Cup Car Shifter --> Teardown & SHIFT-RIGHT Solution upgrade

#1

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Thread Starter

The Cup shifter came standard on all factory 996 GT3 Cup racecars. It is derived from, and nearly identical to, the street 996 shifter - the cradle, shift lever and housing, and shifter yoke are all carried over from the street unit.

(OEM Cup Car shifter)

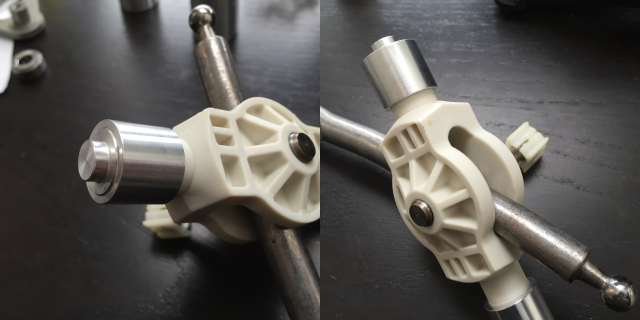

The only upgraded components are the shifter bushings (that the shift lever housing rotates left-right within). The street unit utilizes rubber/plastic bushings:

(OEM 996 shifter bushings: plastic sleeve bearing > rubber insulator > plastic snap-in housing)

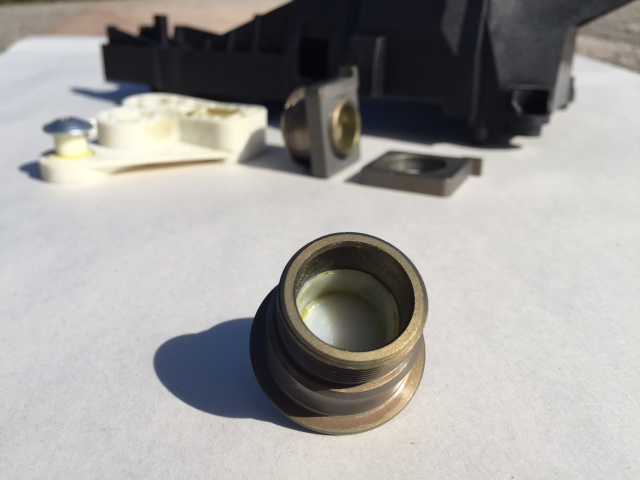

Whereas the Cup version replaces these with plastic-lined aluminum bushings:

(Cup shifter bushing: plastic sleeve bearing > aluminum threaded housing)

This one difference makes a big improvement over the street unit through increased durability and enhanced shifting precision by eliminating the flex that plagues the plastic bushings. A couple drawbacks, however, still remain with the Cup shifter:

EXCESS SHIFTER PLAY – The aluminum bushings eliminate flex in the shifter mechanism, but the bushings (sleeve/plain bearings) require axial and radial play to prevent binding. When shifting gears, the loads on the shifting mechanism are increased, which further exaggerates the loose tolerances, resulting in imprecise shifting action. Similarly, the shifter yoke rotates about a plain bearing with loose tolerances, so there’s a delay in actuating the shifter cable with side-side shifter motion. This plastic bearing continually degrades over time, resulting in further diminished performance.

