Air Fuel Ratio under boost Question :

#1

Three Wheelin'

Thread Starter

Join Date: Sep 2001

Location: Calgary, Alberta, Canada

Posts: 1,596

Likes: 0

Received 0 Likes

on

0 Posts

Got the Wideband O2 all working and datalogging finally, what a cool piece of equipment! Anyways, the last few months of tuning on my SDS equipped 951 has been purely from my *** dyno, Blitz Power Meter, and listening for any sign of knock. So my first datalog of my air fuel ratio shows a perfectly flat AFR of 10.5:1. Very shocked that my tuning of the RPM/fuel curve was dead on. That seems a bit rich though, so I turned the fuel down, and got a AFR of 11.5:1. The engine started to knock at this AFR. This is at 12psi, 91 octane fuel.

My questions are, what is the optimum AFR under boost? I've seen recommendations of 12.5:1, 12:1, 11:1, no definate "this is what you use" answer. Also, is my timing too agressive? Is that why I have to run so rich to avoid detonation? Lastly, what's better for power, very rich + agressive timing? Or 12.5:1 AFR + mild timing?

My questions are, what is the optimum AFR under boost? I've seen recommendations of 12.5:1, 12:1, 11:1, no definate "this is what you use" answer. Also, is my timing too agressive? Is that why I have to run so rich to avoid detonation? Lastly, what's better for power, very rich + agressive timing? Or 12.5:1 AFR + mild timing?

#2

Three Wheelin'

Join Date: Oct 2001

Location: Seattle, WA

Posts: 1,805

Likes: 0

Received 0 Likes

on

0 Posts

I'm guessing that the knock is a result of residual heat in the combustion chamber. Fuel acts as a coolant. I managed to finish a 25 minute shifter kart race at Seattle International Raceway with a blown head gasket (actually blown o-rings) on my water cooled Honda CR125 race motor. The engine was detonating and was down on power, but it kept running. Once I crossed the finish line, I gently let my foot off the gas to cool the engine. Duh... the engine actually got hotter and seized. World championship Formula Super A karters actually put their hand over their air intake at the end of a straight away to flood the combustion chamber with fuel to keep the engine cool.

At 20 psi at high rpms with a stock intercooler, your intake air temperature is probably getting pretty damn high. Since you have an aftermarket engine management system, you probably already have a way of watching or recording intake air temps already. Obviously this won't work if the temperature sender comes before the intercooler. Compare what the termperature is at 15psi to what it is at 20psi. A bigger or more efficient intercooler may solve this problem. If you can control the combustion chamber temperature, you should be able to lean it out and make more power.

Obviously, another way to solve this is to run less boost or use higher octane fuel. You didn't say what kind of fuel you are using, but I assume it is pump gas.

Finally, you may want to check out water injection. There was a thread on this recently. Water is a superior coolant to fuel, plus you can inject it right after the intercooler, rather than a couple of inches from the combustion chamber. Running the same gas without any changes, you could increase boost or advance timing and run a 12.5:1 air fuel ratio. This is a nice benefit since high octane gas typically costs around $5 US a gallon and water is free.

At 20 psi at high rpms with a stock intercooler, your intake air temperature is probably getting pretty damn high. Since you have an aftermarket engine management system, you probably already have a way of watching or recording intake air temps already. Obviously this won't work if the temperature sender comes before the intercooler. Compare what the termperature is at 15psi to what it is at 20psi. A bigger or more efficient intercooler may solve this problem. If you can control the combustion chamber temperature, you should be able to lean it out and make more power.

Obviously, another way to solve this is to run less boost or use higher octane fuel. You didn't say what kind of fuel you are using, but I assume it is pump gas.

Finally, you may want to check out water injection. There was a thread on this recently. Water is a superior coolant to fuel, plus you can inject it right after the intercooler, rather than a couple of inches from the combustion chamber. Running the same gas without any changes, you could increase boost or advance timing and run a 12.5:1 air fuel ratio. This is a nice benefit since high octane gas typically costs around $5 US a gallon and water is free.

