Ceramic coated pistons & bearings are in w/ pics

#1

Three Wheelin'

Thread Starter

Join Date: Jun 2001

Location: San Jose, CA

Posts: 1,598

Likes: 0

Received 0 Likes

on

0 Posts

Just received my coated pistons and bearings from HPC. Top of the piston was coated with ceramic and the skirts/rod bearings were coated with an slippery black coating. Parts look pretty decent. Two complaints.

1)The top of the pistons were scrubbed with a wheel to get the carbon deposits off and it left some tiny scratches on the top of the piston. The ceramic was layered on top of those scratches but wasn't thick enough to fill them and make em dissappear. I doubt it will affect performance...it just looks less than top notch.

2)The coating on the rod bearings is really thing and I'm not sure how long it will last. Apparently they've had excellent results in durability...i'm just not too sure since it is so thin.

1)The top of the pistons were scrubbed with a wheel to get the carbon deposits off and it left some tiny scratches on the top of the piston. The ceramic was layered on top of those scratches but wasn't thick enough to fill them and make em dissappear. I doubt it will affect performance...it just looks less than top notch.

2)The coating on the rod bearings is really thing and I'm not sure how long it will last. Apparently they've had excellent results in durability...i'm just not too sure since it is so thin.

#4

Three Wheelin'

Thread Starter

Join Date: Jun 2001

Location: San Jose, CA

Posts: 1,598

Likes: 0

Received 0 Likes

on

0 Posts

Adrial,

Call HPC and swain. Swain had more technical detail, but both said the same thing. They both stated that it the skirt coating would reduce any scuffing that might occur against the piston walls (seeing how expensive it is to resleeve one of these, that was a big selling point). As far as the ceramic goes, it has no effect. The coating on the rod bearings should allow the bearings to retain oil better, which will hopefully prevent a thrown #2. Most folks drill their crank...i'm trying a different route (read cheaper).

Travis,

Total cost for all 4 pistons and rod bearings was $162, $128 if you just want to do the pistons. That doesn't include shipping both ways.

Call HPC and swain. Swain had more technical detail, but both said the same thing. They both stated that it the skirt coating would reduce any scuffing that might occur against the piston walls (seeing how expensive it is to resleeve one of these, that was a big selling point). As far as the ceramic goes, it has no effect. The coating on the rod bearings should allow the bearings to retain oil better, which will hopefully prevent a thrown #2. Most folks drill their crank...i'm trying a different route (read cheaper).

Travis,

Total cost for all 4 pistons and rod bearings was $162, $128 if you just want to do the pistons. That doesn't include shipping both ways.

#6

Three Wheelin'

Thread Starter

Join Date: Jun 2001

Location: San Jose, CA

Posts: 1,598

Likes: 0

Received 0 Likes

on

0 Posts

Adrial,

HPC wouldn't divulge the tech details regarding thickness, but I mentioned the 0.003" and i was verbally told and then told again in writing that I would not have to make any changes to account for the thickness of the coatings.

Once I get some plastigauge out and install the rod bearings I'll let you know what the clearances come out to be. From what I was told i'm guessing less than 0.001".

On a side note: I went into this knowing that I will be one of the guinea pigs for this coating. I don't know of anyone else using it in their 944. I know lyndsey racing sells some stuff coated now, but I haven't seen anyone using it. After doing some homework, I'm confident in the technology....what I'm not confident in, is whether or not there is any performance to be gained.

HPC wouldn't divulge the tech details regarding thickness, but I mentioned the 0.003" and i was verbally told and then told again in writing that I would not have to make any changes to account for the thickness of the coatings.

Once I get some plastigauge out and install the rod bearings I'll let you know what the clearances come out to be. From what I was told i'm guessing less than 0.001".

On a side note: I went into this knowing that I will be one of the guinea pigs for this coating. I don't know of anyone else using it in their 944. I know lyndsey racing sells some stuff coated now, but I haven't seen anyone using it. After doing some homework, I'm confident in the technology....what I'm not confident in, is whether or not there is any performance to be gained.

