Adding windage ports to 2.5 blocks

#1

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

I searched, and found some references to having windage ports machined, but no details or direct discussion about it. So I just wanted to hear people's thoughts on this. Obviously, Porsche thought it was a good idea, so the 104mm blocks got them. I'm sure it would help on the 2.5s as well.

I just open up a hole where the metal above the mains is slightly machined for piston clearance?

Is this something I can do myself in my shop, or machinist only?

I just open up a hole where the metal above the mains is slightly machined for piston clearance?

Is this something I can do myself in my shop, or machinist only?

#2

Rennlist Member

LR can do it for like $325. From the LR link below, some details.

http://www.lindseyracing.com/hptalk/0808.htm

"One of the most recent additions to our Machine Work and Engine Services we can perform on your 2.5L engine is what we call our "Windage Port". This can be described as a port or opening at the base of the cylinders. One opening is between the base of cylinders number 1 and 2, and the other is between cylinders 3 and 4.

This wasn't an idea we came up with, but rather Porsche did. You can see it on the '89 2.7L and 3.0L 944S2 and 968 blocks from the factory. What we did was try to understand why they may have added this port to those later years blocks. You would think it was an improvement in either performance or reliability, or both! We refer to it as Cylinder Pumping.

We have noticed that there is a much lower, almost non existent, incidence of rod bearing failure on these 104mm bore blocks. Have you ever heard of a bearing failure on a 968 or 944S2? We don't recall hearing about one. Even one that has been turbo charged and seeing higher bearing loads. Seeing how both the 2.5L and 3.0L engines use the same bearings, oil pump, block oiling passage ways, crank (except stroke length), pick up tube and more, what's the difference? Well... one big difference is the windage port.

On a conventional V8, V6 or opposed cylinder engine like a 911's Flat 6, when one cylinder is on the down stroke, the cylinder opposite or across from it is on the up stroke. So the air trapped below the piston moves from one cylinder to the other easily. The volume of air there simply shifts or exchanges from one cylinder to the next like passing a ball back and forth between your hands.

On the Inline 4 cylinder engine, like the 944's, the cylinders are not opposed. The air beneath the piston doesn't have the same nice easy ability to move from one cylinder to it's adjacent cylinder. The air is somewhat compressed and has to work around the crankshaft throws and engine girdle to get to the next cylinder. Since the oil pan practically touches the girdle, there is almost no room for this to easily happen. This backwards compressing of the air is not productive and can rob horsepower. That's why drawing a vacuum on the block can increase horsepower such as with a well engineered dry sump system.

Now imagine oil coming off the crankshaft from the main and rod bearings and falling to the pan from front to rear as this is happening. Lots of oil to the tune of several gallons a minute.

The oil from cylinder number 1 is falling into the front of the oil pan. It needs to make it to the back of the oil pan where the oil pump pickup is. When the piston from cylinder number 2 comes down, the air from behind that piston is squeezed or forced forward towards cylinder number 1 since that piston is going up. This oil is traveling in the opposite direction of the pick up tube. Oil coming from the front half of the crankshaft, cylinders 1 and 2, is being pushed back and forth and would have a hard time moving down the pan towards the oil pickup. This oil and air mix is being whipped up by this back and forth motion and you have a rotating crankshaft adding to the problem as well.

We don't feel this problem is as important on the back two cylinders because of the deep sump portion of the oil pan, but the crankshaft is still in the way and keeping this cylinder pumping from happening as easily as possible. So like Porsche, we do two ports. The ports are above the crankshaft and the shifting or trading of air from one cylinder to the next can happen with less disturbance.

Is this the answer to connecting rod bearing failure? Time will tell on this one. Porsche felt sure there was good reason to do it. You can bet it wasn't to increase problems or reduce performance.

We simply tooled up to be able to machine this port on the 2.5L blocks that never had it. Since first offering it in June, almost everybody who's block we are working with opts for this modification to be added once describing it to them. This modification can be performed on any 2.5L 944 or 944 Turbo block for a charge of $325.00."

http://www.lindseyracing.com/hptalk/0808.htm

"One of the most recent additions to our Machine Work and Engine Services we can perform on your 2.5L engine is what we call our "Windage Port". This can be described as a port or opening at the base of the cylinders. One opening is between the base of cylinders number 1 and 2, and the other is between cylinders 3 and 4.

This wasn't an idea we came up with, but rather Porsche did. You can see it on the '89 2.7L and 3.0L 944S2 and 968 blocks from the factory. What we did was try to understand why they may have added this port to those later years blocks. You would think it was an improvement in either performance or reliability, or both! We refer to it as Cylinder Pumping.