#3

Rage,

I've been recently looking at as many ignition maps ( Alan's TEC III, Huntley Racing chip/Stock chip/Europroducts chip courtesy of Rob) as I can get my hands on and I'm thinking that your advance is pretty aggressive at 12 psi for 91 octane. I too have experienced detonation after I pulled the fuel back a little. After talking to Ross at SDS I've implemented an advance strategy that allowed me to eliminate the detonation and keep the fuel ratio better (I don't know where it's at precisely, It's just less rich than it was). Look at your most recent /accurate dyno and find your torque peak and reduce the rpm ign values that coincide with the peak by a couple, three degrees and then bring the advance back up when the torque drops off. I was having detonation at even lower boost pressures where it coincided with the greatest BMEP. Reducing the rpm ign values rather than man ret ensures that when the troublesome boost pressure and BMEP coincide the advance comes back a bit.

I've been recently looking at as many ignition maps ( Alan's TEC III, Huntley Racing chip/Stock chip/Europroducts chip courtesy of Rob) as I can get my hands on and I'm thinking that your advance is pretty aggressive at 12 psi for 91 octane. I too have experienced detonation after I pulled the fuel back a little. After talking to Ross at SDS I've implemented an advance strategy that allowed me to eliminate the detonation and keep the fuel ratio better (I don't know where it's at precisely, It's just less rich than it was). Look at your most recent /accurate dyno and find your torque peak and reduce the rpm ign values that coincide with the peak by a couple, three degrees and then bring the advance back up when the torque drops off. I was having detonation at even lower boost pressures where it coincided with the greatest BMEP. Reducing the rpm ign values rather than man ret ensures that when the troublesome boost pressure and BMEP coincide the advance comes back a bit.

#4

Three Wheelin'

Join Date: Oct 2001

Location: Seattle, WA

Posts: 1,805

Likes: 0

Received 0 Likes

on

0 Posts

Oops, I saw 20psi in your sig and assumed that was what you were running. After seeing the 12psi, I would agree with Russ and retard the timing, then tune the fuel to get to 12.5:1. Use a dyno to see which strategy makes more power. There is not necessarily a right and a wrong way to do this. Most likely, running less advance and leaner on the fuel will result in less engine stress, more power, and better fuel economy.

#5

Race Director

"My questions are, what is the optimum AFR under boost? I've seen recommendations of 12.5:1, 12:1, 11:1, no definate "this is what you use" answer"

Ok, here's a definitive answer:

As we can see, the AF-ratio that gives the highest combustion-pressure in the chamber is centered around 12.5:1.

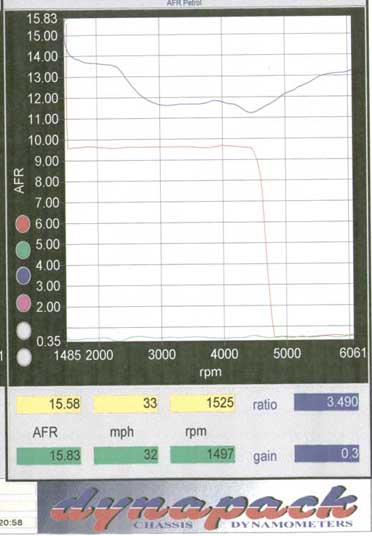

Here's a before & after dyno chart of our runs from last weekend. We started out with the classical aftermarket-chip curve of a way too-rich mid-range. These were EuroProduct chips, but a set of <a href="http://boards.rennlist.com/upload/DanWorleyK27Stg2Chips.jpg" target="_blank">AutoThority chips exhibit the same behavior</a>. After cleaning up the mid-range, we saw an increase of 20% across the mid-range:

Our final AF-ratio is confined to a narrow 12.2-12.8:1 band. Also the final run was on an extremely hot 180K-mile car; 162-degreesF on intercooler and 155-degreesF on intake-manifold. On your car, you can probably expect to see a 50-60 lb-ft increase in torque by simply adjusting your AF-ratio.

