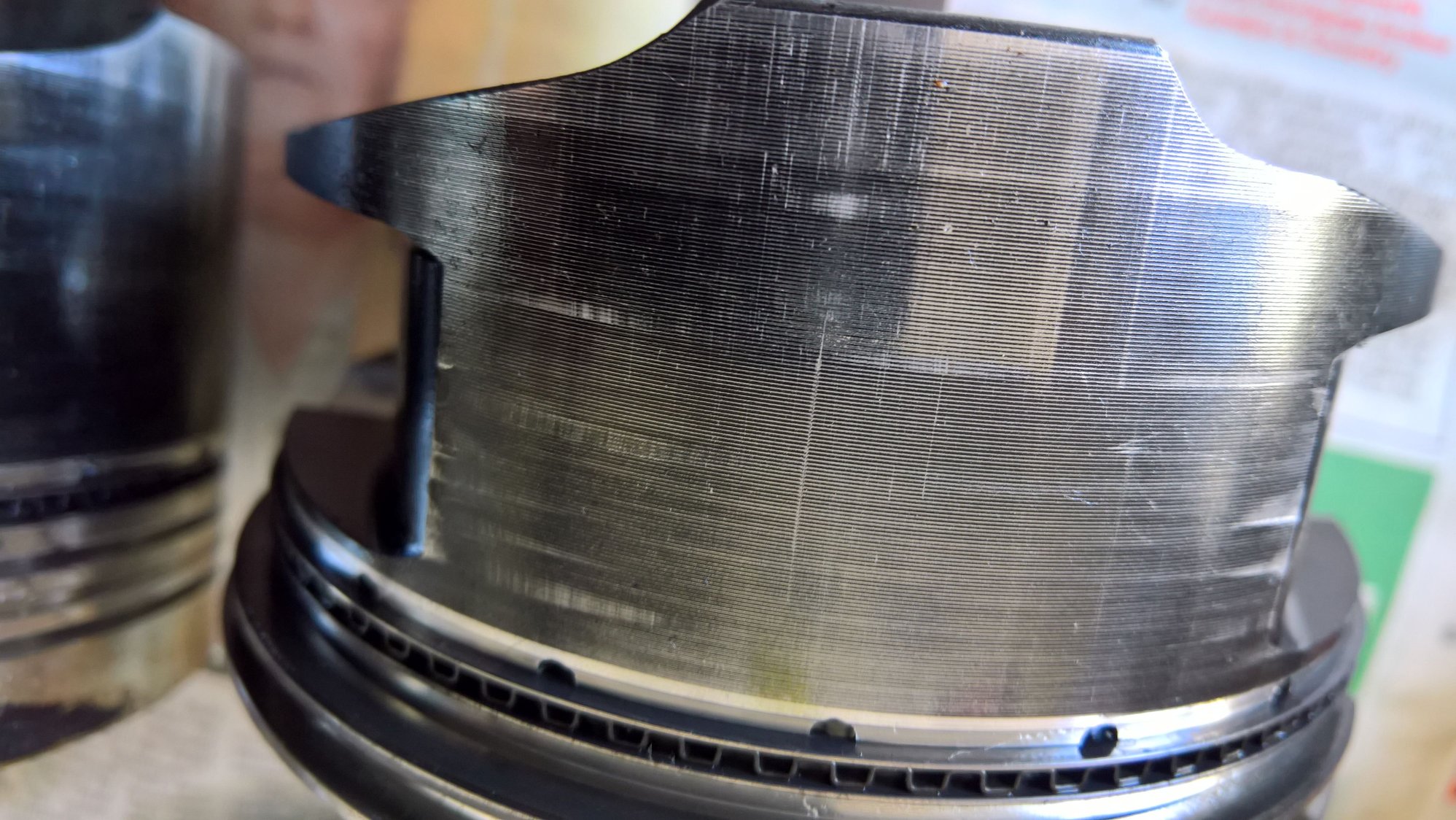

Not sure how many miles were on those pistons....that could be a normal look for thousands of miles.

If those were in an Alusil bore, they never had a chance.

If they were in a cast iron/steel bore, they did not have enough piston to wall clearance or they did not enough "cam" built into the piston design.

If those were in an Alusil bore, they never had a chance.

If they were in a cast iron/steel bore, they did not have enough piston to wall clearance or they did not enough "cam" built into the piston design.