We have noticed that there is a much lower, almost non existent, incidence of rod bearing failure on these 104mm bore blocks. Have you ever heard of a bearing failure on a 968 or 944S2? We don't recall hearing about one. Even one that has been turbo charged and seeing higher bearing loads. Seeing how both the 2.5L and 3.0L engines use the same bearings, oil pump, block oiling passage ways, crank (except stroke length), pick up tube and more, what's the difference? Well... one big difference is the windage port.

On a conventional V8, V6 or opposed cylinder engine like a 911's Flat 6, when one cylinder is on the down stroke, the cylinder opposite or across from it is on the up stroke. So the air trapped below the piston moves from one cylinder to the other easily. The volume of air there simply shifts or exchanges from one cylinder to the next like passing a ball back and forth between your hands.

On the Inline 4 cylinder engine, like the 944's, the cylinders are not opposed. The air beneath the piston doesn't have the same nice easy ability to move from one cylinder to it's adjacent cylinder. The air is somewhat compressed and has to work around the crankshaft throws and engine girdle to get to the next cylinder. Since the oil pan practically touches the girdle, there is almost no room for this to easily happen. This backwards compressing of the air is not productive and can rob horsepower. That's why drawing a vacuum on the block can increase horsepower such as with a well engineered dry sump system.

Now imagine oil coming off the crankshaft from the main and rod bearings and falling to the pan from front to rear as this is happening. Lots of oil to the tune of several gallons a minute.

The oil from cylinder number 1 is falling into the front of the oil pan. It needs to make it to the back of the oil pan where the oil pump pickup is. When the piston from cylinder number 2 comes down, the air from behind that piston is squeezed or forced forward towards cylinder number 1 since that piston is going up. This oil is traveling in the opposite direction of the pick up tube. Oil coming from the front half of the crankshaft, cylinders 1 and 2, is being pushed back and forth and would have a hard time moving down the pan towards the oil pickup. This oil and air mix is being whipped up by this back and forth motion and you have a rotating crankshaft adding to the problem as well.

We don't feel this problem is as important on the back two cylinders because of the deep sump portion of the oil pan, but the crankshaft is still in the way and keeping this cylinder pumping from happening as easily as possible. So like Porsche, we do two ports. The ports are above the crankshaft and the shifting or trading of air from one cylinder to the next can happen with less disturbance.

Is this the answer to connecting rod bearing failure? Time will tell on this one. Porsche felt sure there was good reason to do it. You can bet it wasn't to increase problems or reduce performance.

We simply tooled up to be able to machine this port on the 2.5L blocks that never had it. Since first offering it in June, almost everybody who's block we are working with opts for this modification to be added once describing it to them. This modification can be performed on any 2.5L 944 or 944 Turbo block for a charge of $325.00."

#3

Drifting

I had a local shop do it on my rebuild but due to other reasons I haven't had

the opportunity to see the benefits just yet.

M

the opportunity to see the benefits just yet.

M

#4

Race Car

We started looking more and more into this in the mid 2000's when I was at Ford. The assertion that it doesn't matter on V-engines isn't quite right. Certainly an inline will be more sensitive to it, but it very much matters. Initially, just ports were put in there. But if you think about it, that port has to be as efficient as the intake and valve does, because the same amount of air is displaced below the piston as above. So we started doing proper design work on those ports to optimize flow, and it was worth a few horsepower. The thing you have to watch out for is that it can leak to a weakened block. A perfect system would be where each cylinder were perfectly sealed. Either under pressure or under vacuum - the delta P would help either push up or pull down the cylinder. Ports can certainly make a difference, and if I could add them for that kind of cost, I'd probably go for it. But one of the big benefits of a dry sump is that is creates such a vacuum under the piston that you don't have to deal with windage.

I've heard enough stories of the 3.0L's having #2 failures that I'm not convinced that this is going to be helpful there. But it should be helpful for performance.

I've heard enough stories of the 3.0L's having #2 failures that I'm not convinced that this is going to be helpful there. But it should be helpful for performance.

#5

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

Hmm, great info!

I'm building the engine for my DE car, and trying to make it a nice solid engine that I can beat on. I'm starting with lapped alusil cylinders, balanced & polished crank, used pistons and RARST rods, and will fill the block with Moroso block filler (leaving 1.5" at the top). I'm also adding a pickup tube brace, oil pan baffle, and large oil cooler. In my mind, these are the worthwhile things for a DE car. I really think I should have these windage ports added too.

Almost looks like I can do it with a dremel and then a file.

I'm building the engine for my DE car, and trying to make it a nice solid engine that I can beat on. I'm starting with lapped alusil cylinders, balanced & polished crank, used pistons and RARST rods, and will fill the block with Moroso block filler (leaving 1.5" at the top). I'm also adding a pickup tube brace, oil pan baffle, and large oil cooler. In my mind, these are the worthwhile things for a DE car. I really think I should have these windage ports added too.

