Another 3.4 Cam deviation / VarioCam issue / P1341 thread?

#1

If I could bother any of you kind M96 3.4 professionals to watch a 7 minute video of what I have going on, I would be greatly appreciative, and i owe you a beer if we cross paths.

https://youtu.be/_kZfLKbN7pY

Backstory on the car. I bought this 2001 911 C4 a little over a week ago, knowing it had this issue, "P1341 Camshaft adjustment bank 1 below limit value". In my opinion, the price I paid for the car was fair with the issue at hand, and I'm ready to dive into it and figure out the culprit, once I get home with the car. I will be trailering it.

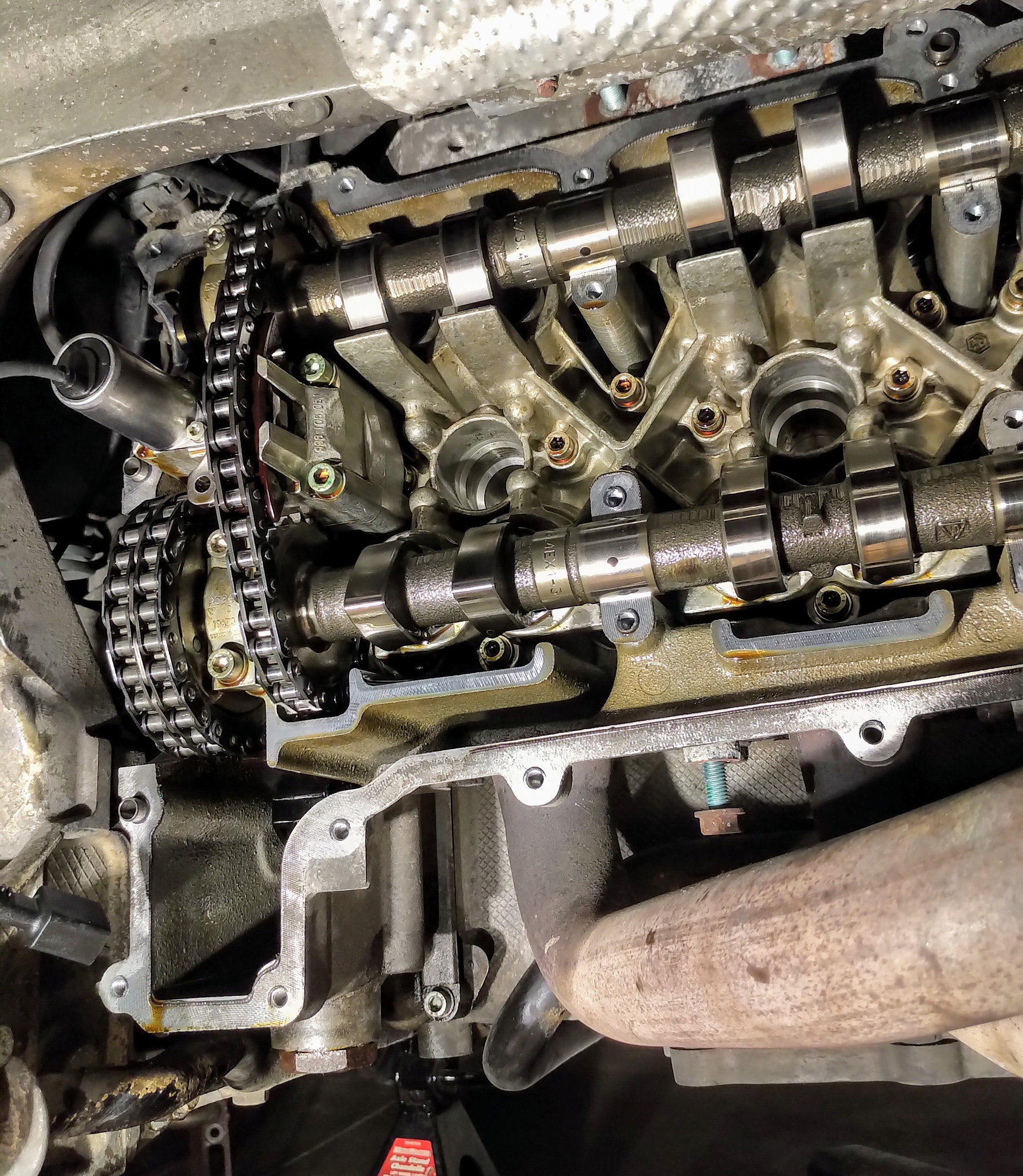

From my limited knowledge, the bank 1 cam deviation could be due to worn out VarioCam actuator chain guides, but the "laziness" of the bank 1 "actual cam angle" when compared to bank 2 could be a host of different things, including but not limited to the actuator, the solenoid, or a wiring issue.

I know I have some troubleshooting ahead of me, but wanted to at least post this so I have something to think about on my 17 hour drive home with the car behind me

TIA

https://youtu.be/_kZfLKbN7pY

Backstory on the car. I bought this 2001 911 C4 a little over a week ago, knowing it had this issue, "P1341 Camshaft adjustment bank 1 below limit value". In my opinion, the price I paid for the car was fair with the issue at hand, and I'm ready to dive into it and figure out the culprit, once I get home with the car. I will be trailering it.

From my limited knowledge, the bank 1 cam deviation could be due to worn out VarioCam actuator chain guides, but the "laziness" of the bank 1 "actual cam angle" when compared to bank 2 could be a host of different things, including but not limited to the actuator, the solenoid, or a wiring issue.

I know I have some troubleshooting ahead of me, but wanted to at least post this so I have something to think about on my 17 hour drive home with the car behind me

TIA

Last edited by Jdi; 03-10-2021 at 02:51 AM.

#4

I don't have time to watch the video, but it sounds like the kind of symptoms I had and I really wanted it to be just a sensor. But in reality you just have to accept that it's normal maintenance to replace the variocam wear pads, chains, actuators and solenoids around 60k miles with a 3.4 engine. Did that and it has been running perfectly for a year now.

#5

Congratulations on your C4. I also have a 2001 C4 - recently purchased with the same fault code. Looks like we are in the same boat.

