Heater Core sprung a leak

#1

After a search I didnt find much. Whats the best process to bypass the heater. Just plug the outlet from the engine and inlet to the Y pipe. Or loop the two. I might as well remove the control valve all together as its new and wont be needed until I fix the core.

#2

You have to block coolant from escaping the block so the valve is an effective way of doing that- I simply disconnect the vacuum line, undo the actuator arm and wire the actuation lever in the closed position. Beyond that I made a hose connection from the valve outlet back to the coolant system to close the system once more. You also need to close the now temporarily redundant vac line. The only time I operate the valve manually is when filling the system with fresh coolant.

My heater was fine I just do not use the heater over here.

My heater was fine I just do not use the heater over here.

The following users liked this post:

GUMBALL (01-17-2021)

#4

Last edited by grepin; 01-17-2021 at 02:35 AM.

#5

The valve is a unidirectional disc valve with a spring designed to close the disc and when the system is pressurised the force applied further assists sealing albeit the differential pressure component is going to be very small or so I would think.

The valve is not designed to be a tight shut off classification but for sure will seal way tighter than most middle age men! For sure one should not rely on the valve and leave the other end open to the engine bay- that would be rather dumb ***! I actually tested a new valve with 15 psig across the disc and it held tight [to my surprise] but as they age and with heat quite conceivable they will leak a few drops here and there but that is operationally irrelevant- obviously Porsche thought they were tight enough.

In my case I did not want to leave the cooler with stagnant coolant and possibly risk corrosion damage thus I took the core out of the loop. The hoses going to and from the cooler thus have to be interdicted be interdicted and thus joined together at some point. They will be flooded and pressurised but there will be no flow in that part of the system. On my LHD system I did this just behind the 1/4 bank.

The nuances of achieving such are a bit different in your case because of the RHD configuration but the process configuration is identical. If you are hell bent on removing the valve altogether there is no harm in that either - you just have to achieve a positive isolation either side of where the valve was- my point of view was why create an additional problem to solve when the solution is in front of your eyes but then I have a new spare valve and new hoses in my parts bin for if and when I ever want to reinstate the heater circuit.

The valve is not designed to be a tight shut off classification but for sure will seal way tighter than most middle age men! For sure one should not rely on the valve and leave the other end open to the engine bay- that would be rather dumb ***! I actually tested a new valve with 15 psig across the disc and it held tight [to my surprise] but as they age and with heat quite conceivable they will leak a few drops here and there but that is operationally irrelevant- obviously Porsche thought they were tight enough.

In my case I did not want to leave the cooler with stagnant coolant and possibly risk corrosion damage thus I took the core out of the loop. The hoses going to and from the cooler thus have to be interdicted be interdicted and thus joined together at some point. They will be flooded and pressurised but there will be no flow in that part of the system. On my LHD system I did this just behind the 1/4 bank.

The nuances of achieving such are a bit different in your case because of the RHD configuration but the process configuration is identical. If you are hell bent on removing the valve altogether there is no harm in that either - you just have to achieve a positive isolation either side of where the valve was- my point of view was why create an additional problem to solve when the solution is in front of your eyes but then I have a new spare valve and new hoses in my parts bin for if and when I ever want to reinstate the heater circuit.

#7

Pulling the HVAC unit is quite major task- probably one of those things that looks intimidating but after one has done it does not seem as bad as one first feared! As long as the ac evaporator holds I can work around other problems. I had my blower motor bearing crap out on me last year so I pulled the bonnet off, removed the motor from above and then pulled the recirc flap assembly with a view to replacing the actuator [easy] and resealing the flap- that is almost impossible! Herman wrote a procedure for this that requires what is tantamount to major surgery to get the flap out and work it some. I removed the unit from my late S4 after it was wrecked and to be fair the job was not too bad. Whether i would have got it all back together again and working that is another matter altogether.

Last edited by FredR; 01-17-2021 at 05:37 AM.

