Nose lift, CPO, PCNA

#46

Rennlist Member

looks like my FAL is on its way out too (seriously?) system raises, but no "lift" indicator, and will only lower when speed limit exceeded...

sigh

sigh

#47

Rennlist Member

Thread Starter

Out of warranty? I really hope I can keep the old unit so I can look into which pressure switch might have malfunctioned, or if it's a thermal switch or whatever. If we end up able to determine who's having issues with up/down, corresponding or repeat malfunctions-which of the switches are more prone to failure, we might be able to service the units ourselves.

Also, from reading the 991 forums, I think there's a bulletin about tightening the line connectors. I believe these are banjo bolts and if they leak, the shocks won't be filled all the way.

Also, from reading the 991 forums, I think there's a bulletin about tightening the line connectors. I believe these are banjo bolts and if they leak, the shocks won't be filled all the way.

#48

Rennlist Member

I had my system repaired recently. "Lift" wouldn't appear and the system would stay in the lifted mode until about after a couple of minutes of driving. The button would intermittently work. Service record shows cause being the level control pressure switch. Part numbers listed for replaced items are:

997-341-963-90 and

997-341-967-90.

997-341-963-90 and

997-341-967-90.

The following 2 users liked this post by MJFDDS:

Elliotw44 (05-24-2021),

porsche526 (05-27-2023)

#49

Rennlist Member

Out of warranty? I really hope I can keep the old unit so I can look into which pressure switch might have malfunctioned, or if it's a thermal switch or whatever. If we end up able to determine who's having issues with up/down, corresponding or repeat malfunctions-which of the switches are more prone to failure, we might be able to service the units ourselves.

Also, from reading the 991 forums, I think there's a bulletin about tightening the line connectors. I believe these are banjo bolts and if they leak, the shocks won't be filled all the way.

Also, from reading the 991 forums, I think there's a bulletin about tightening the line connectors. I believe these are banjo bolts and if they leak, the shocks won't be filled all the way.

I'll hook up my durametric and see if I can read any fault codes...

btw are we talking about the connectors at the compressor or bellows end or both?

I had my system repaired recently. "Lift" wouldn't appear and the system would stay in the lifted mode until about after a couple of minutes of driving. The button would intermittently work. Service record shows cause being the level control pressure switch. Part numbers listed for replaced items are:

997-341-963-90 and

997-341-967-90.

997-341-963-90 and

997-341-967-90.

the compressor when the bellows are full, low pressure trips when they are

empty ...

at $350 they are not a cheap part but compared to replacing the whole thing its a bargain...

clearly the speed sensitive switch still works that empties the bellows when the car exceeds 30mph...

so I am guessing that my fault has to do with the system sensing that the bellows are fully inflated.

#50

Originally Posted by Larry Cable

so I am guessing that my fault has to do with the system sensing that the bellows are fully inflated.

Can we use that to diagnose? I mean; as we don't see 'lift' show, and if this is due to the system not measuring that pressure has been reached, the compressor would continuously run, and some safety valve will bleed pressure?

If this is the case, wouldn't we be relatively sure that it is either that high pressure switch or the compressor that is not able to build pressure (hopefully not the issue)? Unless we have a leak in the system.

#51

Rennlist Member

So, you are thinking the high pressure switch is the issue? In that case, the compressor should continue to run, right? Are you able to determine that?

Can we use that to diagnose? I mean; as we don't see 'lift' show, and if this is due to the system not measuring that pressure has been reached, the compressor would continuously run, and some safety valve will bleed pressure?

If this is the case, wouldn't we be relatively sure that it is either that high pressure switch or the compressor that is not able to build pressure (hopefully not the issue)? Unless we have a leak in the system.

Can we use that to diagnose? I mean; as we don't see 'lift' show, and if this is due to the system not measuring that pressure has been reached, the compressor would continuously run, and some safety valve will bleed pressure?

If this is the case, wouldn't we be relatively sure that it is either that high pressure switch or the compressor that is not able to build pressure (hopefully not the issue)? Unless we have a leak in the system.

as you can see the car lift, *but* "LIFT" is never indicated on the dash, and pressing the button to lower it does not work, you have to exceed 30mph to

cause it to lower

not too mention there appears to be 3 pressure switches on the unit so not

sure what the function of that is.

I'll have to do some more diagnosis (durametric readout) and maybe check

the air lines at both ends

#52

I wish it was that straight forward, clearly the compressor on my car is working,

as you can see the car lift, *but* "LIFT" is never indicated on the dash, and pressing the button to lower it does not work, you have to exceed 30mph to

cause it to lower

not too mention there appears to be 3 pressure switches on the unit so not

sure what the function of that is.

I'll have to do some more diagnosis (durametric readout) and maybe check

the air lines at both ends

as you can see the car lift, *but* "LIFT" is never indicated on the dash, and pressing the button to lower it does not work, you have to exceed 30mph to

cause it to lower

not too mention there appears to be 3 pressure switches on the unit so not

sure what the function of that is.

I'll have to do some more diagnosis (durametric readout) and maybe check

the air lines at both ends

I have checked with my Duremetric, and see no info on this, but please do double check.

Post #10 states through another interface that a thermal switch has been activated and based on this others suggest that temperature might be the issue. Either from external sources (cooling pipes) or from the compressor overheating.

Larry suggests (post #30) to start with the thermal sensor, but I'm not sure of his reason for this.

My logic tells me that we should try and replace the two others, starting with the high pressure switch. MJFDDS has (ost #48) had these two replaced which fixed his problem of LIFT not being displayed and hence the button now working to lower the axel.

His reply has been exactly what I have been waiting for to get a better chance of replacing the right one. But please join in and challenge my logic, so we can figure this thing out.

Also, looking at the setup under the car the other day (posted pics in post #29), the cooling pipes are an issue to get up there to replace the switch. To me it looks like the wiring to the switch will come without a connector, as wires from all switches are joining in one single connector. Fitting wires to the connector with the unit installed on the car looks impossible to me.

Have anyone tried removing the unit? Is it as simple as emptying coolant, removing cooling pipes and then dropping the FAL unit (4 bolts or so)? I'm mostly concerned with the aluminimum cooling pipes and their rubber connectors. I don't know if they will post a problem?

#53

Rennlist Member

In case the compressor is the failing object and not providing the needed pressure, then the switch would never activate and LIFT will not get shown. I see the compressor as a possible point of failure, but hoping one of the switches is it.

I have checked with my Duremetric, and see no info on this, but please do double check.

Post #10 states through another interface that a thermal switch has been activated and based on this others suggest that temperature might be the issue. Either from external sources (cooling pipes) or from the compressor overheating.

Larry suggests (post #30) to start with the thermal sensor, but I'm not sure of his reason for this.

My logic tells me that we should try and replace the two others, starting with the high pressure switch. MJFDDS has (ost #48) had these two replaced which fixed his problem of LIFT not being displayed and hence the button now working to lower the axel.

His reply has been exactly what I have been waiting for to get a better chance of replacing the right one. But please join in and challenge my logic, so we can figure this thing out.

Also, looking at the setup under the car the other day (posted pics in post #29), the cooling pipes are an issue to get up there to replace the switch. To me it looks like the wiring to the switch will come without a connector, as wires from all switches are joining in one single connector. Fitting wires to the connector with the unit installed on the car looks impossible to me.

Have anyone tried removing the unit? Is it as simple as emptying coolant, removing cooling pipes and then dropping the FAL unit (4 bolts or so)? I'm mostly concerned with the aluminimum cooling pipes and their rubber connectors. I don't know if they will post a problem?

I have checked with my Duremetric, and see no info on this, but please do double check.

Post #10 states through another interface that a thermal switch has been activated and based on this others suggest that temperature might be the issue. Either from external sources (cooling pipes) or from the compressor overheating.

Larry suggests (post #30) to start with the thermal sensor, but I'm not sure of his reason for this.

My logic tells me that we should try and replace the two others, starting with the high pressure switch. MJFDDS has (ost #48) had these two replaced which fixed his problem of LIFT not being displayed and hence the button now working to lower the axel.

His reply has been exactly what I have been waiting for to get a better chance of replacing the right one. But please join in and challenge my logic, so we can figure this thing out.

Also, looking at the setup under the car the other day (posted pics in post #29), the cooling pipes are an issue to get up there to replace the switch. To me it looks like the wiring to the switch will come without a connector, as wires from all switches are joining in one single connector. Fitting wires to the connector with the unit installed on the car looks impossible to me.

Have anyone tried removing the unit? Is it as simple as emptying coolant, removing cooling pipes and then dropping the FAL unit (4 bolts or so)? I'm mostly concerned with the aluminimum cooling pipes and their rubber connectors. I don't know if they will post a problem?

#54

Rennlist Member

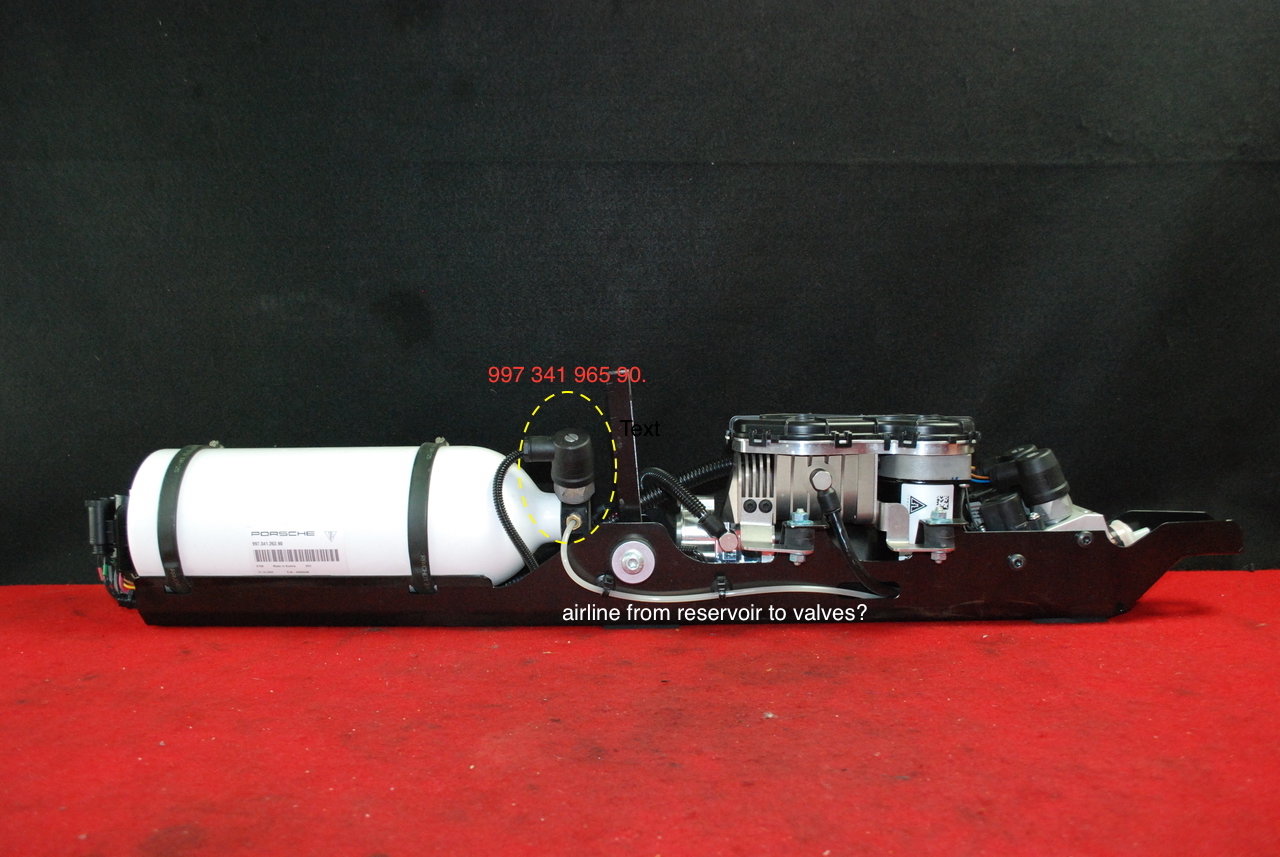

aha the 3rd pressure switch is between the compressor and the reservior

#55

Rennlist Member

There are 4 pressure switches, no detailed images, but here are some online search results:

http://www.porschesandiegoparts.com/...he/99734196790

http://www.localpartsshop.com/oe-porsche/99734196490

http://www.localpartsshop.com/oe-porsche/99734196390

http://www.porschesandiegoparts.com/...he/99734196590

Sonnen Porsche offers discounts too:

https://sonnenporscheoemparts.com/pa...&siteid=215405

http://www.porschesandiegoparts.com/...he/99734196790

http://www.localpartsshop.com/oe-porsche/99734196490

http://www.localpartsshop.com/oe-porsche/99734196390

http://www.porschesandiegoparts.com/...he/99734196590

Sonnen Porsche offers discounts too:

https://sonnenporscheoemparts.com/pa...&siteid=215405

#56

Rennlist Member

There is a technical article floating around that describes the lift system in quite a bit of detail. I tracked this article down at some point and have a text-only version. I just re-read and it specifically talks about the temperature switch:

Safety functions

For safety reasons, the control system includes various blocking conditions for which activation of the lift system is prevented or interrupted.

Activation of the lift system is permitted only if the vehicle has not exceeded a speed of 50 km/h. This limit prevents the changed vehicle aerodynamics of the raised vehicle from affecting the driving dynamics. If the speed limit is exceeded in raised position, the vehicle is automatically lowered to the basic level again.

Lowering of the vehicle is permitted only when the doors are closed. This condition prevents damage to the doors when parking over raised objects such as a kerb.

Frequent operation of the lift function in succession imposes a constant demand on the compressor to maintain the required system pressure. This can place a great thermal load on the compressor, especially if the outside temperatures are high. For this reason, a protective function contin-

uously monitors the compressor temperature. The temperature switch sends a signal to the control unit if the maximum permissible temperature is exceeded. The lifting function will then be deactivated until the compressor is ready for use again.

From the diagnostic readout you included above, it appears that your temperature limit is 'active', which I read to indicate that it is currently set, or limiting operation of the compressor. If this was taken right after the unit cycled numerous times, it might make sense. if was taken after an extended period of non-operation, then by definition the sensor is bad!

Safety functions

For safety reasons, the control system includes various blocking conditions for which activation of the lift system is prevented or interrupted.

Activation of the lift system is permitted only if the vehicle has not exceeded a speed of 50 km/h. This limit prevents the changed vehicle aerodynamics of the raised vehicle from affecting the driving dynamics. If the speed limit is exceeded in raised position, the vehicle is automatically lowered to the basic level again.

Lowering of the vehicle is permitted only when the doors are closed. This condition prevents damage to the doors when parking over raised objects such as a kerb.

Frequent operation of the lift function in succession imposes a constant demand on the compressor to maintain the required system pressure. This can place a great thermal load on the compressor, especially if the outside temperatures are high. For this reason, a protective function contin-

uously monitors the compressor temperature. The temperature switch sends a signal to the control unit if the maximum permissible temperature is exceeded. The lifting function will then be deactivated until the compressor is ready for use again.

From the diagnostic readout you included above, it appears that your temperature limit is 'active', which I read to indicate that it is currently set, or limiting operation of the compressor. If this was taken right after the unit cycled numerous times, it might make sense. if was taken after an extended period of non-operation, then by definition the sensor is bad!

and extracted a lot of out it, as follows:

components:

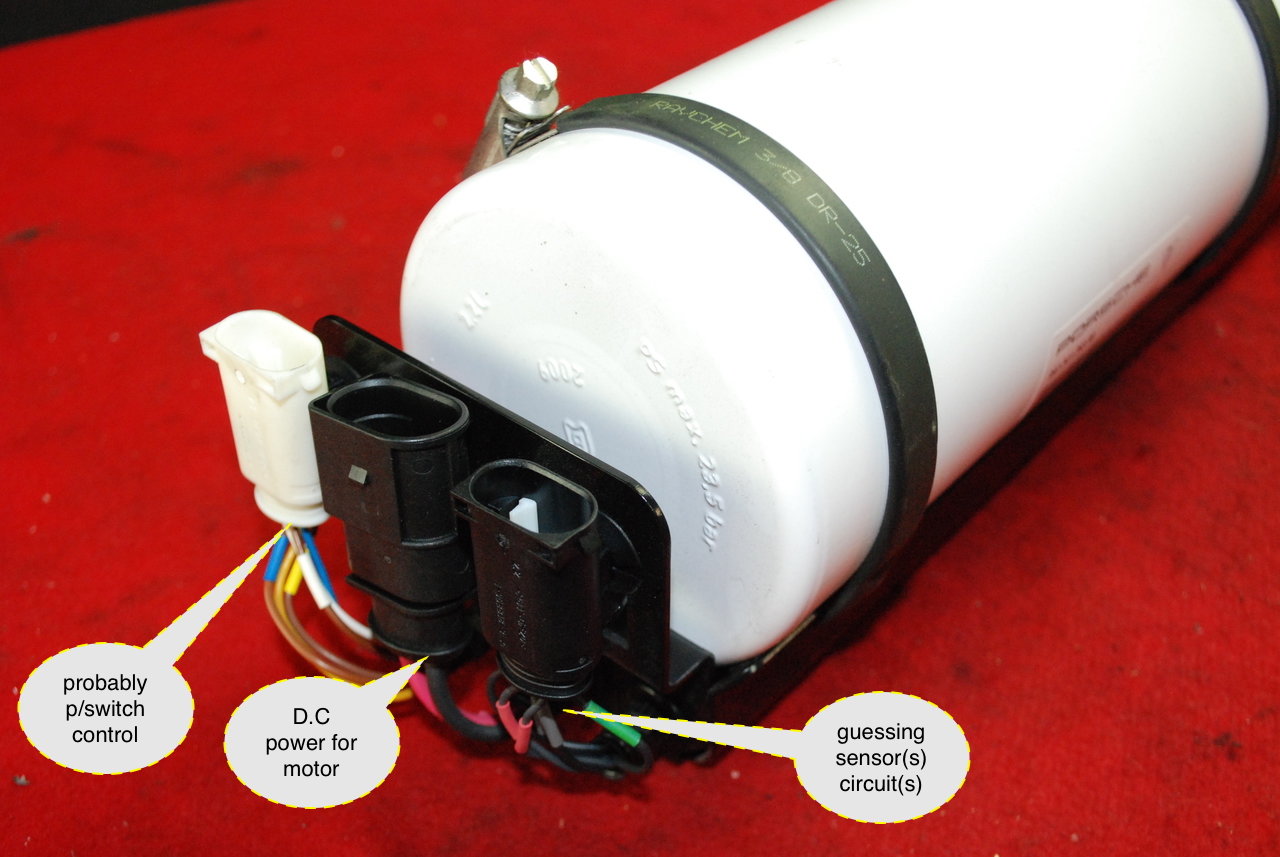

- function module (compressor, reservoir and valve block)

- front shocks

- control unit (I dont know where that is)

who made the piece of crap:

"Together with the system supplier, Ventrex Automotive, it was possible to develop the system for the market within a very brief time."

function:

"The compressor generates the required system pressure of 18 bar and delivers it to the pressure reservoir. A pressure switch permanently monitors the pressure level in the reservoir and the compressor automatically adjusts the pressure if necessary"

So the compressor fills the reservoir via the valve block and I think this is the 965 valve located between the compressor and the reservoir.

"Two electromagnetic valves on the valve block control the pressure build-up in the front axle shock absorbers"

I think these are the 963 and 964/7 valves ...

"This valve block also accommodates two other pressure switches that provide the basic information for the vehicle lift position."

aha, not listed as separate parts, but if these signal the up/down position of the FAL, then if one of these failed then this would probably cause the "LIFT"

indicator to malfunction.

"The conventional suspension strut at the front axle is used as a pneumatic cylinder for the lift function. Pneumatic connecting lines conduct the compressed air generated in the function module into the corresponding working chambers of the shock absorbers. "

so the air from the reservoir inflates the bladders...

"The overall system is controlled by a modular electronic control unit which processes system information such as the vehicle speed and the air pressure in the pressure reservoir and shock absorbers.

The driver operates the lift function with a button in the centre console. When the driver activates the lift function by pressing the button, the ?lift valve? on the valve block opens and allows compressed air to flow from the pressure reservoir into the corresponding front axle shock absorber chambers

"

So the air flows from the reservoir into the bladders through the valve block which is probably controlled by one or both of the pressure switches 963,4/7?

"When the pressure of 13 bar required for the raised position is reached, this is detected by a pressure switch and signalled to the control unit. The ?lift valve? is then closed again automatically and the ?LIFT? logo in the instrument cluster indicates the raised position to the driver"

So if the 13bar pressure sensor fails, or the system does not pressurize to 13bar then LIFT wont be displayed.

