Powerflex bushes

#31

Three Wheelin'

Join Date: Dec 2004

Location: Halifax, Nova Scotia , Canada

Posts: 1,779

Likes: 0

Received 0 Likes

on

0 Posts

Kris,

I agree. The steel bush sleeves are a possible PIA ! Thats how the hacksaw

( careful !! ) and cold chisel approach developed.

Take your time and even I can do it !!!

As you said , no huge change to the car , just a tighter feel from the front .

Strange that these void bushes were never needed pre 964 !

I guess thats progress !!

Geoff

I agree. The steel bush sleeves are a possible PIA ! Thats how the hacksaw

( careful !! ) and cold chisel approach developed.

Take your time and even I can do it !!!

As you said , no huge change to the car , just a tighter feel from the front .

Strange that these void bushes were never needed pre 964 !

I guess thats progress !!

Geoff

#32

5th Gear

Join Date: Jan 2007

Location: Diss Norfolk - UK

Posts: 5

Likes: 0

Received 0 Likes

on

0 Posts

Geoff,

Are the voids in both bushes and where do they sit, 12 and 6 O'clock or 3 and 9?

In your work to development the powerflex bushes did you feel any difference in the kinematics during braking and wheel bump caused by the change in complaince (hardness and lack of voids).

I would assume that the voids are 12 and 6 O'clock to give greater vertical compliance for the ride benefits quoted. Did you compare the hardness of the rubber to the final version of the powerflex bush to the OEM? It would be interesting to know how different it is. The article states it is softer than most poly bush kits for other cars, which is good to hear.

Still contemplating which way to go....... don't want to loose the pliance that the car offers for long journeys or increase noise / harshness transmission through to the chassis!

Steve

Are the voids in both bushes and where do they sit, 12 and 6 O'clock or 3 and 9?

In your work to development the powerflex bushes did you feel any difference in the kinematics during braking and wheel bump caused by the change in complaince (hardness and lack of voids).

I would assume that the voids are 12 and 6 O'clock to give greater vertical compliance for the ride benefits quoted. Did you compare the hardness of the rubber to the final version of the powerflex bush to the OEM? It would be interesting to know how different it is. The article states it is softer than most poly bush kits for other cars, which is good to hear.

Still contemplating which way to go....... don't want to loose the pliance that the car offers for long journeys or increase noise / harshness transmission through to the chassis!

Steve

#33

Three Wheelin'

Join Date: Dec 2004

Location: Halifax, Nova Scotia , Canada

Posts: 1,779

Likes: 0

Received 0 Likes

on

0 Posts

Steve,

From memory ! the voids are at 3 and 6 .The idea is that the front of the wishbone can deflect horizontally when a bump etc comes along .

The wishbone rear bush is pretty well solid as it is responsible for track.

That way front toe can change when a bump etc comes along.

The RS has a slightly harder rear bush but the same front bush.

Because some front compliance needs to remain a few trials and Powerflex experience with other cars was how the bush material was arrived at .

On the road I noticed a slightly more positive steering response but comfort/noise levels were unchanged .I have been running the same set of bushes for 3/4 years now.

For serious track use it would be possible to use harder bush material .

All this was done because it irritated the hell out of me that a perfectly good wishbone was going for scrap because the rubber bushes had gone west .

My tiny bit for the 964/993 community .

Just in case anyone asks I have no commercial link to the Powerflex bushes !!

Geoff

From memory ! the voids are at 3 and 6 .The idea is that the front of the wishbone can deflect horizontally when a bump etc comes along .

The wishbone rear bush is pretty well solid as it is responsible for track.

That way front toe can change when a bump etc comes along.

The RS has a slightly harder rear bush but the same front bush.

Because some front compliance needs to remain a few trials and Powerflex experience with other cars was how the bush material was arrived at .

On the road I noticed a slightly more positive steering response but comfort/noise levels were unchanged .I have been running the same set of bushes for 3/4 years now.

For serious track use it would be possible to use harder bush material .

All this was done because it irritated the hell out of me that a perfectly good wishbone was going for scrap because the rubber bushes had gone west .

