3 Liter 16v Turbo build

#16

Professional Hoon

Rennlist Member

Rennlist Member

Join Date: Jan 2010

Location: Melbourne, Australia

Posts: 7,090

Likes: 0

Received 4 Likes

on

4 Posts

944-106-021-24 for the pump.

Waste of money for a TT set up on the left hand side. and you're very limited on space. Unless it's a 700 hp race car with gates and exhaust dumped straight down.

If the turbo is water cooled, it should be water cooled.

Why would you put the turbo at the front for looks? More weight infront of the wheels = bad

turbo infront of engine covering belts = bad & longer time to change belts.

If you want to show off your turbo get an intake from http://www.frontrangefabrication.com/

Forgot to add. Standard intercoolers are easy to find.

And with a turbo like the 6262, don't be surprised if you do go over 400 rwhp at ~15-18 psi.

Waste of money for a TT set up on the left hand side. and you're very limited on space. Unless it's a 700 hp race car with gates and exhaust dumped straight down.

If the turbo is water cooled, it should be water cooled.

Why would you put the turbo at the front for looks? More weight infront of the wheels = bad

turbo infront of engine covering belts = bad & longer time to change belts.

If you want to show off your turbo get an intake from http://www.frontrangefabrication.com/

Forgot to add. Standard intercoolers are easy to find.

And with a turbo like the 6262, don't be surprised if you do go over 400 rwhp at ~15-18 psi.

Last edited by Paulyy; 12-11-2012 at 03:49 AM.

#17

Three Wheelin'

Thread Starter

Thanks for the number!

The twin turbo setup was just to put an example, not for me to reprodure, as i also have to get my engine in a smaller angle and make a complete new header!

The T6262 is only oil cooled so no water is needed!

I've taken a look at the site but couldn't find any pictures.. I'll just start scavaging around rennlist

And you're right about the wear of the belts and getting more weight in front of the car.. I was just wondering if anyone did it before!

Do you know what the pricing should be on a stock intercooler?

And finally; i'm not thinking of getting to 15psi, i'll start at 6 and will probably go on to about 11 but i won't do much more because of reliability.

The twin turbo setup was just to put an example, not for me to reprodure, as i also have to get my engine in a smaller angle and make a complete new header!

The T6262 is only oil cooled so no water is needed!

I've taken a look at the site but couldn't find any pictures.. I'll just start scavaging around rennlist

And you're right about the wear of the belts and getting more weight in front of the car.. I was just wondering if anyone did it before!

Do you know what the pricing should be on a stock intercooler?

And finally; i'm not thinking of getting to 15psi, i'll start at 6 and will probably go on to about 11 but i won't do much more because of reliability.

#18

Professional Hoon

Rennlist Member

Rennlist Member

Join Date: Jan 2010

Location: Melbourne, Australia

Posts: 7,090

Likes: 0

Received 4 Likes

on

4 Posts

https://rennlist.com/forums/924-931-...rbo-parts.html

probably a few things you may need there. intercooler pipes will be to small though.

https://rennlist.com/forums/944-turb...ff-by-frf.html

probably a few things you may need there. intercooler pipes will be to small though.

https://rennlist.com/forums/944-turb...ff-by-frf.html

#19

Three Wheelin'

Thread Starter

Thanks! So i'll know what the pricing on those parts should be. Another member of Rennlist is located in Holland (Jan Mertens from Dutch Rennsport) so i'll get most parts from him.

At the topic of FRF i dont see any pictures..

