Dyno tests

#49

Addict

Rennlist Lifetime Member

Rennlist Lifetime Member

#50

Addict

Rennlist Member

Rennlist Member

Thread Starter

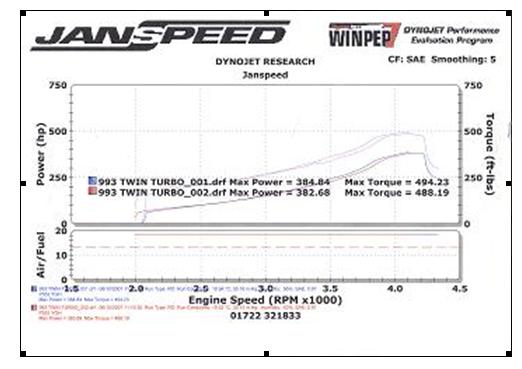

Good timing with this run Gordon, and with an ECU which happens to have real certified torque numbers from an engine dyno..

RS Tuning Stage 1 kit includes modified turbochargers (yours I am guessing are standard ?) and quoted output is 448PS with 581NM (427lb/ft)

The dynojet shows 672NM

Who knows why they only revved the engine to ~4250rpm, did they think that was it ?

Kevin mentions loading. What exactly is happening to get these silly torque numbers which most dynos seem to spew out and how does the likes of a Maha (Kevin's and PhD's I believe also) work to measure the torque more accurately ?

RS Tuning Stage 1 kit includes modified turbochargers (yours I am guessing are standard ?) and quoted output is 448PS with 581NM (427lb/ft)

The dynojet shows 672NM

Who knows why they only revved the engine to ~4250rpm, did they think that was it ?

Kevin mentions loading. What exactly is happening to get these silly torque numbers which most dynos seem to spew out and how does the likes of a Maha (Kevin's and PhD's I believe also) work to measure the torque more accurately ?

#51

Addict

Rennlist Member

Rennlist Member

TB,

I have an old article from Germanmotorcars that is a pretty good primer on the differences between the inertia based (Dynojet) and loading eddy current based (Mustang, MAHA) chassis dynos and how power, tq are calculated:

I have an old article from Germanmotorcars that is a pretty good primer on the differences between the inertia based (Dynojet) and loading eddy current based (Mustang, MAHA) chassis dynos and how power, tq are calculated:

This discussion revolves around chassis dynamometer's and is intended to be informative and thought provoking. There are two types of chassis dynamometers on the market, inertia and loading. An inertia dynamometer (such as DynoJet) does not measure torque, but measures acceleration. A loading dynamometer applies resistance that is measured (using some type of strain gauge.)

The most often heard discussion is that what factor can be applied to rear wheel horsepower to reflect crankshaft horsepower. This is where we need to understand how the rear wheel horsepower number was derived. Since the DynoJet seems to be widely used and numbers quoted are those from a DynoJet, we are going to use them as our inertia dynamometer example.

First it is important to have an understanding of how DynoJet gets their horsepower numbers. Power in mechanical terms is the ability to accomplish a specified amount of work in a given amount of time. By definition, one horsepower is equal to applying a 550 pound force through a distance of 1 foot in one second. In real terms, it would take 1 HP to raise a 550 pound weight up 1 foot in 1 second. So to measure horsepower, we need to know force (in pounds) and velocity (in feet per second). Dynojet's inertial dynamometer measures power according to the terms just described. It measures velocity directly by measuring the time it takes to rotate two heavy steel drums one turn. It measures force at the surface of the drum by indirectly measuring it's acceleration. Acceleration is simply the difference in velocity at the surface of the drums from one revolution to the next. The force applied to the drums is calculated from acceleration using Newton's 2nd law, Force = Mass * Acceleration. Since the mass of the drums is know and acceleration has been measured, Power (horsepower) can now be calculated. Torque is then calculated using the horsepower number: Torque = Horsepower * 5252 / RPM.

