Default Anyone ever see ECU chips like these? What are 'Thompson Cams'?

#46

Archive Gatekeeper

Rennlist Member

Rennlist Member

Just the set of S3s that got converted into S4-compatibles. I can do those too for grins, there are a bunch of presets in the software for valve lash settings, the degree of 'aggression' of the solid lifters (would have thought that solid was solid, need to figure out WTH they mean...), etc. More more practice on standard cams, the better I should do on the custom grinds.

#47

Race Car

DOn't forget to map the SEs..

"PORSCHE PRESS RELEASE : 4th MARCH 1988 - A new model, the 928S Series 4 with Sport Equipment, has been added to the flagship series of Porsche High Performance road car range. Aimed specifically at the truly enthusiastic driver, the car features a modified engine and exhaust system, a new close-ratio 5-speed gearbox, a limited slip differential plus Sports Suspension.

As a result of the above changes, the Gran Turismo appeal of the 928S Series 4 has been enhanced by developing its sporting character. Top speed is now 173 mph and acceleration time has been reduced to 5.3 seconds (0-62mph).

The more sporting character of the 5.0 litre 32-valve V8 engine has been achieved with the installation of special higher profile camshafts, a modified engine management unit controlling the LH-Jetronic fuel injection and EZK electronic ignition systems plus a modified exhaust system with twin tailpipes.

Available only with a Manual transmision, the new 928S Series 4 with Sport Equipment (or SE), has a new 5-speed close-ratio gearbox with a 20mm shorter gear lever. The final drive ratio is 2.73:1 compared to 2.64:1 on the standard 5-speed transmission and a limited slip differential is included as standard equipment.

The sports suspension comprises front springs which are 10% firmer; Sport shock absorbers; 17mm wider rear track; plus special wider lighter disc style forged alloy 8Jx16 road wheels at the front, and 9Jx16 at the rear. These are fitted with 225/50vr16 and 245/45vr16 ultra low profile performance tyres respectively.

In the 1988 model year, the new Porsche 928S Series 4 with Sport Equipment will be avialable in only four colours - Grand Prix White, Guards Red, Black and Metallic Silver. Each car will be finished with the same interior trim comprising full black leather and electrically height adjustable Sport seats with special black/red pinstripe cloth inlays and red piping."

Now I need to see a photo of the underside of Rogers to see what the deal is with the exhaust....

5.3 sec, well that's downright acceptable.

"PORSCHE PRESS RELEASE : 4th MARCH 1988 - A new model, the 928S Series 4 with Sport Equipment, has been added to the flagship series of Porsche High Performance road car range. Aimed specifically at the truly enthusiastic driver, the car features a modified engine and exhaust system, a new close-ratio 5-speed gearbox, a limited slip differential plus Sports Suspension.

As a result of the above changes, the Gran Turismo appeal of the 928S Series 4 has been enhanced by developing its sporting character. Top speed is now 173 mph and acceleration time has been reduced to 5.3 seconds (0-62mph).

The more sporting character of the 5.0 litre 32-valve V8 engine has been achieved with the installation of special higher profile camshafts, a modified engine management unit controlling the LH-Jetronic fuel injection and EZK electronic ignition systems plus a modified exhaust system with twin tailpipes.

Available only with a Manual transmision, the new 928S Series 4 with Sport Equipment (or SE), has a new 5-speed close-ratio gearbox with a 20mm shorter gear lever. The final drive ratio is 2.73:1 compared to 2.64:1 on the standard 5-speed transmission and a limited slip differential is included as standard equipment.

The sports suspension comprises front springs which are 10% firmer; Sport shock absorbers; 17mm wider rear track; plus special wider lighter disc style forged alloy 8Jx16 road wheels at the front, and 9Jx16 at the rear. These are fitted with 225/50vr16 and 245/45vr16 ultra low profile performance tyres respectively.

In the 1988 model year, the new Porsche 928S Series 4 with Sport Equipment will be avialable in only four colours - Grand Prix White, Guards Red, Black and Metallic Silver. Each car will be finished with the same interior trim comprising full black leather and electrically height adjustable Sport seats with special black/red pinstripe cloth inlays and red piping."

Now I need to see a photo of the underside of Rogers to see what the deal is with the exhaust....

5.3 sec, well that's downright acceptable.

#48

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,230

Received 463 Likes

on

248 Posts

Rob from my chart in post #31 the lifts measured are very close to to yours. We both got 8.95mm intake lift. I cannot say if the lift of a new intake lobe is 9.00mm and the old cams are worn 0.05mm or if it is 8.95mm from the factory. However this is a very small difference only being of academic significance.

