The Dyno Thread

#17

Former Vendor

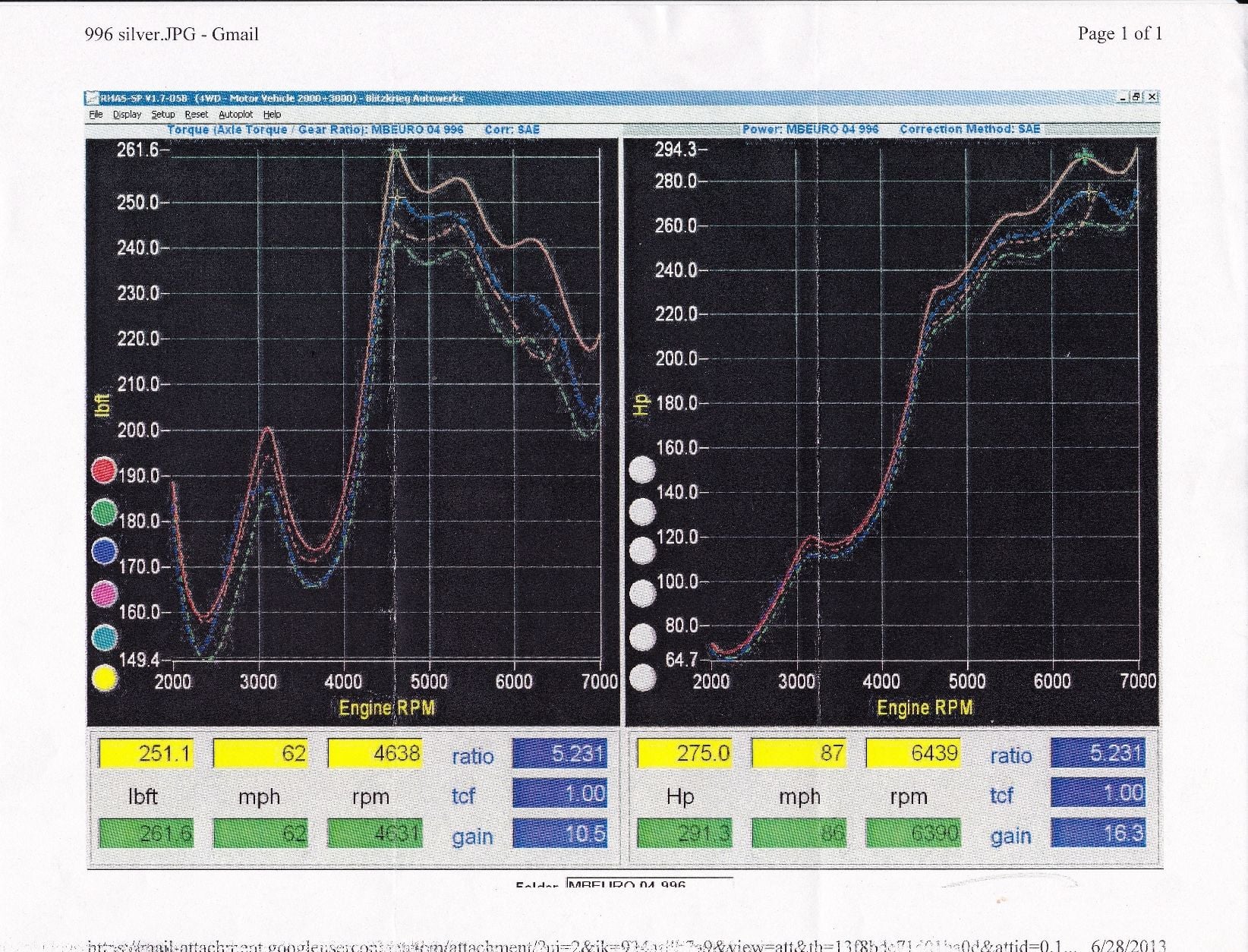

The torque dip at 3200 is often removed with "smoothing" settings in the software. The 5,252 RPM dip is the same. This basically comes from the actuation of the variable valve lift, and then again by the variable valve timing.