My tiny bit for the 964/993 community .

Just in case anyone asks I have no commercial link to the Powerflex bushes !!

Geoff

#35

5th Gear

Join Date: Jan 2007

Location: Diss Norfolk - UK

Posts: 5

Likes: 0

Received 0 Likes

on

0 Posts

Geoff, thanks for the info. I read your article, I and I'm sure others appreciate it when people encourage solutions come to market like you have. Myself and a colleague (993 owner) have been discussing what to do as we both need to change the bushes / arms.

Hows the weather treating you over in Canada, do you have to drive a C4 now?

Rgds

Steve

Hows the weather treating you over in Canada, do you have to drive a C4 now?

Rgds

Steve

#36

Three Wheelin'

Join Date: Dec 2004

Location: Halifax, Nova Scotia , Canada

Posts: 1,779

Likes: 0

Received 0 Likes

on

0 Posts

Steve,

I have had a C4 for years ! Brought it over with me. Thing to watch is not the weather but the salt . We have had a bit of -20C but great sunshine to go with it during the day.

Canada is a great country and so big . Nova Scotia is about 1/3rd the size of the UK with a population of 1 million people ! One of those best kept secrets .

Wish I had come here years ago .

All the best

Geoff

I have had a C4 for years ! Brought it over with me. Thing to watch is not the weather but the salt . We have had a bit of -20C but great sunshine to go with it during the day.

Canada is a great country and so big . Nova Scotia is about 1/3rd the size of the UK with a population of 1 million people ! One of those best kept secrets .

Wish I had come here years ago .

All the best

Geoff

#37

Nordschleife Master

Hey guys, once again, sorry to bump an old thread, but I had a question about the Powerflex bushings I bought and will be installing soon.

The forward bushing on the front control arms, on the OEM piece, the metal sleeve/washer piece has a notch on it that slots into the subframe and prevents the piece from rotating when you're torquing down the forward bolt (the bolt threads into the sleeve, not the subframe).

On the Walrod bushings, the OEM center metal sleeve/washer is reused.

On the Powerflex bushings, they include a replacement center metal sleeve/washer and this replacement piece does not have a notch on it like the OEM piece.

So my question is, what keeps the center sleeve piece on the Powerflex bushings from rotating when you're assembling/torquing down the forward bolt on the control arms?

The forward bushing on the front control arms, on the OEM piece, the metal sleeve/washer piece has a notch on it that slots into the subframe and prevents the piece from rotating when you're torquing down the forward bolt (the bolt threads into the sleeve, not the subframe).

On the Walrod bushings, the OEM center metal sleeve/washer is reused.

On the Powerflex bushings, they include a replacement center metal sleeve/washer and this replacement piece does not have a notch on it like the OEM piece.

So my question is, what keeps the center sleeve piece on the Powerflex bushings from rotating when you're assembling/torquing down the forward bolt on the control arms?

#39

Skippy

Rennlist Member

Rennlist Member

Funny to see this thread being resurrected. I didn't even remember that I posted the article but I do remember what a complete PITA job it was. Sorry but I don't recall the notch or its absence. Good luck.

#41

Nordschleife Master

Okay, to answer my question above, the Powerflex bushing center section is longer than the OEM piece and it has a built in spot to hold the piece w/ a spanner while you torque the bolt.

You can see it in my pic here, far right.

The far left bushing was the first one I attempted to remove and it was a total nightmare. The rubber piece did not come out very well, so it made judging my cuts into the metal sleeve very challenging, and the result was it was a total mess to remove the sleeve. The middle one was my 2nd attempt and it went much more smoothly. 1st one took several hours to remove, the 2nd one took about 45 minutes start to finish.

Next question.

So when I insert the big front bushing into the arm, I notice the fit is not very pressed. Sure, it requires a bit of an effort to insert the bushing into the arm, but once it is inserted, it takes very little effort for the bushing to spin inside the arm. I know it's not suppose to do that.

In the article posted in this thread, it mentions using thread locker adhesive in the event the bushing wants to spin in the arm.

Did anyone else experience this and what was your solution? I currently have an email out to Powerflex customer service regarding what they recommend to solve this issue.

