997.2 PCM Audio stopped

#31

Rennlist Member

#33

Three Wheelin'

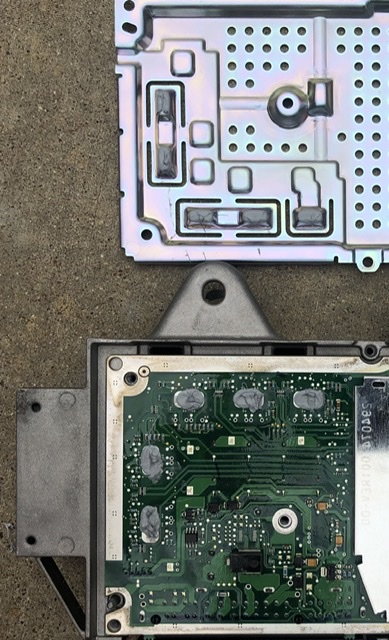

I did crack the amp back open today and put down a layer of thermal paste so hopefully that will fix the issue. Mine has only cut out a few times though and almost always on road trips, which I do not have any soon that I am aware of. I also put paste on the shield side to help with some thermal conductivity. There was no paste there from the manufacturer.

#34

RL Community Team

Rennlist Member

Rennlist Member

So I just gob some on?..... looks pretty simple. On the shield side, looks like you had to "pile it up" as the shield does not touch the board... correct? Any special paste or is it pretty generic?

Yep, I am still wrong, always wrong, and on top of that, I should have known.

Bulging cans..... sounds like a girl I dated in Cleveland.

Thermal switch.... do you guys know how to identify it on the board? I am handy with a soldering iron... if I knew how to identify it..... maybe just replace that too. no?

Peace

Bruce in Philly

Yep, I am still wrong, always wrong, and on top of that, I should have known.

Bulging cans..... sounds like a girl I dated in Cleveland.

Thermal switch.... do you guys know how to identify it on the board? I am handy with a soldering iron... if I knew how to identify it..... maybe just replace that too. no?

Peace

Bruce in Philly

#35

Three Wheelin'

So I just gob some on?..... looks pretty simple. On the shield side, looks like you had to "pile it up" as the shield does not touch the board... correct? Any special paste or is it pretty generic?

Yep, I am still wrong, always wrong, and on top of that, I should have known.

Bulging cans..... sounds like a girl I dated in Cleveland.

Thermal switch.... do you guys know how to identify it on the board? I am handy with a soldering iron... if I knew how to identify it..... maybe just replace that too. no?

Peace

Bruce in Philly

Yep, I am still wrong, always wrong, and on top of that, I should have known.

Bulging cans..... sounds like a girl I dated in Cleveland.

Thermal switch.... do you guys know how to identify it on the board? I am handy with a soldering iron... if I knew how to identify it..... maybe just replace that too. no?

Peace

Bruce in Philly

The metal shield does touch the board, but barely and there was no thermal paste to help conductivity. Zoom in on the big silver pads and you will see how lacking the contact was and why I put down paste.

#36

Racer

I like Thermal Grizzly compound. It's computer nerd stuff, but it is made by someone who knows what they're doing. The Kryonaut and Aeronaut are both good and would work well here. (do not get the Conductonaut - that's actually liquid metal and highly corrosive to aluminum). Note the working temperature of the Kryonaut is -250c to +350c.

http://www.thermal-grizzly.com/en/products

(widely available on Amazon and computer places)

If you're going to replace the fan, I recommend the Noctua. High quality, very long life, wide temperature range and extremely quiet. Best you can buy. My second choices would include Delta, Panasonic or some other brand you've ever heard of.

I would be a little reluctant to use a weird brand from the "China Ecosystem" (ie, chinesium crapshoot).

The most suspect caps are the ones in the power section. The 8 big electrolytics and the handful of surface mount electrolytics near it. There may not be physical signs of failure though. They tend to fail "open" meaning they just lose their capacity and increase resistance. The only way to test them is with a capacitor checker.

Also - just eyeball the circuit board carefully with a strong light and a magnifying glass. You might spot where something has been hot, or the solder has gotten bad over time. It is all lead-free crappy ROHS solder.

http://www.thermal-grizzly.com/en/products

(widely available on Amazon and computer places)

If you're going to replace the fan, I recommend the Noctua. High quality, very long life, wide temperature range and extremely quiet. Best you can buy. My second choices would include Delta, Panasonic or some other brand you've ever heard of.

I would be a little reluctant to use a weird brand from the "China Ecosystem" (ie, chinesium crapshoot).

The most suspect caps are the ones in the power section. The 8 big electrolytics and the handful of surface mount electrolytics near it. There may not be physical signs of failure though. They tend to fail "open" meaning they just lose their capacity and increase resistance. The only way to test them is with a capacitor checker.

Also - just eyeball the circuit board carefully with a strong light and a magnifying glass. You might spot where something has been hot, or the solder has gotten bad over time. It is all lead-free crappy ROHS solder.

#37

RL Community Team

Rennlist Member

Rennlist Member

Question about the cans....... if just one went bad, would that cause the whole amp to cut out as we experience? Should it just cause the one channel to go? In other words, what if I went ahead and re-placed those big caps? Odd that would do the job?

Peace

Bruce in Philly

Peace

Bruce in Philly

#38

Rennlist Member

Electrolytic capacitors are one of the high failure items in any amplifier (along with power resistors). They act like a reservoir for the power in the amp. The "river" that supplies the reservoir can surge or be a trickle but the reservoir allows a nice even flow of water (current) out that can be controlled. They are under a lot of load, so they can fail. Since they are almost always wired in parallel to each other, when one fails, the whole system doesn't work. They can be tested, but you have to desolder them to effectively test them so you end up replacing them all. Now should YOU, Bruce In Philly do this? How good are you are desoldering? You don't want to damage the board and you should have the proper soldering iron, desoldering wick, rosin core solder for the new caps, etc... Your call.

#39

Rennlist Member

By the way, I have similar issues with my PCM. It will reboot about 2 or 3 times a year always while I am driving and about 3 weeks ago I had the "sub only" sound issue which was resolved the next time I fired up the car.

#40

Three Wheelin'

The sub only sound is what we are talking about and hoping to fix. It may be thermally related, but we are trying to figure that out.

#41

Racer

That would point to a failure in the DC-DC voltage booster.

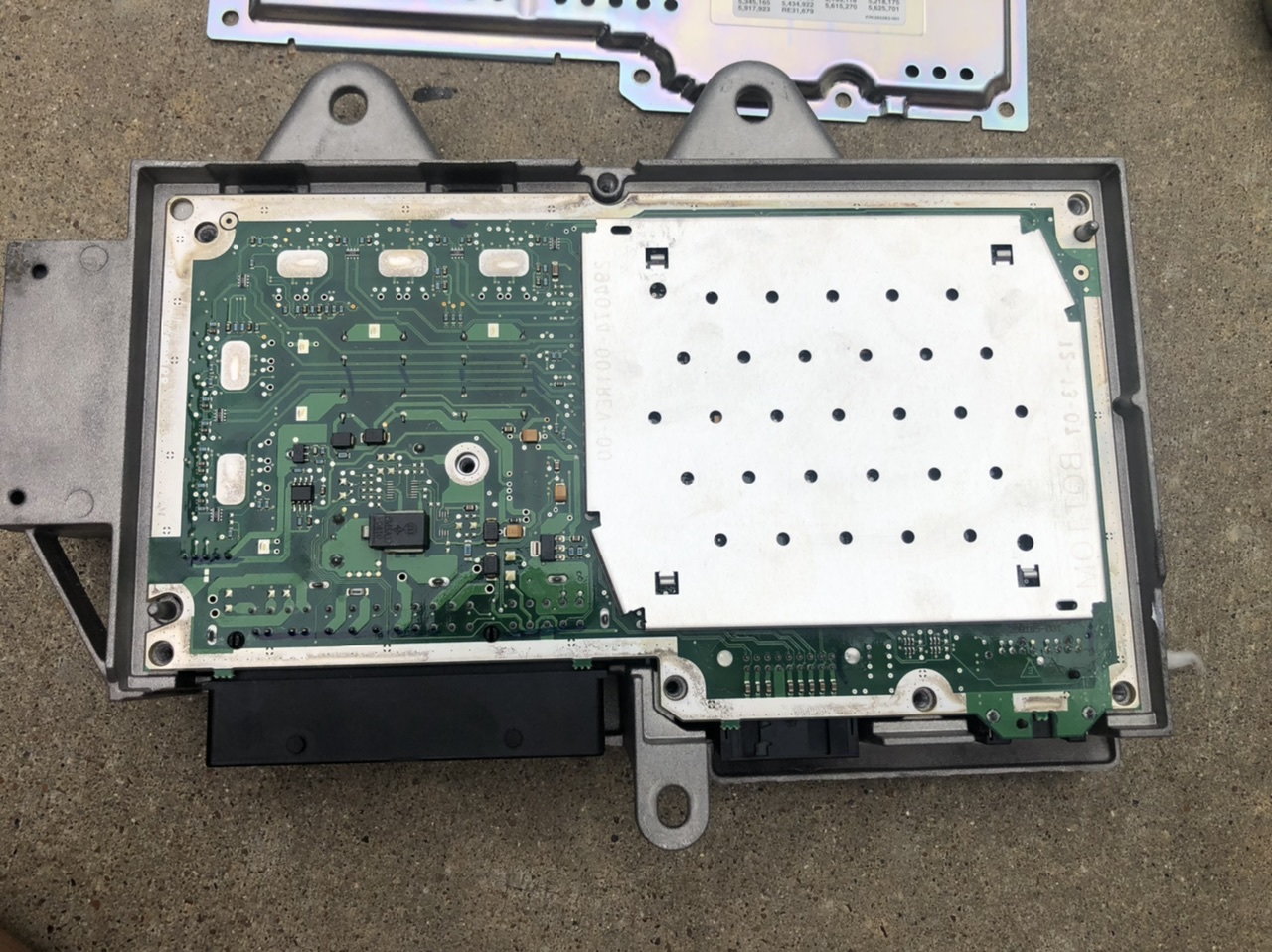

The amp works by boosting the 12v up to something higher, probably 40-50v. This supplies the power amplifier chips with enough juice to produce the desired wattage to the 4 or 8 ohm speakers. (ohms, not just a good idea, it's the law).

The sub has it's own power amp, independent from the Bose amp. If the sub is woofing but the speakers are silent, that says the DSP section of the Bose module is happily processing data and sending it out. That probably means all the digital and D/A domain stuff is working.

That leaves the power amps and the power supply. The common point for all 10 channels is the power supply section, that does the boosting. The 5 chips around the edge are the power amps. The similar looking one in the corner near all the electrolytics drives the DC-DC converter. The transformer, the caps and rectifier are all part of that too.

The following 2 users liked this post by larrysb:

JustinCase (06-03-2020),

PV997 (06-02-2020)

#42

RL Community Team

Rennlist Member

Rennlist Member

Great stuff, so back to the "if it is thermal related"...... what is the most likely culprit? I suspect overheating and therefore went ahead and ordered a new fan and will pick up some paste this week. But of course, these two approaches may have nothing to do with the issue., but it is an easy hail mary pass.

I have resurrected my old Nikko Tuner (a beautiful sounding tuner from the '70s by just replacing all the caps in the power supply section), and I repaired my pair of very high-end VTL 300 Deluxe tube monoblock amps by just pulling the covers and replacing all the monster bulging cans (caps) (I did shock myself so yes, I proved it again that I am stupid). Also on the list are a few old monitors... again the cans in the power supplies. I am a total hack but was able to do the work (actually I am fearless and figure if I break it, I will just replace it from eBay and chalk it up to entertainment expense). So I would never claim my soldering skills to be even average, I was able to pull off a few jobs.

So... a question about caps..... as you noted, caps fail over time..... but do they fail or just change value? My understanding is an amp or whatever will just work until they fail as with a power supply... no? edjumacate me. In other words, getting hot doesn't then cause them to fail only to resurrect when cooled.... I never heard of a cap acting that way.... but again, I am don't know what I am talking about.... just going from very limited experience.

I find this electronics stuff fascinating and real black art.... therefore I would love to rip something apart and break it.

Peace

Bruce in Philly

I have resurrected my old Nikko Tuner (a beautiful sounding tuner from the '70s by just replacing all the caps in the power supply section), and I repaired my pair of very high-end VTL 300 Deluxe tube monoblock amps by just pulling the covers and replacing all the monster bulging cans (caps) (I did shock myself so yes, I proved it again that I am stupid). Also on the list are a few old monitors... again the cans in the power supplies. I am a total hack but was able to do the work (actually I am fearless and figure if I break it, I will just replace it from eBay and chalk it up to entertainment expense). So I would never claim my soldering skills to be even average, I was able to pull off a few jobs.

So... a question about caps..... as you noted, caps fail over time..... but do they fail or just change value? My understanding is an amp or whatever will just work until they fail as with a power supply... no? edjumacate me. In other words, getting hot doesn't then cause them to fail only to resurrect when cooled.... I never heard of a cap acting that way.... but again, I am don't know what I am talking about.... just going from very limited experience.

I find this electronics stuff fascinating and real black art.... therefore I would love to rip something apart and break it.

Peace

Bruce in Philly

#43

Racer

So... a question about caps..... as you noted, caps fail over time..... but do they fail or just change value? My understanding is an amp or whatever will just work until they fail as with a power supply... no? edjumacate me. In other words, getting hot doesn't then cause them to fail only to resurrect when cooled.... I never heard of a cap acting that way.... but again, I am don't know what I am talking about.... just going from very limited experience.

Peace

Bruce in Philly

Peace

Bruce in Philly

So the capacitors that tend to fail are aluminum electrolytic. They are constructed of two pieces of thin aluminum foil, separated by a paper or other fiber soaked in a liquid solution, usually a water-glycol with some other stuff in it. The insulating layer is a very thin layer of oxide on the aluminum. When the capacitor is rolled up and stuffed into the can, it is "formed" by applying electric current to the terminals. That causes a chemical reaction between the liquid and the aluminum and grows that ultra-thin layer of insulating aluminum oxide. Result, lots of capacitance, small space, cheap price. After forming, the wet (damp) paper's only job is to serve as a conductor between the aluminum foil layers.

Over time, a couple of things happen. Heat drives off the water and it permeates out through the rubber plug and lead wires. The oxide layer can breakdown too, resulting in a loss of value. Sometimes, a short will develop from some mechanical imperfection, or the lead wires come unbonded from the foil or what have you.

The usual slow failure is that the capacitance value will reduce and something called "equivalent series resistance" will increase, making the circuit fail to perform.

I bought a Las Vegas condo that was empty for about 10 years and had never been occupied. All the appliances still had the manuals and styrofoam in them from construction. The oven had failed because cheap caps on the control board totally went bad. Bosch had no boards, so I just replaced all the caps and it was fine again.

There's your education in capacitors.

So getting back to this amp: The heart of it is a power supply that boosts the 12v up to 40-50v or so. It does this by switching the power at 40-80khz, through the transformer to boost it, then it is rectified by by high speed diode pack on the bottom of the board, applied to the big filter capacitors you see. That in turn, powers the class-D amplifier chips that drive the speakers.

The only way to check those big caps are to unsolder them and test them for capacity and ESR. I have that kind of equipment in my home lab. But it would likely be as efficient to just replace them with new, just because.

Open up the amp, write down the value and voltage. Carefully measure the dimensions of the can and the lead spacing. (millimeters). Go to Digikey or Mouser or whoever you like and do a parametric search on farads/volts and size. You want same capacity, and voltage the same or higher than the originals. Then pick the expensive ones with the highest temperature rating and the longest hours life. You want 105c and at least 2000hrs.

I'd probably replace the surface mount ones as well, (the smaller silver cylinders) while screwing around with it. Same deal, identical value, voltage at least as high, same size and footprint, high temperature and hours. Surface mount is a bit trickier than through-hole. You don't want to damage the board traces.

The following 3 users liked this post by larrysb:

#45

Rennlist Member

Yeah, I'll second that.

@larrysb that was incredibly helpful for when the time comes that I (or my brilliant son) has to take on this task. Just a great explanation and you deserve a mighty tip o' the hat for taking the time to educate the rest of us.

Thx!

Bob

@larrysb that was incredibly helpful for when the time comes that I (or my brilliant son) has to take on this task. Just a great explanation and you deserve a mighty tip o' the hat for taking the time to educate the rest of us.

Thx!

Bob