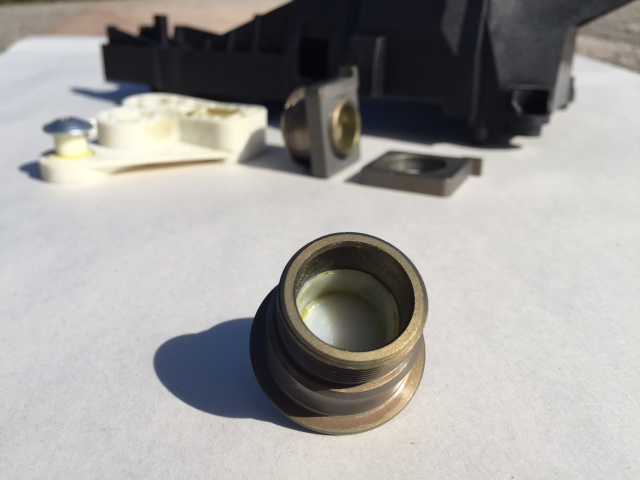

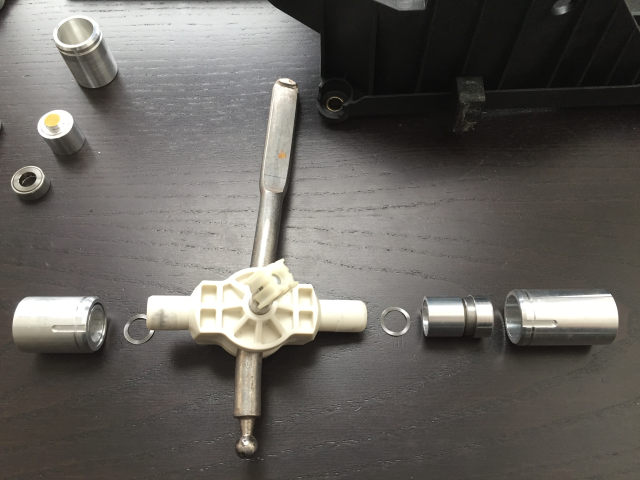

(Cup shifter components: plastic yoke sleeve bearing, plastic yoke, and aluminum bushings)

LONG SHIFTER THROW – The throw of the 996 Cup transmission is shorter than on the street transmission - so with equivalent shifters, the throw will always be longer on the street car.

(fore-aft cable travel on the 996.2 Cup car is 38mm, whereas cable travel on a 997.1 Carrera S is 49.5mm)

Therefore, using the Cup shifter on your street car will yield noticeably longer shifter throws, especially when installed on a 997, since the 997 standard throw shifter already reduces shifter throw by 15% versus the 996 standard throw shifter.

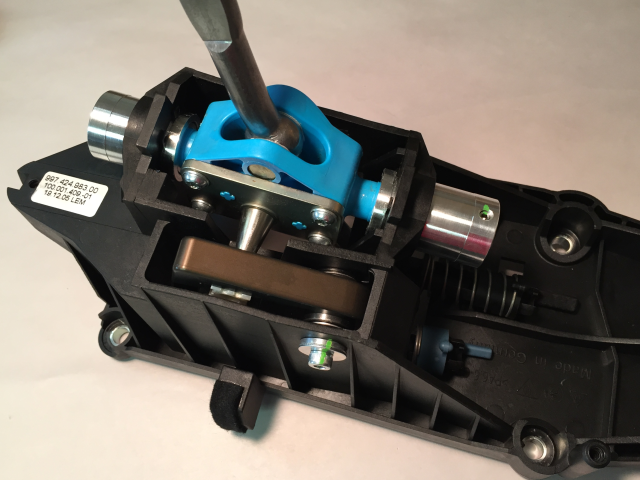

In order to address the shortcomings with the OEM shifter, and those that remained with the Cup unit, Function-First Performance developed the SHIFT-RIGHT Solution as a comprehensive kit to transform your OEM shifter into an exacting instrument with which to control the transmission. The retrofit kit replaces the flexible and imprecise OEM pivot points (shifter bushings and yoke) with billet aluminum and heavy-duty ball bearing components, while retaining the factory shifter’s reliable parts (shifter cradle and lever) to ensure longevity under all driving conditions.

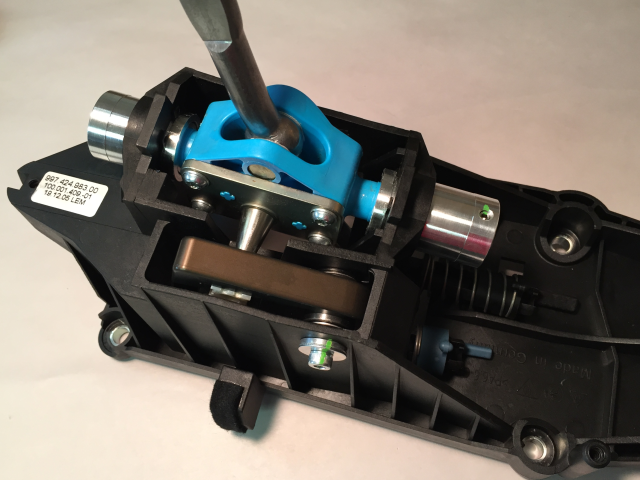

(Cup shifter with SHIFT-RIGHT Solution – now essentially a standard 996 shifter with SRS upgrade)

