Shift rod

#1

Rennlist Member

Thread Starter

Join Date: Nov 2010

Location: Central California

Posts: 3,484

Likes: 0

Received 14 Likes

on

13 Posts

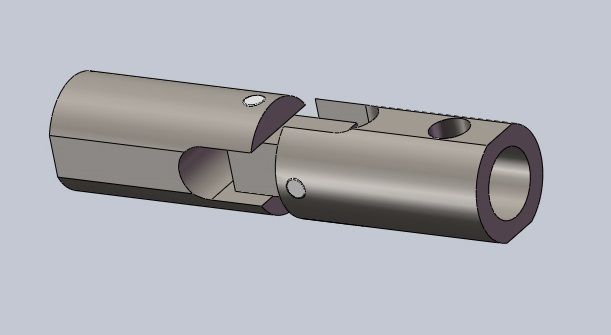

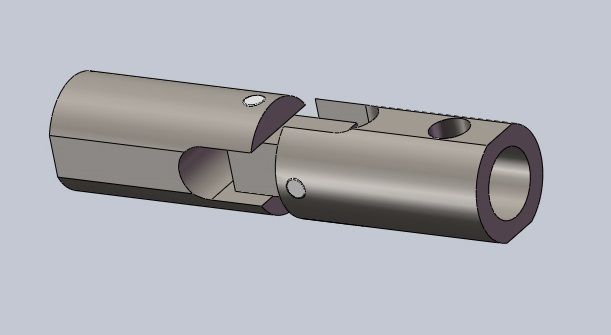

My latest home-grown project is a shift rod. Wow!!!! if none of you have installed the FDM "Golden Rod", do it now! I cannot believe the slop in the ridiculous diaphragm shift coupler. A couple of pics of the old rod with the coupler and what I intend on replacing it with. I'll try and load the video of how bad it is.

I'll keep you posted.

I'll keep you posted.

I'll keep you posted.

I'll keep you posted.

Last edited by OverBoosted28; 01-22-2014 at 06:10 PM.

#2

Burning Brakes

Tha'ts a hefty looking U-Joint!

You will need to machine a piece to fit snugly over the shifter rod that's sticking out of the transmisson and weld it to the U-joint then weld the U-joint to your cut shaft.

Be VERY careful aligning the u-joint when you weld it to the shaft, it's very sensitive to rotational mistakes and will throw the shifter handle to one side or the other.

I ended up adding a piece of threaded rod with a jam-nut to mine after welding, installing, cutting, welding, installing, cutting, welding, installing, crying!

You will need to machine a piece to fit snugly over the shifter rod that's sticking out of the transmisson and weld it to the U-joint then weld the U-joint to your cut shaft.

Be VERY careful aligning the u-joint when you weld it to the shaft, it's very sensitive to rotational mistakes and will throw the shifter handle to one side or the other.

I ended up adding a piece of threaded rod with a jam-nut to mine after welding, installing, cutting, welding, installing, cutting, welding, installing, crying!

#3

Rennlist Member

Thread Starter

Join Date: Nov 2010

Location: Central California

Posts: 3,484

Likes: 0

Received 14 Likes

on

13 Posts

I had already contemplated both of those points. I was going to center the shifter side of u-joint vertically so as to be in line with the actual shifter. The trans side of the u-joint will sit laterally. Did you buy a bushing to reduce the u-joint at the shift shaft/trans or mill one?

#5

Rennlist Member

Thread Starter

Join Date: Nov 2010

Location: Central California

Posts: 3,484

Likes: 0

Received 14 Likes

on

13 Posts

$$$$$$$$. U-joint was $40 bucks and I can do it myself. Of course I would love to buy the rod already done, but can't justify the cost when I can make one myself. Like I said before some of us can't really afford these cars. When you have F'd up priorities you figure out ways to get things done.

Also wanted to tell those that can afford it to buy the FDM quality product because I believe ALL our cars would benefit from it. Hell, if you really want to throw money away find a real RS rod and buy that one :-)

Also wanted to tell those that can afford it to buy the FDM quality product because I believe ALL our cars would benefit from it. Hell, if you really want to throw money away find a real RS rod and buy that one :-)

Trending Topics

#8

You already spent $40. If u can copy the FDM GR for less than $200 from here then have at it. Having said that, this is one item in particular I would want no part of fabricating on my own... Good luck though! Keep us posted.

#9

Rennlist Member

I'm with the OP .... some of you guys just don't get it!  It is not always the money - rather the satisfaction of a DIY that works far better that OE.

It is not always the money - rather the satisfaction of a DIY that works far better that OE.

Re the cut & paste of a 'stout' universal to a stock shift rod, take a look at my mod back in '09 DIY RS clone.

Make up a simple jig as shown, and it will be dimensionally correct once welded.

The U-joint I had used which received all the disparaging remarks is exactly the same joint that every 993 driver clutches between his mitts when steering the car ..... ya'know, the one responsible for that fine steering feedback. Actually works quite well on a shift rod too ....

is exactly the same joint that every 993 driver clutches between his mitts when steering the car ..... ya'know, the one responsible for that fine steering feedback. Actually works quite well on a shift rod too ....

It is not always the money - rather the satisfaction of a DIY that works far better that OE.

It is not always the money - rather the satisfaction of a DIY that works far better that OE.Re the cut & paste of a 'stout' universal to a stock shift rod, take a look at my mod back in '09 DIY RS clone.

Make up a simple jig as shown, and it will be dimensionally correct once welded.