Trending Topics

#8

Three Wheelin'

Thread Starter

Join Date: Jun 2001

Location: San Jose, CA

Posts: 1,598

Likes: 0

Received 0 Likes

on

0 Posts

Passed on the mains. I'm doing what some referred to as a "dirty rebuild". Basically, I'm leaving the crank in place and not touching it. If I had removed the crank I would have done those bearings too though.

#9

Three Wheelin'

Join Date: Oct 2002

Location: Gulf Shores, Alabama

Posts: 1,841

Likes: 0

Received 0 Likes

on

0 Posts

I've heard from a longtime porsche mechanic that the mains in the 944 series will last a very, very long time. Several times what the rod bearings will last.

#10

PLease do update us when you have everything assemble, or when you go in again. This will be the only way we can find out what happens with these coatings.

#11

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Passed on the mains. I'm doing what some referred to as a "dirty rebuild". Basically, I'm leaving the crank in place and not touching it.

PLEASE keep us posted on the coatings. I have posted a similar question over on the 928 boards about this "voodoo coating" stuff on the skirts.

I understand that the coating on the factory pistons it is TIN and is only a player on the break-in period on the motor. The only reason they dont use it now is ENVIROMENTAL REASONS. Other alternative have been found..just what works in our cars/bore

Ill post a article below that a fellow 928 offered up.

I mean we have 928 motors will well over 150k...some 200k....Im sure you have 951s/944 in the same boat. How long does the factory coating last...There is NO WAY ANYONE can say "forever"...it has to wear off IMHO.

So i asked the 928 list.....

What is the caoting?

How is it applied at the factory?

How long does it last?

How do you know when it has worn of?

What are the effects when it does wear off?

150k ..200k mile motors..still running fine as far as i can tell!

Any input to these questions. We all need an alternative method for aftermarket pistons in our cars. The 928 folks are in the same boat as you all when it comes to this stuff. Well, maybe not the same boat...we having a U-boat and all

Last edited by Tony; 02-08-2004 at 12:46 AM.

#12

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Il post another question or two here about the ceramic tops.

Whats the verdict on cermic tops and detonation? I hear two stories..

One being that the coatings keep the heat in the combustion chamber not allowing it to escape through the body of the piston itself...rings...skirts..oil contact etc etc. Heat is energy..HP..but at what expense with the coating?

higher heat in the chamber to a point increases the onset of detonation.

The other is that the coating keeps the surface of the pisotn crown cooler and prevents it from getting hot....and acting almost like a heat sink.. Keepign the piston cooler lowers the amount of heat transfer from it into the combustion chamber ..lower temps keeps detonation at bay.

I have my psiotns all cleaned up and this thing ready to bolt up...i really dunno what route to take. The way i see it ...since i have machined my stock 10:1 pistons to 8.7:1 and effectively reduced the onset of detonation bya lower Cr , all things being equal, that the coating will help keep thermal stress on the piston to a minimum...help it run cooler..and help maintain some structural integrity.

How far down did the cermaic "top" extened? just the crown or to the first ring land??

Any inpout is appreciated...this is new territory for teh S4 motor in the 928. You guys over here have lots of experience with boost..heat...etc..

The fact that the S4 5.0L is very similar in design to the 951/44 makes this board a great resource to me.

Hopfeully not hijacking the thread here..but...

Just want to share and perhaps get input.