I’ll dissect the SHIFT-RIGHT Solution in an upcoming post to showcase its features and the decisions behind the design, but for now I thought the teardown of the OEM and Cup shifter units would provide some good insight into the inner workings of the factory shifters.

.

(OEM Cup Car shifter)

The only upgraded components are the shifter bushings (that the shift lever housing rotates left-right within). The street unit utilizes rubber/plastic bushings:

(OEM 996 shifter bushings: plastic sleeve bearing > rubber insulator > plastic snap-in housing)

Whereas the Cup version replaces these with plastic-lined aluminum bushings:

(Cup shifter bushing: plastic sleeve bearing > aluminum threaded housing)

This one difference makes a big improvement over the street unit through increased durability and enhanced shifting precision by eliminating the flex that plagues the plastic bushings. A couple drawbacks, however, still remain with the Cup shifter:

EXCESS SHIFTER PLAY – The aluminum bushings eliminate flex in the shifter mechanism, but the bushings (sleeve/plain bearings) require axial and radial play to prevent binding. When shifting gears, the loads on the shifting mechanism are increased, which further exaggerates the loose tolerances, resulting in imprecise shifting action. Similarly, the shifter yoke rotates about a plain bearing with loose tolerances, so there’s a delay in actuating the shifter cable with side-side shifter motion. This plastic bearing continually degrades over time, resulting in further diminished performance.

(Cup shifter components: plastic yoke sleeve bearing, plastic yoke, and aluminum bushings)

LONG SHIFTER THROW – The throw of the 996 Cup transmission is shorter than on the street transmission - so with equivalent shifters, the throw will always be longer on the street car.

(fore-aft cable travel on the 996.2 Cup car is 38mm, whereas cable travel on a 997.1 Carrera S is 49.5mm)

Therefore, using the Cup shifter on your street car will yield noticeably longer shifter throws, especially when installed on a 997, since the 997 standard throw shifter already reduces shifter throw by 15% versus the 996 standard throw shifter.

In order to address the shortcomings with the OEM shifter, and those that remained with the Cup unit, Function-First Performance developed the SHIFT-RIGHT Solution as a comprehensive kit to transform your OEM shifter into an exacting instrument with which to control the transmission. The retrofit kit replaces the flexible and imprecise OEM pivot points (shifter bushings and yoke) with billet aluminum and heavy-duty ball bearing components, while retaining the factory shifter’s reliable parts (shifter cradle and lever) to ensure longevity under all driving conditions.

(Cup shifter with SHIFT-RIGHT Solution – now essentially a standard 996 shifter with SRS upgrade)

I’ll dissect the SHIFT-RIGHT Solution in an upcoming post to showcase its features and the decisions behind the design, but for now I thought the teardown of the OEM and Cup shifter units would provide some good insight into the inner workings of the factory shifters.

.

__________________

Comprehensive Shifting Solutions for your Porsche.

.

Comprehensive Shifting Solutions for your Porsche.

#4

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Thread Starter

The SHIFT-RIGHT Solution kit has been out for a couple months now. I did an initial production run of 10 units back in September, and there are some reviews out there.

Here's an excerpt from the 996 Turbo forum thread:

https://rennlist.com/forums/996-turb...ifter-kit.html

Highly recommend, whether you have a stock shifter or a short shift kit, it removed all the slop in the pivots and transfer mechanisms. I think it actually helps the 2-3 shift smoothness as well where it used to hang up if you tried to force it too quickly before, maybe since there is ZERO play now, it's just straight shooting.

