The silly little question thread ...

#796

Rennlist Member

The pressure gauge needle wobbles up and down randomly....as if a screw is maybe loose... I re-tightened all electric connections but still behaves strangely... purchased new OEM VDO sender from Porsche and trying to install by pulling out manifold but it will not budge...guess no choice but to find 24mm crowfoot and try to unbolt old sender...

#798

Yes. I pulled out the passenger side intake manifold and Air flow meter/air filter box assemblies. The oil temp/pressure sender manifold won't come out. Just bout tried everything. Thinking if it won't come out and there is no leakage in the area I shud just take out the pressure sender by loosening the 24mm bolt.

#799

I have the notch on pulley aligned with the notch on crank and "Z1" mark aligned...distributor rotor is confirmed that I am at cylinder #1...

1) I can sense a very slight play of the rocker arm (can almost hear a small ticking noise)....is this normal and when using the feeler gauge, does it matter which side of the rocker arm is pressed or lifted?

2) is there a torque setting for the bolt used to lock the valve adjustment screw?

1) I can sense a very slight play of the rocker arm (can almost hear a small ticking noise)....is this normal and when using the feeler gauge, does it matter which side of the rocker arm is pressed or lifted?

2) is there a torque setting for the bolt used to lock the valve adjustment screw?

#800

Burning Brakes

This might help https://rennlist.com/forums/964-foru...-freeplay.html

The torque is 18 ft-lb. But if you focus too much on the torque for the lock nut, you will likely miss getting the gap set correctly. You should be tightening the lock nut lightly while moving the feeler gauge until the you just start to feel some slight resistance on the gauge, then tightening the nut down fully when you know the gap is where you want it. Focus on the gap, not the torque of the lock nut. It's more important to get the gap right than the torque. As long as the nut is secure the torque will be close enough.

The torque is 18 ft-lb. But if you focus too much on the torque for the lock nut, you will likely miss getting the gap set correctly. You should be tightening the lock nut lightly while moving the feeler gauge until the you just start to feel some slight resistance on the gauge, then tightening the nut down fully when you know the gap is where you want it. Focus on the gap, not the torque of the lock nut. It's more important to get the gap right than the torque. As long as the nut is secure the torque will be close enough.

#801

finally got the sucker out...the 24mm crowfoot I purchased was too thick and wud not fit into the oil pressure sender bolt as the manifold cylinder head diameter is slightly larger than the bolt (i.e. the crowfoot wud not fit all the way into the bolt)....so I figured I was going to chuck the old sender anyways so used that as leverage to vice grip it and pull the thing out....it worked!...

#802

Rennlist Member

finally got the sucker out...the 24mm crowfoot I purchased was too thick and wud not fit into the oil pressure sender bolt as the manifold cylinder head diameter is slightly larger than the bolt (i.e. the crowfoot wud not fit all the way into the bolt)....so I figured I was going to chuck the old sender anyways so used that as leverage to vice grip it and pull the thing out....it worked!...

#803

Rennlist Member

I have the notch on pulley aligned with the notch on crank and "Z1" mark aligned...distributor rotor is confirmed that I am at cylinder #1... 1) I can sense a very slight play of the rocker arm (can almost hear a small ticking noise)....is this normal and when using the feeler gauge, does it matter which side of the rocker arm is pressed or lifted? 2) is there a torque setting for the bolt used to lock the valve adjustment screw?

#806

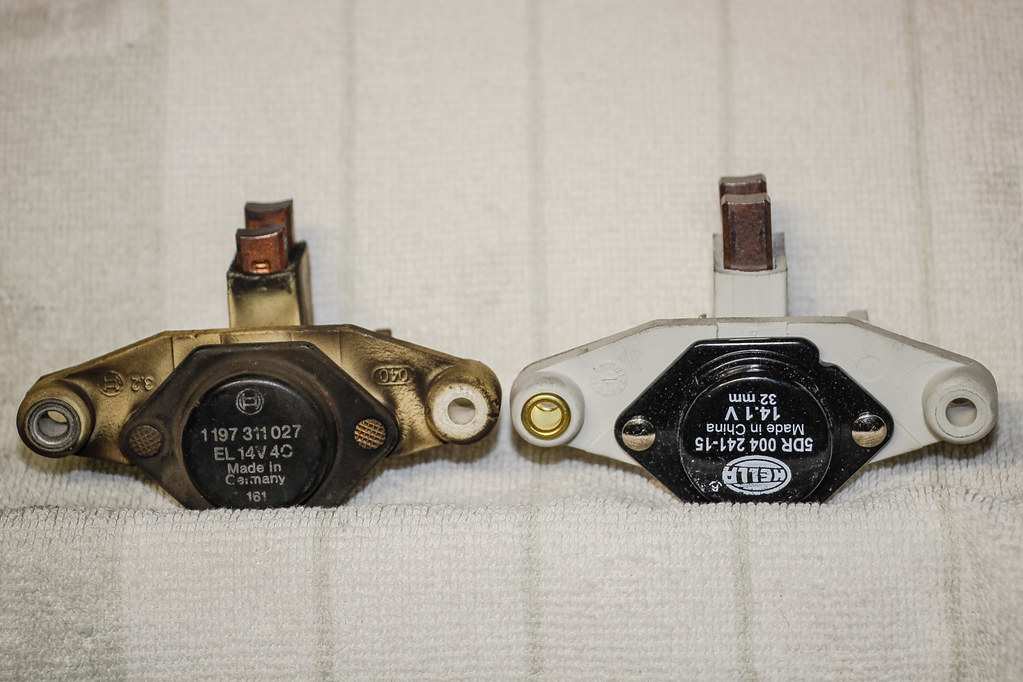

1) pulled out the alternator/cooling fan assembly...is there a way to visually inspect the voltage regulator for replacement?

2) I've doused the fan bearing area with lubricant to pull the fan out tomorrow, but how do I get the fan shroud out please?

thank you

2) I've doused the fan bearing area with lubricant to pull the fan out tomorrow, but how do I get the fan shroud out please?

thank you

#807

Rennlist Member

2. The shroud is a push fit. The alternator rests on a ridge in the shroud. If you put the alternator fan side down the shroud will come off the back or the alternator will fall forward. I first took off the fan with a specially made puller, then put planks of wood under the shroud and lightly tapped on the back of the alternator and it came out.

#808

Drifting

#809

Instructor

Join Date: Mar 2004

Location: North Carolina, USA

Posts: 129

Likes: 0

Received 0 Likes

on

0 Posts

just a thought but if that is the original alternator fan, you might want to replace it with an aluminum one. My original magnesium one fragmented on me and cut a belt!

#810