You can see it in my pic here, far right.

The far left bushing was the first one I attempted to remove and it was a total nightmare. The rubber piece did not come out very well, so it made judging my cuts into the metal sleeve very challenging, and the result was it was a total mess to remove the sleeve. The middle one was my 2nd attempt and it went much more smoothly. 1st one took several hours to remove, the 2nd one took about 45 minutes start to finish.

Next question.

So when I insert the big front bushing into the arm, I notice the fit is not very pressed. Sure, it requires a bit of an effort to insert the bushing into the arm, but once it is inserted, it takes very little effort for the bushing to spin inside the arm. I know it's not suppose to do that.

In the article posted in this thread, it mentions using thread locker adhesive in the event the bushing wants to spin in the arm.

Did anyone else experience this and what was your solution? I currently have an email out to Powerflex customer service regarding what they recommend to solve this issue.

#43

I replaced mine last weekend with the Walrod bushings. I am very pleased with the bushings!

As you mentioned the Powerflex threaded bushing insert is not notched like the OE insert. I can't imagine what would hold the threaded insert in place when torque is applied to the bolt--especially considering the amount of grease that is applied to these poly bushings.

Yes, when installing the Walrod bushings, the OE inserts are reused. I would send them back and buy the Walrod bushings.

As you mentioned the Powerflex threaded bushing insert is not notched like the OE insert. I can't imagine what would hold the threaded insert in place when torque is applied to the bolt--especially considering the amount of grease that is applied to these poly bushings.

Yes, when installing the Walrod bushings, the OE inserts are reused. I would send them back and buy the Walrod bushings.

#44

Nordschleife Master

I think I may have beat up the OEM sleeves a bit during removal since I had no plans to reuse them.

We'll see what Powerflex comes up w/. I sent them some pics and explanation of what I'm experiencing.

We'll see what Powerflex comes up w/. I sent them some pics and explanation of what I'm experiencing.