"Frequent operation of the lift function in succession imposes a constant demand on the compressor to maintain the required system pressure. This can place a great thermal load on the compressor, especially if the outside temperatures are high. For this reason, a protective function contin-

uously monitors the compressor temperature. The temperature switch sends a signal to the control unit if the maximum permissible temperature is exceeded. The lifting function will then be deactivated until the compressor is ready for use again.

"

clearly overheating or failure of the temp sensor disables the system

"Furthermore, a so-called anti-play function is integrated to prevent unnecessary up and down movements of the vehicle and the associated burden on the compressor. It limits the number of lifting activations to six within 60 s. If this number is exceeded, a corresponding protective function is triggered and manual activation of the lifting function remains blocked for 2 min."

I guess this would be handled by the control unit?

"A wheel-guiding suspension strut with an upside-down shock absorber has been installed in the GT3 for several vehicle generations, 4. With this shock absorber system, the shock absorber tube, guided in two plain bushes in an outer tube, performs the task of guiding the wheel. The actual shock absorber piston rod sticks out of the bottom of the shock absorber tube and is in turn bolted together with the outer tube base.

This design results in a hollow space between the guide tube and outer tube. The volume of this space changes with the suspension compression and can

therefore be used as a pneumatic cylinder. In order to use the shock absorber for this purpose, the outer tube had to be modified. It was fitted with a separate base which is constructed with or without seals and compressed air connection depending on the type (with/without lift system). The stop buffer integrated into the pressure space was also provided with air guide channels which are required to admit air and release it from the suspension strut.

As additional measures, it was necessary to modify the seal between the outer tube and shock absorber tube and to change the shock absorber seal package and fix it in axial direction for a secure seat under pressure application.

Overall, the result is a very simple lift suspension strut which is nearly neutral in terms of cost, space requirement and weight compared to a conventional suspension strut.

"

interesting so the shock itself is modified too?

"The TSC200 compressor used, 5, meets the high demands in terms of size, weight, performance and sound emission. It is a new development from Ventrex Automotive. The compressor (maintenance-free dry-running compressor) functions according to a two-stage principle and thereby realises an ideal relationship between size and performance. The compressor, driven by a high-speed DC motor via a toothed belt, is characterised by its quiet operation.

An integrated adsorption air dryer with regeneration function reduces the water content in the compressed air and includes both a drain valve unit and a maximum

pressure limiting function. The compact unit measures 224 x 148 x 84?mm, weighs only 2.4 kg and is fastened via elastomer decoupling elements to the unit carrier of the function module.

A special feature of the compressor is its modular design. Different power variants can be realised as required by adapting the drive ratio and possibly the motor; active fan cooling can be integrated as an option. The supply diagram, 6, shows the compressor characteristic selected for use in the GT3 lift system.

"

So lets try and put all this together into possible failure modes:

1) FAL control module failure (not sure where this is located in the car - havent found it on PET):

- nothing works; no light on the button nothing, probably throws error code appropriate to its failure

2) compressor failure:

- motor burns out, drive belt breaks, thermal sensor failure

- probably throws appropriate fault code (except perhaps belt failure)

- no compression occurs

- probably requires function unit replacement, or at least some specialist to repair/replace the TSC200 compressor unit

3) pressurization failure:

- system leak somewhere between function unit and shock

- system may partially or erratically function

- probably solvable by replacing air lines or other pressure components

4) shocks leaking air:

- same as (3)

5) valve failure:

- reservoir fails to fill or empty?

- replace pressure switches as necessary (depending on failure mode)

wish we had the illustrations...

Last edited by Larry Cable; 09-18-2016 at 05:51 PM.

#57

Rennlist Member

Thread Starter

If removing the whole unit involves getting coolant pipes out of the way, I'd say it's an added nightmare-

The answer might come from indie shops or forum sponsors that see this thread and can shed some light-

As a last ditch effort once warranty is expired, I'd say buying all the switches and replacing one by one until the system works would help figure out which one corresponds to the problem(Lift not lighting up on the dash, or in my case Lift Malfunction)

My friend's shop does not have a PIWIS, and his system seemed incomplete in the 997 menu.