Once they have these numbers a series of correction factors are applied, some made public, some hidden as proprietary secrets. The public correction factor is the SAE correction factor. This formula assumes a mechanical efficiency of 85%. The formula used is: Where: CF= 1.18 * (29.22/Bdo) * ((Square Root(To+460)/537)) – 0.18. To = Intake air temperature in degrees F, Bdo = Dry ambient absolute barometric pressure. This correction factor is meant to predict output in varying atmospheric conditions and is a +/- 7%. The proprietary correction factor is supposed to reflect the loss of power from the crankshaft to the rear wheels.

A Loading Dynamometer applies resistance to the dyne's roller(s) , typically using either a water brake or a current eddy brake. In either case, the amount of force is measure using a strain gauge. The measured force is torque which is a real, indisputable measurement of the actual output at the wheel. Horsepower than can be calculated: Hp = Trq * 5252 / RPM.

A Dynamometer can only measure actual power at the output location. Actual power produced AND delivered by an engine will be highest if measured at the crankshaft, lower at the transmission output shaft and even lower, but more meaningful, still, at the rear wheels. The power that you use is the power at the rear wheels. Some Dynamometer companies add to measured rear wheel power readings a factor that is based on ESTIMATED rear wheel power losses (under what power conditions? 3.0 ltr.? 5.0 ltr.? Under coasting conditions? with a 185/70/15 radial tire? a 335/35/18 radial tire? New heavy radial tire vs. worn old, light, racing tire? Who knows?) In short, there is NO meaningful "average" tire to get a correct rear tire power transmission loss measurement for all cars - so obviously, unless they actually measure the power lost in the rear tires, under driven load conditions, NO dyno company should BE ADDING incorrect power figures into the measured power. It's simply wrong. The fact that they add varying amounts of power to the actual, "true" amount of power delivered and measured to the surface of the drive roller creates a situation that makes it an onerous task to compare power figures from different brands of dynamometer systems. On simple inertial dynamometers, some (most) companies use an average for the inertial mass value of the engine, transmission, driveshaft, axles and rear wheels. This is saying that a 4 cylinder, 2.0 ltr. Porsche 914 has the same rotating mass and same rear wheels as a 8 cylinder, 5.0 ltr. Porsche 928 S+4. This simply is not so and wrong.

It's expensive to measure frictional losses in the engine and drivetrain, requiring the dyno to be able to drive the vehicle with engine off. Add the cost of a 50+hp electric motor, controlled power supply, etc. It's just not likely that $20,000 dyno will be equipped with that equipment. It is also common for dynamometer companies to add to the power readings by adding transmission and driveshaft losses back into the measured power readings. Some companies make a concerted effort try to measure frictional losses and, optionally, add the power to the measured readings. Other companies - some that would surprise you - say that it's not important and give a blanket, single factor for frictional losses in every engine. Some simply say that there is a meaningful "average" for every car,( 4 stroke/ 4 cylinder/ 4 speed transmission, 4 stroke/ 8 cylinder/ automatic transmission) and apply it to every car and that it is not a significant difference. Blanket estimates of "average" losses and corrections are, quite simply, incorrect. At the upper levels of the industry, (we are talking about $150,000 - $500,000 AC or DC 4 quadrant dynamometers) it is not tolerated - shouldn't be - and needn't be. There is a dyno company that actually has different versions of software that displays their own identical data files as different amounts of power depending on whether you use the DOS version or the Windows version of their software!!

True, rear wheel horsepower is the standard of measuring the power that is actually delivered to the rear wheels. It is honest, true, fair and duplicable. It is the ONLY standard that can be duplicated by the entire industry - regardless of the dyno manufacturer. From my experience and that of many others, when comparing True, rear wheel horsepower to DJHP you must apply a factor. It appears that this is a sliding scale based on horsepower but the best estimate is 1.05 to 1.21 (maybe higher). What this means is that for those of you trying to calculate what your crankshaft horsepower is based on DJHP, and are adding 15%, the most common number I hear, you are actually doubling (at least) the factor. Why? Because DJHP already has a puff number added into their DJHP. Lets say DJHP shows 200 hp and you add 15%, you get 230 hp crankshaft horsepower. In reality DJ has already added in 15 or 20% to their 200 DJHP number. How does this help us.? It does not, and is fact harmful to the many dynamometer test facilities that report only what the dyno actually measured. I can not tell you of the many discussions that we have had as to why the horsepower numbers we recorded lower than that of DJ. For those manufacturers that use DJHP as proof of their claims, can you imagine the shock your customers get when the horsepower number of a vehicle tested on a load bearing dyno do not come close to their claim.