So now to the real pressing matters:

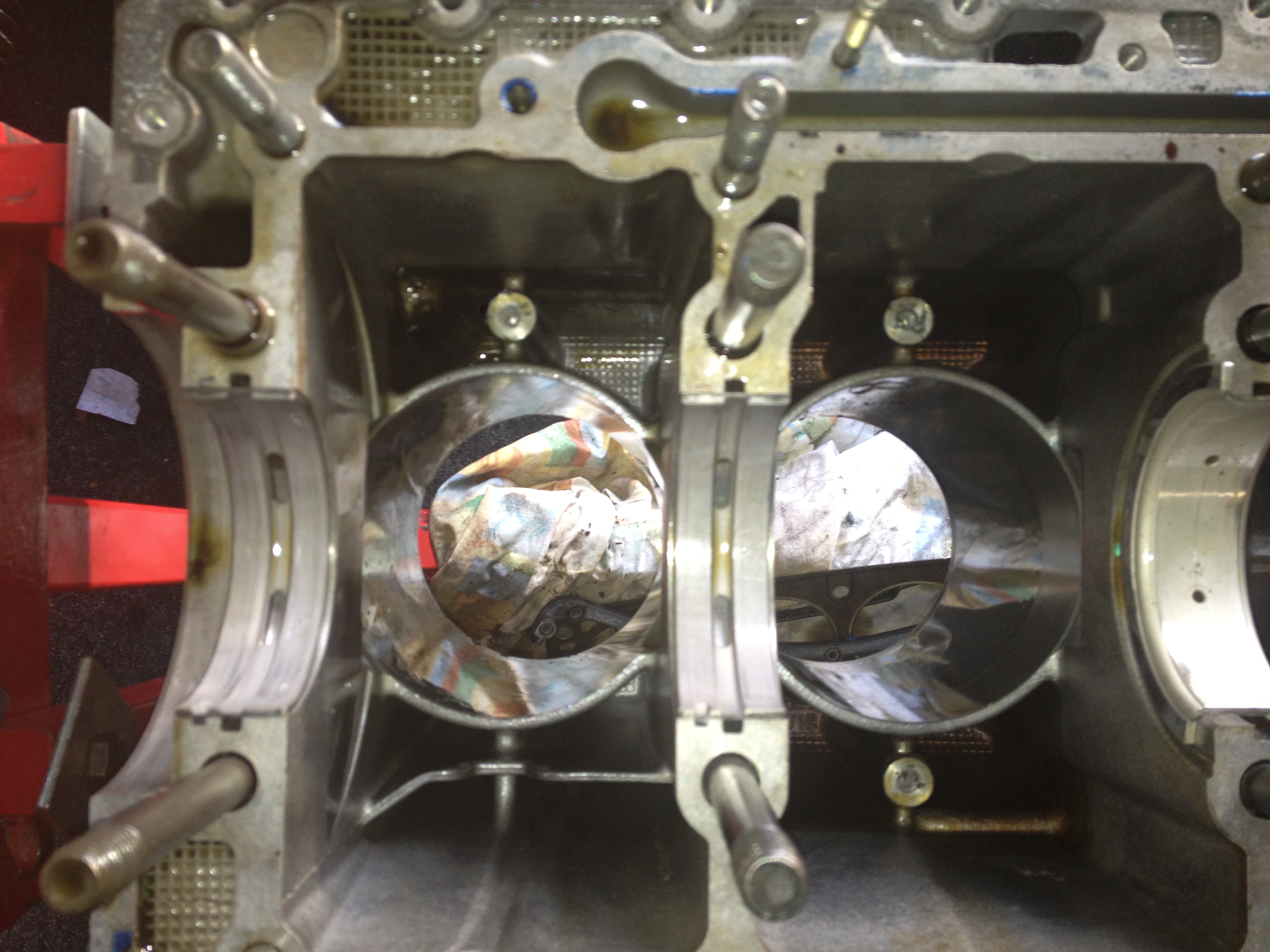

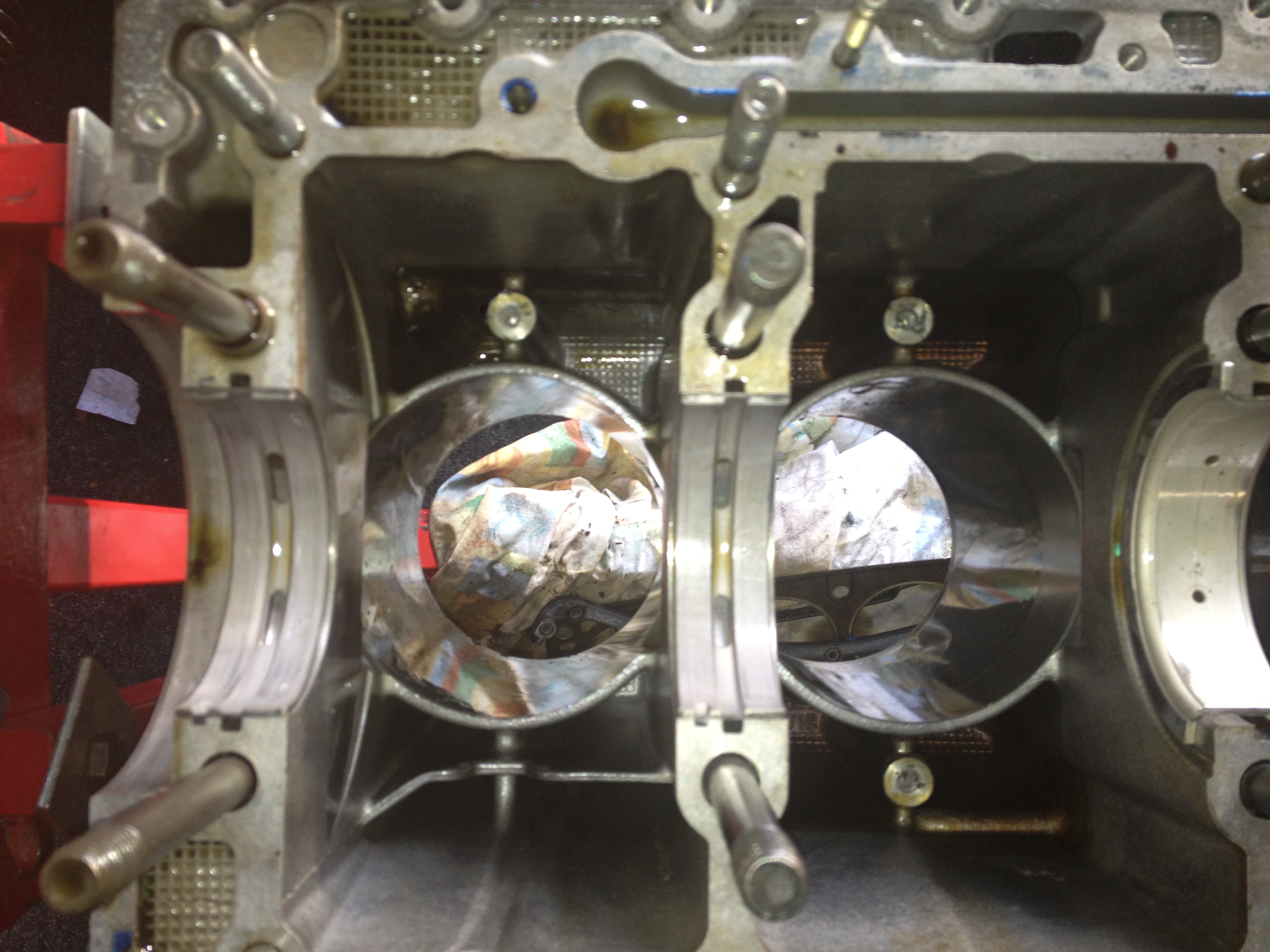

Today i lifted the head.. And i found something that i don't really like. I'll try to get some pics up later but it comes down to the fact that cil 2 and 3 have over about 5cm of length and 2cm width a raw surface. I don't know yet what has happened as i didnt have time to get the pistons out so i'll check that tomorrow.

So the first thing i did was contact my engine machine shop to ask for the prices for sleeving, which really didn't scare me off; 90 euro's per cilinder (about 120$)

So that, together with some new pistons will set me back about 800 total as there is no need to get pistons which have to be alusil compatible, right?!

At the topic of FRF i dont see any pictures..