"Also, is my timing too agressive? Is that why I have to run so rich to avoid detonation?"

Most likely. AF-ratio and ignition timing are two completely separate factors. One should tune AF-ratio with the sole purpose of extracting the most power from each power stroke. Then tune ignition to be on the safe side of detonation. Trying to use extra fuel to combat knock/detonation is simply a sweep-it-under-the-rug cover-up measure. It's masking the true source of your detonation such as hot-spots in the chamber, insufficient fuel-atomization or swirl (inadequate squish/quench zones), or just too much ignition advance for the conditions. Remember with a more efficient engine and more air & fuel in the combustion chamber (you've probably cramming in twice as much as stock), you don't need as much advance because the mixture burns faster.

Also as Steve mentioned, the stock intercooler may not be the most efficient once you're trying to flow twice as much air across it. We'd have to measure the outlet temperatures to know for sure though.

From looking at your timing maps, with 10 degrees manual retard @ 12psi, you'll have:

16 degrees advance @2000rpm

26 degrees advance @3000rpm

26 degrees advance @4000rpm

26 degrees advance @5000rpm

25 degrees advance @6000rpm

Which does look a tad agressive. In contrast the stock chips have:

17 degrees advance @2000rpm

15 degrees advance @3000rpm

19 degrees advance @4000rpm

19 degrees advance @5000rpm

20 degrees advance @6000rpm

So I would recommend backing off the ignition a bit.

Ok, here's a definitive answer:

As we can see, the AF-ratio that gives the highest combustion-pressure in the chamber is centered around 12.5:1.

Here's a before & after dyno chart of our runs from last weekend. We started out with the classical aftermarket-chip curve of a way too-rich mid-range. These were EuroProduct chips, but a set of <a href="http://boards.rennlist.com/upload/DanWorleyK27Stg2Chips.jpg" target="_blank">AutoThority chips exhibit the same behavior</a>. After cleaning up the mid-range, we saw an increase of 20% across the mid-range:

Our final AF-ratio is confined to a narrow 12.2-12.8:1 band. Also the final run was on an extremely hot 180K-mile car; 162-degreesF on intercooler and 155-degreesF on intake-manifold. On your car, you can probably expect to see a 50-60 lb-ft increase in torque by simply adjusting your AF-ratio.

"Also, is my timing too agressive? Is that why I have to run so rich to avoid detonation?"

Most likely. AF-ratio and ignition timing are two completely separate factors. One should tune AF-ratio with the sole purpose of extracting the most power from each power stroke. Then tune ignition to be on the safe side of detonation. Trying to use extra fuel to combat knock/detonation is simply a sweep-it-under-the-rug cover-up measure. It's masking the true source of your detonation such as hot-spots in the chamber, insufficient fuel-atomization or swirl (inadequate squish/quench zones), or just too much ignition advance for the conditions. Remember with a more efficient engine and more air & fuel in the combustion chamber (you've probably cramming in twice as much as stock), you don't need as much advance because the mixture burns faster.

Also as Steve mentioned, the stock intercooler may not be the most efficient once you're trying to flow twice as much air across it. We'd have to measure the outlet temperatures to know for sure though.

From looking at your timing maps, with 10 degrees manual retard @ 12psi, you'll have:

16 degrees advance @2000rpm

26 degrees advance @3000rpm

26 degrees advance @4000rpm

26 degrees advance @5000rpm

25 degrees advance @6000rpm

Which does look a tad agressive. In contrast the stock chips have:

17 degrees advance @2000rpm

15 degrees advance @3000rpm

19 degrees advance @4000rpm

19 degrees advance @5000rpm

20 degrees advance @6000rpm

So I would recommend backing off the ignition a bit.