Proper tuning, especially on highly modified engines greatly affect the power difference. Due to the fact that the DJ dyno's sweep so quickly on sweep hp tests, there is no way to properly tune a fuel map. What you get is the acceleration and full throttle maps both triggered during the test, ending up over-rich, affecting the horsepower. The other factor that needs to be taken into account is that DJ dynos assume that every vehicle has the same rotating mass - they don't - and that disregard is another reason why the hp conversion figures are different. The most accurate measurement of rear wheel horsepower is in Steady State Mode (inertia is not a factor in power equation.) The inertial mass changes on each car affects the DJ power, but not the true, rear wheel horsepower. There's another message in the above example, besides the average true, rear wheel horsepower to DJHP conversion factor - It's up to the more experienced reader to figure it out.

Chassis dyne HP, What is it? What to call it? DynoJet = "DJHP". It's not really proper to call "DJHP" "rwhp", as neither the Mustang, DynoJet, Fuchs, Superflow or Land and Sea will necessarily produce the same numbers as a DJ dyno, except by luck - and the whole idea of true, rear wheel horsepower is that EVERY dyno manufacturer HAS the capability to provide those numbers! The Superflow chassis dynes, the Mustang, Land and Sea are all capable of measuring power in steady state mode and producing the same numbers - they all measure torque. Torque x rpm / 5252 = horsepower. We've not diddled with physics! The only factor that is added to the measured reading, in true, rear wheel horsepower, is the additional energy (dyne parasitics) required to spin the dyno(s) roller to whatever speed the roller is turning at - logical, proper and required for any measuring instrument, torque x rpm / 5252 = horsepower + parasitic power = true, rear wheel horsepower.

Chassis dyne HP, What can inflate HP readings on a dyno, but not really make more engine power in the real world? A few things can affect HP when using inertia dynos (not a dyne in Steady State Mode) to measure power (what else would you do??:-): Changing to light, worn race rear tires will improve power output on an inertia dyno, but, not improve real world top speed. A heavier (brand new street) tire that replaced the above, light, worn tire, will decrease measured power on an inertia dyno, but not decrease real world top speed. Lighter wheels are a good thing! Better acceleration in lower gears, especially 1st and 2nd (accelerating less inertial mass!). Better handling is possible, too! Driving hard on worn, light tires is foolish and is not being recommended.

Problems with Inertia dyno test procedure and fuel injected vehicles: A Sweep Test (hold throttle wide open and sweep from low rpm to high rpm) will often trigger the Acceleration Fuel Map, along with the Main Fuel Map, causing the fuel mixture readings to indicate dyno operator that the motor is overly rich. This would cause the tuner to lean out the main fuel map. Of course, in the real world, upper gears, the acceleration rate of the engine is much slower than what they tested, doesn't trigger the Acceleration Fuel Map, and the engine ends up a lot leaner in reality in top gear. It's not that common of a problem, since most people never drive that fast for that long to cause engine damage. Work around: Tune full throttle fueling in real world usage at dragstrip (to best trap speed) or in Steady State Mode on different dyno.