So now to the real pressing matters:

Today i lifted the head.. And i found something that i don't really like. I'll try to get some pics up later but it comes down to the fact that cil 2 and 3 have over about 5cm of length and 2cm width a raw surface. I don't know yet what has happened as i didnt have time to get the pistons out so i'll check that tomorrow.

So the first thing i did was contact my engine machine shop to ask for the prices for sleeving, which really didn't scare me off; 90 euro's per cilinder (about 120$)

So that, together with some new pistons will set me back about 800 total as there is no need to get pistons which have to be alusil compatible, right?!

#21

Three Wheelin'

Thread Starter

Haha thanks! Which also mean that i can get myself some compression lowering pistons which gives me the opportunity to get some more boost and more bhp..

#22

Three Wheelin'

Thread Starter

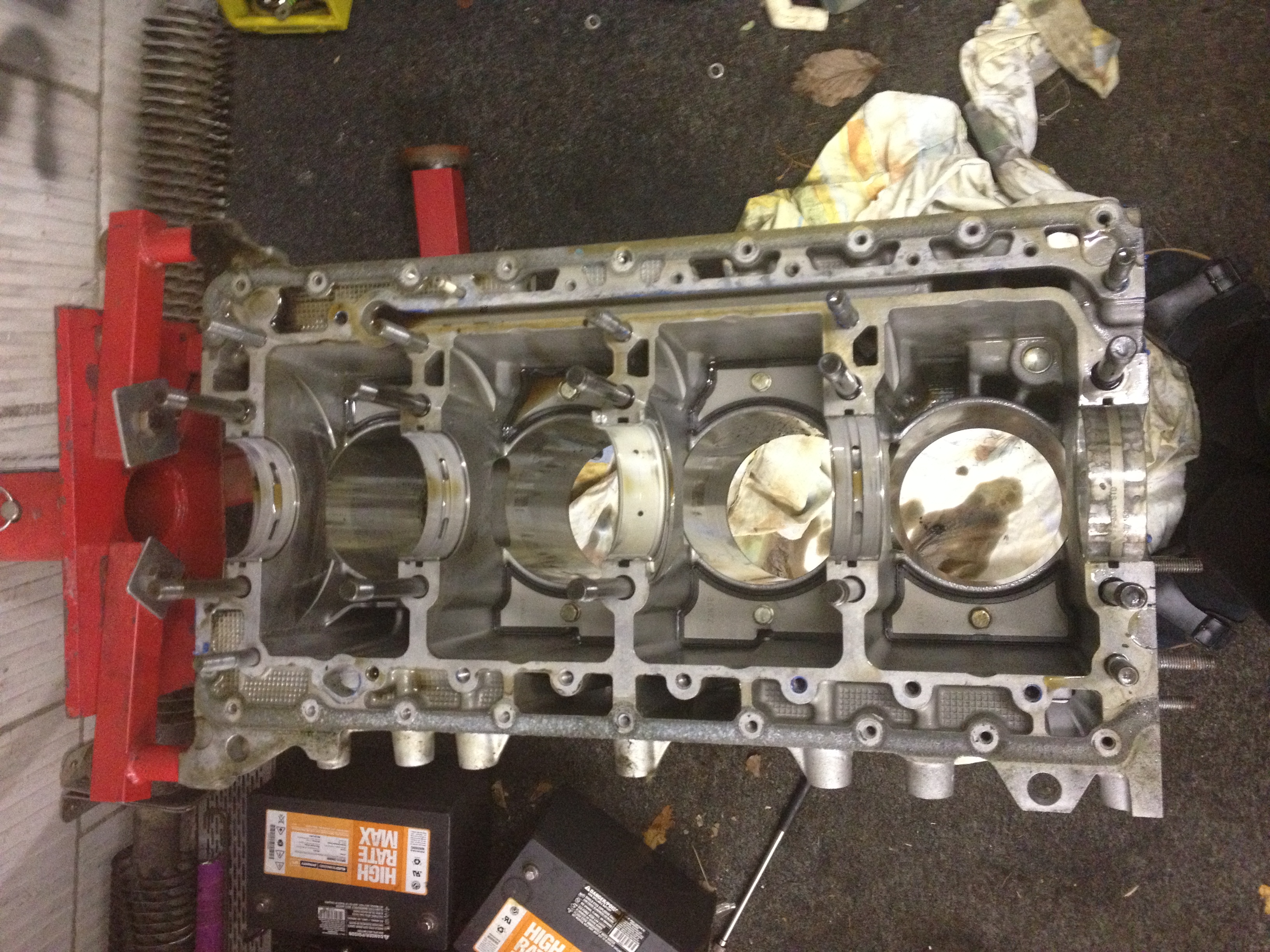

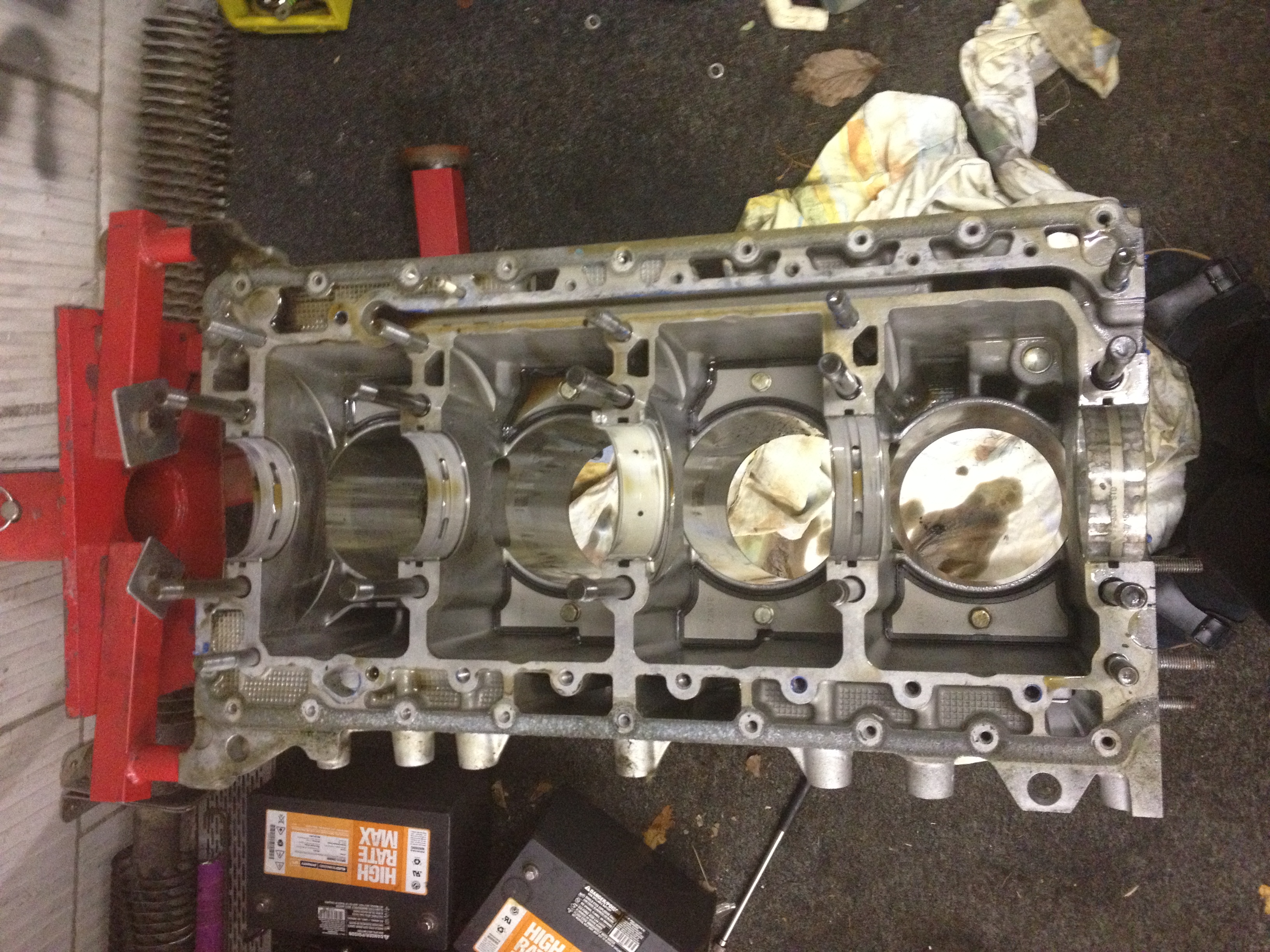

So here an update.

I got the engine completely disassembled this morning and got it degreased (is that the way to say it?..)

Almost everything went well.. Except for 1 bolt. there are 6 plates in the bottom of the cylinderblock. Every plate is holded in place by 1 m6 bolt. Every bolt is tightened with a bucket of loctite.. So silly me started on the first one and thought.. ahh, just a little more, it'll hold; snap! So one of those bolts snapped and i have to get that one out. The other ones did come out with a lot of loosening and tightening.

Can anyone tell me if those bolts are specials or just normal 8.8 steel bolts?

Here are the pics:

Tomorrow i'll go to the machine shop to start talking about what how and prices..

Btw, here some pics of last saturday.. We had some fun in the snow!

I got the engine completely disassembled this morning and got it degreased (is that the way to say it?..)

Almost everything went well.. Except for 1 bolt. there are 6 plates in the bottom of the cylinderblock. Every plate is holded in place by 1 m6 bolt. Every bolt is tightened with a bucket of loctite.. So silly me started on the first one and thought.. ahh, just a little more, it'll hold; snap! So one of those bolts snapped and i have to get that one out. The other ones did come out with a lot of loosening and tightening.

Can anyone tell me if those bolts are specials or just normal 8.8 steel bolts?

Here are the pics:

Tomorrow i'll go to the machine shop to start talking about what how and prices..

Btw, here some pics of last saturday.. We had some fun in the snow!

#24

Three Wheelin'

#25

Three Wheelin'

Thread Starter

Justin! Thanks a lot for the link, really interesting rebuild. Only this what is going different on my build is that i'm putting in metal sleeves instead of nicasil!

Thanks, i'll just put in some new regular 8.8 steel bolts and get the loctite out of the holes..

Today i went to the machine shop to talk about what to do and what not to so here is a small list of what is going to happen:

Metal sleeves (dry sleeves) will be put into the engine

New pistons, for a lowered compression ratio (8.5)

Rods will stay the same(except for balancing), talked about it with the rebuilder and he agreed that for 450bhp these will do very fine