#6

Nordschleife Master

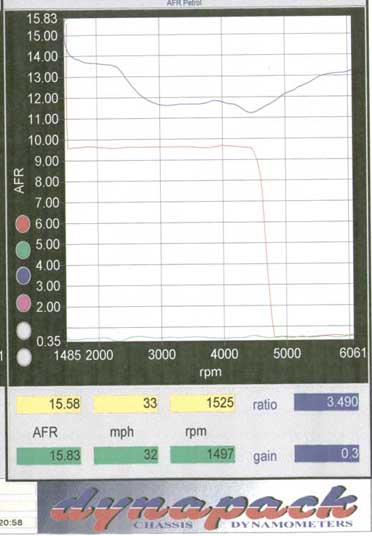

Here's my a/f ratio from my bone stock dyno run at stock boost with stock boost control system and stock chips...

As you can see...the A/F curve is far from flat...so I think that autothority and all the tuners just moved the entire curve around...and by doing this made an already pre-exisiting condition worse. The a/f curve that Danno showed is sweet and what I strive for.

I'm very interested in seeing how my a/f curve looks with Steve R chips look...

If it doesn't look good I may look into asking a fellow rennlister to hook me up with a nice a/f curve for some $$ Or maybe a piggyback fuel controller...

Or maybe a piggyback fuel controller...

I remember it was mentioned before...but I never saw a conclusion. Anybody ever tried the Apexi S-AFC on a 944/951?

As you can see...the A/F curve is far from flat...so I think that autothority and all the tuners just moved the entire curve around...and by doing this made an already pre-exisiting condition worse. The a/f curve that Danno showed is sweet and what I strive for.

I'm very interested in seeing how my a/f curve looks with Steve R chips look...

If it doesn't look good I may look into asking a fellow rennlister to hook me up with a nice a/f curve for some $$

Or maybe a piggyback fuel controller...

Or maybe a piggyback fuel controller...I remember it was mentioned before...but I never saw a conclusion. Anybody ever tried the Apexi S-AFC on a 944/951?

#7

Three Wheelin'

Thread Starter

Join Date: Sep 2001

Location: Calgary, Alberta, Canada

Posts: 1,596

Likes: 0

Received 0 Likes

on

0 Posts

Awesome info, very informative. Thanks everyone for their contributions, more tuning work this weekend, will let you know how it goes!

Trending Topics

#9

Race Director

Ok busted, the cat's out of the bag! The first test was run with the stock AFM and airbox installed. The mods were EuroProduct chips and manual boost-controller for 16.5psi.

The final run was with our MAP-sensor Stg.1 upgrade kit installed running at 14.5psi (scale of boost not drawn on chart above). We're still awaiting our custom-tuned chip which should give us another 5% torque across the rev range.

You may also notice that the benefits to a free-flowing intake is most noticeable when you have the highest flow levels, i.e. at high-RPMs. However, the efficiency of the stock K26/6 turbo (even K26/8 on TurboS) goes down in the higher-RPM ranges and heats up the intake-charge too much. Even with using a boost-controller to keep boost up (we only lost 0.25psi from max-boost in high-RPMs), the increased heat generated causes the torque-curve to drop.

I suspect with an aftermarket turbo at the same level of boost, you'll have a flatter torque curve above 5000rpm.

The final run was with our MAP-sensor Stg.1 upgrade kit installed running at 14.5psi (scale of boost not drawn on chart above). We're still awaiting our custom-tuned chip which should give us another 5% torque across the rev range.

You may also notice that the benefits to a free-flowing intake is most noticeable when you have the highest flow levels, i.e. at high-RPMs. However, the efficiency of the stock K26/6 turbo (even K26/8 on TurboS) goes down in the higher-RPM ranges and heats up the intake-charge too much. Even with using a boost-controller to keep boost up (we only lost 0.25psi from max-boost in high-RPMs), the increased heat generated causes the torque-curve to drop.