#45

Nordschleife Master

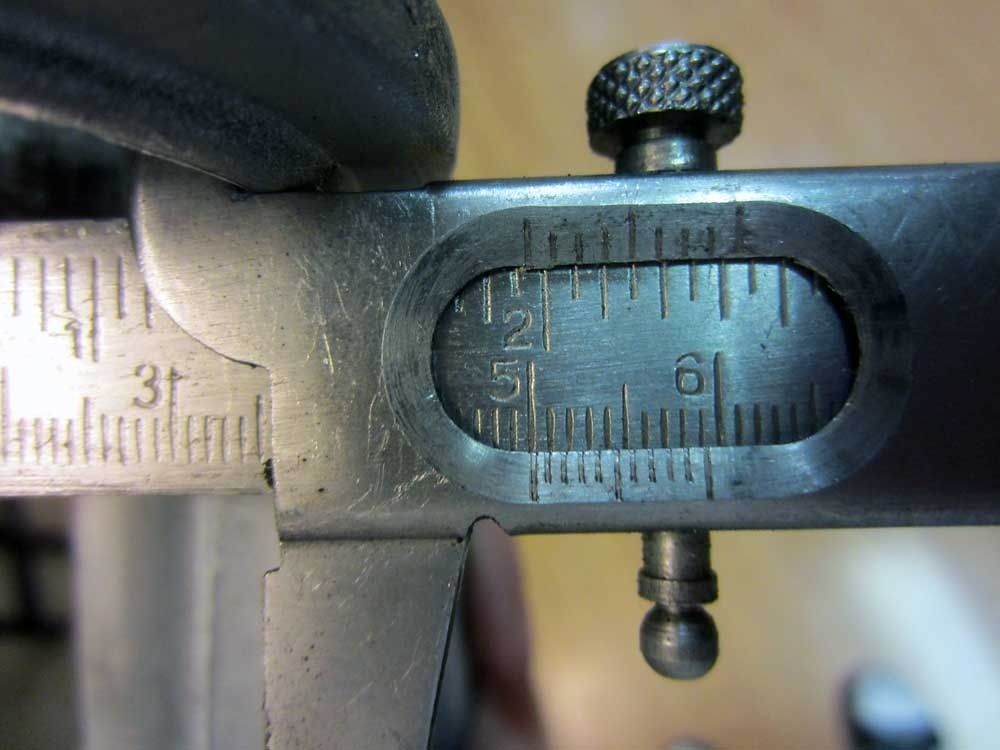

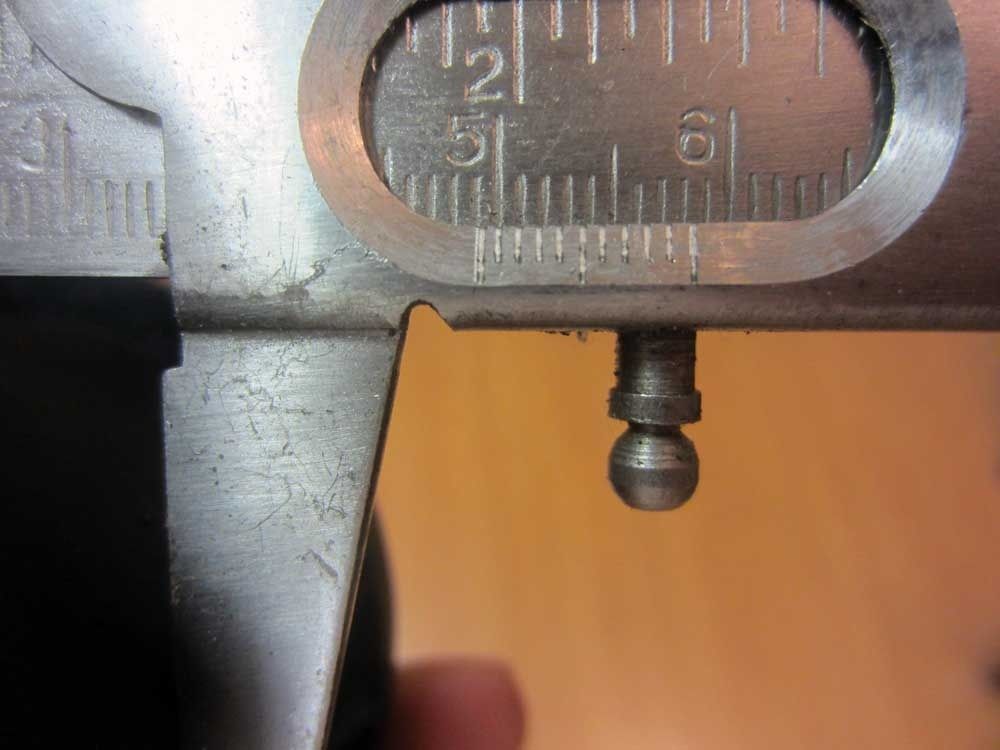

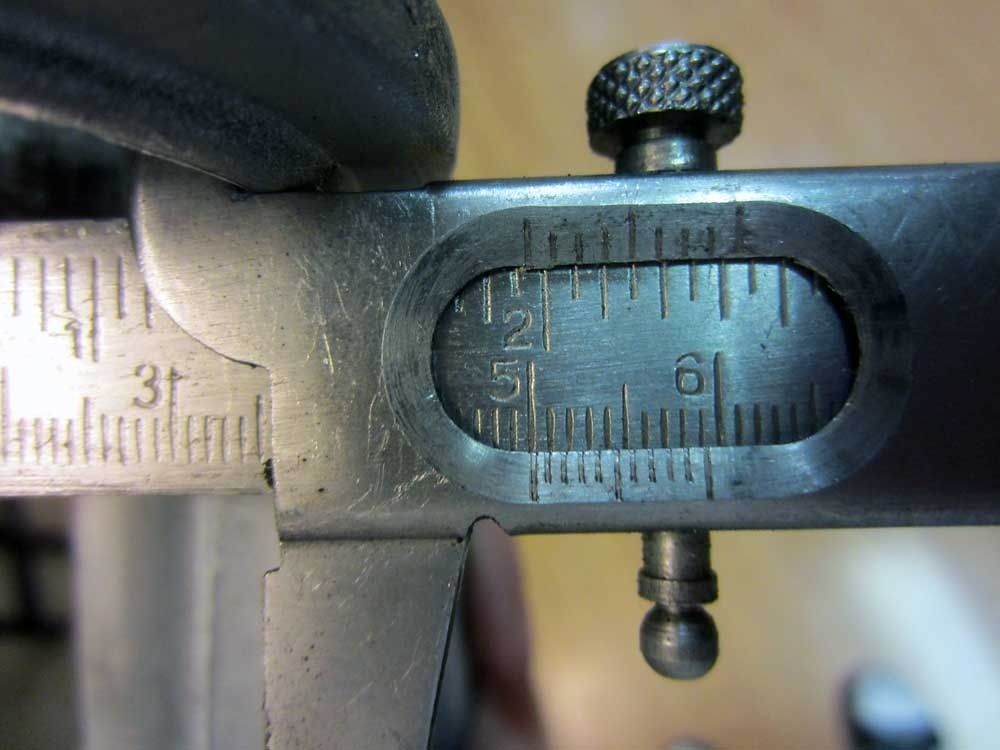

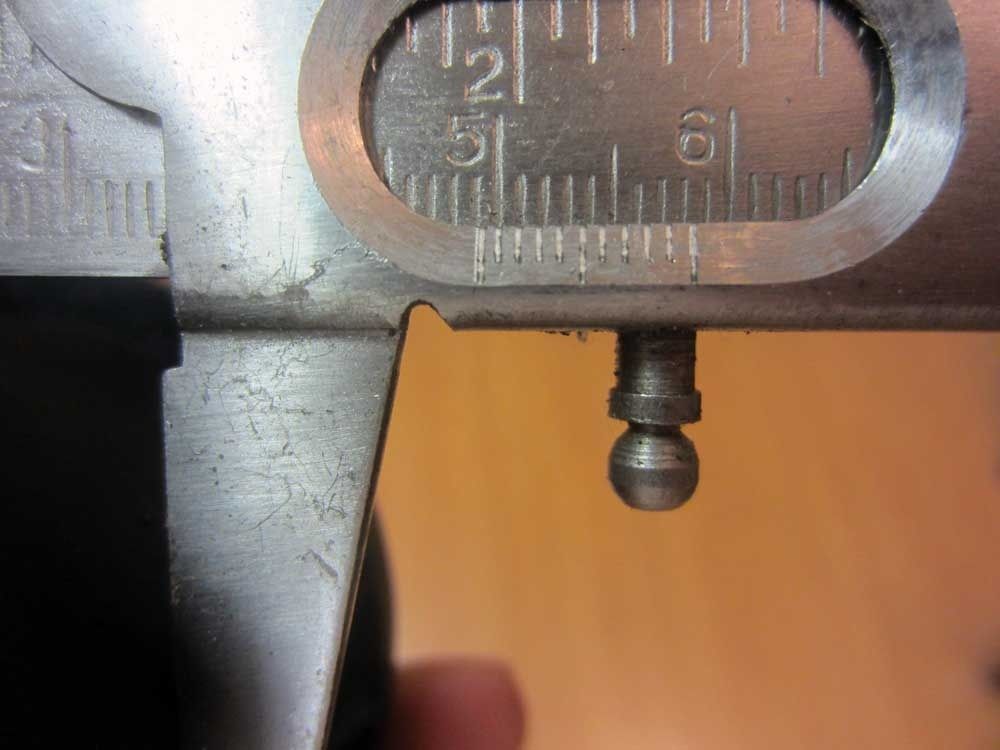

Some pics.

Diameter of arm on the side bushing is pushed in through.

Diameter of arm on the front side of the opening

Diameter of Powerflex bushing PFF57-101

Bushing and arm assembly.

It's not so loose it is falling out, but it's loose enough that it spins relatively freely in the arm.

Diameter of arm on the side bushing is pushed in through.

Diameter of arm on the front side of the opening

Diameter of Powerflex bushing PFF57-101

Bushing and arm assembly.

It's not so loose it is falling out, but it's loose enough that it spins relatively freely in the arm.