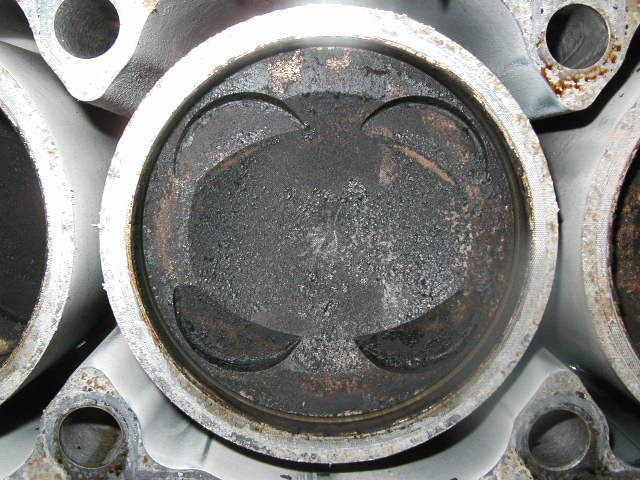

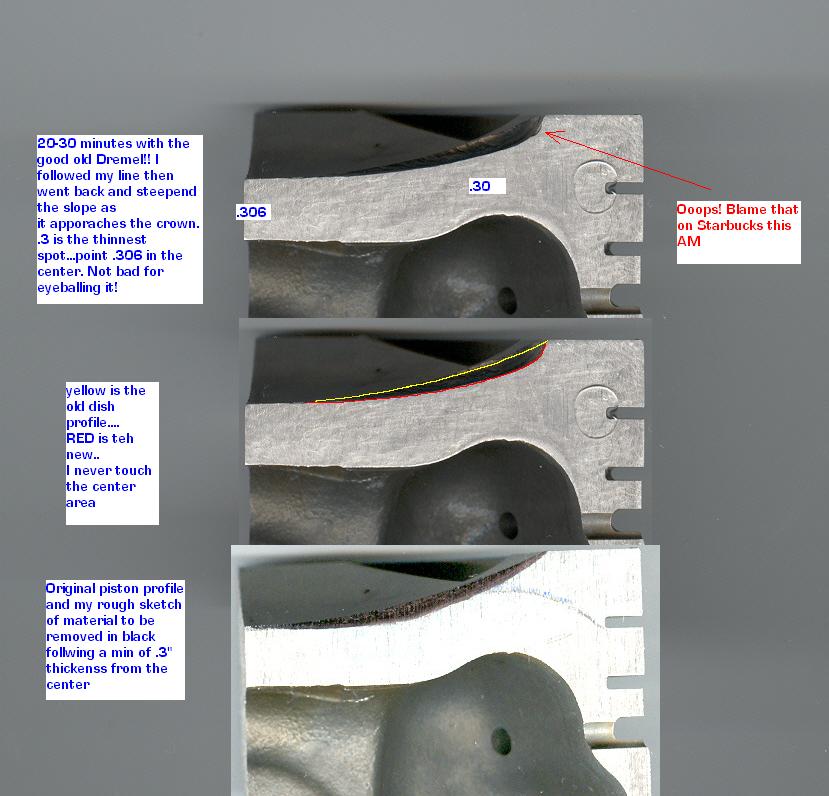

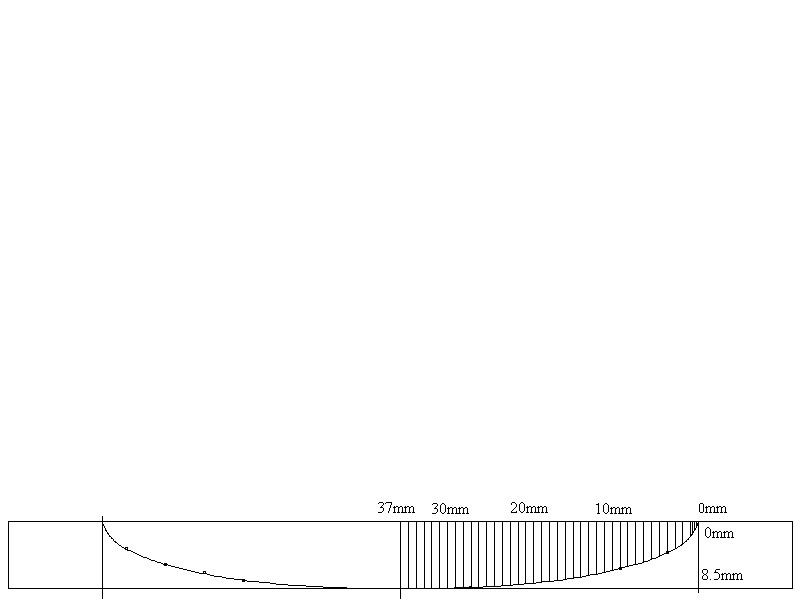

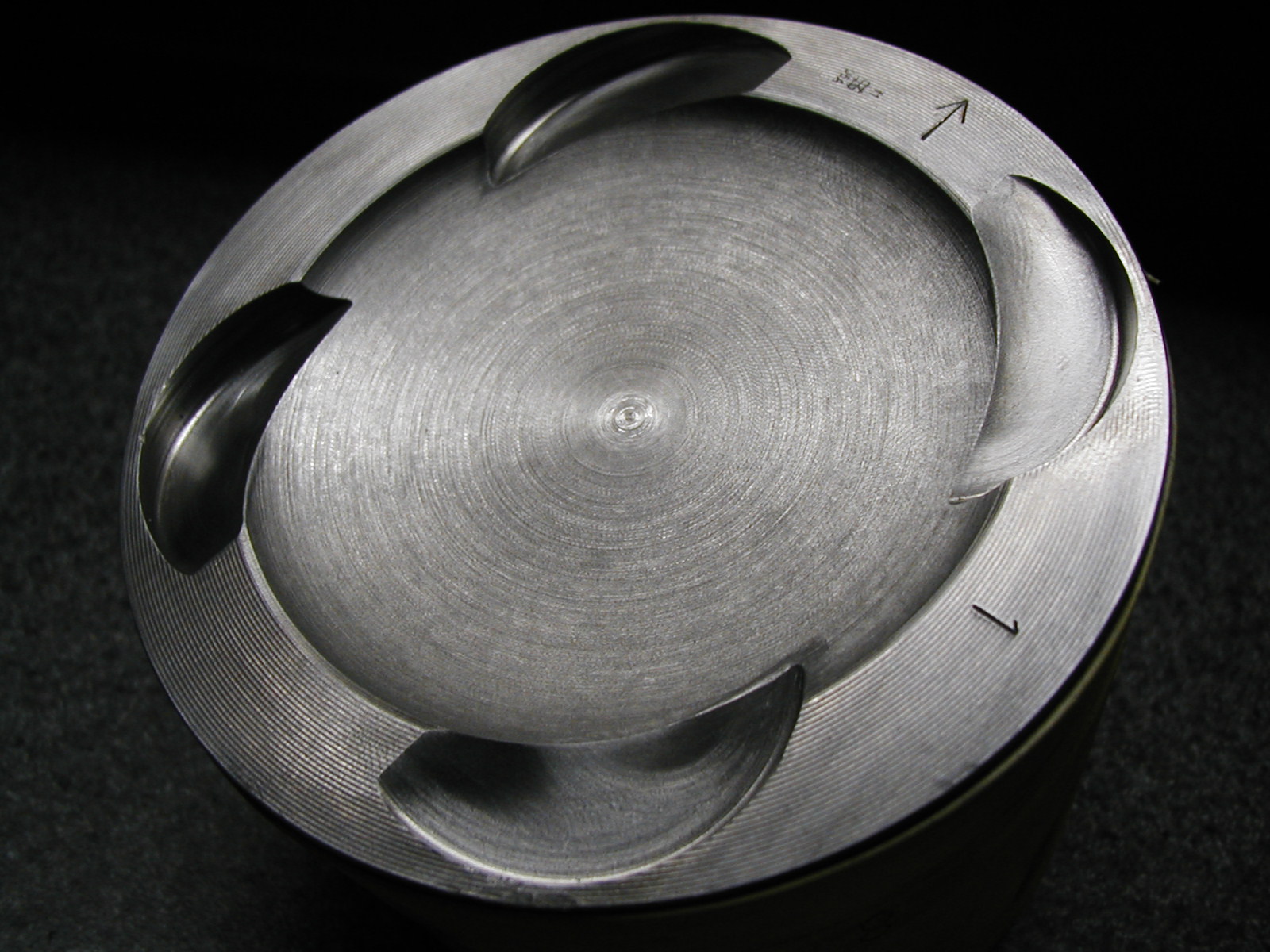

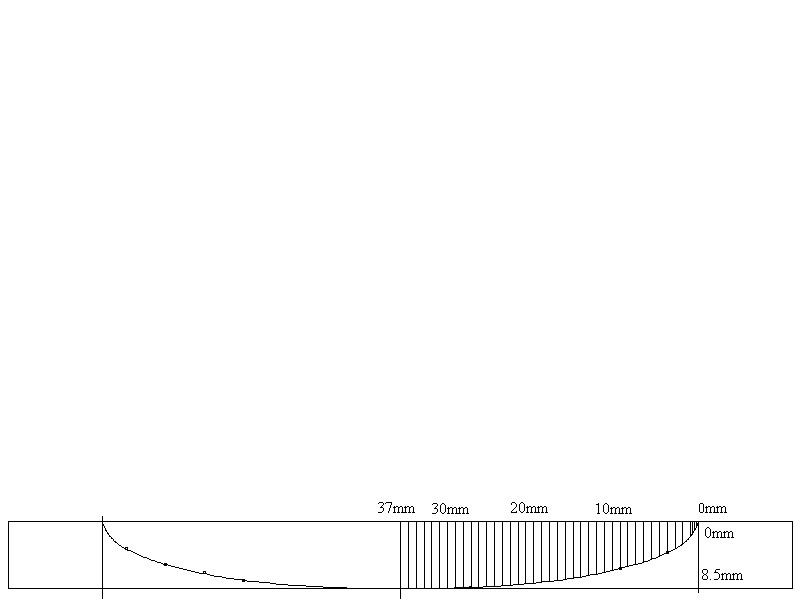

these are my machined pistons....6cc added to the dish by INCREASING the slope of the dish...not its depth...although the maching did extend to the center as seen in the pics, the surface there was basically "skimmed"

The goal..

11psi..maybe 13 if needed for 500rwhp with a greater margin of detonation saftey than the current stock 10:1 set up. FYI..we already have cars running 525 rwhp on 10:1..pump gas..11-13psi. I want better detonation protection at the same level of boost. Also have the Vegas summers to deal with.

Anyway...blah blah blah...pictures

BEFORE

The idea..profile on a sacrificial piston...

measure..draw up a profile..take it to a shop...

AFTER!!

My idea a reality...now if it works?!!?!?

Ceramic coat????

Whats the verdict on cermic tops and detonation? I hear two stories..

One being that the coatings keep the heat in the combustion chamber not allowing it to escape through the body of the piston itself...rings...skirts..oil contact etc etc. Heat is energy..HP..but at what expense with the coating?

higher heat in the chamber to a point increases the onset of detonation.

The other is that the coating keeps the surface of the pisotn crown cooler and prevents it from getting hot....and acting almost like a heat sink.. Keepign the piston cooler lowers the amount of heat transfer from it into the combustion chamber ..lower temps keeps detonation at bay.

I have my psiotns all cleaned up and this thing ready to bolt up...i really dunno what route to take. The way i see it ...since i have machined my stock 10:1 pistons to 8.7:1 and effectively reduced the onset of detonation bya lower Cr , all things being equal, that the coating will help keep thermal stress on the piston to a minimum...help it run cooler..and help maintain some structural integrity.

How far down did the cermaic "top" extened? just the crown or to the first ring land??