Very satisifed

Bill

You can see full details on the SHIFT-RIGHT retrofit kit here:

https://rennlist.com/forums/996-turb...ifter-kit.html

Here's an excerpt from the 996 Turbo forum thread:

https://rennlist.com/forums/996-turb...ifter-kit.html

Highly recommend, whether you have a stock shifter or a short shift kit, it removed all the slop in the pivots and transfer mechanisms. I think it actually helps the 2-3 shift smoothness as well where it used to hang up if you tried to force it too quickly before, maybe since there is ZERO play now, it's just straight shooting.

Very satisifed

Bill

You can see full details on the SHIFT-RIGHT retrofit kit here:

https://rennlist.com/forums/996-turb...ifter-kit.html

#7

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Thread Starter

In continuation of the original post, I wanted give everyone a deeper look into how the SHIFT-RIGHT Solution improves upon the strengths of the OEM shifter assembly while eliminating its shortcomings.

To sum it up, the SHIFT-RIGHT Solution replaces the plastic bushings and pivot connections of the OEM shifter assembly with ball bearings and machined aluminum parts, eliminating the flex and excess play that plagues the stock setup. Plus, it preserves the strongest parts of the OEM shifter assembly for increased durability and reduced cost.

But here’s an in-depth look into how and why all that was achieved…

DESIGN REQUIREMENTS

Implement high-capacity ball bearings.

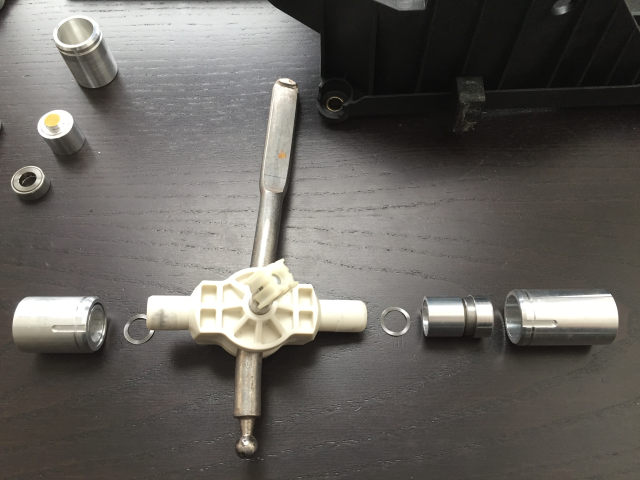

The only way to remove endplay from the pivot points, while simultaneously allowing for smooth operation, is through utilizing ball bearings in a configuration that allows for pre-loading them. And a key design consideration is the selection of an appropriate bearing to deliver durability and reliability. The front and rear bearings, within which the shift lever assembly rotates left-right, experience a majority of their loads axially (in-line with its axis), so high-capacity hardened steel thrust ball bearings were chosen. The shift lever assembly is entirely supported by these 2 ball bearings, and are pre-loaded via the rear set screw to eliminate all fore-aft play. Their high-capacity is especially important under repetitive and high stress conditions like track driving, and in shifting configurations that remove dampening features (rubber cable ends) as with Cup shifter cables.

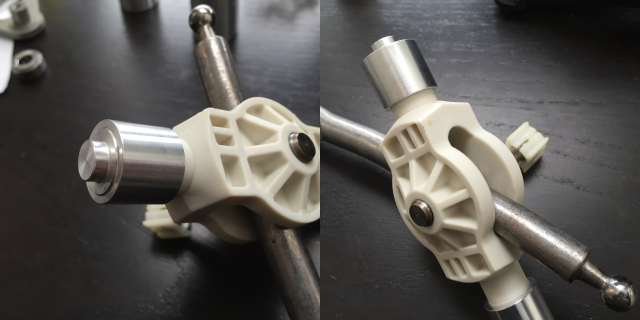

And to ensure that all left-right shift lever force is transferred to the transmission, the shifter yoke is mounted on 2 deep-groove ball bearings to eliminate any lateral play when transitioning between the gear rows (i.e. shifts 2-3 & 4-5).