My duration figures are closer to the published figures than yours. It can be a slight measurement error.

Have you been doing repetitive measurements? When the setup is done it is important to rotate the camshaft several turns and the dial indicator have to come back to zero every time the lifter is on the base circle. I have seen cams where the base circle had a certain runout of up to 0.10mm which actually is not acceptable and may depend from flex at the grinding process.

┼ke

My duration figures are closer to the published figures than yours. It can be a slight measurement error.

Have you been doing repetitive measurements? When the setup is done it is important to rotate the camshaft several turns and the dial indicator have to come back to zero every time the lifter is on the base circle. I have seen cams where the base circle had a certain runout of up to 0.10mm which actually is not acceptable and may depend from flex at the grinding process.

┼ke

#49

Archive Gatekeeper

Rennlist Member

Rennlist Member

Given Ake's sound advice about repetition and making sure there's no runout on the base circle (there isn't, on either set of cams mounted up in the test head...), tonight I measured one pair of GTS cams from my '93.

Either I am way off on my measurements (don't think so since the S4s I measured are pretty close) or the 'published' values are way off.

First, here's a more comprehensive report on the stock S4 cams, marked up a bit: 8.95/8.01 mm lift, 202/196 duration @ 1mm lift, 105.7 LSA. 309.5 mm2 intake lobe area, 273.5 mm2 exhaust lobe area.

Then the GTS cam measurements. I get an LSA of 114, way different from the 118.5 I've seen, and the durations at 1mm lift are 210 and 200, vs. 228 and 196 'published'.

If the published lift/duration for GT cams are correct (10mm/9mm and 219/205 @ 1mm), then it's no wonder why they wake up a GTS......

GTS:

Either I am way off on my measurements (don't think so since the S4s I measured are pretty close) or the 'published' values are way off.

First, here's a more comprehensive report on the stock S4 cams, marked up a bit: 8.95/8.01 mm lift, 202/196 duration @ 1mm lift, 105.7 LSA. 309.5 mm2 intake lobe area, 273.5 mm2 exhaust lobe area.

Then the GTS cam measurements. I get an LSA of 114, way different from the 118.5 I've seen, and the durations at 1mm lift are 210 and 200, vs. 228 and 196 'published'.

If the published lift/duration for GT cams are correct (10mm/9mm and 219/205 @ 1mm), then it's no wonder why they wake up a GTS......

GTS:

#50

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,230

Received 463 Likes

on

248 Posts

Rob, your measurements of the GTS intake cam (I have not measured the GTS exhaust) confirms that the duration at 1mm lift is way off from the factory published figure. My measurements GTS intake, lift 9.49mm, duration at 1mm 212.5 degrees (factory duration figure 228 degrees @ 1mm). About base circle runout the stock factory cams are good but I have quite often seen aftermarket performance cams having a certain smaller runout of up to 0.03mm. It will be interesting to see your results when you start measuring the custom grinds.

┼ke

┼ke

#52

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,230

Received 463 Likes

on

248 Posts

Just the set of S3s that got converted into S4-compatibles. I can do those too for grins, there are a bunch of presets in the software for valve lash settings, the degree of 'aggression' of the solid lifters (would have thought that solid was solid, need to figure out WTH they mean...), etc. More more practice on standard cams, the better I should do on the custom grinds.

┼ke

#53

Archive Gatekeeper

Rennlist Member

Rennlist Member

Best if the valve is off the seat a little when the lifter is on the base circle.

#54

Nordschleife Master

Excellent info. It now all makes sense. The GT cams in a GTS make more power than GTS cams because of two reasons. First, the GT cams have more duration, which increases top end torque but reduces the mid range torque compared to the GTS cams. Second, the lower mid-range torque due to longer duration is then recovered by the tighter LSA of the GT cams (GT 110, GT 114). The only downside is slightly poorer idle caused by both differences, which can be cured by increasing the idle rpm a little.

#56

Unless its a Dodge, which means its just broken.

#57

Nordschleife Master

My handmade chart is showing the timing of 1987 928S4 cams in the engine. Note the 1987 cams are marked differently but are the same compared to later models. As you say Tuomo, these cams are way too small for a serious NA engine performance build. On the chart note the non-existing opening ramps which make the hydraulic grind impossible to run on solid lifters.

#59

One of the approach to take account of maximum piston cfm demand is to set the valve to 10% lower from the maximum camshaft lift in flowbench.

With this setup you need to reach the needed cfm to make desired power level. This approach also makes sure the desired hp numbers should be reached in real life.

Ake, have you heard this approach before?

Pipemax will also show the max. piston cfm demand for each engine setup.