I suspect with an aftermarket turbo at the same level of boost, you'll have a flatter torque curve above 5000rpm.

#11

Race Director

Nope, not easily. You could burn custom chips with the changes you see that would be needed from the dyno charts. Then plug them in and do another dyno run. But that's clumbersome and time-consuming. You could also use an EPROM emulator for instant changes.

#12

Addict

Rennlist Member

Rennlist Member

Join Date: May 2001

Location: Melbourne, Florida

Posts: 942

Likes: 0

Received 0 Likes

on

0 Posts

Danno,

Since the cat's kind'a out of the bag, are you willing to post hp charts comparing the stock afm vs. map yet?

Also, this thread got me thinking again about why the sds system with map that Russ installed ran out of injectors with the stock k26/6 and (I'm guessing that) Travis's with link map/dme didn't. Any thoughts on this? And finally, let us know when you have your system all packaged up and ready.

Russ,

Did you ever run your 26/6 on a dyno? Also, did you get your car all put back together with the new head, turbo, and injectors?

Rob

Since the cat's kind'a out of the bag, are you willing to post hp charts comparing the stock afm vs. map yet?

Also, this thread got me thinking again about why the sds system with map that Russ installed ran out of injectors with the stock k26/6 and (I'm guessing that) Travis's with link map/dme didn't. Any thoughts on this? And finally, let us know when you have your system all packaged up and ready.

Russ,

Did you ever run your 26/6 on a dyno? Also, did you get your car all put back together with the new head, turbo, and injectors?

Rob

#13

Race Director

"why the sds system with map that Russ installed ran out of injectors with the stock k26/6 and (I'm guessing that) Travis's with link map/dme didn't."

Actually we're running the injectors up to 100% duty cycle above 6000rpm in 4th gear as well. Fifth gear hits the injector limit at 5800rpm. That's at 2.8 bar of fuel-pressure. We're going to be bundling a 3-bar FPR with our kit to keep the myriad of tuning variables under control.

"are you willing to post hp charts comparing the stock afm vs. map yet?"

Hmmm, we don't like to quote HP numbers because they're really good just for bragging rights and chest-thumping and we don't want to do that. Unless you have a CVT that can keep the engine at the peak-HP RPM all the time, HP numbers aren't representative of real-world performance. Besides, the real limitation of HP-gains is the stock turbo anyway. We'll give you before & after HP comparisons on a car where the turbo isn't a limitation to remove that variable so MAP vs. AFM differences can be isolated.

If you extraplote from the chart above, you can see that the torque increase is about 10% in the upper RPMs. So max-HP would be about 10%. But it's really the 25% increase in torque across the RPM-range that most people use that will be most noticable (even with adjustments for lower-boost final-run).

Here's some numbers that really make a difference:

stock '86 951 @ 16.5psi (our 180K-mile test car's a little worn-out)

----------------

0-60: 6.3-6.6 sec

1/4-mile: 14.5-14.7 sec

MAP-sensor '86 951 @14.5psi

----------------

0-60: 5.1-5.3 sec

1/4-mile: 13.6-13.8 sec

80-120mph: 4 seconds faster (that's 600ft ahead if you do side-by-side roll-on comparison)

Actually we're running the injectors up to 100% duty cycle above 6000rpm in 4th gear as well. Fifth gear hits the injector limit at 5800rpm. That's at 2.8 bar of fuel-pressure. We're going to be bundling a 3-bar FPR with our kit to keep the myriad of tuning variables under control.

"are you willing to post hp charts comparing the stock afm vs. map yet?"

Hmmm, we don't like to quote HP numbers because they're really good just for bragging rights and chest-thumping and we don't want to do that. Unless you have a CVT that can keep the engine at the peak-HP RPM all the time, HP numbers aren't representative of real-world performance. Besides, the real limitation of HP-gains is the stock turbo anyway. We'll give you before & after HP comparisons on a car where the turbo isn't a limitation to remove that variable so MAP vs. AFM differences can be isolated.