#21

Former Vendor

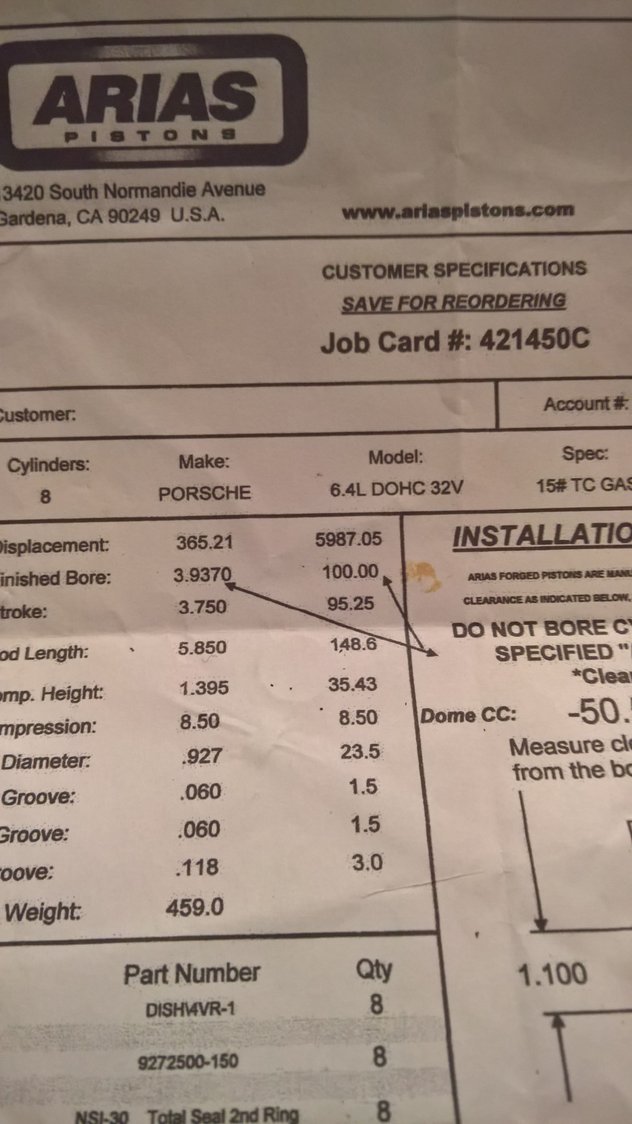

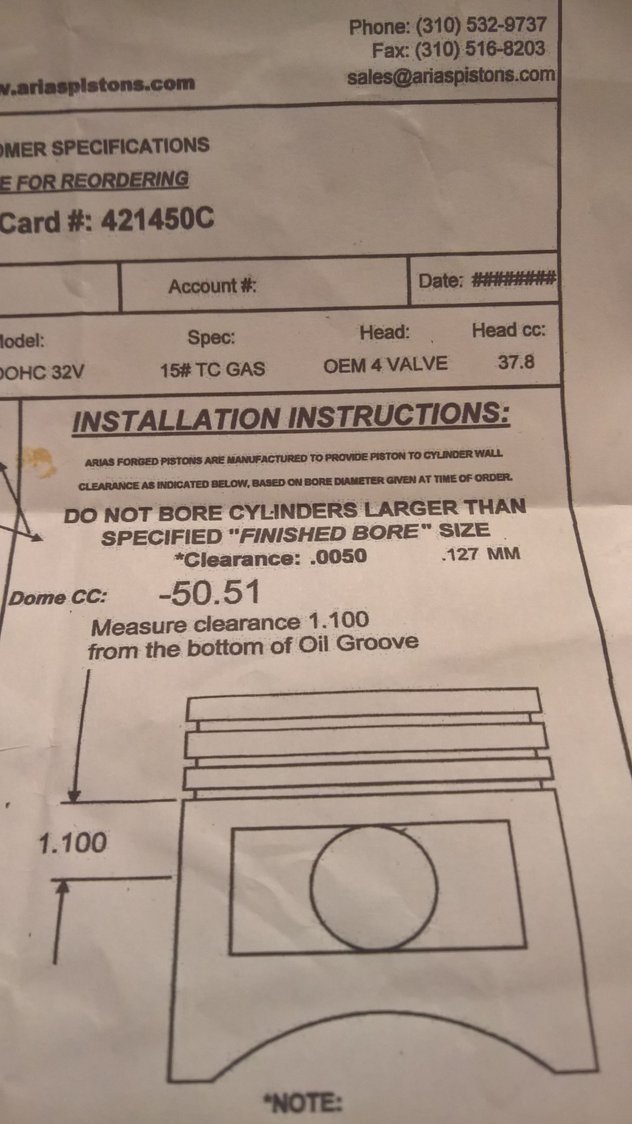

Since I have not idea of the aluminum alloy used, difficult to comment, but their desired .005" of clearance is a whole bunch of clearance.

