EPS Eternal fix Cylindrical roller bearing ims with oil feed

#107

Rennlist Member

"actually after you made your comment, you waved goodby. That is was I was commenting on."

Ok... and that "leaves me in charge" how? For some reason I thought waving goodbye meant...goodbye, not "now I'm in charge"

Ok... and that "leaves me in charge" how? For some reason I thought waving goodbye meant...goodbye, not "now I'm in charge"

#108

I've seen a lot of advertisements for this EPS product on the forum and I've heard good things about it elsewhere. But I couldn't help wondering about two things not mentioned in this thread thus far. Wouldn't the roller bearings have more rotational friction and inertia than ball bearings (at least if they have the same diameter)? (This would seem consistent with them producing greater heat (though I can see other possible reasons).)

And if so, could this (slightly) reduce power from the engine and/or throttle respone and/or the ability of the valves which are ultmately driven by the IMS to respond quickly?

(And no, as may already be obvious, I'm not an engineer. But I hope that even by the high standards of this thread, it's still OK to ask questions if I'm not chief bearing engineer for a (full sized) helicopter manufacturer, just not to answer them ;-) )

And if so, could this (slightly) reduce power from the engine and/or throttle respone and/or the ability of the valves which are ultmately driven by the IMS to respond quickly?

(And no, as may already be obvious, I'm not an engineer. But I hope that even by the high standards of this thread, it's still OK to ask questions if I'm not chief bearing engineer for a (full sized) helicopter manufacturer, just not to answer them ;-) )

#109

The slotted oil pump drive key is a really neat idea, have just ordered one, will get it fitted in the next few months, preventative maintenance and it's about time to do the clutch anyway at 200,000 km and the rear main seal has been on and off leaking, but it seems to have "gone dry" for the last 10,000 km.

Hats off to the person who thought of this, really so simple, bet those who have gone to great lengths to design and get into manufacture direct oil feed systems are wondering why they didn't think of it, and I bet some of them will chime in (here or elsewhere) and say they thought of it but for this and that reason their product is better, will be interesting to see what they say, and this is the sort of thing that it's very hard to have the last word on human creativity being what it is.

A friend is a mechanical engineer, and I asked him the question "how much would this weaken the drive" and he said "although it depends on what the starting point is (i.e. how good is the original product) probably just as serviceable and if better material and if the slot is in the correct place and properly machined there may be no measurable difference".

Although I'm not an engineer the design is really neat and appeals to me, a slow drip feed or even a very slow squirt into the tube where the other end is a bearing that has had both seals removed would never do much more than coat the inside of the tube with oil and thereby constantly lubricate the bearing as the oil returns to the sump, and my guess is that it would not do any harm to the engine balance, think harmonic balancer.

And should have said, already have the Flat 6 ceramic bearing kit to fit but will now remove both seals.

All constructive comments welcome.

Hats off to the person who thought of this, really so simple, bet those who have gone to great lengths to design and get into manufacture direct oil feed systems are wondering why they didn't think of it, and I bet some of them will chime in (here or elsewhere) and say they thought of it but for this and that reason their product is better, will be interesting to see what they say, and this is the sort of thing that it's very hard to have the last word on human creativity being what it is.

A friend is a mechanical engineer, and I asked him the question "how much would this weaken the drive" and he said "although it depends on what the starting point is (i.e. how good is the original product) probably just as serviceable and if better material and if the slot is in the correct place and properly machined there may be no measurable difference".

Although I'm not an engineer the design is really neat and appeals to me, a slow drip feed or even a very slow squirt into the tube where the other end is a bearing that has had both seals removed would never do much more than coat the inside of the tube with oil and thereby constantly lubricate the bearing as the oil returns to the sump, and my guess is that it would not do any harm to the engine balance, think harmonic balancer.

And should have said, already have the Flat 6 ceramic bearing kit to fit but will now remove both seals.

All constructive comments welcome.

Hello,

Did you end up installing this bearing(roller)? Any updates?

Thanks!

#110

Thank you for your questions. We have sold over 5,000 units since we started to sell our EPS Cylindrical IMS Bearing in 2013, and we have NOT had a single report of failure.

The reason why our IMS Cylindrical Bearing does not fail is because it is made of a completely different technology than the traditional ball bearing at Porsche and LN. The reason for the IMS failure is due to the type of bearing that is employed. LN and Porsche use a ball bearing that applies the load on a single point of about 1.0mm. Our EPS IMS Cylindrical bearing spreads out the pressure point, applying the load on approximately 15mm.

Regarding any doubts on whether oil lubrication is the problem, here is why it isn’t. The bearing is positioned at the bottom of the oil pan, so it is essentially submerged in oil at all times. Lubrication is not the problem here.

If you have any questions, please feel free to reach out to us.

Thanks,

EPS Team

epsauto.com

Last edited by EPSAuto; 08-23-2017 at 03:14 PM.