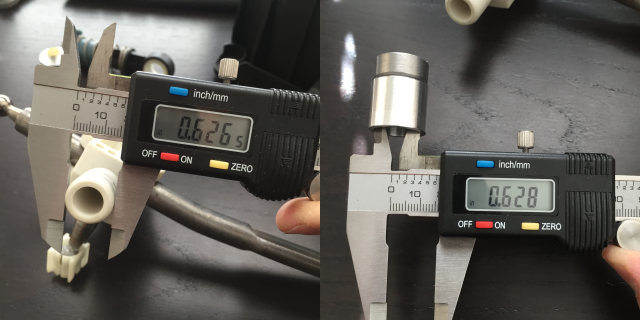

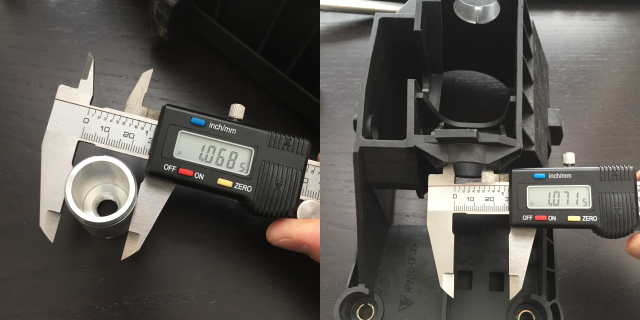

Tightly tolerance machined parts for unprecedented fit and operation.

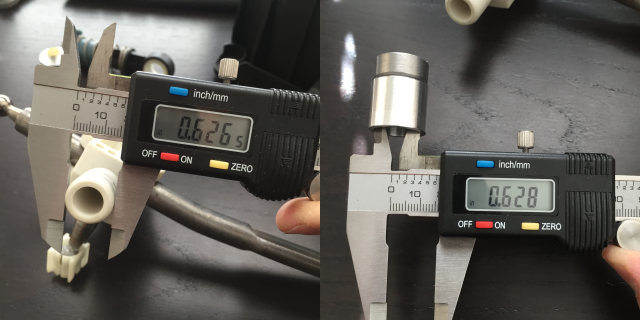

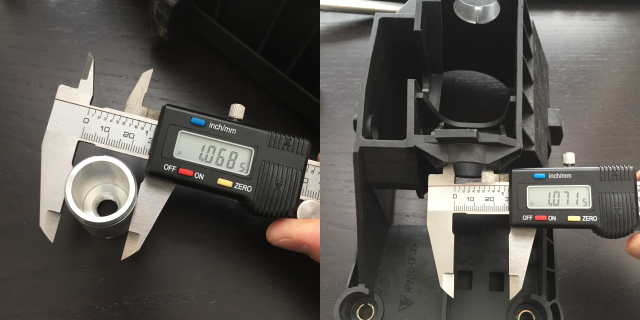

In order to deliver superior fit and operation, all machined parts need to be tightly toleranced to both each other and the existing OEM shifter mechanism in which it’s being installed – any failure here would negate the benefits achieved with the ball bearings. As such, special care was taken in the design and tolerancing of all 6 unique machined parts of the SHIFT-RIGHT Solution retrofit kit to guarantee a close-fitting assembly – all slip-fits are within 0.003” of one another (see pics below). Additionally, in order to safeguard the high wear contact points of the shifter yoke and preserve those tolerances, it is hardcoat anodized with a Teflon impregnation for reduced friction.

Utilize the OEM shifter cradle and shift lever assembly to ensure factory fitment and keep costs down.

The OEM shifter cradle is a one-piece design molded from glass-fiber reinforced plastic, and as such is extremely rigid, making it an excellent platform within which to upgrade the shifter mechanism. And the OEM shift lever uses a beefy steel lever that can reliably handle the abuse of repetitive high loads. By re-using these OEM pieces, durability is preserved and upgrade costs are minimized.

RESULTS

So what does all this mean for the driver, in practical terms?

Fewer Missed Shifts.

Eliminating shifter play yields predictable and consistent shifter feel for confident gear engagement – no more second guessing whether the car is in the desired gear or not. Each shift is delivered with certainty.

Efficient Gear Changes.

Reducing the friction in the shifter mechanism delivers smooth and uninhibited shift lever path of travel. Reducing shifter flex maximizes the shifting energy transferred to the transmission gear selector arm. What you put in is what you get out.

High Quality Feel.

Removing the flex, play, and overall sloppiness of OEM shifter assembly eliminates the cheap feel every time you reach for the gear lever. You’re driving a Porsche!

To sum it up, the SHIFT-RIGHT Solution replaces the plastic bushings and pivot connections of the OEM shifter assembly with ball bearings and machined aluminum parts, eliminating the flex and excess play that plagues the stock setup. Plus, it preserves the strongest parts of the OEM shifter assembly for increased durability and reduced cost.

But here’s an in-depth look into how and why all that was achieved…

DESIGN REQUIREMENTS

Implement high-capacity ball bearings.

The only way to remove endplay from the pivot points, while simultaneously allowing for smooth operation, is through utilizing ball bearings in a configuration that allows for pre-loading them. And a key design consideration is the selection of an appropriate bearing to deliver durability and reliability. The front and rear bearings, within which the shift lever assembly rotates left-right, experience a majority of their loads axially (in-line with its axis), so high-capacity hardened steel thrust ball bearings were chosen. The shift lever assembly is entirely supported by these 2 ball bearings, and are pre-loaded via the rear set screw to eliminate all fore-aft play. Their high-capacity is especially important under repetitive and high stress conditions like track driving, and in shifting configurations that remove dampening features (rubber cable ends) as with Cup shifter cables.

And to ensure that all left-right shift lever force is transferred to the transmission, the shifter yoke is mounted on 2 deep-groove ball bearings to eliminate any lateral play when transitioning between the gear rows (i.e. shifts 2-3 & 4-5).

Tightly tolerance machined parts for unprecedented fit and operation.

In order to deliver superior fit and operation, all machined parts need to be tightly toleranced to both each other and the existing OEM shifter mechanism in which it’s being installed – any failure here would negate the benefits achieved with the ball bearings. As such, special care was taken in the design and tolerancing of all 6 unique machined parts of the SHIFT-RIGHT Solution retrofit kit to guarantee a close-fitting assembly – all slip-fits are within 0.003” of one another (see pics below). Additionally, in order to safeguard the high wear contact points of the shifter yoke and preserve those tolerances, it is hardcoat anodized with a Teflon impregnation for reduced friction.

Utilize the OEM shifter cradle and shift lever assembly to ensure factory fitment and keep costs down.

The OEM shifter cradle is a one-piece design molded from glass-fiber reinforced plastic, and as such is extremely rigid, making it an excellent platform within which to upgrade the shifter mechanism. And the OEM shift lever uses a beefy steel lever that can reliably handle the abuse of repetitive high loads. By re-using these OEM pieces, durability is preserved and upgrade costs are minimized.

RESULTS

So what does all this mean for the driver, in practical terms?

Fewer Missed Shifts.

Eliminating shifter play yields predictable and consistent shifter feel for confident gear engagement – no more second guessing whether the car is in the desired gear or not. Each shift is delivered with certainty.

Efficient Gear Changes.

Reducing the friction in the shifter mechanism delivers smooth and uninhibited shift lever path of travel. Reducing shifter flex maximizes the shifting energy transferred to the transmission gear selector arm. What you put in is what you get out.

High Quality Feel.

Removing the flex, play, and overall sloppiness of OEM shifter assembly eliminates the cheap feel every time you reach for the gear lever. You’re driving a Porsche!

Trending Topics

#8

Interesting. I just read through the install instructions. Seems a bit involved since the shifter assembly plastic bearing is cut apart during the install and some of the tightening operations have lots of warning disclaimers.

First remove the center console and disconnect cables, easy enough. Can the rest of the install be done with the shifter still installed in the car? Or does the OEM shifter need to be removed and "operated on" at the bench? How difficult of an install project is this for a DIY person?

