New I/C cores available..

#31

Addict

Rennlist Lifetime Member

Rennlist Lifetime Member

In theory, wouldn't a water cooled IC allow the wild heat to be dissipated at more suitable location such as the front of the car and the plumbing itself can be used to get rid of some of the heat. And since an IC is part radiator and part heat sink it stands to reason that the heat sink portion would perform much better what with water's greater specific heat? Significant packaging problem on an air cooled car though.

Any ideas on who makes Ruf's ICs for the CTR?

Any ideas on who makes Ruf's ICs for the CTR?

#32

Intermediate

Join Date: Apr 2006

Location: Cambridge, UK

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

sfl993t4, you are right and I had forgotten that part of the cycle!! The only thing is that water has a much larger thermal capacity than air and can thus store heat better. So, whilst at full throttle the water in the cooling system would increase in temperature a little and could be cooled a few moments later once the throttle is closed. Similar to air but with a larger thermal content. Also, you would probably mount the water cooler in a position were it could see the optimum air flow.

It just goes to show - you have to look at the complete picture; not just the little bit you're focused on!

Richard.

It just goes to show - you have to look at the complete picture; not just the little bit you're focused on!

Richard.

#33

Addict

Rennlist Member

Rennlist Member

Ruf's I/Cs are nothing special, the original CTR heat soaked very badly but that was partly due to not getting the airflow through the cores due to the packaging - the CTR2 I/Cs according to LAT's measurements do not appear to be very efficient, I think LAT reported 70DegC IAT in 30DegC ambient at ~280kph.....

As a balanced engine package the Rufs work well but could obviously benefit from more advanced intercooling.....

As a balanced engine package the Rufs work well but could obviously benefit from more advanced intercooling.....

#34

Nordschleife Master

These latest threads on intercoolers have been very interesting. I would be interested in knowing some concrete datapoints in addition to what we have here.

1) I'd be interested in knowing how much power is lost due to the reduction in air density due to the change in intake air temperature from the various intercoolers.

2) I'd be interested in knowing how much power is lost due to the ECU reducing ignition timing to compensate for the higher intake air temperature. In addition, how many degrees of ignition timing is retarded for every 10 degree C change in IAT.

It has been my experience that #2 is more of a impact to performance than #1.

1) I'd be interested in knowing how much power is lost due to the reduction in air density due to the change in intake air temperature from the various intercoolers.

2) I'd be interested in knowing how much power is lost due to the ECU reducing ignition timing to compensate for the higher intake air temperature. In addition, how many degrees of ignition timing is retarded for every 10 degree C change in IAT.

It has been my experience that #2 is more of a impact to performance than #1.

#35

Intermediate

Join Date: Apr 2006

Location: Cambridge, UK

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

Geoffrey, I think you are absolutely correct. I do not retard the timing with increasing air temp (until it gets silly) so I can see power drop off associated with inlet charge temperature. The reason I decided on new intercoolers was simply that a reduction in air inlet temp can be directly related to engine life. Not only have I seem inlet temps reduce but I see a corresponding decrease in EGT and oil temps - all entirely predicatable. I trust that I will see increased life of barrels, pistons and cylinder heads but I'm not expecting much! I have logged much more consistent power this year but some of that is down to cool ambient conditions. Under similar ambient the new coolers are reducung the charge by a good 15C more than the old. To be specific, with an inlet charge temperature of 118C the post intercooler temperature is now 37C in an ambient of 25C. These figures are taken at the end of Hanger Straight at Silverstone and the car had been at 100% throttle for quite some time. The temperatures appeared to be just about steady state too.

As for power, one can easily do the sums assuming isentropic efficiency. I'll sort it out tonight and give you my steer on it tomorrow.

Richard.

As for power, one can easily do the sums assuming isentropic efficiency. I'll sort it out tonight and give you my steer on it tomorrow.

Richard.

#36

Nordschleife Master

Cool. If you are not retarding the ignition timing with increasing air temp would it follow that perhaps your ignition timing is not optimized at the lower intake air temps? IE, if you have 20 degrees at 1bar at 5000rpm at IAT of 30C and that represents the optimum ignition angle for that site, if you increase the IAT, the it suggests that the engine may detonate due to the higher "in cylinder" temps. My feeling on this is that this type of tuning is best done on an engine dyno where you can tightly control all of the environmental variables and few test cells exist like that.

How have you been able to log engine performance on the track? I've been considering using a torque sensor on a drive axle connected to my MoTeC DAQ.

To be specific, what type of EGT are you seeing in both tests and at what boost pressure level?

How have you been able to log engine performance on the track? I've been considering using a torque sensor on a drive axle connected to my MoTeC DAQ.

To be specific, what type of EGT are you seeing in both tests and at what boost pressure level?

#37

Intermediate

Join Date: Apr 2006

Location: Cambridge, UK

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

Geoffrey, I specifically do not map the engine near to the detonation limit - its too expensive and turbos can go wrong very quickly! There is no doubt that I could increase the performance by running closer to the edge but I choose not to do so.