If you extraplote from the chart above, you can see that the torque increase is about 10% in the upper RPMs. So max-HP would be about 10%. But it's really the 25% increase in torque across the RPM-range that most people use that will be most noticable (even with adjustments for lower-boost final-run).

Here's some numbers that really make a difference:

stock '86 951 @ 16.5psi (our 180K-mile test car's a little worn-out)

----------------

0-60: 6.3-6.6 sec

1/4-mile: 14.5-14.7 sec

MAP-sensor '86 951 @14.5psi

----------------

0-60: 5.1-5.3 sec

1/4-mile: 13.6-13.8 sec

80-120mph: 4 seconds faster (that's 600ft ahead if you do side-by-side roll-on comparison)

#14

Nordschleife Master

[quote]Originally posted by Danno:

<strong>[b][i

Here's some numbers that really make a difference:

stock '86 951 @ 16.5psi (our 180K-mile test car's a little worn-out)

----------------

0-60: 6.3-6.6 sec

1/4-mile: 14.5-14.7 sec

MAP-sensor '86 951 @14.5psi

----------------

0-60: 5.1-5.3 sec

1/4-mile: 13.6-13.8 sec

80-120mph: 4 seconds faster (that's 600ft ahead if you do side-by-side roll-on comparison)</strong><hr></blockquote>

WOW! thats some improvement...

I'd love to see some similar test data for a lower mileage (better engine condition) 26/8 car...

How do you measure the injector duty cycle? Is that something that the Link system can do?

I've been leaning towards the Apexi S-AFC...but now I just don't know...

How much of those gains do you think you can attribute to a free-er flowing intake? And how much do you think you can attribute to the near-perfect a/f ratio?

TIA,

Adrial

<strong>[b][i

Here's some numbers that really make a difference:

stock '86 951 @ 16.5psi (our 180K-mile test car's a little worn-out)

----------------

0-60: 6.3-6.6 sec

1/4-mile: 14.5-14.7 sec

MAP-sensor '86 951 @14.5psi

----------------

0-60: 5.1-5.3 sec

1/4-mile: 13.6-13.8 sec

80-120mph: 4 seconds faster (that's 600ft ahead if you do side-by-side roll-on comparison)</strong><hr></blockquote>

WOW! thats some improvement...

I'd love to see some similar test data for a lower mileage (better engine condition) 26/8 car...

How do you measure the injector duty cycle? Is that something that the Link system can do?

I've been leaning towards the Apexi S-AFC...but now I just don't know...

How much of those gains do you think you can attribute to a free-er flowing intake? And how much do you think you can attribute to the near-perfect a/f ratio?

TIA,

Adrial

#15

Instructor

Join Date: Mar 2002

Location: spartanburg, SC

Posts: 194

Likes: 0

Received 0 Likes

on

0 Posts

[quote]How do you measure the injector duty cycle? Is that something that the Link system can do?<hr></blockquote>

Lindsey racings Air/Fuel monitor does air/fuel ratios and percentage of injector usage

check it out <a href="http://www.lindseyracing.com/fuelmon.htm" target="_blank">here</a>

i am eargerly awaiting the release of Dannos MAP conversion kit. i caint hardly freakin wait <img src="graemlins/jumper.gif" border="0" alt="[jumper]" /> .

Danno,

is there a stage made for upgraded turbos. or will we need to tune that in ourselves?

Sean

Lindsey racings Air/Fuel monitor does air/fuel ratios and percentage of injector usage

check it out <a href="http://www.lindseyracing.com/fuelmon.htm" target="_blank">here</a>

i am eargerly awaiting the release of Dannos MAP conversion kit. i caint hardly freakin wait <img src="graemlins/jumper.gif" border="0" alt="[jumper]" /> .

Danno,

is there a stage made for upgraded turbos. or will we need to tune that in ourselves?

Sean