Any inpout is appreciated...this is new territory for teh S4 motor in the 928. You guys over here have lots of experience with boost..heat...etc..

The fact that the S4 5.0L is very similar in design to the 951/44 makes this board a great resource to me.

Hopfeully not hijacking the thread here..but...

Just want to share and perhaps get input.

these are my machined pistons....6cc added to the dish by INCREASING the slope of the dish...not its depth...although the maching did extend to the center as seen in the pics, the surface there was basically "skimmed"

The goal..

11psi..maybe 13 if needed for 500rwhp with a greater margin of detonation saftey than the current stock 10:1 set up. FYI..we already have cars running 525 rwhp on 10:1..pump gas..11-13psi. I want better detonation protection at the same level of boost. Also have the Vegas summers to deal with.

Anyway...blah blah blah...pictures

BEFORE

The idea..profile on a sacrificial piston...

measure..draw up a profile..take it to a shop...

AFTER!!

My idea a reality...now if it works?!!?!?

Ceramic coat????

Last edited by Tony; 02-08-2004 at 12:53 AM.

#13

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

hope this helps a bit...

In Chrysler Corp.'s Jeep engines, a new dry-film piston coating process--one that eliminates traditional tin plating--has overcome a potential irksome environmental challenge and simultaneously attains a Chrysler corporate goal to produce quieter, more efficient engines.

For several decades, the auto industry used tin as a "sacrificial" coating to protect the aluminum piston from scuffing on the iron bore during break-in. The tin eventually wears off.

But a rigorous regulatory climate has pushed tin plating costs upward. Efforts by the federal Environmental Protection Agency and allied state agencies to remove heavy metals from the environment have tightened restrictions on permits, waste disposal and other activities. In the same period, increasing use of dry-film coatings has helped to stabilize and in some cases reduce their costs.

Dow Corning Corp., developer of the Molykote D-10 anti-friction coating used for the Jeep pistons, says Chrysler's Jeep engine application is believed to be the first large-scale production use of such a coating in the U.S. Molykote D-10 includes graphite and a proprietary resin that provides noise dampening and some lubricity, while bonding the graphite to the piston skirt.

"The biggest problem for us," says Chuck Beffel, quality and product engineering manager at Chrysler's Kenosha, WI, engine plant, "was to make a clean break, because we didn't want to mix tin and Molykote pistons in a given engine. We had to run out of tin plated at the same time the Molykoted pistons started coming on line."

Mr. Beffel says partially finished pistons come from Dana Corp. in Pueblo, CO, and go through final machining at the Kenosha plant; before Chrysler began using the new coating, the pistons would then have to be sent to Milwaukee for tin plating.

"We're (the Kenosha plant) not able to do it because we're not a player," says Mr. Beffel. "That's a different environmental situation because it's a heavy metal. You've got to have the permits and such to have heavy metal on site. There are not that many houses that even do (tin plating) any more." ..................................Tony ... This states the tin was for "break in lubrication " and would confirm what you have observed which is that it wears off at varying rates .

For several decades, the auto industry used tin as a "sacrificial" coating to protect the aluminum piston from scuffing on the iron bore during break-in. The tin eventually wears off.

But a rigorous regulatory climate has pushed tin plating costs upward. Efforts by the federal Environmental Protection Agency and allied state agencies to remove heavy metals from the environment have tightened restrictions on permits, waste disposal and other activities. In the same period, increasing use of dry-film coatings has helped to stabilize and in some cases reduce their costs.

Dow Corning Corp., developer of the Molykote D-10 anti-friction coating used for the Jeep pistons, says Chrysler's Jeep engine application is believed to be the first large-scale production use of such a coating in the U.S. Molykote D-10 includes graphite and a proprietary resin that provides noise dampening and some lubricity, while bonding the graphite to the piston skirt.