Should have sounded like an old Detroit Diesel, when cold!

...I'm currently using modern "box" pistons, which have a desired .002" of clearance, in Nicosil bores.

#22

RL Community Team

Rennlist Member

Rennlist Member

That's the type of skirt scuffing (and I assume complementary bore scoring) we see in M96 and M97 (996 and 997) 911 engines from the piston either rocking in the bore or from the tolerance being too tight and it seizing at the bottom of the stroke when dissimilar metals expand at different rates dueig warm up. This is also exacerbated by overly rich running during warm up which washes the protective oil film from the cylinder walls.

#23

Former Vendor

That's the type of skirt scuffing (and I assume complementary bore scoring) we see in M96 and M97 (996 and 997) 911 engines from the piston either rocking in the bore or from the tolerance being too tight and it seizing at the bottom of the stroke when dissimilar metals expand at different rates dueig warm up. This is also exacerbated by overly rich running during warm up which washes the protective oil film from the cylinder walls.

"Almost a 100 years of incredibly stupid German piston engineering."

#25

Three Wheelin'

I'm just curious as with my Weber carb setup the engine seems to run best with AFR's "11...12" ... i can dial in 13 but not running "good" on idle "sound" and revving .

Of course this is all without load ... dyno should prove more ...

The carb's also seem to like a lot advance , 20░ at idle , all in before 3000 rpm .

#26

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,235

Received 467 Likes

on

250 Posts

Both Venolia and Arias pistons are made of similar design.

The pistons are made with much more taper and ovality than we usually see from other piston manufacturer. I believe that particular design is for race engines having cast iron blocks. They also recommend considerably more piston to wall clearance than we normally see, probably from the heat expansion of the aluminum alloy used (2618-T61) and to minimize engine break-in time.

The industry standard is 2618-T61 aluminum forged pistons when strength and durability are the prime considerations. Silicon-aluminum alloys have great wear characteristics because the silicon particulate hardens the alloy and reduces the thermal coefficient of expansion. However, silicon-aluminum alloys can turn brittle and become prone to fracturing when subjected to extreme stress. The failure rate of silicon alloy pistons in severe-duty, racing applications is quite high. With a piston made of a silicon alloy, such as the 4032 or MS75, once a crack starts, it doesn't stop until the piston suffers a catastrophic failure. In the rare case of a crack in a 2618-T61 piston, the crack will migrate to an area of lower stress and stop. 2618-alloy pistons keep their shape under extreme pressures and high RPM's. The result is proper ring seal and high heat transfer plus greatly reduced cylinder wall failure.

The measuring point on these instructions is very high up on the skirt. Down low at the bottom of skirt the piston diameter is larger hence smaller clearance.

I have a new Venolia piston here which will go into a BMW 3,6L six.

Above top ring the diameter is 92,35 mm (3.636").

Below oil ring 93,28 mm (3.672").

At bottom of skirt 93,39 mm (3.677")

At bottom of skirt parallell to the wrist pin 93,09 mm (3.665") - ovality.

You can see the difference.

One other thing I have seen on US-made forged pistons and which I am not happy with is the large distance between the pin bosses (often 1.500 inches) which create more bending stress on the wrist pin. The gap between the pin bosses and the con rod small end should be kept as small as possible.

Arias Pistons are now owned by CP-Carillo.

┼ke

Last edited by Strosek Ultra; 03-11-2021 at 06:18 AM.

The following users liked this post:

worf928 (03-11-2021)

#27

Former Vendor

I can tell you that even with very good honing equipment, there will generally be a variance from cylinder to cylinder. And pistons, even CNC machined, have some tolerance.

I always end up "matching" individual pistons to individual bores to get the best fit....especially important with the Factory Porsche pistons. Those things are like fingerprints...no two are the same, these days!

And it is very common to find entire sets of pistons, in the same group #, which vary by .02mm.

If you have a piston/bore which looks normal, measure that one and see how it compares to the ones that were damaged.

BTW....I've never used a piston that has the piston diameter measured in the location that they specify.

I'm also not used to seeing those wear lines on the sides of the piston, in the middle of the piston skirt....My pistons are considerably "oval" than yours. (I have a unique "cam" profile for machining that is used for my pistons.)