If you guys really want comparisons, get the raw data broken down every 250 RPM across the board, then average the TQ and HP. This is the main thing that I look at when grading my engines. I pay zero attention to the peak numbers, other than to average the data from 500 RPM before, and 500 RPM peak. I am concerned about increasing power across the entire rev range, not just at peak.

Lots of people think that just because they have a higher peak power value that the engine is more powerful. Thats not the case, especially with stock displacement engines, which generally lose power down low, as a compromise to make more power up top.

If you guys really want comparisons, get the raw data broken down every 250 RPM across the board, then average the TQ and HP. This is the main thing that I look at when grading my engines. I pay zero attention to the peak numbers, other than to average the data from 500 RPM before, and 500 RPM peak. I am concerned about increasing power across the entire rev range, not just at peak.

Lots of people think that just because they have a higher peak power value that the engine is more powerful. Thats not the case, especially with stock displacement engines, which generally lose power down low, as a compromise to make more power up top.

#19

Rennlist Member

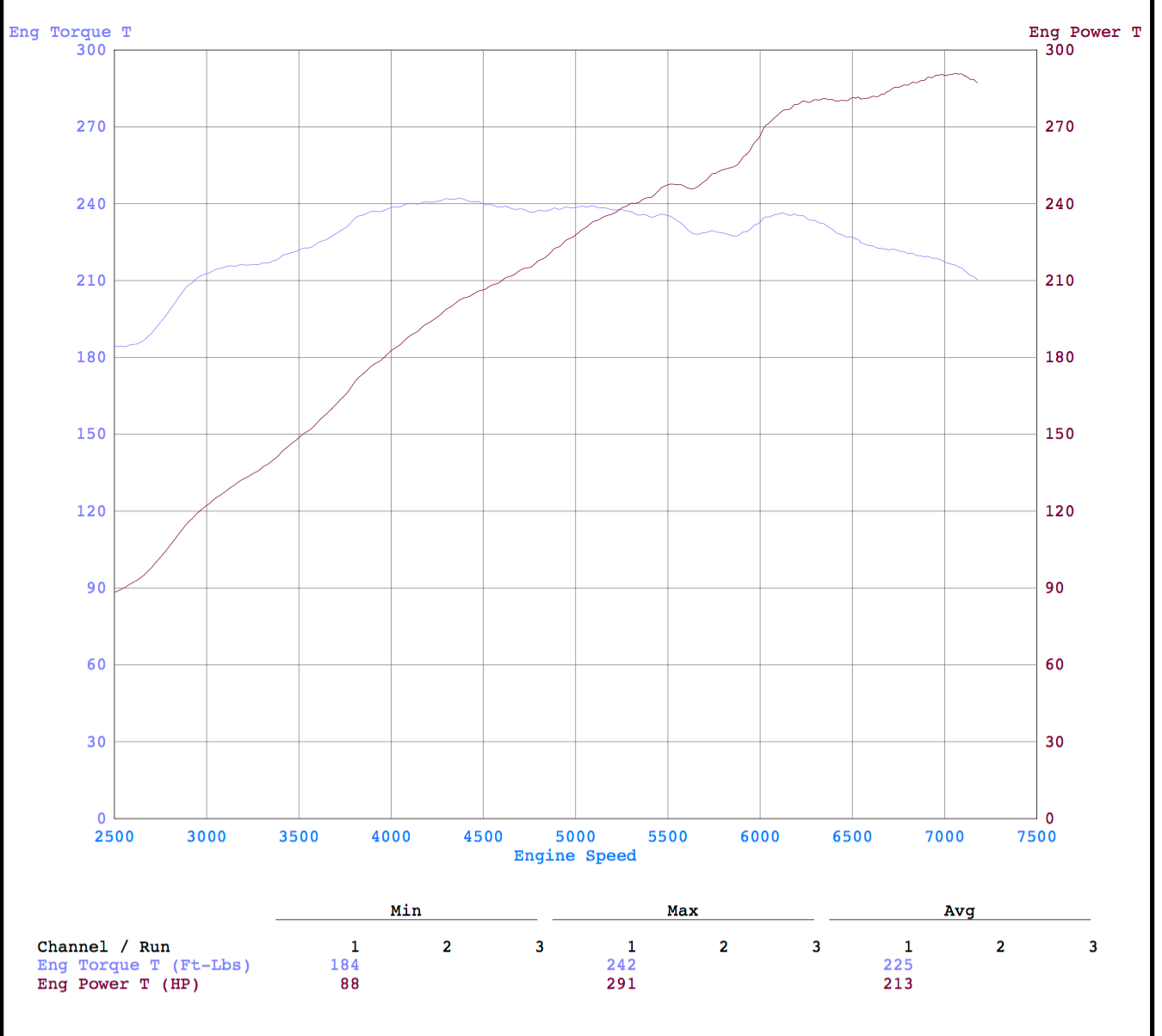

3.8 rebuild after break in miles, front drive decoupled for dyno runs. I've driven 30,000 miles since then. Maybe one day I'll do a custom tune. Fabspeed 200 cell cats and bmc air filter only.

#20

The torque dip at 3200 is often removed with "smoothing" settings in the software. The 5,252 RPM dip is the same. This basically comes from the actuation of the variable valve lift, and then again by the variable valve timing.