You can optimize tuning for a DJ dyno and make big numbers - and you can tune the engine to make the best power under load on a load bearing dyno and blow off the big DJ dyno numbers. Can a tuner cheat and make a load bearing dyno read higher? The only way that could happen is in a Sweep Test - Sweep Tests are the least reliable of all tests, period. There is NO question about that. Since the Rotating Mass is a variable in a Sweep Test (NOT a Steady State Test!), the actual inertia factor entered affects the final HP figure - Tell the software that the vehicle has a lot of rotating mass to accelerate, and the HP number increases. (torque, rpm, acceleration rate and mass are the factors) - just like DJ dyno ignoring the difference in mass of all cars - So - true HP, again - Steady State Test - No acceleration, mass makes no difference, anymore. Torque, RPM and dyne parasitics. Period. True. Can you make a Steady State Test read higher? Really hard to do - The software will NOT take data unless speed and load are completely stable - eliminating cheating. As far as atmospheric conditions making a +/- 10% difference? Unless you REALLY mess with the barometric pressure (and you can look at every atmospheric factor on the test report sheet - it's hard coded to display - and not an option), it is simply, absolutely impossible to do without obvious evidence. Are final tuning optimal dyno settings different on an Inertia dyno vs. a load bearing dyno? For many reasons, final tune settings are different - and, since most load bearing dyno's will do both , there is a choice of tests - from a DJ style Sweep Test to Steady State. Having a choice of those types of tests to do and seeing what the results on the track are, most tuners will choose the Steady State Test over a Sweep Test. Without a doubt - the Steady State test Mode is the most consistently superior method of tuning - anybody who has the capability to do it will echo that sentiment - it's only an arguable point with those who can't do it properly. One of the reasons why the load bearing dyno will provide settings that work better in the real world is that combustion chamber temperatures are more in line with the actual operating temperatures that the engine.

Does altitude make any difference at all in horsepower? The engine couldn't give 2 hoots at what altitude it is tested at - it only cares what the air pressure, temperature and humidity is. Sea level at 28.02 inches baro is exactly the same as 4000 ft at 28.02 inches, as far as the engine is concerned. When tested at 5000 ft, we get virtually exactly the same power (corrected to atmospheric conditions, of course) as we do at sea level - It's just about 24%-25% less on the track! I am confused why some dyno operators insist on putting altitude on their charts and swear that it's a factor.

Crankshaft horsepower vs. true rear wheel horsepower. That's a tough one. As each vehicle is different, the best way is to dyno the engine and then dyno the vehicle to see exactly what the loss is. The best estimate I can give you based on experience and research is take crankshaft horsepower, subtract 14.5% ( search SAE ), take that, and subtract around 10% to 15% and you'll get about true horsepower at the rear wheels. The actual formula contains a curve for power loss through gears and there's another curve for power lost in a tire. Remember, too - that unless you dyno your engine you are only likely to get a crankshaft number from the manufacturer and that's probably a "good" one that the marketing department is providing.

The most often heard discussion is that what factor can be applied to rear wheel horsepower to reflect crankshaft horsepower. This is where we need to understand how the rear wheel horsepower number was derived. Since the DynoJet seems to be widely used and numbers quoted are those from a DynoJet, we are going to use them as our inertia dynamometer example.

First it is important to have an understanding of how DynoJet gets their horsepower numbers. Power in mechanical terms is the ability to accomplish a specified amount of work in a given amount of time. By definition, one horsepower is equal to applying a 550 pound force through a distance of 1 foot in one second. In real terms, it would take 1 HP to raise a 550 pound weight up 1 foot in 1 second. So to measure horsepower, we need to know force (in pounds) and velocity (in feet per second). Dynojet's inertial dynamometer measures power according to the terms just described. It measures velocity directly by measuring the time it takes to rotate two heavy steel drums one turn. It measures force at the surface of the drum by indirectly measuring it's acceleration. Acceleration is simply the difference in velocity at the surface of the drums from one revolution to the next. The force applied to the drums is calculated from acceleration using Newton's 2nd law, Force = Mass * Acceleration. Since the mass of the drums is know and acceleration has been measured, Power (horsepower) can now be calculated. Torque is then calculated using the horsepower number: Torque = Horsepower * 5252 / RPM.

Once they have these numbers a series of correction factors are applied, some made public, some hidden as proprietary secrets. The public correction factor is the SAE correction factor. This formula assumes a mechanical efficiency of 85%. The formula used is: Where: CF= 1.18 * (29.22/Bdo) * ((Square Root(To+460)/537)) – 0.18. To = Intake air temperature in degrees F, Bdo = Dry ambient absolute barometric pressure. This correction factor is meant to predict output in varying atmospheric conditions and is a +/- 7%. The proprietary correction factor is supposed to reflect the loss of power from the crankshaft to the rear wheels.

A Loading Dynamometer applies resistance to the dyne's roller(s) , typically using either a water brake or a current eddy brake. In either case, the amount of force is measure using a strain gauge. The measured force is torque which is a real, indisputable measurement of the actual output at the wheel. Horsepower than can be calculated: Hp = Trq * 5252 / RPM.

A Dynamometer can only measure actual power at the output location. Actual power produced AND delivered by an engine will be highest if measured at the crankshaft, lower at the transmission output shaft and even lower, but more meaningful, still, at the rear wheels. The power that you use is the power at the rear wheels. Some Dynamometer companies add to measured rear wheel power readings a factor that is based on ESTIMATED rear wheel power losses (under what power conditions? 3.0 ltr.? 5.0 ltr.? Under coasting conditions? with a 185/70/15 radial tire? a 335/35/18 radial tire? New heavy radial tire vs. worn old, light, racing tire? Who knows?) In short, there is NO meaningful "average" tire to get a correct rear tire power transmission loss measurement for all cars - so obviously, unless they actually measure the power lost in the rear tires, under driven load conditions, NO dyno company should BE ADDING incorrect power figures into the measured power. It's simply wrong. The fact that they add varying amounts of power to the actual, "true" amount of power delivered and measured to the surface of the drive roller creates a situation that makes it an onerous task to compare power figures from different brands of dynamometer systems. On simple inertial dynamometers, some (most) companies use an average for the inertial mass value of the engine, transmission, driveshaft, axles and rear wheels. This is saying that a 4 cylinder, 2.0 ltr. Porsche 914 has the same rotating mass and same rear wheels as a 8 cylinder, 5.0 ltr. Porsche 928 S+4. This simply is not so and wrong.

It's expensive to measure frictional losses in the engine and drivetrain, requiring the dyno to be able to drive the vehicle with engine off. Add the cost of a 50+hp electric motor, controlled power supply, etc. It's just not likely that $20,000 dyno will be equipped with that equipment. It is also common for dynamometer companies to add to the power readings by adding transmission and driveshaft losses back into the measured power readings. Some companies make a concerted effort try to measure frictional losses and, optionally, add the power to the measured readings. Other companies - some that would surprise you - say that it's not important and give a blanket, single factor for frictional losses in every engine. Some simply say that there is a meaningful "average" for every car,( 4 stroke/ 4 cylinder/ 4 speed transmission, 4 stroke/ 8 cylinder/ automatic transmission) and apply it to every car and that it is not a significant difference. Blanket estimates of "average" losses and corrections are, quite simply, incorrect. At the upper levels of the industry, (we are talking about $150,000 - $500,000 AC or DC 4 quadrant dynamometers) it is not tolerated - shouldn't be - and needn't be. There is a dyno company that actually has different versions of software that displays their own identical data files as different amounts of power depending on whether you use the DOS version or the Windows version of their software!!

True, rear wheel horsepower is the standard of measuring the power that is actually delivered to the rear wheels. It is honest, true, fair and duplicable. It is the ONLY standard that can be duplicated by the entire industry - regardless of the dyno manufacturer. From my experience and that of many others, when comparing True, rear wheel horsepower to DJHP you must apply a factor. It appears that this is a sliding scale based on horsepower but the best estimate is 1.05 to 1.21 (maybe higher). What this means is that for those of you trying to calculate what your crankshaft horsepower is based on DJHP, and are adding 15%, the most common number I hear, you are actually doubling (at least) the factor. Why? Because DJHP already has a puff number added into their DJHP. Lets say DJHP shows 200 hp and you add 15%, you get 230 hp crankshaft horsepower. In reality DJ has already added in 15 or 20% to their 200 DJHP number. How does this help us.? It does not, and is fact harmful to the many dynamometer test facilities that report only what the dyno actually measured. I can not tell you of the many discussions that we have had as to why the horsepower numbers we recorded lower than that of DJ. For those manufacturers that use DJHP as proof of their claims, can you imagine the shock your customers get when the horsepower number of a vehicle tested on a load bearing dyno do not come close to their claim.