First remove the center console and disconnect cables, easy enough. Can the rest of the install be done with the shifter still installed in the car? Or does the OEM shifter need to be removed and "operated on" at the bench? How difficult of an install project is this for a DIY person?

#10

Makes sense, good to know. So remove console, disconnect shifter cables, remove shifter assembly and work on the bench. What about the next steps? There are install instructions on FF's website. How difficult is the surgery on the shifter in those instructions? I've done a lot of DIY parts swaps but this is more of parts modifications. You need to cut out the old plastic bearing with a utility knife, slide in new parts, torque down carefully not to damage bearing raceways but no torque specs listed, etc.

I like that this kit claims better performance than OEM. An upgraded shifter like Numeric's or Porsche's cup car is on my wish list so maybe this kit could work for me. I also like that the list price is roughly half of competing solutions requiring the whole shifter assembly to be replaced. But I'd be nervous for two reasons: (1) the difficulty level of modifying the OEM assembly on the bench and (2) you permanently modify your OEM shifter, there's no going back with your original part once you install this. You would need to replace the shifter with a different OEM one if you wanted to go back to stock.

Price is attractive though, especially if the performance meets expectations.

I like that this kit claims better performance than OEM. An upgraded shifter like Numeric's or Porsche's cup car is on my wish list so maybe this kit could work for me. I also like that the list price is roughly half of competing solutions requiring the whole shifter assembly to be replaced. But I'd be nervous for two reasons: (1) the difficulty level of modifying the OEM assembly on the bench and (2) you permanently modify your OEM shifter, there's no going back with your original part once you install this. You would need to replace the shifter with a different OEM one if you wanted to go back to stock.

Price is attractive though, especially if the performance meets expectations.

#11

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Thread Starter

So I didn't mean for the installation instructions to come off as intimidating - just very thorough! This is absolutely a DIY for most people - if you have the required tools and follow the directions step by step, you should have no issues at all. Modifying the OEM shifter only adds 30mins to the install. And I even included comprehensive steps for removing the OEM center console.

As for installing the SHIFT-RIGHT Solution in the OEM shifter cradle, it's really no different than installing an aftermarket short shifter. The only extra step is replacing the OEM shifter yoke with the upgraded unit. All the bearings are pre-installed in the components, so despite there being 7 machined aluminum pieces and 4 ball bearings, there are really only 3 parts + hardware in the kit.

The torque advisories are in bold and highlighted so that people won't glance over them. It doesn't add any difficulty to the process, you just need to be mindful of it. And since people generally have a tendency to over-tighten nuts/bolts, I wanted to be extra careful in pointing out the proper installation technique for the ball bearing components.

If there are any questions or recommendations to make the steps clearer, please let me know and I can update the install guide!

As for installing the SHIFT-RIGHT Solution in the OEM shifter cradle, it's really no different than installing an aftermarket short shifter. The only extra step is replacing the OEM shifter yoke with the upgraded unit. All the bearings are pre-installed in the components, so despite there being 7 machined aluminum pieces and 4 ball bearings, there are really only 3 parts + hardware in the kit.

The torque advisories are in bold and highlighted so that people won't glance over them. It doesn't add any difficulty to the process, you just need to be mindful of it. And since people generally have a tendency to over-tighten nuts/bolts, I wanted to be extra careful in pointing out the proper installation technique for the ball bearing components.

If there are any questions or recommendations to make the steps clearer, please let me know and I can update the install guide!

#13

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Thread Starter

I'll also be rolling out a core exchange program for OEM 997 shifters. These will be priced a little higher than the kit itself (to account for the installation costs) plus a core deposit, but the price will remain very competitive as compared to the alternative shifter options on the market.

I'll have some more details shortly.

I'll have some more details shortly.

#14

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Thread Starter

Due to several requests, I've put together a Group Buy for the SHIFT-RIGHT Solution. Please visit the following link for full details:

https://rennlist.com/forums/parts-ma...shift-kit.html

Ends Feb 1, 2016!

https://rennlist.com/forums/parts-ma...shift-kit.html

Ends Feb 1, 2016!