The U-joint I had used which received all the disparaging remarks

is exactly the same joint that every 993 driver clutches between his mitts when steering the car ..... ya'know, the one responsible for that fine steering feedback. Actually works quite well on a shift rod too ....

is exactly the same joint that every 993 driver clutches between his mitts when steering the car ..... ya'know, the one responsible for that fine steering feedback. Actually works quite well on a shift rod too ....

#10

Rennlist Member

That's one thing I enjoy about this board too - the diversity from the above DIY all the way to those who can do open checkbook 9Meister projects and everything inbetween - it's all good - keep it coming.

#11

Burning Brakes

Agreed with Garth, although money can be a very important factor! I was too cheap to buy a $40 u-joint so I made one... I was putting my wife through college at the time so I was broke and had WAY too much free time on weekends...

I didn't take any real pictures of this part, but it's my U-joint combination transmission mounting point. The body is 1" OD 304 stainless and the "yoke" is 1/2" stainless key stock.

I didn't take any real pictures of this part, but it's my U-joint combination transmission mounting point. The body is 1" OD 304 stainless and the "yoke" is 1/2" stainless key stock.

#12

Rennlist Member

Thread Starter

Join Date: Nov 2010

Location: Central California

Posts: 3,484

Likes: 0

Received 14 Likes

on

13 Posts

I found a steel 3/4" X 5/8" sleeve/bushing that'll be perfect for the shift shaft mount side of the u-joint. Just like the rear control arms I fabbed up, I went overkill on it so I couldn't kick myself for under engineering it and having to fix it later. Thanks for the above encouragement. I can't stand it when people say "why don't you just have someone else do it". I know exactly whats in there when I do it myself and don't have to try and figure out what they did or didn't do. Also for the most part, I trust no one. :-)

Another note: I appreciate all of the great things that alot of these manufacturers have produced and would love to be able to buy all of them and then pay someone else to put it in. That won't happen. So those of you that can afford to do so, help out our sponsoring manufacturers and buy their products. Thanks

Another note: I appreciate all of the great things that alot of these manufacturers have produced and would love to be able to buy all of them and then pay someone else to put it in. That won't happen. So those of you that can afford to do so, help out our sponsoring manufacturers and buy their products. Thanks

Last edited by OverBoosted28; 01-23-2014 at 01:45 PM.

#13

Instructor

Love the "home grown" approach. I too enjoy the hands on approach to owning. Here is a crummy pic of mine in the works. The shifter shaft was .634", so a 5/8"id u-joint can be utilized if it is opened up a small amount. The threaded setting pin goes completely through the shaft. I plan on using a longer bolt with a nylon locker on the other side as a back-out safety in lieu of lock-tight.

Do you have a c4/turbo? Looks different than mine. offset bushing for driveshaft clearance?

PS. Came across your previous post regarding adjustable rear links.... love it.

i can see how this would be very sensative to rotational positioning.

i cut my shifter rod down and slid in an intermediate piece. fits snugly inside the shift lever. this gives the ability of tacking after install to fine-tune x/y position of shift lever.

Do you have a c4/turbo? Looks different than mine. offset bushing for driveshaft clearance?

PS. Came across your previous post regarding adjustable rear links.... love it.

Tha'ts a hefty looking U-Joint!

You will need to machine a piece to fit snugly over the shifter rod that's sticking out of the transmisson and weld it to the U-joint then weld the U-joint to your cut shaft.

Be VERY careful aligning the u-joint when you weld it to the shaft, it's very sensitive to rotational mistakes and will throw the shifter handle to one side or the other.

I ended up adding a piece of threaded rod with a jam-nut to mine after welding, installing, cutting, welding, installing, cutting, welding, installing, crying!

You will need to machine a piece to fit snugly over the shifter rod that's sticking out of the transmisson and weld it to the U-joint then weld the U-joint to your cut shaft.

Be VERY careful aligning the u-joint when you weld it to the shaft, it's very sensitive to rotational mistakes and will throw the shifter handle to one side or the other.

I ended up adding a piece of threaded rod with a jam-nut to mine after welding, installing, cutting, welding, installing, cutting, welding, installing, crying!

i cut my shifter rod down and slid in an intermediate piece. fits snugly inside the shift lever. this gives the ability of tacking after install to fine-tune x/y position of shift lever.

Last edited by jason89i; 01-23-2014 at 01:09 PM.

#14

RL Community Team

Rennlist Member

Rennlist Member

I wonder if someone took the coupler out of a 80s vintage Carrera it could be adapted. It had a nylon bushing that isolated vibration but was rather stable. I also seem to remember it had some adjustability.

#15

Nordschleife Master

I applaud those guys (and girls) that venture to create solutions/improvements on their own, at one point even the Golden Rod was an idea, that came to market.

I am thankful for those that innovate, and bring these enhancements to the rest of us. I do not have the tooling or skills to manufacture a shift rod on my own, but I am thankful that FDM did have the skills and the capability to deliver it to those of us that don't DIY.

Ditto with the tie rod pinning, and kudos for sharing it with the rest of us.

OP should not be slammed for sharing, that is what this forum is about.

An even CHEAPER solution was to remove the rubber bushing and replace with a bunch of washers. I think that is in the archives as well, not as elegant as a swivel joint, but probably even cheaper.

I am thankful for those that innovate, and bring these enhancements to the rest of us. I do not have the tooling or skills to manufacture a shift rod on my own, but I am thankful that FDM did have the skills and the capability to deliver it to those of us that don't DIY.

Ditto with the tie rod pinning, and kudos for sharing it with the rest of us.

OP should not be slammed for sharing, that is what this forum is about.

An even CHEAPER solution was to remove the rubber bushing and replace with a bunch of washers. I think that is in the archives as well, not as elegant as a swivel joint, but probably even cheaper.