Piston CFM Column = is the CFM @28in. the Engine really wants at 6440 RPM

Cyl Head CFM Column = is what you say the Engine is getting.

you are saying this by your Volumetric Efficiency Input

If you have no real Ve% Dyno Data , ... a good starting point is to :

Adjust the Volumetric Efficiency % Input until the Peak Cylinder Head CFM

matches your FlowBench CFM data at your Camshaft's max Valve Lift point.

Usually Peak Cylinder Head and Piston CFM Demand occurs 70 to 80 deg ATDC

Crank Head Piston Piston Piston Volume Crank Rod-to- Rod-to-

Angle CFM @ CFM @ Depth Speed CC per Rotate Bore Crank

Degree 28 in. 28 in. inches Ft/Min degree TimeSec Angle Angle

0.0 0.0 0.0 0.0000 0.0 0.00 .00000 0.00 180.00

0,5 2,0 2,5 0,0001 57,8 0,01 ,00001 0,13 179,37

1,0 4,1 5,1 0,0003 115,6 0,06 ,00003 0,26 178,74

1,5 6,1 7,6 0,0007 173,4 0,13 ,00004 0,39 178,11

2,0 8,1 10,1 0,0012 231,1 0,24 ,00005 0,53 177,47

2,5 10,1 12,6 0,0019 288,9 0,37 ,00006 0,66 176,84

3,0 12,2 15,2 0,0027 346,6 0,54 ,00008 0,79 176,21

3,5 14,2 17,7 0,0037 404,2 0,73 ,00009 0,92 175,58

4,0 16,2 20,2 0,0048 461,8 0,96 ,00010 1,05 174,95

4,5 18,2 22,7 0,0061 519,4 1,21 ,00012 1,18 174,32

5,0 20,3 25,2 0,0075 576,9 1,49 ,00013 1,31 173,69

5,5 22,3 27,7 0,0090 634,3 1,81 ,00014 1,45 173,05

6,0 24,3 30,2 0,0108 691,6 2,15 ,00016 1,58 172,42

6,5 26,3 32,7 0,0126 748,9 2,52 ,00017 1,71 171,79

. . .