There was however a 996 GT3 menu, but I don't even think they had lift systems

I'll ask him to see if he can upgrade his software for future diagnosis

My Durametric Enthusiast was pretty much worthless-

Looking through my 997 Technical Information .pdf I don't see a section on the Lift System-

The answer might come from indie shops or forum sponsors that see this thread and can shed some light-

As a last ditch effort once warranty is expired, I'd say buying all the switches and replacing one by one until the system works would help figure out which one corresponds to the problem(Lift not lighting up on the dash, or in my case Lift Malfunction)

My friend's shop does not have a PIWIS, and his system seemed incomplete in the 997 menu.

There was however a 996 GT3 menu, but I don't even think they had lift systems

I'll ask him to see if he can upgrade his software for future diagnosis

My Durametric Enthusiast was pretty much worthless-

Looking through my 997 Technical Information .pdf I don't see a section on the Lift System-

#58

Rennlist Member

If removing the whole unit involves getting coolant pipes out of the way, I'd say it's an added nightmare-

The answer might come from indie shops or forum sponsors that see this thread and can shed some light-

As a last ditch effort once warranty is expired, I'd say buying all the switches and replacing one by one until the system works would help figure out which one corresponds to the problem(Lift not lighting up on the dash, or in my case Lift Malfunction)

My friend's shop does not have a PIWIS, and his system seemed incomplete in the 997 menu.

There was however a 996 GT3 menu, but I don't even think they had lift systems

I'll ask him to see if he can upgrade his software for future diagnosis

My Durametric Enthusiast was pretty much worthless-

Looking through my 997 Technical Information .pdf I don't see a section on the Lift System-

The answer might come from indie shops or forum sponsors that see this thread and can shed some light-

As a last ditch effort once warranty is expired, I'd say buying all the switches and replacing one by one until the system works would help figure out which one corresponds to the problem(Lift not lighting up on the dash, or in my case Lift Malfunction)

My friend's shop does not have a PIWIS, and his system seemed incomplete in the 997 menu.

There was however a 996 GT3 menu, but I don't even think they had lift systems

I'll ask him to see if he can upgrade his software for future diagnosis

My Durametric Enthusiast was pretty much worthless-

Looking through my 997 Technical Information .pdf I don't see a section on the Lift System-

I wont bother connecting my durametric then.

if any of the pressure sensors (not the switches) have gone, or the compressor thermal cutout has given up, I think the only resort is either to

completely replace the unit, or take it to an "expert" indie shop that can

source and replace either the pressure sensors or the TSC compressor itself.

would be interesting to see if the factory/workshop manuals have any insights into diagnosing the problems?

I fear that probably the only way to solve this is to get someone under a car with a multi-meter and attempt to observe voltage changes across the components (which would in itself probably be quite destructive to the wirimg)

I think you need to get someone to attach a PIWIS to your car and get any additional fault codes downloaded as a starting point, you need all the info

you can get in order to start the diagnosis, but if it is not a failed switch or

a pressure leak, I think the answer is get a new unit

#59

I have had Porsche check for errors on my system with the LIFT fault, and there were none.

The sensors themselves look simple enough to replace as does dropping the unit. Only the issue here is the mentioned coolant pipes (check out the pics in my earlier post).

Just need someone to chime in with experience on removing them.

Also workshop manual info would be very relevant here.

The sensors themselves look simple enough to replace as does dropping the unit. Only the issue here is the mentioned coolant pipes (check out the pics in my earlier post).

Just need someone to chime in with experience on removing them.

Also workshop manual info would be very relevant here.

#60

Rennlist Member

I have had Porsche check for errors on my system with the LIFT fault, and there were none.

The sensors themselves look simple enough to replace as does dropping the unit. Only the issue here is the mentioned coolant pipes (check out the pics in my earlier post).

Just need someone to chime in with experience on removing them.

Also workshop manual info would be very relevant here.

The sensors themselves look simple enough to replace as does dropping the unit. Only the issue here is the mentioned coolant pipes (check out the pics in my earlier post).

Just need someone to chime in with experience on removing them.

Also workshop manual info would be very relevant here.

actually if there were no fault codes, I think this is probably a *good* thing, since I am sure that any compressor failures would throw such, and a

compressor failure means a new unit.

I think you should check for air leaks between the unit and the shocks...

btw I think if any one of the 3 pressure switches fail, the unit would fail to function.