If you guys really want comparisons, get the raw data broken down every 250 RPM across the board, then average the TQ and HP. This is the main thing that I look at when grading my engines. I pay zero attention to the peak numbers, other than to average the data from 500 RPM before, and 500 RPM peak. I am concerned about increasing power across the entire rev range, not just at peak.

Lots of people think that just because they have a higher peak power value that the engine is more powerful. Thats not the case, especially with stock displacement engines, which generally lose power down low, as a compromise to make more power up top.

If you guys really want comparisons, get the raw data broken down every 250 RPM across the board, then average the TQ and HP. This is the main thing that I look at when grading my engines. I pay zero attention to the peak numbers, other than to average the data from 500 RPM before, and 500 RPM peak. I am concerned about increasing power across the entire rev range, not just at peak.

Lots of people think that just because they have a higher peak power value that the engine is more powerful. Thats not the case, especially with stock displacement engines, which generally lose power down low, as a compromise to make more power up top.

Please import this raw data into Excel and see what you think.

Cheers,

Scotty

#21

Rennlist Member

Thread Starter

What's the best way to get RPM on a Dynonet? I would like to use the same shop again since they did my HP baseline but they are clueless when it comes to p-cars.

#22

Former Vendor

Inductive pick up on one of the coil pack leads. We also sometimes use an optical pick up with a target on the crank pulley.

#24

Willing to bet you can extract another 5-8hp with a tuned ecu.

The following users liked this post:

joe-1972 (07-29-2021)

#26

......

Last edited by 501Max; 06-16-2016 at 08:31 PM.

#27

Rennlist Member

Thread Starter

Now that's a good looking dyno. Great low end torque and look at the power band from 5-7k. Very nice.

#28

Rennlist Member

Join Date: Nov 2008

Location: Mooresville, IN (Life Long Cheesehead)