Crank Head Piston Piston Piston Volume Crank Rod-to- Rod-to-

Angle CFM @ CFM @ Depth Speed CC per Rotate Bore Crank

Degree 28 in. 28 in. inches Ft/Min degree TimeSec Angle Angle

74,8 189,9 236,5 1,3411 5409,3 267,94 ,00194 14,72 90,48

74,9 189,9 236,5 1,3439 5409,6 268,50 ,00194 14,73 90,37

75,0 189,9 236,5 1,3467 5409,9 269,06 ,00194 14,73 90,27

75,1 189,9 236,5 1,3495 5410,2 269,62 ,00194 14,74 90,16

75,2 190,0 236,6 1,3523 5410,4 270,18 ,00195 14,75 90,05

75,3 190,0 236,6 1,3551 5410,7 270,74 ,00195 14,75 89,95

75,4 190,0 236,6 1,3579 5410,9 271,30 ,00195 14,76 89,84

75,5 190,0 236,6 1,3608 5411,1 271,86 ,00195 14,77 89,73

75,6 190,0 236,6 1,3636 5411,2 272,42 ,00196 14,77 89,63

75,7 190,0 236,6 1,3664 5411,4 272,99 ,00196 14,78 89,52

75,8 190,0 236,6 1,3692 5411,5 273,55 ,00196 14,79 89,41

75,9 190,0 236,6 1,3720 5411,6 274,11 ,00196 14,79 89,31

76,0 190,0 236,6 1,3748 5411,7 274,67 ,00197 14,80 89,20

76,1 190,0 236,6 1,3776 5411,8 275,23 ,00197 14,81 89,09

76,2 190,0 236,6 1,3804 5411,9 275,79 ,00197 14,81 88,99

76,3 190,0 236,6 1,3832 5411,9 276,35 ,00197 14,82 88,88

76,4 190,0 236,6 1,3860 5411,9 276,91 ,00198 14,83 88,77

76,5 190,0 236,6 1,3888 5411,9 277,47 ,00198 14,83 88,67

76,6 190,0 236,6 1,3916 5411,9 278,03 ,00198 14,84 88,56

76,7 190,0 236,6 1,3944 5411,9 278,59 ,00198 14,85 88,45

76,8 190,0 236,6 1,3972 5411,8 279,15 ,00199 14,85 88,35

76,9 190,0 236,6 1,4001 5411,7 279,71 ,00199 14,86 88,24

77,0 190,0 236,6 1,4029 5411,6 280,28 ,00199 14,87 88,14

77,1 190,0 236,6 1,4057 5411,5 280,84 ,00200 14,87 88,03

77,2 190,0 236,6 1,4085 5411,4 281,40 ,00200 14,88 87,92

77,3 190,0 236,6 1,4113 5411,2 281,96 ,00200 14,88 87,82

77,4 190,0 236,6 1,4141 5411,0 282,52 ,00200 14,89 87,71

77,5 190,0 236,6 1,4169 5410,9 283,08 ,00201 14,90 87,60

77,6 190,0 236,6 1,4197 5410,6 283,64 ,00201 14,90 87,50

77,7 190,0 236,6 1,4225 5410,4 284,20 ,00201 14,91 87,39

77,8 189,9 236,5 1,4253 5410,2 284,76 ,00201 14,91 87,29

With this setup you need to reach the needed cfm to make desired power level. This approach also makes sure the desired hp numbers should be reached in real life.

Ake, have you heard this approach before?

Pipemax will also show the max. piston cfm demand for each engine setup.

Piston CFM Column = is the CFM @28in. the Engine really wants at 6440 RPM

Cyl Head CFM Column = is what you say the Engine is getting.

you are saying this by your Volumetric Efficiency Input

If you have no real Ve% Dyno Data , ... a good starting point is to :

Adjust the Volumetric Efficiency % Input until the Peak Cylinder Head CFM

matches your FlowBench CFM data at your Camshaft's max Valve Lift point.

Usually Peak Cylinder Head and Piston CFM Demand occurs 70 to 80 deg ATDC

Crank Head Piston Piston Piston Volume Crank Rod-to- Rod-to-

Angle CFM @ CFM @ Depth Speed CC per Rotate Bore Crank

Degree 28 in. 28 in. inches Ft/Min degree TimeSec Angle Angle

0.0 0.0 0.0 0.0000 0.0 0.00 .00000 0.00 180.00

0,5 2,0 2,5 0,0001 57,8 0,01 ,00001 0,13 179,37

1,0 4,1 5,1 0,0003 115,6 0,06 ,00003 0,26 178,74

1,5 6,1 7,6 0,0007 173,4 0,13 ,00004 0,39 178,11

2,0 8,1 10,1 0,0012 231,1 0,24 ,00005 0,53 177,47

2,5 10,1 12,6 0,0019 288,9 0,37 ,00006 0,66 176,84

3,0 12,2 15,2 0,0027 346,6 0,54 ,00008 0,79 176,21

3,5 14,2 17,7 0,0037 404,2 0,73 ,00009 0,92 175,58

4,0 16,2 20,2 0,0048 461,8 0,96 ,00010 1,05 174,95

4,5 18,2 22,7 0,0061 519,4 1,21 ,00012 1,18 174,32

5,0 20,3 25,2 0,0075 576,9 1,49 ,00013 1,31 173,69

5,5 22,3 27,7 0,0090 634,3 1,81 ,00014 1,45 173,05

6,0 24,3 30,2 0,0108 691,6 2,15 ,00016 1,58 172,42

6,5 26,3 32,7 0,0126 748,9 2,52 ,00017 1,71 171,79

. . .