Head will be checked. The head will be machined on the edges to make sure that the "round" of the piston is the same size as the head.

Crankshaft will probably be knive-edged and balanced

All bolts and studs will be replaced. Not sure if i'm going for ARP or standard..

Balance shafts will be removed and we'll make our own caps.

Turbo oil-line will come from the return of the oil cooler

And last but not least; DTA engine management

Thats about it. I'll be putting a lot of money into it but it's better get it done right the first time than spending money again next time..

Today i went to the machine shop to talk about what to do and what not to so here is a small list of what is going to happen:

Metal sleeves (dry sleeves) will be put into the engine

New pistons, for a lowered compression ratio (8.5)

Rods will stay the same(except for balancing), talked about it with the rebuilder and he agreed that for 450bhp these will do very fine

Head will be checked. The head will be machined on the edges to make sure that the "round" of the piston is the same size as the head.

Crankshaft will probably be knive-edged and balanced

All bolts and studs will be replaced. Not sure if i'm going for ARP or standard..

Balance shafts will be removed and we'll make our own caps.

Turbo oil-line will come from the return of the oil cooler

And last but not least; DTA engine management

Thats about it. I'll be putting a lot of money into it but it's better get it done right the first time than spending money again next time..

#30

I would keep the balance shafts.

http://www.autozine.org/technical_sc...ne/smooth2.htm