Adding windage ports to 2.5 blocks

#16

Addict

Rennlist Member

Rennlist Small

Business Sponsor

Rennlist Member

Rennlist Small

Business Sponsor

I gotta admire the determination!!

if you want to try it again you might have better luck using an end mill tool bit in the drill.

if you want to try it again you might have better luck using an end mill tool bit in the drill.

#18

Drifting

#20

Maybe after a cross drilled crank, dry sump, expensive race oil, and having the shortblock sent to the Vatican for blessing

#21

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

At the time, I hated doing all that work and I thought I'd never do it again. But once I figured out the right technique, it wasn't so bad. I'd definitely do it again to the next block. Chris, I'll try the end mill idea. There is a mill and lathe in the shop where I work, and I kept looking over, thinking "I wish I could just mill this bastard!"

Yes, my drill is ancient, but it still works!

I forgot whether I mentioned it, but this block also has the block filler (like Sid). I think I'll use a 3.0L block next time - not just because of the windage ports, but also the raised coolant passage floor and webbed cylinders. But for now, this 2.5 block should be fun. If something happens and this engine doesn't work out well, I'll be out my time but it's been a good learning experience.

#22

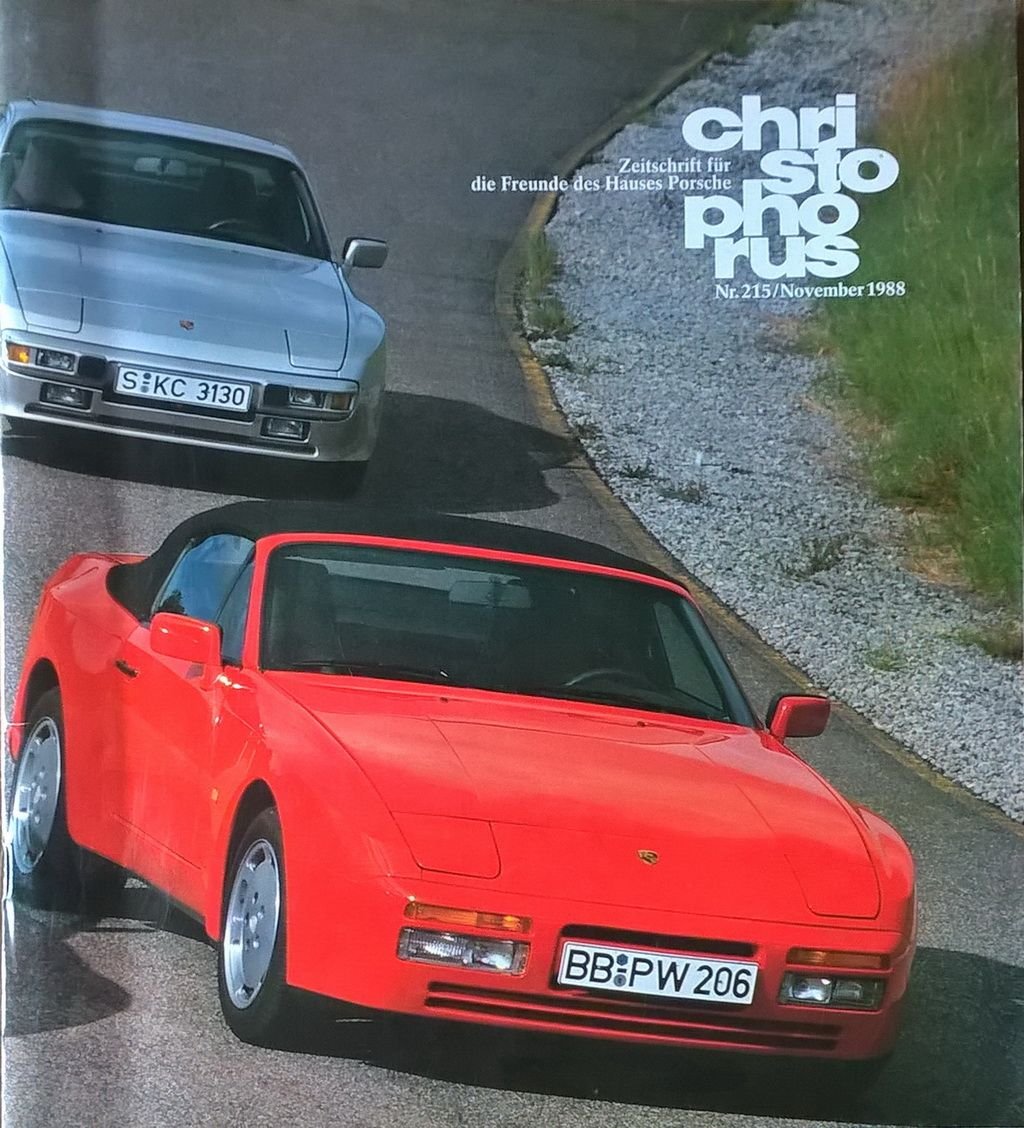

It's from the factory magazine "christophorus" Nr. 215/Nov. 1988:

#24

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

It's always a hoot when we make up a name for something or a process and it becomes the standard term people call it. Windage Port is one example of this.

Good article, although very short. It backs up what we figured was a common sense modification after noticing Porsche did it on later model year blocks. We have had customers report they can tell a performance gain after it being the only modification done to the engine.

Good article, although very short. It backs up what we figured was a common sense modification after noticing Porsche did it on later model year blocks. We have had customers report they can tell a performance gain after it being the only modification done to the engine.

__________________

Mike or Dave Lindsey

www.lindseyracing.com

U.S. 1-877-943-3565

Other 1-405-947-0137

Mike or Dave Lindsey

www.lindseyracing.com

U.S. 1-877-943-3565

Other 1-405-947-0137

#25

RL Community Team

Rennlist Member

Rennlist Member

Thread Starter

HFB, very nice find! Thanks for sharing and also for translating, viele Danke!

Mike, what kind of performance gains? Power? I only did this because I thought it would help to reduce oil foaming. Track car, engine is being rebuilt, hoping for many years of (ab)use.

Mike, what kind of performance gains? Power? I only did this because I thought it would help to reduce oil foaming. Track car, engine is being rebuilt, hoping for many years of (ab)use.

#27

Drifting

Just sent my 2.5L block to Lindsey for windage port modification, piston oil squirters, decking to fix the block surfacing cleaning by a "so called mechanic" and Nikasil cylinder walls because the block blue prints fine but not surfaces not acceptable for race engine

#28

Three Wheelin'

I did my ports myself on two blocks.. EZ, Just a Really coarse Carbide Burr and Lots of WD-40 to keep the bit from loading up... I have thought about Nikasil a VERY good option... But because I have a friend with a machine shop, I purchased all the alu-sil tooling for less than Nikasil- ing one block. Now I can do 15 blocks.. I'm a firm believer in these ports... I'm running an 86 pan on the racecar for 3 years no issues.

#30

Three Wheelin'

Yes, a right angle Air Die grinder, the trick is the coarse burr, and the WD-40, I did not make HUGE holes in it.. Just like 3/4" Round.. If It took me 20 min to do it it...it was allot... The tool will always be at an angle when grinding you cant hit it straight on. I know Porsche opened up the bottom to follow that casting.. Allot of air can move through a 3/4 hole and you just need it to prevent that slug of air from frothing the oil.. I also left the Middle Boss alone... so 2 holes were good enough because pistons 2 and 3 are on the same plane... Just between 1 and 2 and 3 and 4... This way the Air is getting sucked from the piston going up and pushed from the adjacent piston going down.