Proper tuning, especially on highly modified engines greatly affect the power difference. Due to the fact that the DJ dyno's sweep so quickly on sweep hp tests, there is no way to properly tune a fuel map. What you get is the acceleration and full throttle maps both triggered during the test, ending up over-rich, affecting the horsepower. The other factor that needs to be taken into account is that DJ dynos assume that every vehicle has the same rotating mass - they don't - and that disregard is another reason why the hp conversion figures are different. The most accurate measurement of rear wheel horsepower is in Steady State Mode (inertia is not a factor in power equation.) The inertial mass changes on each car affects the DJ power, but not the true, rear wheel horsepower. There's another message in the above example, besides the average true, rear wheel horsepower to DJHP conversion factor - It's up to the more experienced reader to figure it out.

Chassis dyne HP, What is it? What to call it? DynoJet = "DJHP". It's not really proper to call "DJHP" "rwhp", as neither the Mustang, DynoJet, Fuchs, Superflow or Land and Sea will necessarily produce the same numbers as a DJ dyno, except by luck - and the whole idea of true, rear wheel horsepower is that EVERY dyno manufacturer HAS the capability to provide those numbers! The Superflow chassis dynes, the Mustang, Land and Sea are all capable of measuring power in steady state mode and producing the same numbers - they all measure torque. Torque x rpm / 5252 = horsepower. We've not diddled with physics! The only factor that is added to the measured reading, in true, rear wheel horsepower, is the additional energy (dyne parasitics) required to spin the dyno(s) roller to whatever speed the roller is turning at - logical, proper and required for any measuring instrument, torque x rpm / 5252 = horsepower + parasitic power = true, rear wheel horsepower.

Chassis dyne HP, What can inflate HP readings on a dyno, but not really make more engine power in the real world? A few things can affect HP when using inertia dynos (not a dyne in Steady State Mode) to measure power (what else would you do??:-): Changing to light, worn race rear tires will improve power output on an inertia dyno, but, not improve real world top speed. A heavier (brand new street) tire that replaced the above, light, worn tire, will decrease measured power on an inertia dyno, but not decrease real world top speed. Lighter wheels are a good thing! Better acceleration in lower gears, especially 1st and 2nd (accelerating less inertial mass!). Better handling is possible, too! Driving hard on worn, light tires is foolish and is not being recommended.

Problems with Inertia dyno test procedure and fuel injected vehicles: A Sweep Test (hold throttle wide open and sweep from low rpm to high rpm) will often trigger the Acceleration Fuel Map, along with the Main Fuel Map, causing the fuel mixture readings to indicate dyno operator that the motor is overly rich. This would cause the tuner to lean out the main fuel map. Of course, in the real world, upper gears, the acceleration rate of the engine is much slower than what they tested, doesn't trigger the Acceleration Fuel Map, and the engine ends up a lot leaner in reality in top gear. It's not that common of a problem, since most people never drive that fast for that long to cause engine damage. Work around: Tune full throttle fueling in real world usage at dragstrip (to best trap speed) or in Steady State Mode on different dyno.

You can optimize tuning for a DJ dyno and make big numbers - and you can tune the engine to make the best power under load on a load bearing dyno and blow off the big DJ dyno numbers. Can a tuner cheat and make a load bearing dyno read higher? The only way that could happen is in a Sweep Test - Sweep Tests are the least reliable of all tests, period. There is NO question about that. Since the Rotating Mass is a variable in a Sweep Test (NOT a Steady State Test!), the actual inertia factor entered affects the final HP figure - Tell the software that the vehicle has a lot of rotating mass to accelerate, and the HP number increases. (torque, rpm, acceleration rate and mass are the factors) - just like DJ dyno ignoring the difference in mass of all cars - So - true HP, again - Steady State Test - No acceleration, mass makes no difference, anymore. Torque, RPM and dyne parasitics. Period. True. Can you make a Steady State Test read higher? Really hard to do - The software will NOT take data unless speed and load are completely stable - eliminating cheating. As far as atmospheric conditions making a +/- 10% difference? Unless you REALLY mess with the barometric pressure (and you can look at every atmospheric factor on the test report sheet - it's hard coded to display - and not an option), it is simply, absolutely impossible to do without obvious evidence. Are final tuning optimal dyno settings different on an Inertia dyno vs. a load bearing dyno? For many reasons, final tune settings are different - and, since most load bearing dyno's will do both , there is a choice of tests - from a DJ style Sweep Test to Steady State. Having a choice of those types of tests to do and seeing what the results on the track are, most tuners will choose the Steady State Test over a Sweep Test. Without a doubt - the Steady State test Mode is the most consistently superior method of tuning - anybody who has the capability to do it will echo that sentiment - it's only an arguable point with those who can't do it properly. One of the reasons why the load bearing dyno will provide settings that work better in the real world is that combustion chamber temperatures are more in line with the actual operating temperatures that the engine.