Crank Head Piston Piston Piston Volume Crank Rod-to- Rod-to-

Angle CFM @ CFM @ Depth Speed CC per Rotate Bore Crank

Degree 28 in. 28 in. inches Ft/Min degree TimeSec Angle Angle

74,8 189,9 236,5 1,3411 5409,3 267,94 ,00194 14,72 90,48

74,9 189,9 236,5 1,3439 5409,6 268,50 ,00194 14,73 90,37

75,0 189,9 236,5 1,3467 5409,9 269,06 ,00194 14,73 90,27

75,1 189,9 236,5 1,3495 5410,2 269,62 ,00194 14,74 90,16

75,2 190,0 236,6 1,3523 5410,4 270,18 ,00195 14,75 90,05

75,3 190,0 236,6 1,3551 5410,7 270,74 ,00195 14,75 89,95

75,4 190,0 236,6 1,3579 5410,9 271,30 ,00195 14,76 89,84

75,5 190,0 236,6 1,3608 5411,1 271,86 ,00195 14,77 89,73

75,6 190,0 236,6 1,3636 5411,2 272,42 ,00196 14,77 89,63

75,7 190,0 236,6 1,3664 5411,4 272,99 ,00196 14,78 89,52

75,8 190,0 236,6 1,3692 5411,5 273,55 ,00196 14,79 89,41

75,9 190,0 236,6 1,3720 5411,6 274,11 ,00196 14,79 89,31

76,0 190,0 236,6 1,3748 5411,7 274,67 ,00197 14,80 89,20

76,1 190,0 236,6 1,3776 5411,8 275,23 ,00197 14,81 89,09

76,2 190,0 236,6 1,3804 5411,9 275,79 ,00197 14,81 88,99

76,3 190,0 236,6 1,3832 5411,9 276,35 ,00197 14,82 88,88

76,4 190,0 236,6 1,3860 5411,9 276,91 ,00198 14,83 88,77

76,5 190,0 236,6 1,3888 5411,9 277,47 ,00198 14,83 88,67

76,6 190,0 236,6 1,3916 5411,9 278,03 ,00198 14,84 88,56

76,7 190,0 236,6 1,3944 5411,9 278,59 ,00198 14,85 88,45

76,8 190,0 236,6 1,3972 5411,8 279,15 ,00199 14,85 88,35

76,9 190,0 236,6 1,4001 5411,7 279,71 ,00199 14,86 88,24

77,0 190,0 236,6 1,4029 5411,6 280,28 ,00199 14,87 88,14

77,1 190,0 236,6 1,4057 5411,5 280,84 ,00200 14,87 88,03

77,2 190,0 236,6 1,4085 5411,4 281,40 ,00200 14,88 87,92

77,3 190,0 236,6 1,4113 5411,2 281,96 ,00200 14,88 87,82

77,4 190,0 236,6 1,4141 5411,0 282,52 ,00200 14,89 87,71

77,5 190,0 236,6 1,4169 5410,9 283,08 ,00201 14,90 87,60

77,6 190,0 236,6 1,4197 5410,6 283,64 ,00201 14,90 87,50

77,7 190,0 236,6 1,4225 5410,4 284,20 ,00201 14,91 87,39

77,8 189,9 236,5 1,4253 5410,2 284,76 ,00201 14,91 87,29

#60

Nordschleife Master

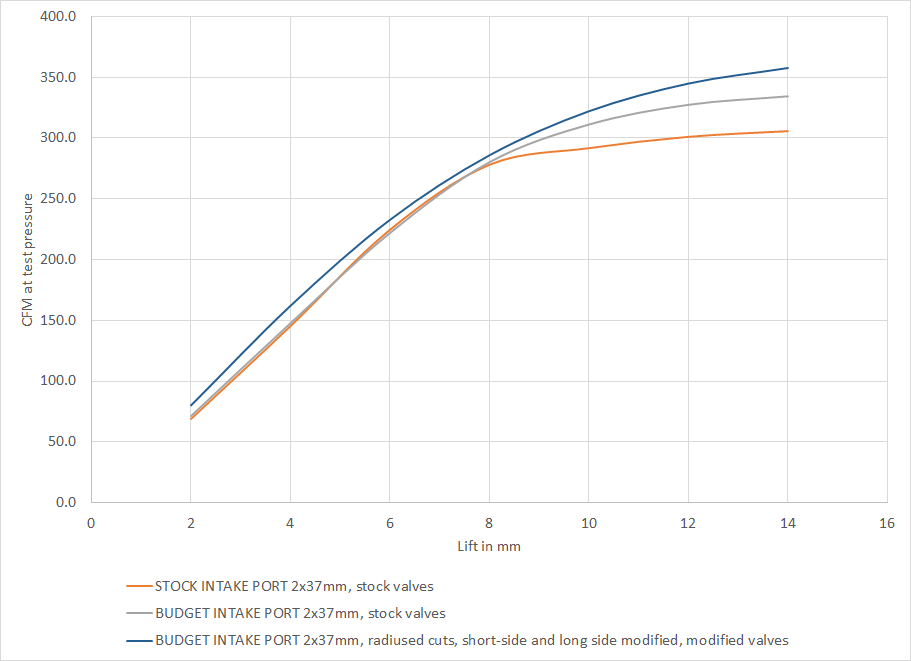

If we accept the working hypothesis that flow capacity below peak piston speed matters much more than flow capacity above peak piston speed, then the second port in the graph would not make any more power with stock S4 cams than the stock port. There's virtually no difference in flow capacity below 7.7mm lift.

The stock port seems to work pretty well up to 8mm lift. From that I'd conjecture that for performance cams that lift 8mm or less by the maximum piston speed point at 75.5 crankshaft degrees ABDC, porting that increases high lift flow isn't cost effective.

Of course, one can try to improve flow at low and medium lifts. Contrast the second port with the third port. The third port has the capability of flowing much more at lifts lower than 7.7mm. That port has the potential of making more power with stock S4 cams, provided that the engine can use that flow capacity.

In any case, these S4 heads flow so much out of the box that very few 928 engines can actually use that air flow capacity.