I haven't done the road test yet, but this will be my next step. I've also read that it can either be the pads or the actuator.

These actuators seem to get most of the blame in the forums - especially bank 1. I wonder why bank 1.

The ending of your video was particularly interesting as the sound/RPM change was quite different between bank 1 and 2.

My plan, after the road test, is to remove the engine for easier access. I know it can be done with the motor in place, but I have low-rise lift and I think pulling the motor out will make it easier, and also give me a chance to do a few other jobs while it's out.

Looking forward to reading about your progress.

I haven't done the road test yet, but this will be my next step. I've also read that it can either be the pads or the actuator.

These actuators seem to get most of the blame in the forums - especially bank 1. I wonder why bank 1.

The ending of your video was particularly interesting as the sound/RPM change was quite different between bank 1 and 2.

My plan, after the road test, is to remove the engine for easier access. I know it can be done with the motor in place, but I have low-rise lift and I think pulling the motor out will make it easier, and also give me a chance to do a few other jobs while it's out.

Looking forward to reading about your progress.

The following users liked this post:

TexSquirrel (03-11-2021)

#6

I had 2 solenoids go bad within 6 months of each other. The 2nd time, my DME needed to be repaired due to a failed/burned transistor. I also had all 4 tensioner pads replaced at this time, because my cam deviations were out of spec.

Trending Topics

#8

What I've been meaning to ask is, as far as cam deviation goes, do you hook up the durametric and drive around to see cam deviation figures or does it save the most recent or extreme readings. Now that I have durametric, it'll be one of the first things I look at it.

#9

You see it live, with the engine running. No need to drive around, but it is good to have the engine at temp.

The following users liked this post:

nrp3 (03-12-2021)

#10

Not knowing how they operate I don't know how it is possible that both the solenoid and the actuator would fail at the same time.

Is there a test to determine if it's the solenoid or actuator?

#11

Originally Posted by Migliore;[url=tel:17290779

17290779]So only the solenoids were replaced? That is sort of good news as some posts indicate the actuators also fail.

Not knowing how they operate I don't know how it is possible that both the solenoid and the actuator would fail at the same time.