Does altitude make any difference at all in horsepower? The engine couldn't give 2 hoots at what altitude it is tested at - it only cares what the air pressure, temperature and humidity is. Sea level at 28.02 inches baro is exactly the same as 4000 ft at 28.02 inches, as far as the engine is concerned. When tested at 5000 ft, we get virtually exactly the same power (corrected to atmospheric conditions, of course) as we do at sea level - It's just about 24%-25% less on the track! I am confused why some dyno operators insist on putting altitude on their charts and swear that it's a factor.

Crankshaft horsepower vs. true rear wheel horsepower. That's a tough one. As each vehicle is different, the best way is to dyno the engine and then dyno the vehicle to see exactly what the loss is. The best estimate I can give you based on experience and research is take crankshaft horsepower, subtract 14.5% ( search SAE ), take that, and subtract around 10% to 15% and you'll get about true horsepower at the rear wheels. The actual formula contains a curve for power loss through gears and there's another curve for power lost in a tire. Remember, too - that unless you dyno your engine you are only likely to get a crankshaft number from the manufacturer and that's probably a "good" one that the marketing department is providing.

#52

Addict

Rennlist Member

Rennlist Member

Thread Starter

Eclou

Thanks for the read, this still doesn't really expain how certain load type dynos still give these wonky torque readings, whilst the only one (I have seen) which doesn't (Maha) has limitations (by virtue of grip) in actually measuring over 750NM

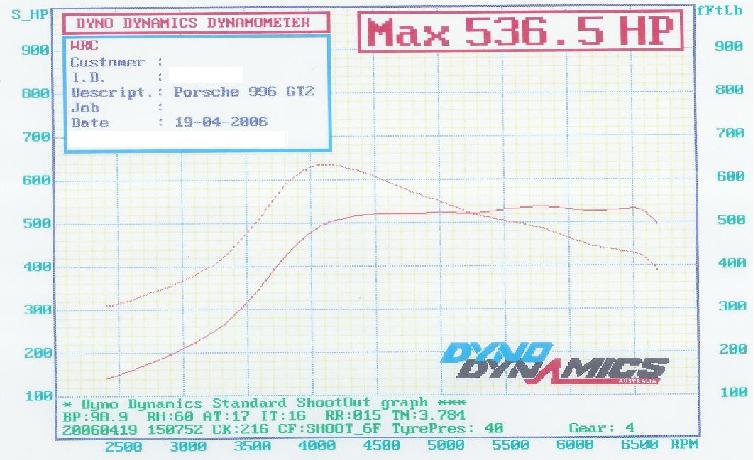

Here is the classic from a a while back, the Weltmiester Dyno Dynamics Magnetic eddy current retarder which is supposed to provide the load needed to give accurate readings and indeed does seem to give good maximum power numbers however like the others the torque numbers are silly.

From memory this dyno is for a 996GT2 with just ECU/Exhaust mods - 870NM

Thanks for the read, this still doesn't really expain how certain load type dynos still give these wonky torque readings, whilst the only one (I have seen) which doesn't (Maha) has limitations (by virtue of grip) in actually measuring over 750NM

Here is the classic from a a while back, the Weltmiester Dyno Dynamics Magnetic eddy current retarder which is supposed to provide the load needed to give accurate readings and indeed does seem to give good maximum power numbers however like the others the torque numbers are silly.

