Throttle body sizing (theoretical and real world)

#1

Race Car

Thread Starter

So as to avoid further derailment of a thread below, I figured I'd start a new one. I'm not going to brag about my credentials, I'll just say I used to do this for a living at the OEM level, and did pretty damn well there. And I actually went to an engineering school. Since what brought this up was a sword fight about who knows what in another thread.

Is a bigger trottle body going to make more power? Depends. Let's start with what at OEM has to deal with when selecting one. Among the many targets that must be met, there's this one that I highly doubt anyone here would have ever considered - idle speed. Throttle bodies aren't perfect, they leak (i.e. air will bypass the blade, and enter the plenum). The smaller the throttle body, the easier it is to control idle, especially when dealing with all of the production variability of all the other systems that are a source of air for the engine (purge system, EGR leaks, PCV system, brake booster and other vacuum leaks, etc.).

So they will usually be sized as small as they can.

That doesn't mean they necessarily need to be bigger. The thing that very few people who aren't engineers understand is that the loss associated with expansion is THE SAME as the loss associated with compression. In other words, if you have a 65mm tube, and put in a section that is 70mm, you will increase you losses. If you put in one that is 60sqmm, your losses will be the same as with the 70. So yeah, same power with the small one as the big one, and the most with the "right" one. Note I should use area, rather than diameter, but I think you get my point.

Design comes into play. The sizes of the induction system and the plenum are factors. Induction system is usually larger, as it somewhat funnels the air constantly down from infinity (on the other side of the filer). The intake manifold may have packaging constraints, as well. I've seen two engines just a wee bit short of target go up in size of TB to meet them, with tradeoffs made in other things (idle speed). Was the first Bullitt in 2002? I think that was one. But for the most part, they are sized pretty appropriately. Side note, the intake manifold is usually a tad larger than the throttle body bore to account for stack-up.

Getting back to the paragraph above, if you have stock sized intercooler pipes, and haven't touched the inside of the intake manifold, the stock throttle body is probably the right size - and making it bigger may likely cause a drop. If you changed that stuff, it probably isn't.

So how do you pick the right size? Here is what I did with my old Ford (2.3 Turbo that I stroked to 2.5L). I went with the outlet size of the intercooler, and tried to match that. That got me I think a 65mm. The problem with most of these things is that they are designed for NA applications, and they are constantly tapering down in size (which is needed, kind of like bellmouths, just drawn out over a great distance). Mine would have needed about a 3" pipe to match up, so I stuck the pipe inside of it, and attached my hose to that, so I could keep things as close to the same size as possible. I ignored the throttle plate, but in theory, you shouldn't.

So at the end of the day, whatever the outlet pipe size on the intercooler is should in theory be the same as the ID of the throttle body (technically a tad larger to account for the throttle plate). And the intercooler pipe should also be sized the same way. If all of that is bigger than the stock throttle body, you will likely realize a benefit. If they are not bigger, then you likely won't.

So at the end of teh day, on our cars, if everything else is stock, you likely won't realize a benefit. If you've got bigger pipes and have increased the size of the opening in hte manifold, you probably do want one. My personal take on this is that I generally like them smaller, as small changes to throttle input won't have as drastic a change. This is biased largely by the fact that I'm more interested in racing than anything else.

And since the measuring thing came up - 10/2.5% horsepower is huge as far as being able to measure it. And I have NEVER seen a dyno that didn't have correction factors, so even if there was day to day variability, the dyno operator, if worth his salt, would have accounted for that.

Also, I won't see every reply to this, so I won't answer them.

Is a bigger trottle body going to make more power? Depends. Let's start with what at OEM has to deal with when selecting one. Among the many targets that must be met, there's this one that I highly doubt anyone here would have ever considered - idle speed. Throttle bodies aren't perfect, they leak (i.e. air will bypass the blade, and enter the plenum). The smaller the throttle body, the easier it is to control idle, especially when dealing with all of the production variability of all the other systems that are a source of air for the engine (purge system, EGR leaks, PCV system, brake booster and other vacuum leaks, etc.).

So they will usually be sized as small as they can.

That doesn't mean they necessarily need to be bigger. The thing that very few people who aren't engineers understand is that the loss associated with expansion is THE SAME as the loss associated with compression. In other words, if you have a 65mm tube, and put in a section that is 70mm, you will increase you losses. If you put in one that is 60sqmm, your losses will be the same as with the 70. So yeah, same power with the small one as the big one, and the most with the "right" one. Note I should use area, rather than diameter, but I think you get my point.

Design comes into play. The sizes of the induction system and the plenum are factors. Induction system is usually larger, as it somewhat funnels the air constantly down from infinity (on the other side of the filer). The intake manifold may have packaging constraints, as well. I've seen two engines just a wee bit short of target go up in size of TB to meet them, with tradeoffs made in other things (idle speed). Was the first Bullitt in 2002? I think that was one. But for the most part, they are sized pretty appropriately. Side note, the intake manifold is usually a tad larger than the throttle body bore to account for stack-up.

Getting back to the paragraph above, if you have stock sized intercooler pipes, and haven't touched the inside of the intake manifold, the stock throttle body is probably the right size - and making it bigger may likely cause a drop. If you changed that stuff, it probably isn't.

So how do you pick the right size? Here is what I did with my old Ford (2.3 Turbo that I stroked to 2.5L). I went with the outlet size of the intercooler, and tried to match that. That got me I think a 65mm. The problem with most of these things is that they are designed for NA applications, and they are constantly tapering down in size (which is needed, kind of like bellmouths, just drawn out over a great distance). Mine would have needed about a 3" pipe to match up, so I stuck the pipe inside of it, and attached my hose to that, so I could keep things as close to the same size as possible. I ignored the throttle plate, but in theory, you shouldn't.

So at the end of the day, whatever the outlet pipe size on the intercooler is should in theory be the same as the ID of the throttle body (technically a tad larger to account for the throttle plate). And the intercooler pipe should also be sized the same way. If all of that is bigger than the stock throttle body, you will likely realize a benefit. If they are not bigger, then you likely won't.

So at the end of teh day, on our cars, if everything else is stock, you likely won't realize a benefit. If you've got bigger pipes and have increased the size of the opening in hte manifold, you probably do want one. My personal take on this is that I generally like them smaller, as small changes to throttle input won't have as drastic a change. This is biased largely by the fact that I'm more interested in racing than anything else.

And since the measuring thing came up - 10/2.5% horsepower is huge as far as being able to measure it. And I have NEVER seen a dyno that didn't have correction factors, so even if there was day to day variability, the dyno operator, if worth his salt, would have accounted for that.

Also, I won't see every reply to this, so I won't answer them.

The following users liked this post:

kipv (10-19-2019)

#2

Race Car

Join Date: Mar 2012

Location: Austin TX, drinking beer in the garage

Posts: 3,602

Likes: 0

Received 7 Likes

on

7 Posts

Excellent write up that confirmed what I've been thinking all this time. Plenty of people on here will swear that the stock TB is fine until you hit 100000 rwhp but obviously if the diameter of all the intake piping is much larger than the stock TB, than that is going to be your flow bottleneck. I'd be interested to know what effect the decreased charge velocity has during the intake stroke when using a TB much larger than stock. If a 65mm throttle body is worth even 2% power across the board than its more than worth it to me. The N/A guys would go to the end of the world to pick up 10 real world hp.

#4

Rennlist Member

Thanks for the info Harry.

On my 3.1L I logged the pressure drop across the stock TB and found over a 1 psi pressure drop (at 20 psi boost). This was with 2.375" ID (60mm) IC pipes and the 56mm stock TB.

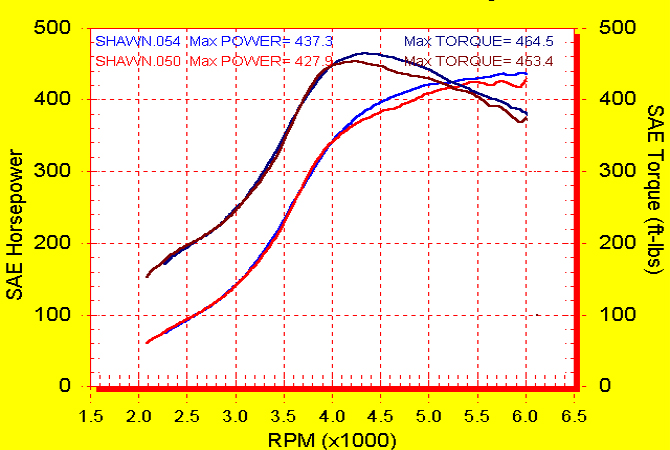

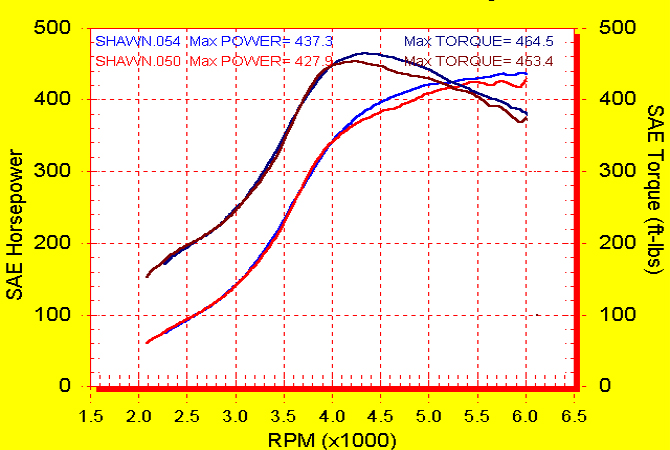

Therefore we found a cheap ($30) Mustang 65mm TB that is pretty straight forward to adapt. I dyno'd before (stock 56mm TB) and after (65mm TB) at 20 psi and here is the result:

Actually the boost pressure was just a tad lower on the Mustang TB run. Same dyno, same very good operator. Based on this data, my rule of thumb would be that north of about 350 rwhp one should consider a larger TB. Obviously many factors but I think a reasonable rule of thumb.

On my 3.1L I logged the pressure drop across the stock TB and found over a 1 psi pressure drop (at 20 psi boost). This was with 2.375" ID (60mm) IC pipes and the 56mm stock TB.

Therefore we found a cheap ($30) Mustang 65mm TB that is pretty straight forward to adapt. I dyno'd before (stock 56mm TB) and after (65mm TB) at 20 psi and here is the result:

Actually the boost pressure was just a tad lower on the Mustang TB run. Same dyno, same very good operator. Based on this data, my rule of thumb would be that north of about 350 rwhp one should consider a larger TB. Obviously many factors but I think a reasonable rule of thumb.

#5

Addict

Rennlist Member

Rennlist Small

Business Sponsor

Rennlist Member

Rennlist Small

Business Sponsor

BTW - the intake manifold opening is about 65mm....the typical 2.5" aftermarket intercooler pipes are about 63mm....the intercooler in/out are a tad less but the output on most turbos used on 944s are 2".

Most of the higher power builds I do have 2.5" compressor outputs and 2.5" piping with a 65mm throttle body. use a 'systems' approach to your projects!

In other words....Harry is right (as always)

Most of the higher power builds I do have 2.5" compressor outputs and 2.5" piping with a 65mm throttle body. use a 'systems' approach to your projects!