Trending Topics

#8

Nah probably not. However I intend to pull the dash anyway to refurb and do the instrument cluster as well. I might as well do it if I am that far. I also need to get the aircon working. Now I do need that in Adelaide. I may end up in there anyway. I have already done a full intake refresh including timing belt and WP change myself. I am sure I can work it out. I got the car as a non runner and now its back on the road. Sadistically I enjoy working on it somewhat more than driving. Maybe not quite....

Last edited by grepin; 01-17-2021 at 05:51 AM.

#10

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Joined: Oct 2001

Posts: 20,506

Likes: 549

From: Bend, Oregon

If you look at some of the assembly-line pictures from back-in-the-day, you'll see how car assembly starts with a guy with a heater core in one hand and the evaporator in the other, walking into the first assembly station. As he continues, people start bolting stuff to them until there's a whole car ready to go. Pretty impressive process. Know that accessing those parts is pretty much the reverse. Start unbolting stuff until all you have left is the heater core and evaporator. Grab the replacements, then follow the original factory process to put the car back together.

At least it seems like that sometimes....

At least it seems like that sometimes....

The following users liked this post:

Hey_Allen (01-19-2021)

#11

Here is a "sidebar" question:

Can you install a shut off valve between the outlet at the back of the head and the heater core ?? Thinking of "hot summer days"

Will that cause other issues ??

Can you install a shut off valve between the outlet at the back of the head and the heater core ?? Thinking of "hot summer days"

Will that cause other issues ??

#12

The valve is a unidirectional disc valve with a spring designed to close the disc and when the system is pressurised the force applied further assists sealing albeit the differential pressure component is going to be very small or so I would think.

The valve is not designed to be a tight shut off classification but for sure will seal way tighter than most middle age men! For sure one should not rely on the valve and leave the other end open to the engine bay- that would be rather dumb ***! I actually tested a new valve with 15 psig across the disc and it held tight [to my surprise] but as they age and with heat quite conceivable they will leak a few drops here and there but that is operationally irrelevant- obviously Porsche thought they were tight enough.

In my case I did not want to leave the cooler with stagnant coolant and possibly risk corrosion damage thus I took the core out of the loop. The hoses going to and from the cooler thus have to be interdicted be interdicted and thus joined together at some point. They will be flooded and pressurised but there will be no flow in that part of the system. On my LHD system I did this just behind the 1/4 bank.

The nuances of achieving such are a bit different in your case because of the RHD configuration but the process configuration is identical. If you are hell bent on removing the valve altogether there is no harm in that either - you just have to achieve a positive isolation either side of where the valve was- my point of view was why create an additional problem to solve when the solution is in front of your eyes but then I have a new spare valve and new hoses in my parts bin for if and when I ever want to reinstate the heater circuit.

The valve is not designed to be a tight shut off classification but for sure will seal way tighter than most middle age men! For sure one should not rely on the valve and leave the other end open to the engine bay- that would be rather dumb ***! I actually tested a new valve with 15 psig across the disc and it held tight [to my surprise] but as they age and with heat quite conceivable they will leak a few drops here and there but that is operationally irrelevant- obviously Porsche thought they were tight enough.

In my case I did not want to leave the cooler with stagnant coolant and possibly risk corrosion damage thus I took the core out of the loop. The hoses going to and from the cooler thus have to be interdicted be interdicted and thus joined together at some point. They will be flooded and pressurised but there will be no flow in that part of the system. On my LHD system I did this just behind the 1/4 bank.

The nuances of achieving such are a bit different in your case because of the RHD configuration but the process configuration is identical. If you are hell bent on removing the valve altogether there is no harm in that either - you just have to achieve a positive isolation either side of where the valve was- my point of view was why create an additional problem to solve when the solution is in front of your eyes but then I have a new spare valve and new hoses in my parts bin for if and when I ever want to reinstate the heater circuit.

#13

I bypass leaking heater cores on a frequent, temporary basis, until it is convenient (both for my shop and the client) to take them out and replace...generally incorporating other needed work.

On left hand drive cars, the heater control valve, sans heater core, just makes routing the hoses more complex (and provides two more places for leaks to occur), so I remove it until we replace the heater core.

Last edited by GregBBRD; 01-17-2021 at 06:46 PM.

#14

Leave it in, take it out....completely moot once the heater core is completely abandoned and both ends disconnected.

I bypass leaking heater cores on a frequent, temporary basis, until it is convenient (both for my shop and the client) to take them out and replace...generally incorporating other needed work.

On left hand drive cars, the heater control valve, sans heater core, just makes routing the hoses more complex (and provides two more places for leaks to occur), so I remove it until we replace the heater core.

I bypass leaking heater cores on a frequent, temporary basis, until it is convenient (both for my shop and the client) to take them out and replace...generally incorporating other needed work.

On left hand drive cars, the heater control valve, sans heater core, just makes routing the hoses more complex (and provides two more places for leaks to occur), so I remove it until we replace the heater core.

Is just blanking it the wrong thing to do. Obviously at the block and at the Y pipe. Or is looping it better. Either way is just as easy.

#15

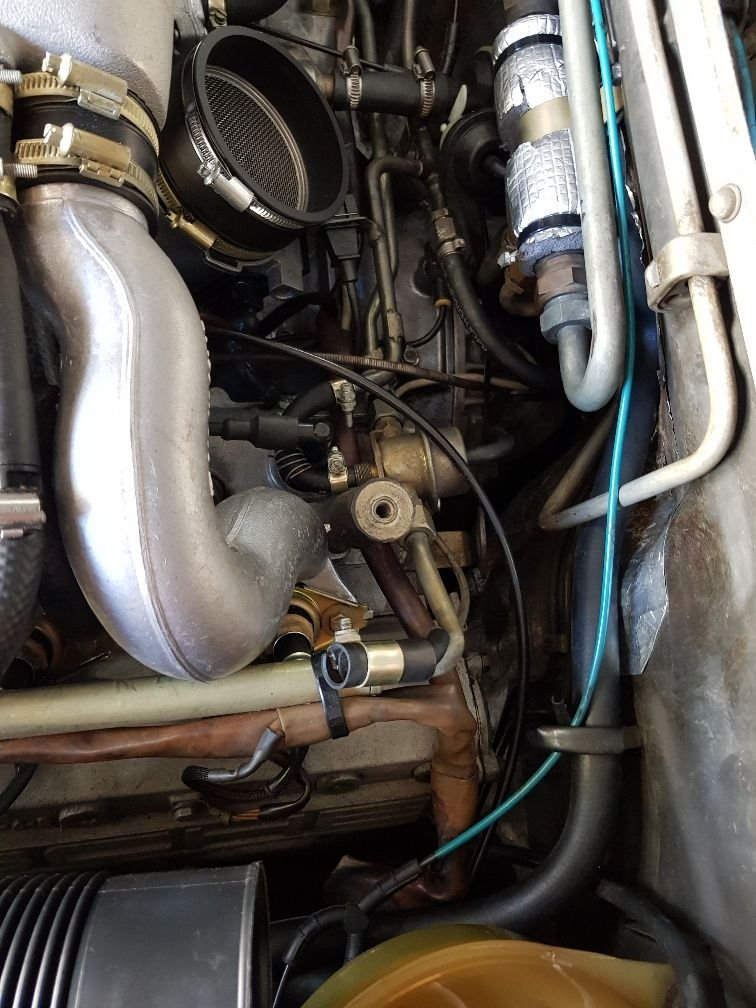

The OP asked how it was done and I explained in principle how I did it and why- in my case it was to preserve the heater core as I never use it. The layout on the RHD models is somewhat different but the principle remains the same. If there is any confusion I will happily post a pic of what I did.