#111

Thank you for your interest in our product. Our EPS IMS bearing differentiates from that of LN because it is based on a completely different technology. LN uses a ball bearing that applies the load on a pin point of about 1.0mm. Our EPS IMS bearing is cylindrical, meaning that it applies the load across the total length of the cylinder, approximately 15mm.

The reason for the IMS failure is due to the type of bearing that is employed. The LN ball bearing is incapable of carrying the load applied on it even with proper lubrication. Also, since LN’s ball bearing is open caged, it fails with the same or greater frequency than the factory bearing.

To give you a little reference on how the ball bearing is inferior to the cylindrical bearing, you can take a look at Porsche’s attempt to correct the IMS problem throughout the years. Porsche changed the ball bearing 3 different times. First, a single row of 47mm, then a double row of 47mm, and finally a single row of 62mm. All three bearings failed.

Our EPS Patented Cylindrical bearing does not fail because the load is spaced out across the entire surface area of the cylinder.

Hope this clarifies your doubts. If you have any questions, please feel free to reach out to us.

Thanks,

EPS Team

epsauto.com

Last edited by EPSAuto; 08-23-2017 at 03:13 PM.

#112

Drifting

The Apples to Apples comparison for the EPS product would be with the RND cylindrical roller bearing.

You may find their description rather dry. (pun?) It lacks the hyperbole and nonsense of EPS.

The technical differences between a generic (EPS or EBay) cylindrical roller bearing and the RND will make some eyes glaze over with boredom.

http://imsretrofit.com/roller-bearings/

and

http://rndengines.com/roller-bearing-ims-retrofit-kit/

But to the geeks the differences are quite clear, significant and cost effective.

I wish the RND bearing had been available when I did mine.

You may find their description rather dry. (pun?) It lacks the hyperbole and nonsense of EPS.

The technical differences between a generic (EPS or EBay) cylindrical roller bearing and the RND will make some eyes glaze over with boredom.

http://imsretrofit.com/roller-bearings/

and

http://rndengines.com/roller-bearing-ims-retrofit-kit/

But to the geeks the differences are quite clear, significant and cost effective.

I wish the RND bearing had been available when I did mine.

#113

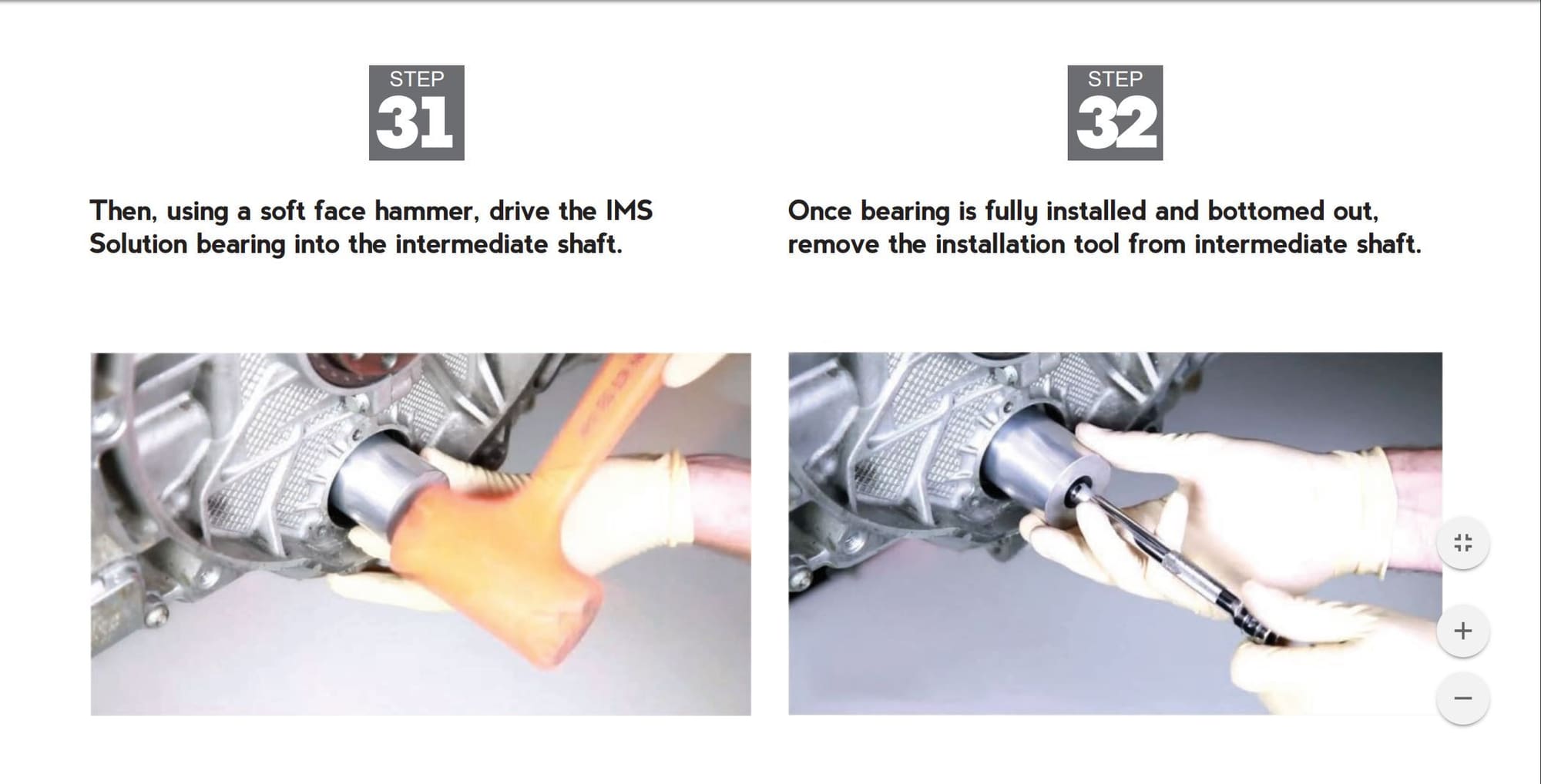

Just installed EPS Eternal Fix on my 199 boxster 986 woth 5 chain motor, all is well. Very easy install except maybe couple things to add to previous suggestions:

-do not tighten supplied IMS bearing flange bolts to 13-15lbs torque, bolt will snap. Mine twisted off @12lb. Called EPS and they suggested 10lb/ft torque. I reused old bolts with thread locker @10lb/ft torque. I Tighetend center nut to 24lb/ft torque as it felt very tight to me (Not 30-35 as recomended in EPS instructions)

-like said before somewhere, the bearing will stop where it needs to be, not the installation tool. I just whacked it until it wouldnt go anymore and then whacked it some more to make sure

Very well built kit, and EPS picked up the phone and answered my questions. I installed their upgraded clutch kit btw, and new LUK flywheel from rockauto. With new bolts of course. So far 700miles and it hasnt blown up.

my engine ate 10 quarts of DT40 and its right at the top bar per electric and dipstick meters. If anyone is interested here is a video of me doing ims install and oil feed mod, look through my videos. I am not pro youtooober, just thought i would share my findings. Not much out there about EPS Eternal Fix.

my first post btw.

-do not tighten supplied IMS bearing flange bolts to 13-15lbs torque, bolt will snap. Mine twisted off @12lb. Called EPS and they suggested 10lb/ft torque. I reused old bolts with thread locker @10lb/ft torque. I Tighetend center nut to 24lb/ft torque as it felt very tight to me (Not 30-35 as recomended in EPS instructions)

-like said before somewhere, the bearing will stop where it needs to be, not the installation tool. I just whacked it until it wouldnt go anymore and then whacked it some more to make sure

Very well built kit, and EPS picked up the phone and answered my questions. I installed their upgraded clutch kit btw, and new LUK flywheel from rockauto. With new bolts of course. So far 700miles and it hasnt blown up.

my engine ate 10 quarts of DT40 and its right at the top bar per electric and dipstick meters. If anyone is interested here is a video of me doing ims install and oil feed mod, look through my videos. I am not pro youtooober, just thought i would share my findings. Not much out there about EPS Eternal Fix.

my first post btw.

#114

Rennlist Member

#117

Former Vendor

Those are the instructions for the IMS Solution. You are installing a solid bushing into the IMS housing bore when doing this, not driving in a ball bearing, or roller bearing like other technologies. I invented the Faultless IMS tool to mechanically deliver IMS retrofit components without the necessity of a hammer.

#118

So at 1:05 in the video, it looks to me like the back of the center bolt flange pretty much seals the back of the bearing from the inside of the IMS shaft. I see a hole in the center of the back but can't see if it lets oil into the bearing.

I also wonder how much oil the IMS shaft holds and how often it gets refreshed?

When I install an IMS bearing, I freeze the bearing and use a heat gun on the IMS shaft, then the bearing slides in without pounding.

I also wonder how much oil the IMS shaft holds and how often it gets refreshed?

When I install an IMS bearing, I freeze the bearing and use a heat gun on the IMS shaft, then the bearing slides in without pounding.

#119

Rennlist Member

Those are the instructions for the IMS Solution. You are installing a solid bushing into the IMS housing bore when doing this, not driving in a ball bearing, or roller bearing like other technologies. I invented the Faultless IMS tool to mechanically deliver IMS retrofit components without the necessity of a hammer.

http://imsretrofit.com/wp-content/up...arranty-2y.pdf

I 100% agree, the faultless tools are the best way to go, but I just wanted to point out that the guy in the video was following instructions.

#120

Former Vendor

Yes, but if you don't buy the faultless tools, your dual row retrofits are driven in similarly with the regular ims tools correct?

The Faultless tool can deliver all forms of IMS Retrofit, but is only REQUIRED for the Single Row Pro.