In other words....Harry is right (as always)

Trending Topics

#10

Race Car

Thread Starter

Glad Chris posted. I had no idea the stock TB was that small relative to the rest of the system (and that word is truly the key to any build). Based on that alone, you should pick up power if you make it all match the same 65-ish mm size. Even if you don't need it (and if you think about it, on a 4 banger, you only ever have one cylinder filling at a time, and stock valve size is only 45mm (off memory), so that's all you really "need"), you will simply because you will be getting rid of losses.

#11

Race Car

Thread Starter

.......but the terminology we use is actually that MIT is the Georgia Tech of the North

.......but the terminology we use is actually that MIT is the Georgia Tech of the North

That said, one of my friends from Ford was working on the side with Rehagen when they went into Grand Am. He left Ford and went to Michael Waltrip Racing, then to Germain where he is today. All while racing a Mustang in IT-E, then AIX. He's an MIT grad.

#12

Drifting

Join Date: Aug 2009

Location: Bangkok, Thailand, Milpitas, CA & Weeki Wachee, FL

Posts: 2,239

Likes: 0

Received 2 Likes

on

1 Post

Well there you go! As usual learn something from all of your posts! Hell, I can't even say we have a football team this year.

They are now calling this weekend's clash The World's Largest Pity Party! So bad we can't even have a cocktail anymore.

They are now calling this weekend's clash The World's Largest Pity Party! So bad we can't even have a cocktail anymore.

#14

Rennlist Member

Rules of thumb like that work pretty well with naturally aspirated applications (one of the problems I dealt with was solved by snagging a throttle body off of a 3.5L 4V V6 that was in development to use on a 4.6L 2V that made about the same power, launching in 2007). With turbos - throw it all out the window. Throttle bodies, and any orifice for that matter, control VOLUME, horsepower is dictated by MASS. 350hp at say 6,000RPM out of, let's say a 2.5L 2V at 20PSI will need a smaller throttle body than 350hp at say 6600RPM out of a 3.0L 16V at 12PSI. They will both be flowing the same mass of air (roughly 35#/min), but the 3.0L will be flowing a higher volume (about 30% more). If you really need a rule of thumb, look at valve area as a guideline.

Glad Chris posted. I had no idea the stock TB was that small relative to the rest of the system (and that word is truly the key to any build). Based on that alone, you should pick up power if you make it all match the same 65-ish mm size. Even if you don't need it (and if you think about it, on a 4 banger, you only ever have one cylinder filling at a time, and stock valve size is only 45mm (off memory), so that's all you really "need"), you will simply because you will be getting rid of losses.

Glad Chris posted. I had no idea the stock TB was that small relative to the rest of the system (and that word is truly the key to any build). Based on that alone, you should pick up power if you make it all match the same 65-ish mm size. Even if you don't need it (and if you think about it, on a 4 banger, you only ever have one cylinder filling at a time, and stock valve size is only 45mm (off memory), so that's all you really "need"), you will simply because you will be getting rid of losses.

I was doing some "ideal" valve size calculations and it looks like with my 3.1L (102mm bore, 94.75mm stroke) my 47mm intake valves become limiting after about 5100 rpm. This seems to correlate with some of what I have seen on dyno runs.

#15

Rennlist Member

Harry, always keen to read your posts. Just wondering how you make the assertion that the best engineers come out of the US though? Not saying that this is Untrue, and also follow your logic re Ford could make a Ferrari but not visa-versa but it seems a broad sweeping statement all the same?

Re Throttle bodies. Good to see a bit more discussion about this rather than guesstimations. I've been advised by people bigger can be better but too big can be bad. Too big can reduce driveability and velocity. Heard similar thing about people reducing the the size of ports to increase velocity.

I'm sure if you designed a throttle body and intake setup you could sell these via Racers Edge.

Re Throttle bodies. Good to see a bit more discussion about this rather than guesstimations. I've been advised by people bigger can be better but too big can be bad. Too big can reduce driveability and velocity. Heard similar thing about people reducing the the size of ports to increase velocity.

I'm sure if you designed a throttle body and intake setup you could sell these via Racers Edge.