Porsche 997: Brake Modifications

Maybe you drive your Porsche 911 Carrera hard on occasion. By doing so, your brakes seem to soften up with the pedal needing to be pushed further and further downward during your runs. Maybe, you wonder if there might be some modifications you could make to your braking system to help it run cooler, with less fade, and more control. Continue reading to find out what you can do.

This article applies to the Porsche 997 (2005-2012).

There are a number of steps one can take to improve the performance of their Porsche 997 braking system. The following list of modifications starts with the simplest, least expensive, and works its way up to the most complicated, more expensive.

Racing Brake Fluid

DIY Cost – $19-$85 per liter bottle

Professional Cost – $80-$100 for labor

Skill Level – Easy; but bleeding the brake system is required.

Racing brake fluids are specially formulated for performance driving. Plus, it meets the Department of Transportation (DOT) specification they are designed for. DOT 3, DOT 4, and DOT 5.1 are all compatible, as well as glycol-based. DOT 5.1 is the choice of many track drivers as it not only has a much higher boiling point (518 degrees F, 270 degrees C, dry), but it also resists moisture contamination longer than DOT 3 or DOT 4. Also, it features improved compressibility.

Many enthusiasts tend to switch from the Porsche-branded brake fluid to brands such as ATE, Motul, Castrol, Brembo, AP, Pentosin, or others because of the availability, cost, and/or experience with their performance. Different brands of racing fluids shouldn't be mixed, and should be replaced every year or sooner depending on how hard they've been used. A 32 oz. (1 liter) bottle of brake fluid is typically enough to flush out your brake system, along with your clutch. Recommended for its availability and cost.

Pro Tip

Some drivers alternate different color brake fluids of the same brand, such as ATE Gold and ATE Super Blue, to make it visually apparent when the new fluid has worked its way through the system. This helps prevent using more fluid than what's actually needed.

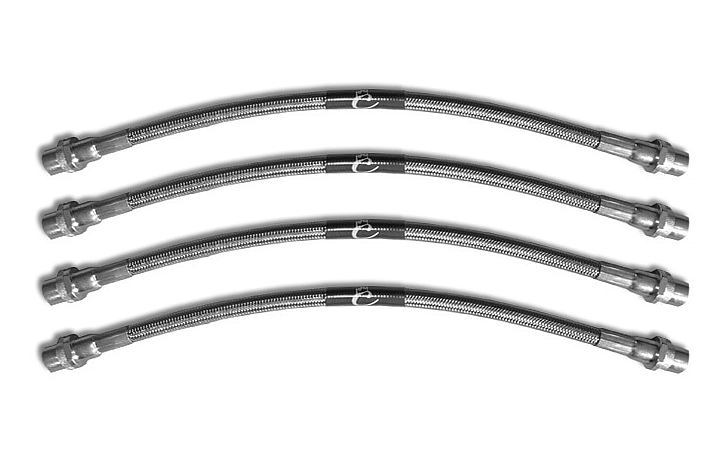

Stainless Steel Braided Brake Lines

DIY Cost – $75-$150 for four lines

Professional Cost – $80-$200 for labor, including bleeding

Skill Level – Easy; but bleeding the brake system is required.

While the stainless steel braided wrapping of these brake lines is often credited with helping to prevent the walls of the line from expanding during high-performance driving—thus, improving pedal response,—most experts agree that this hard outer covering can actually be more helpful for deflecting any impact and abrasion from road debris.

Some available stainless steel braided brake lines are listed as being DOT compliant, and having been individually tested to 4500 PSI. Recommended for its improved pedal response.

Racing Brake Pads

DIY Cost – $175-$350 for two pads

Professional Cost – $80-$100 for labor (plus a hefty mark-up on the brake pads if purchased through the dealer or repair shop)

Skill Level – Moderate; successfully "bedding in" the pads is required.

Racing brake pads are specifically formulated just for high-friction and high-temperature racing use to reduce brake fade. Many can result in more chirping and squealing, or excessive rotor wear and dirty wheels if used for normal driving. Racing brake pad manufacturers include Pagid, Hawk, Carbotech, GiroDisc, Mersen (Carbone Lorraine), Ferodo Racing, and PFC Bremse (Performance Friction).

Be aware that many racing brake pads produce less stopping friction in cold temperatures, which is another reason why they're very often only used on the track. In addition, as most aren't compatible with Porsche brake pad wear sensors, they will require regular inspection. Recommended for track racing.

Brake Air Ducts

DIY Cost – $30-$290 for two front end air ducts

Professional Cost – $80-$100 for labor (plus a hefty mark-up on the air ducts if purchased through the dealer or repair shop).

Skill Level – Easy; but the ducts and/or wheel-well liners may have to be trimmed to attain a proper fit.