From memory this dyno is for a 996GT2 with just ECU/Exhaust mods - 870NM

#54

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Nice Maha run TB..

The limitations with the Dyno Dynamic dyno's are wheel speed shutting down the runs.. Most runs are done in 3rd gear.. I have seen 205MPH on my DynoPack....

The limitations with the Dyno Dynamic dyno's are wheel speed shutting down the runs.. Most runs are done in 3rd gear.. I have seen 205MPH on my DynoPack....

#55

Addict

Rennlist Member

Rennlist Member

Thread Starter

Proper tuning, especially on highly modified engines greatly affect the power difference. Due to the fact that the DJ dyno's sweep so quickly on sweep hp tests, there is no way to properly tune a fuel map. What you get is the acceleration and full throttle maps both triggered during the test, ending up over-rich, affecting the horsepower. The other factor that needs to be taken into account is that DJ dynos assume that every vehicle has the same rotating mass - they don't - and that disregard is another reason why the hp conversion figures are different. The most accurate measurement of rear wheel horsepower is in Steady State Mode (inertia is not a factor in power equation.) The inertial mass changes on each car affects the DJ power, but not the true, rear wheel horsepower.

http://www.youtube.com/watch?v=vPqQe6qEuRA

The left hand gauge shows the load in Newtons being applied, you can hear the engine straining and see the middle gauge displaying the torque being produced (actually it displays in power but I'm pretty sure it is extrapolating from the torque being measured) from watching this dyno in action one can see that it really attempts to match the torque of the engine it is measuring (hence the slippage issues) and it seems that dynos which don't do this become compromised at guesstimating peak torque ?

Nice Maha run TB..

#56

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Toby I was waiting for the picture to see your bumper cover being removed....

I definitely like pulling off the tires and having a direct bolt to hub method...

I definitely like pulling off the tires and having a direct bolt to hub method...

#57

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

It looks like they had issues with there tires.. Should have got some race slicks...

From the dyno screen it looks like the upper right hand is your RPM and below that was your speedo.. running at 117mph..

From the dyno screen it looks like the upper right hand is your RPM and below that was your speedo.. running at 117mph..

#58

Addict

Rennlist Member

Rennlist Member

Thread Starter

The blower hanging on the left was surplus and all my temperatures were in the green -I guess the fact that they were blowing 10DegC (50DegF) helped...... (

Originally Posted by Kevin

From the dyno screen it looks like the upper right hand is your RPM and below that was your speedo.. running at 117mph

#59

Addict

Rennlist Lifetime Member

Rennlist Lifetime Member

With the cooling they have it isn't neccessary, they blow some serious air at the front of the car and through the engine, check out the hardware

The blower hanging on the left was surplus and all my temperatures were in the green -I guess the fact that they were blowing 10DegC (50DegF) helped...... (

I guess for the majority of cars they do it is over complication....

It maxes out at ~250kph (155mph) in the 5th gear run.

The blower hanging on the left was surplus and all my temperatures were in the green -I guess the fact that they were blowing 10DegC (50DegF) helped...... (

I guess for the majority of cars they do it is over complication....

It maxes out at ~250kph (155mph) in the 5th gear run.

#60

Nordschleife Master

Toby, very nice dyno cell, they definatley did things correctly. I've run a few cup cars on a Dyno Dynamics roller dyno on slicks and they definatley got hot enough to heat cycle the slicks. I don't know that I would want to run the car for a prolonged period of time.

I've also had the opportunity to tune a MoTeC powered 427ci Chevrolet engine (drag car) with a supercharger on a Dyno Dynamcis dyno in FL and did not experience any tire slippage, even with the torque, so it may be just a difference of dynos or roller design compared to the Maha.

I've also had the opportunity to tune a MoTeC powered 427ci Chevrolet engine (drag car) with a supercharger on a Dyno Dynamcis dyno in FL and did not experience any tire slippage, even with the torque, so it may be just a difference of dynos or roller design compared to the Maha.