Almost looks like I can do it with a dremel and then a file.

#6

#7

Race Car

Honestly, for what Lindsey is asking for this service, if they are already working on your block, I'd seriously consider doing it.

Trending Topics

#9

Addict

Rennlist Member

Rennlist Small

Business Sponsor

Rennlist Member

Rennlist Small

Business Sponsor

#10

Addict

Rennlist Member

Rennlist Small

Business Sponsor

Rennlist Member

Rennlist Small

Business Sponsor

The big difference on the 944 set up compared to others is that there is not much clearance between the bottom of the crank girdle and the oil in the pan. That means that the windage form 1 to 2 and 3 to 4 is passing under the girdle in a small space and whipping up the oil. Not a good thing!

#11

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

If my block was at LR, then I would definitely have them do it, but I use local machinists. Shipping to LR would be a lot.

I talked to my machinist today and he said he could do it. I also asked if he could still do it if I tried the dremel first, and he said yes. I figured I'd give it a try and at worst, I'd have him finish it if I gave up.

I spent 1 hour grinding from both sides of the 1-2 wall, and didn't punch through yet. I have about another 8mm to go, so probably another hour. Then likely 2 hours of filing. Yes, really time consuming, but I've spent thousands on machinists in the last few months.

I'm not sure how large I will make the port, I figure I'd rather make it too small than too large - having some of the air still whip past the pan is better than a weakened block, and still an improvement from before.

I talked to my machinist today and he said he could do it. I also asked if he could still do it if I tried the dremel first, and he said yes. I figured I'd give it a try and at worst, I'd have him finish it if I gave up.

I spent 1 hour grinding from both sides of the 1-2 wall, and didn't punch through yet. I have about another 8mm to go, so probably another hour. Then likely 2 hours of filing. Yes, really time consuming, but I've spent thousands on machinists in the last few months.

I'm not sure how large I will make the port, I figure I'd rather make it too small than too large - having some of the air still whip past the pan is better than a weakened block, and still an improvement from before.

#12

If my block was at LR, then I would definitely have them do it, but I use local machinists. Shipping to LR would be a lot.

I talked to my machinist today and he said he could do it. I also asked if he could still do it if I tried the dremel first, and he said yes. I figured I'd give it a try and at worst, I'd have him finish it if I gave up.

I spent 1 hour grinding from both sides of the 1-2 wall, and didn't punch through yet. I have about another 8mm to go, so probably another hour. Then likely 2 hours of filing. Yes, really time consuming, but I've spent thousands on machinists in the last few months.

I'm not sure how large I will make the port, I figure I'd rather make it too small than too large - having some of the air still whip past the pan is better than a weakened block, and still an improvement from before.

I talked to my machinist today and he said he could do it. I also asked if he could still do it if I tried the dremel first, and he said yes. I figured I'd give it a try and at worst, I'd have him finish it if I gave up.

I spent 1 hour grinding from both sides of the 1-2 wall, and didn't punch through yet. I have about another 8mm to go, so probably another hour. Then likely 2 hours of filing. Yes, really time consuming, but I've spent thousands on machinists in the last few months.

I'm not sure how large I will make the port, I figure I'd rather make it too small than too large - having some of the air still whip past the pan is better than a weakened block, and still an improvement from before.

#14

If my block was at LR, then I would definitely have them do it, but I use local machinists. Shipping to LR would be a lot.

I talked to my machinist today and he said he could do it. I also asked if he could still do it if I tried the dremel first, and he said yes. I figured I'd give it a try and at worst, I'd have him finish it if I gave up.

I spent 1 hour grinding from both sides of the 1-2 wall, and didn't punch through yet. I have about another 8mm to go, so probably another hour. Then likely 2 hours of filing. Yes, really time consuming, but I've spent thousands on machinists in the last few months.

I'm not sure how large I will make the port, I figure I'd rather make it too small than too large - having some of the air still whip past the pan is better than a weakened block, and still an improvement from before.

I talked to my machinist today and he said he could do it. I also asked if he could still do it if I tried the dremel first, and he said yes. I figured I'd give it a try and at worst, I'd have him finish it if I gave up.

I spent 1 hour grinding from both sides of the 1-2 wall, and didn't punch through yet. I have about another 8mm to go, so probably another hour. Then likely 2 hours of filing. Yes, really time consuming, but I've spent thousands on machinists in the last few months.

I'm not sure how large I will make the port, I figure I'd rather make it too small than too large - having some of the air still whip past the pan is better than a weakened block, and still an improvement from before.