Is there a test to determine if it's the solenoid or actuator?

Not knowing how they operate I don't know how it is possible that both the solenoid and the actuator would fail at the same time.

Is there a test to determine if it's the solenoid or actuator?

The test to determine if the solenoid is bad has to do with resistance (if itís shorted, itís bad). But no, if one replaces the solenoid and putting 12v to it does not result in an audible click (movement) or results in a visual movement, then the actuator is suspect.

Unfortunately, for 996.1 3.4L 5-chain engines, since the solenoid is $250-$500, and the actuator is $800-$1500, which includes the solenoid, given that the solenoid failure is not uncommon, most people replace the solenoid or both to be safe. And top and bottom pads while youíre in there.

The 996.2 3.6L 3-chain engines changed. That design allows the removable of the solenoid without having to remove the cam cover, and I believe the actuator is also redesigned and much cheaper. The redesign is a variable-actuation mechanism, compared to on/off on the 3.4 engine.

The 3.4 engine turns the solenoids ON when the ignition is powered on, but the engine isnít running. It runs the solenoid OFF from idle to 1300 RPM (unless oil temp is 133C, then itís 1480RPM), and it turns ON from 1300-5120RPM to create a 12.5 degree (25 crank degrees) intake timing underlap (not overlap) for maximum cylinder charging and peak torque. Then it turns back OFF above 5120 to redline, which sets the intake cam timing to back overlap - the default position - which is 12.5 degrees. That overlap at idle helps purge exhaust gases and increases airflow due to ram-air effect at high RPM.

Itís important to note that engine oil is the hydraulic fluid that is used to move the tensioner and pad, which changes the cam timing. So a clogged or dirty oil passage can cause the failure, as well as, failed or highly worn pads. This is why cold starts wear these engines, especially since the tensioners are some of the last in the oil pathways to get oil pressure, and idling after cold start with very little oil pressure and volume ending up on the pads where they are desperately needed. Itís also why doing minimum yearly oil changes are important.

One more thing: the solenoids on each bank share the DME transistor, so one bank can affect the other bank, which is why my DME was logging misfires on all 6 cylinders, even though I only had 1 solenoid failure at that time. So when testing the solenoids, please keep that in mind. It may make sense to read the technical troubleshooting documentation to determine how to test for solenoid actuation one at a time. Some people just hook up a 9V battery to a solenoid and listen for the actuation noise. You can also active with Durametric I believe.

Last edited by Mike Murphy; 03-12-2021 at 12:56 PM.

The following users liked this post:

DSC800 (04-07-2021)

#12

The key to troubleshooting the vario-cam in the 3.4 is that the movement is ON-OFF..(no modulation). The solenoid/wiring/DME controls the ON-OFF, IF "no movement" then these are suspect.

IF the movement is lazy or low when at idle/slow engine speeds(low oil pressure), but better at high engine speed/high oil pressure then the actuator is suspect (internal valve not sealing/sticking).

Like I said in the first post, you need an actuator for bank 1, and need to replace the plastic chain guides/pads.

IF the movement is lazy or low when at idle/slow engine speeds(low oil pressure), but better at high engine speed/high oil pressure then the actuator is suspect (internal valve not sealing/sticking).

Like I said in the first post, you need an actuator for bank 1, and need to replace the plastic chain guides/pads.

#13

It might be worth trying a set of used actuators, they will probably come with the solenoids aswel , also the boxster actuators are the same, I had a used set from my original engine I was keeping spare but sold them to a friend to sort is car out , which they did !

#14

Before I reinstall the valve cover....

Can someone please clarify how I should apply the Drei-Bond 1209 to the flange surface? Notes say 2mm bead but do you spread/flatten the sealant across the surface of the flange with your finger tip?

Also, how long after applying the sealant to the flange surface do you pre-installed the valve cover?

Thank you in advance!

Can someone please clarify how I should apply the Drei-Bond 1209 to the flange surface? Notes say 2mm bead but do you spread/flatten the sealant across the surface of the flange with your finger tip?

Also, how long after applying the sealant to the flange surface do you pre-installed the valve cover?

Thank you in advance!