I always use an engine dyno to do all the mapping as my experience of RRs is hit and miss. Its very difficult to hold an engine at a preset load and tweak the parameters in real time on a rolling road as there is just too much "noise" inbetween the engine and the dyno. There are only a few cells set up in this country to accurately and repeatibly dyno an air cooled engine and I use the one at Engine Developments, better known as Judd. With them you know the power is the power (there is no bull**** whatsoever) and their cells are kept bang up to date and in calibration. Its expensive but at least I know its done right. Frankly, the absolute power is uninportant to me but the relative power from one engine to another is, by that I mean its really important to achieve repeatable dyno runs. We seem to be able to achieve within 5 horsepower at all times and I'm more than happy with that. Its also heartening (sometimes disheartening!) to see the efforts of the winter rebuild and modification program. If we have found more power/torque the dyno tells us and when we have gone the wrong way it tells us that too! Engineering can be a real pain in the **** at times!!

By the way, we water cool the intercoolers when on the dyno so we can keep the inlet charge steady throughout the run. By adjusting the flow rate of water we can then see the effect of increasing (or decreasing) IAT.

Richard.

I always use an engine dyno to do all the mapping as my experience of RRs is hit and miss. Its very difficult to hold an engine at a preset load and tweak the parameters in real time on a rolling road as there is just too much "noise" inbetween the engine and the dyno. There are only a few cells set up in this country to accurately and repeatibly dyno an air cooled engine and I use the one at Engine Developments, better known as Judd. With them you know the power is the power (there is no bull**** whatsoever) and their cells are kept bang up to date and in calibration. Its expensive but at least I know its done right. Frankly, the absolute power is uninportant to me but the relative power from one engine to another is, by that I mean its really important to achieve repeatable dyno runs. We seem to be able to achieve within 5 horsepower at all times and I'm more than happy with that. Its also heartening (sometimes disheartening!) to see the efforts of the winter rebuild and modification program. If we have found more power/torque the dyno tells us and when we have gone the wrong way it tells us that too! Engineering can be a real pain in the **** at times!!

By the way, we water cool the intercoolers when on the dyno so we can keep the inlet charge steady throughout the run. By adjusting the flow rate of water we can then see the effect of increasing (or decreasing) IAT.

Richard.

#38

Addict

Rennlist Member

Rennlist Member

These latest threads on intercoolers have been very interesting. I would be interested in knowing some concrete datapoints in addition to what we have here.

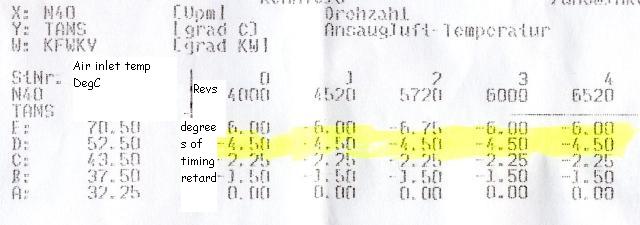

2) I'd be interested in knowing how many degrees of ignition timing is retarded for every 10 degree C change in IAT.

It has been my experience that #2 is more of a impact to performance than #1.

2) I'd be interested in knowing how many degrees of ignition timing is retarded for every 10 degree C change in IAT.

It has been my experience that #2 is more of a impact to performance than #1.

This is what I am reffering to - does it need more explanation ?

#39

Addict

Rennlist Member

Rennlist Member

The numbers I read off the davtron gauge the other day (so not definitively accurate but indicative) WOT in 3rd to 7000rpm a few times: post turbo 85DegC and the post IAT indicated 29DegC in 22degC gave an efficiency of 88.8% so about the same....

#40

In theory, wouldn't a water cooled IC allow the wild heat to be dissipated at more suitable location such as the front of the car and the plumbing itself can be used to get rid of some of the heat. And since an IC is part radiator and part heat sink it stands to reason that the heat sink portion would perform much better what with water's greater specific heat? Significant packaging problem on an air cooled car though.

Any ideas on who makes Ruf's ICs for the CTR?

Any ideas on who makes Ruf's ICs for the CTR?

#41

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

RUF used their neighbour Heinrich Langerer & Reich GmbH & Co for their intercoolers, I am not sure they still do. This company is a pioneer in cooling systems and partnered with Eaton (Borg Warner) long time ago. Like Secan (Honeywell) and Marston (United Technologies), it ended up being bought by an American group called Modine Mfg. as part of other businesses in the portfolio...

So basically all of these European engineering houses are now US companies

So basically all of these European engineering houses are now US companies

#45

Addict

Rennlist Member

RIP

Rennlist Member

RIP

Join Date: Feb 2002

Location: London

Posts: 802

Likes: 0

Received 0 Likes

on

0 Posts

I currently run pre and post AIT sensors and will do so on the new engine. I'll post data once I have it. The new engine should add some interesting data to the general "no more BS" performance topics.

I was looking at some of the old rally car specs and their water usage when running water injection, it wasn't as bad as you might expect, but clearly APITA.

I was looking at some of the old rally car specs and their water usage when running water injection, it wasn't as bad as you might expect, but clearly APITA.