Posts: 5,815

Likes: 0

Received 55 Likes

on

36 Posts

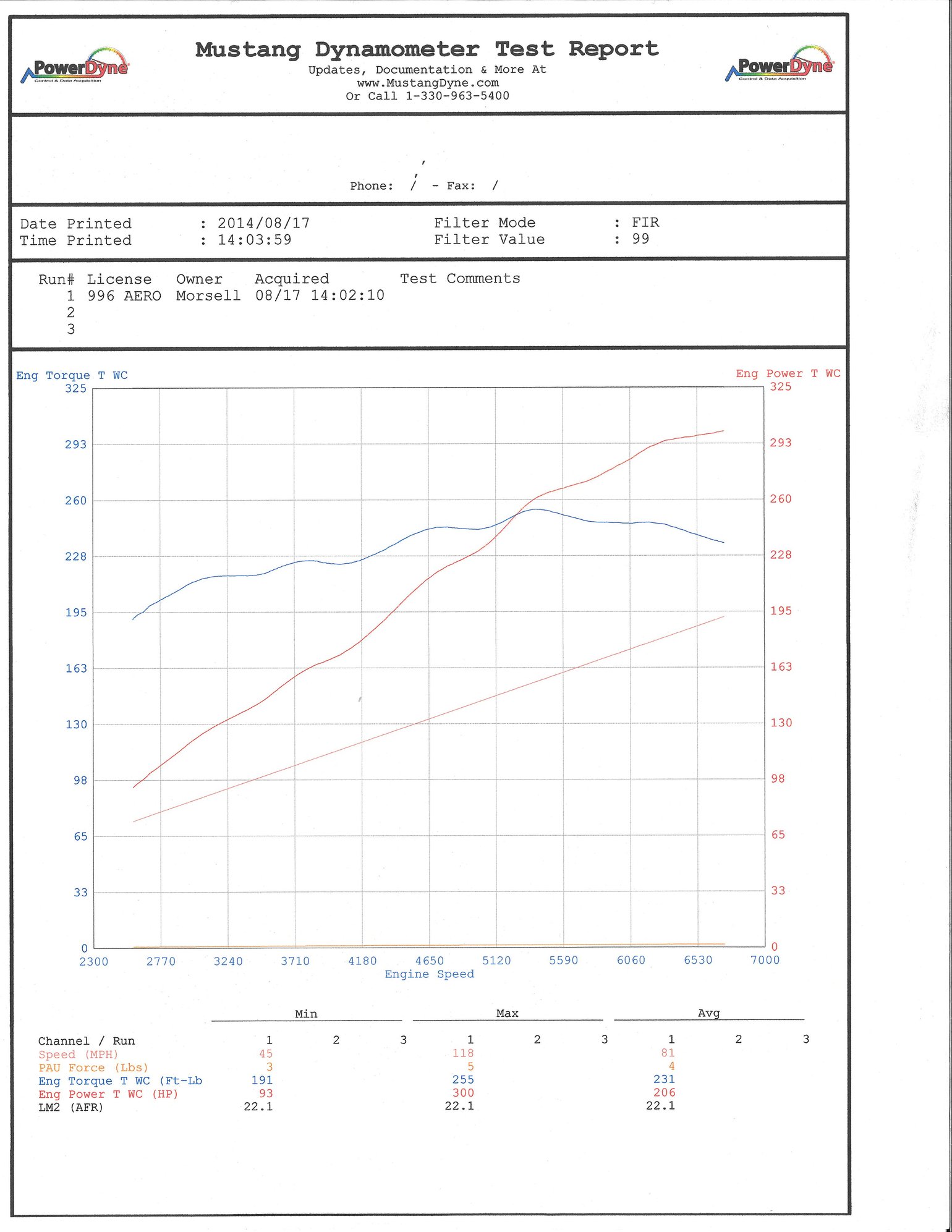

Here is mine. This all taken at the wheels. This will change soon because my car is back at Jake's having some enhancements done. There is no longer a slippery slope...its called a cliff!

Couple comments:

Joe looks like yours has been corrected at the flywheel. I'm thinking you might be 18 to 20% less at the wheels compared to the other plots posted. Tdream1 I'm thinking its the same for you too. Not calling you guys out but just thinking what is feasible with a 3.4.

Couple comments:

Joe looks like yours has been corrected at the flywheel. I'm thinking you might be 18 to 20% less at the wheels compared to the other plots posted. Tdream1 I'm thinking its the same for you too. Not calling you guys out but just thinking what is feasible with a 3.4.

#30

Former Vendor

This is a setting that the Dyno operator can choose which gives the engine the flywheel power rating projection, even though the power is gathered at the wheels.

I have spent thousands of hours of my life using dynamometers. I have 3 under my roof.