#15

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

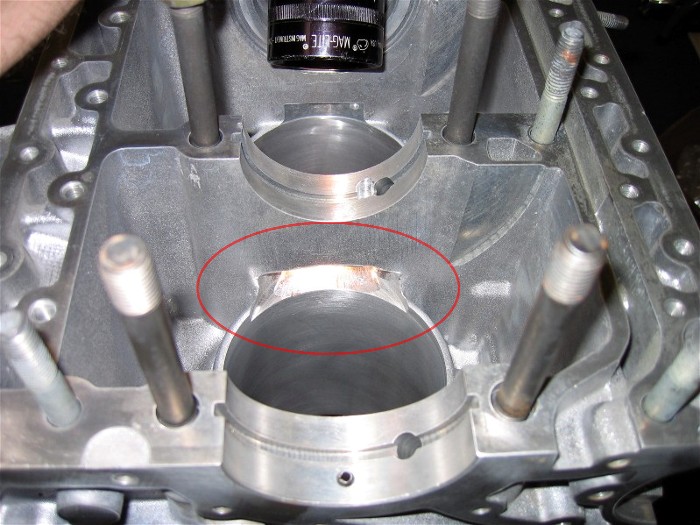

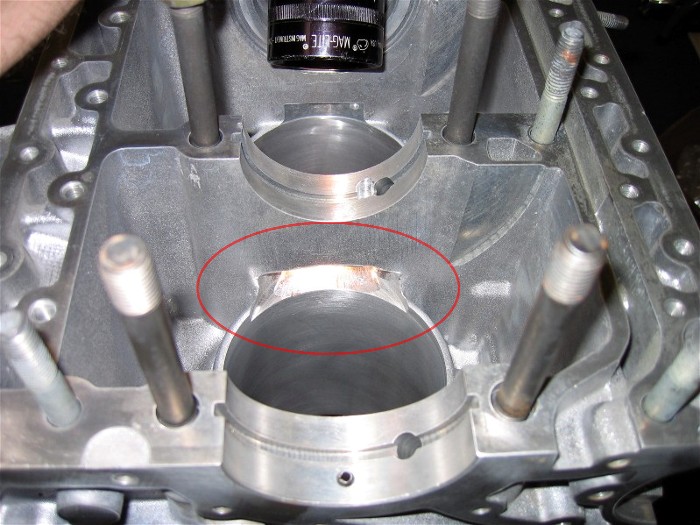

It's 3:25am, I can't sleep, so I was rummaging through my laptop organizing my files. I found the pics I took of my windage port project, so I came back here to share them.

I used a 90-degree chuck for hex-drive bits. This is much smaller than a standard 90-degree chuck. Then, I took a small drill bit (I don't remember, 1/16?), chopped it, had my buddy sharpen it for me, and tried it. The rig barely fit inside the bore. 2 main problems with this: 1. The flutes won't be very long, so once you drill that deep, they clog and you have to clean them; 2. I thought I'd make swiss cheese out of the metal, then knock it out... LOL, yeah right.

Phase two was to use a larger bit (3/16?). This bit was very long, but I managed to cut enough off of the base to barely have some hex-drive left, and get the bit and chuck rig to fit in the bore. This rig drilled through the metal much faster (no clogged flutes), and made useful holes. I drilled a few holes (3 or 4 maybe - I forget). I used oil when drilling. I used a step drill (which is stubby) to open up the holes. Then slipped a small sawblade in a hole, and manually sawed towards another hole. Eventually, I connected all the holes (took hours).

Then I used some very small files to remove some extra crap until the holes seemed decent. I know my ports could have been made larger, but I was getting tired of all the manual labor, and frankly, I think what I have will be sufficient to make a difference. If I ever do this again, I'll go straight for the big drill bit, and make the ports a little bigger.

Not bad for cell phone pics:

I used a 90-degree chuck for hex-drive bits. This is much smaller than a standard 90-degree chuck. Then, I took a small drill bit (I don't remember, 1/16?), chopped it, had my buddy sharpen it for me, and tried it. The rig barely fit inside the bore. 2 main problems with this: 1. The flutes won't be very long, so once you drill that deep, they clog and you have to clean them; 2. I thought I'd make swiss cheese out of the metal, then knock it out... LOL, yeah right.

Phase two was to use a larger bit (3/16?). This bit was very long, but I managed to cut enough off of the base to barely have some hex-drive left, and get the bit and chuck rig to fit in the bore. This rig drilled through the metal much faster (no clogged flutes), and made useful holes. I drilled a few holes (3 or 4 maybe - I forget). I used oil when drilling. I used a step drill (which is stubby) to open up the holes. Then slipped a small sawblade in a hole, and manually sawed towards another hole. Eventually, I connected all the holes (took hours).

Then I used some very small files to remove some extra crap until the holes seemed decent. I know my ports could have been made larger, but I was getting tired of all the manual labor, and frankly, I think what I have will be sufficient to make a difference. If I ever do this again, I'll go straight for the big drill bit, and make the ports a little bigger.

Not bad for cell phone pics: