S4 10:1 C/R, the big lie?

#31

Rennlist Member

Thread Starter

Mark K wrote:

Can anyone confirm this? It seems strange not to include the piston/wall clearance down to the first ring and the squish area in the total C/R.

I'll cc the piston dish at a later date and post the results.

basically, the piston volume is only going to be the volume of the valve cut outs and dish. lots of fluid can seep down to the first ring,and I dont think that is calculated in the overall volume for compression ratios. ( anyone chime in here)

I'll cc the piston dish at a later date and post the results.

#33

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I had brought this up with in an other thread at one point but never got any response, so ill try on this one as it may be more appropriate.

The numbers that Adam came up with are pretty interesting and proved to me that it sure seems like it doesn’t take much to change/vary..or influence the compression ratio in our motor.

The idea I have would be to retain the current stock cast pistons but having some minor machining done to them. The main reason we would like to run forged pistons is obviously for strength which is targeted almost 100% at detonation durability. With what the guys in Wisc. and other places are running boost wise on current 10:1 cast pistons I don’t think detonation has shown its ugly head in most cases. With some minor machining I think the current pistons could run quite comfortably in the 15-19psi range as they currently do in to 9-11psi intercooled range.

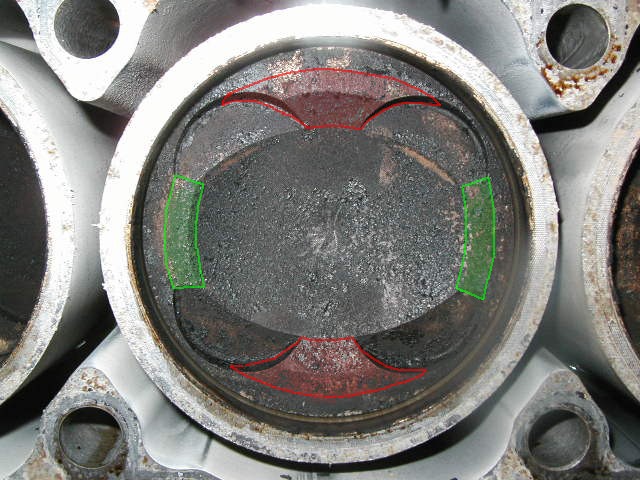

The pistons already have the valve relief machined into them, so why couldn’t one extend the machining to include the red area shown below? If more was desired perhaps into the green? Obviously the amount of material to be removed would be determined by the CR you want to end up with. I think 8.5-9.0:1 would be ideal. With talk of minor changes in cyl head gasket thickness or seeping fluid around the rings influencing the CR results, i really dont think much would have to be removed or would effect the structural integrity of the piston.

Sure would be nice to pop the stock pistons out...refinish the bore, add new rings, have some volume added to the piston and then pop them back in and run 15 psi with no relative worry about detonation issues with your stock matched pistons. Cast YES, but would you really need forged if you arent running into detonation because of lower CR and a safe zone of boost?

I need to get some clay or try to make some measurements of what would have to be removed to get a corresponding CR, but based on Adams numbers in his first post…

To achieve a 8.52:1 CR you would have to add 6.2cc of piston volume (machine out 6.2cc)

695/(75.3+6.2)= 8.52

Using http://www.sciencemadesimple.net/EASYvolume.html to put it in perspective..

6.2 Cubic centimeters equals 0.419294 Tablespoon (that’s not even half a tablespoon!)

To get 8.79:1 remove 3.7cc from piston

To get 8.90:1 remove 2.7cc from piston

To get 9.00.1 remove 1.7cc from piston

Those aren’t very big volumes…and applied across a strategic wide area across the piston like Ive shown wouldn’t be much material….would it??

Input?

The numbers that Adam came up with are pretty interesting and proved to me that it sure seems like it doesn’t take much to change/vary..or influence the compression ratio in our motor.

The idea I have would be to retain the current stock cast pistons but having some minor machining done to them. The main reason we would like to run forged pistons is obviously for strength which is targeted almost 100% at detonation durability. With what the guys in Wisc. and other places are running boost wise on current 10:1 cast pistons I don’t think detonation has shown its ugly head in most cases. With some minor machining I think the current pistons could run quite comfortably in the 15-19psi range as they currently do in to 9-11psi intercooled range.

The pistons already have the valve relief machined into them, so why couldn’t one extend the machining to include the red area shown below? If more was desired perhaps into the green? Obviously the amount of material to be removed would be determined by the CR you want to end up with. I think 8.5-9.0:1 would be ideal. With talk of minor changes in cyl head gasket thickness or seeping fluid around the rings influencing the CR results, i really dont think much would have to be removed or would effect the structural integrity of the piston.

Sure would be nice to pop the stock pistons out...refinish the bore, add new rings, have some volume added to the piston and then pop them back in and run 15 psi with no relative worry about detonation issues with your stock matched pistons. Cast YES, but would you really need forged if you arent running into detonation because of lower CR and a safe zone of boost?

I need to get some clay or try to make some measurements of what would have to be removed to get a corresponding CR, but based on Adams numbers in his first post…

To achieve a 8.52:1 CR you would have to add 6.2cc of piston volume (machine out 6.2cc)

695/(75.3+6.2)= 8.52

Using http://www.sciencemadesimple.net/EASYvolume.html to put it in perspective..

6.2 Cubic centimeters equals 0.419294 Tablespoon (that’s not even half a tablespoon!)

To get 8.79:1 remove 3.7cc from piston

To get 8.90:1 remove 2.7cc from piston

To get 9.00.1 remove 1.7cc from piston

Those aren’t very big volumes…and applied across a strategic wide area across the piston like Ive shown wouldn’t be much material….would it??

Input?

#34

Drifting

Join Date: Jul 2002

Location: Los Angeles, CA

Posts: 3,348

Likes: 0

Received 0 Likes

on

0 Posts

In concept, that looks really do-able...

As long as the backside of the piston is not variably thin.

But I doubt they would bother to make it that elaborate.

It makes more sense that the top is solid, and the valve clearance insets are machined into it...

If that is the case, there is no reason you couldn't cut out more surface area.

And perhaps smooth the overal top, so it does not have hot spots...

The coolest thing, is that machining *might* be able to be done with the engine in the car.

So it could be part of the "weekend" process of installing a supercharger...

As long as the backside of the piston is not variably thin.

But I doubt they would bother to make it that elaborate.

It makes more sense that the top is solid, and the valve clearance insets are machined into it...

If that is the case, there is no reason you couldn't cut out more surface area.

And perhaps smooth the overal top, so it does not have hot spots...

The coolest thing, is that machining *might* be able to be done with the engine in the car.

So it could be part of the "weekend" process of installing a supercharger...

#35

Rennlist Member

why not dig the valve reliefs really deep and make it a non interference engine!! isnt the max valve plunge only about .5" on even a modified cam? I think I remember checking this with my engine at DEVEK when I was building it with them. we did a test moving the valves down and the heads loosely bolted down and pressed the valves down .5" or so. I had a slightly off piston valve cut out, so did some griding to make sure there was enough clearance with the old euro 2 valve on a 86 block and pistons and special cuts. I think there was a lot of material in the piston left, but I dont know how much. Im sure Marc at Devek has thought of this before and there may just not be enough material left to do this. wouldnt it be nice though!! (no worrys of timing belt issue! just run it till it breaks)

MK

MK

#36

Three Wheelin'

Tony, nice communicative pic!

As well as lowering the compression ratio, it is just as important to maintain the squish area too as it plays an equally crucial role in detonation control by creating a controlled hurricane effect within the combustion chamber as the piston rushes to TDC which homogenizes the mixture by minimizing rich and lean spots within the charge, promoting a nice controlled burn.

With that said, and after consulting your ridiculously kick-*** web page:

https://rennlist.com/forums/showthre...845#post930845

..the pics of your combustion chambers reveal that if it were me, I would try to remove as much material from the piston at the 3 and 9 o’clock positions versus the 12 and 6 o’clock positions which appear to be squish zones. As a matter of fact, I wouldn't touch 12 and 6 o'clock at all.

As well as lowering the compression ratio, it is just as important to maintain the squish area too as it plays an equally crucial role in detonation control by creating a controlled hurricane effect within the combustion chamber as the piston rushes to TDC which homogenizes the mixture by minimizing rich and lean spots within the charge, promoting a nice controlled burn.

With that said, and after consulting your ridiculously kick-*** web page:

https://rennlist.com/forums/showthre...845#post930845

..the pics of your combustion chambers reveal that if it were me, I would try to remove as much material from the piston at the 3 and 9 o’clock positions versus the 12 and 6 o’clock positions which appear to be squish zones. As a matter of fact, I wouldn't touch 12 and 6 o'clock at all.

#37

Rennlist Member

Thread Starter

I'm intending on cutting up one of my S4 Pistons so we can see the cross section. I'll do one cut through the valve relief, and one on the X and Y axis so we can all see how much material there is available.

I think cutting the valve reliefs may be a good way to go if there is enough material there. Cutting in Tony's red and green zones, particularly the red zones, looks like it might interfere with the designed in squish properties of the pentroof head design.

I'll post pics of the cut piston after the deed is done. It will be interesting to see how much meat there is to cleave.

I think cutting the valve reliefs may be a good way to go if there is enough material there. Cutting in Tony's red and green zones, particularly the red zones, looks like it might interfere with the designed in squish properties of the pentroof head design.

I'll post pics of the cut piston after the deed is done. It will be interesting to see how much meat there is to cleave.

#40

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

For a great pic of what i was thinking, look at Sterlings web site.

www.928sg.com (i cant copy direct the link here at work)

Click the "The Car"...

then "Block"....

The first picture shows the stock piston vs the one he used. I know his are custom pistons(968 i believe) but the discussion of the "squish" area came up...so how does that piston get away with it if it indeed is a problem?

I think this is a pretty workable approach to lowering the CR in our motors. The machining would be almost in the smae pattern as his aftermarket one....just not as much material removed. Like i said, odds are no more than 6.2cc (.4 tablesppon appx). I think I need to buy a used piston and have one machined to have a "look see".

As a side note, Kiborts idea of a deeper valve relief was a pretty good one! Wouldnt that just be awesome to make the 32v's non-collision motors...i think that would take a bit more careful planning and machining though and would most likely effect the strength of the piston surface. Theres a reason Porsche made the cutouts the way they did.

www.928sg.com (i cant copy direct the link here at work)

Click the "The Car"...

then "Block"....

The first picture shows the stock piston vs the one he used. I know his are custom pistons(968 i believe) but the discussion of the "squish" area came up...so how does that piston get away with it if it indeed is a problem?

I think this is a pretty workable approach to lowering the CR in our motors. The machining would be almost in the smae pattern as his aftermarket one....just not as much material removed. Like i said, odds are no more than 6.2cc (.4 tablesppon appx). I think I need to buy a used piston and have one machined to have a "look see".

As a side note, Kiborts idea of a deeper valve relief was a pretty good one! Wouldnt that just be awesome to make the 32v's non-collision motors...i think that would take a bit more careful planning and machining though and would most likely effect the strength of the piston surface. Theres a reason Porsche made the cutouts the way they did.

#41

Rennlist Member

Thread Starter

Tony wrote:

It doesn't?

Actually, I don't think I characterized it as a "problem" Tony, its just a question if you want to maintain some designed in characteristics of the motor. If taking the material from somewhere else on top of the piston can be done, it would seem to make more sense then to take it from the rim.

I for one am not going to argue with JE's design work as I am not a high performance engine builder, I just play one on TV.

I think Sterling's running a Motec gives him more options in this department, and I believe that Sterling's engine was built to take forced induction which may or may not explain the piston crown design.

Bottom line, Sterling's motor is going to detach many a retina from the acceleration g's regardless of what the top of the piston looks like.

so how does that piston get away with it if it indeed is a problem?

Actually, I don't think I characterized it as a "problem" Tony, its just a question if you want to maintain some designed in characteristics of the motor. If taking the material from somewhere else on top of the piston can be done, it would seem to make more sense then to take it from the rim.

I for one am not going to argue with JE's design work as I am not a high performance engine builder, I just play one on TV.

I think Sterling's running a Motec gives him more options in this department, and I believe that Sterling's engine was built to take forced induction which may or may not explain the piston crown design.

Bottom line, Sterling's motor is going to detach many a retina from the acceleration g's regardless of what the top of the piston looks like.

#42

How much interference does a stock S3 engine have, bone stock?

I would also like to know if the 5.0's could be made into a non interference engine. It might require a whole different piston design.

How special are the 928 pistons? What I mean is, could a person who worked at a piston factory find something we need for our engine that happens to work from another engine?

I would also like to know if the 5.0's could be made into a non interference engine. It might require a whole different piston design.

How special are the 928 pistons? What I mean is, could a person who worked at a piston factory find something we need for our engine that happens to work from another engine?

#43

Nordschleife Master

Waran, the 928 has a special piston.

It has an Ausil block. The pistions have to be coated with something to prevent them from galling on the walls. BWM, I think, is suppost to have some sort of new network polymer that holds up, but apperently they're haveing trouble with it. The 928 uses an iron coating, IIRC, on the aluminum.

One suggested recourse is to buy the 928 forged pistons, or the 944 968 turbo pistons. They're expensive.

One is to coat the block with NiCal coating or sleve, and then run normal pistons.

It has an Ausil block. The pistions have to be coated with something to prevent them from galling on the walls. BWM, I think, is suppost to have some sort of new network polymer that holds up, but apperently they're haveing trouble with it. The 928 uses an iron coating, IIRC, on the aluminum.

One suggested recourse is to buy the 928 forged pistons, or the 944 968 turbo pistons. They're expensive.

One is to coat the block with NiCal coating or sleve, and then run normal pistons.

#44

Is the 'squish' you guys refer to the same thing as 'quench'?

I'm still trying to translate my musclecar knowledge to supercar.

I've heard quench heads/pistons aren't recommended for supercharging,

I assume because the forced induction interferes with the

"hurricane" effect. Is that true? If so, removing the red and green areas

may not be detrimental IF you are adding a blower.

I'm still trying to translate my musclecar knowledge to supercar.

I've heard quench heads/pistons aren't recommended for supercharging,

I assume because the forced induction interferes with the

"hurricane" effect. Is that true? If so, removing the red and green areas

may not be detrimental IF you are adding a blower.

#45

Three Wheelin'

Originally posted by Wolfmaniser

Is the 'squish' you guys refer to the same thing as 'quench'?

Is the 'squish' you guys refer to the same thing as 'quench'?

Originally posted by Wolfmaniser

I've heard quench heads/pistons aren't recommended for supercharging,

I assume because the forced induction interferes with the

"hurricane" effect. Is that true? If so, removing the red and green areas

may not be detrimental IF you are adding a blower.

I've heard quench heads/pistons aren't recommended for supercharging,

I assume because the forced induction interferes with the

"hurricane" effect. Is that true? If so, removing the red and green areas

may not be detrimental IF you are adding a blower.

In Corky's Supercharged! on page 227, he says:

"Consider the 'squish volume' sacred and do not tamper. It is possible to err so badly in removing the squish that the resulting 7-to-1 compression ratio may experience more detonation than a 9-to-1 with proper squish."