"The biggest problem for us," says Chuck Beffel, quality and product engineering manager at Chrysler's Kenosha, WI, engine plant, "was to make a clean break, because we didn't want to mix tin and Molykote pistons in a given engine. We had to run out of tin plated at the same time the Molykoted pistons started coming on line."

Mr. Beffel says partially finished pistons come from Dana Corp. in Pueblo, CO, and go through final machining at the Kenosha plant; before Chrysler began using the new coating, the pistons would then have to be sent to Milwaukee for tin plating.

"We're (the Kenosha plant) not able to do it because we're not a player," says Mr. Beffel. "That's a different environmental situation because it's a heavy metal. You've got to have the permits and such to have heavy metal on site. There are not that many houses that even do (tin plating) any more." ..................................Tony ... This states the tin was for "break in lubrication " and would confirm what you have observed which is that it wears off at varying rates .

#14

In Your Face, Ace

Rennlist Member

Rennlist Member

Originally posted by Tony

The goal..

11psi..maybe 13 if needed for 500rwhp with a greater margin of detonation saftey than the current stock 10:1 set up. FYI..we already have cars running 525 rwhp on 10:1..pump gas..11-13psi. I want better detonation protection at the same level of boost. Also have the Vegas summers to deal with.

Anyway...blah blah blah...pictures

The goal..

11psi..maybe 13 if needed for 500rwhp with a greater margin of detonation saftey than the current stock 10:1 set up. FYI..we already have cars running 525 rwhp on 10:1..pump gas..11-13psi. I want better detonation protection at the same level of boost. Also have the Vegas summers to deal with.

Anyway...blah blah blah...pictures

#15

Three Wheelin'

Thread Starter

Join Date: Jun 2001

Location: San Jose, CA

Posts: 1,598

Likes: 0

Received 0 Likes

on

0 Posts

So i asked the 928 list.....

What is the coating?

How is it applied at the factory?

How long does it last?

How do you know when it has worn of?

What are the effects when it does wear off?

150k ..200k mile motors..still running fine as far as i can tell!

1) You'd have to ask swain or HPC what they put in their coatings but they aren't going to tell you....its a trade secret. Ceramic based coating similar to what you see on ehxaust systems went on the dome. Dry film of sorts on the skirts and bearings.

2) no idea

3) I've seen one honda motor in person that had over 100k on it and the ceramic coating on top seemed to still be there. Swain claims that most diesel motors use it with over 300k and it still holds together

4) Worst case: it chunks off and lands in the turbo. I doubt pieces that big would ever come off so i'm not worried. I don't think you'd ever really know until you tear it down.

5) same as above

I will say that my 944 motor, the piston skirts were scuffed at the sides after 120k miles. It looks like the tin coating had worn off in those places. It wasn't scuffed bad...just enough to wear the coating off. I do beleive that some of the tin still remained on the piston though.

I'll update everyone after my next tear down...but that will be years down the line hopefully.

What is the coating?

How is it applied at the factory?

How long does it last?

How do you know when it has worn of?

What are the effects when it does wear off?

150k ..200k mile motors..still running fine as far as i can tell!

1) You'd have to ask swain or HPC what they put in their coatings but they aren't going to tell you....its a trade secret. Ceramic based coating similar to what you see on ehxaust systems went on the dome. Dry film of sorts on the skirts and bearings.

2) no idea

3) I've seen one honda motor in person that had over 100k on it and the ceramic coating on top seemed to still be there. Swain claims that most diesel motors use it with over 300k and it still holds together

4) Worst case: it chunks off and lands in the turbo. I doubt pieces that big would ever come off so i'm not worried. I don't think you'd ever really know until you tear it down.

5) same as above

I will say that my 944 motor, the piston skirts were scuffed at the sides after 120k miles. It looks like the tin coating had worn off in those places. It wasn't scuffed bad...just enough to wear the coating off. I do beleive that some of the tin still remained on the piston though.

I'll update everyone after my next tear down...but that will be years down the line hopefully.