The front brakes have to handle around 70 percent of the typical braking load, and a load that increases closer to 80 percent during performance runs. Better brake fluid can help to prevent your brakes from boiling, but reducing the amount of heat caused by the friction of fast driving is also important. A good way to reduce this heat, especially for the front brakes, is by blowing the heat of from behind racing wheels wit air ducts (sometimes called "air duct spoilers," or just "cups").

There are new aftermarket entire front ends available with custom build-in ducts, but these can be expensive ($3000). It will also require both installation and repainting. Instead, man driving enthusiasts install aftermarket, under-body air ducts, or upgrade the air ducts that came on their Porsche with ducts that move a greater volume of air. Recommended for its heat reduction.

Some examples:

- Install European 996 GT2 air ducts on a 997 Carrera, Turbo, or GT3 because the European air ducts are larger than the ones that came on these vehicles.

- Put 997 GT3 brake ducts on a 997 Carrera or Turbo.

Replacement Rotors

DIY Cost – $1,200-$2,800 for a pair of rotors

Professional Cost – $80-$200 for labor (plus a hefty mark-up on the rotors if purchased through the dealer or repair shop)

Skill Level – Moderate; a simple procedure to follow, but knowing how to safely position a car on jack stands and bleed a brake system is required.

Aggressive brake pads, or (worse) braking with totally worn-out pads will make a rotor unstable. If this happens, it's possible to replace just the rotor and still keep your stock calipers. Upgrading with replacement rotors—as opposed to a big brake kit—maintains both the OEM brake bias and ABS efficiency.

Available two-piece rotors allows you to reuse the mounting hub ("hat") and just buy a new cast-iron disc when they're needed. Many call them "steel" rotors, but they are generally made from gray cast iron. Usually sold in pairs, replacement rotors are made by GiroDisc, Alcon, AP Racing, Brembo, DBA, and PFC (Performance Friction). Recommended to maintain OEM brake bias and ABS efficiency.

Big Brake System

DIY Cost – $1,500-$3,500 for a front-end brake kit

Professional Cost – $150-$250 for labor (plus a hefty mark-up on the brake kit if purchased through the dealer or repair shop)

Skill Level – Moderate; a simple procedure to follow, but knowing how to safely position a car on jack stands and bleed a brake system is required.

There are numerous manufacturers of specialty brake kits (including PFC Performance Friction, StopTech, WP Pro, and PB), but many choose a high-performance brake kit built around brake pads, calipers, rotors, and new brake lines made by Brembo. Brembo is a major OEM supplier to over forty automotive manufacturers, and also makes specialty aftermarket performance braking systems.

Brake rotor surfaces can be slotted or cross-drilled. Slotted disc surfaces are typically recommended for using racing pad compounds, or driving in hilly areas. Cross-drilled discs run at slightly lower temperatures due to added air flow through the surface of the disk (where the heat is generated). Note, that as these brake kits are somewhat "generic" (that is can be adapted to different makes and models), their calipers typically use a mounting adapter spacer or bracket that has to be mounted to your strut assembly first. Recommended for its adaption to different makes and models.

Pro Tip

Before transferring the brake line over, put your wheel on with two lugs finger tight. Make sure your wheel fits on and spins with no clearance issues by turning it slowly. If the wheel rubs any surface, a wheel spacer and longer lug bolts will be required.

Composite Rotors

DIY Cost – $16,000-$31,000 for a set of four

Professional Cost – $80-$100 for labor (plus a hefty mark-up on the brake kit if purchased through a dealer or repair shop)

Skill Level – Moderate; a simple procedure to follow, but knowing how to safely position a car on jack stands and bleed a brake system is required.

Carbon ceramic brake rotors are for only the most serious track drivers. Carbon ceramic rotors are made from a matrix of special powders, resins, and fibers, which is similar to brake pad construction. They weigh less, have higher thermal conductivity, are more corrosion resistant, and are much more durable than cast iron rotors. They can last over 100,000 miles. So what's their downside? Their downside includes increased noise during low-speed driving, acting soft until they warm up, and, oh yeah, their astronomical cost.

Alcon sells a carbon ceramic brake kit, as does Brembo (Brembo calls them CMM for "carbon ceramic material"), and Porsche (Porsche calls them PCCB for "Porsche Carbon Ceramic Brake"). Recommended for the serious track drivers.

Related Discussions

- Brake Pad Comparisons - Rennlist.com

- Brakes Not Good Enough for Track - Rennlist.com

- Brake Upgrade Choices - Rennlist.com

- Stainless Steel Braided Brake Lines - Rennlist.com

- Carbon Ceramic Brake Kits Discussion - Rennlist.com

- Racing Brake Fluid Chat - Rennlist.com

- Comparison Between Carbon Ceramic and Cast Iron Brakes - Rennlist.com