AC prassure switch question

#1

Thread Starter

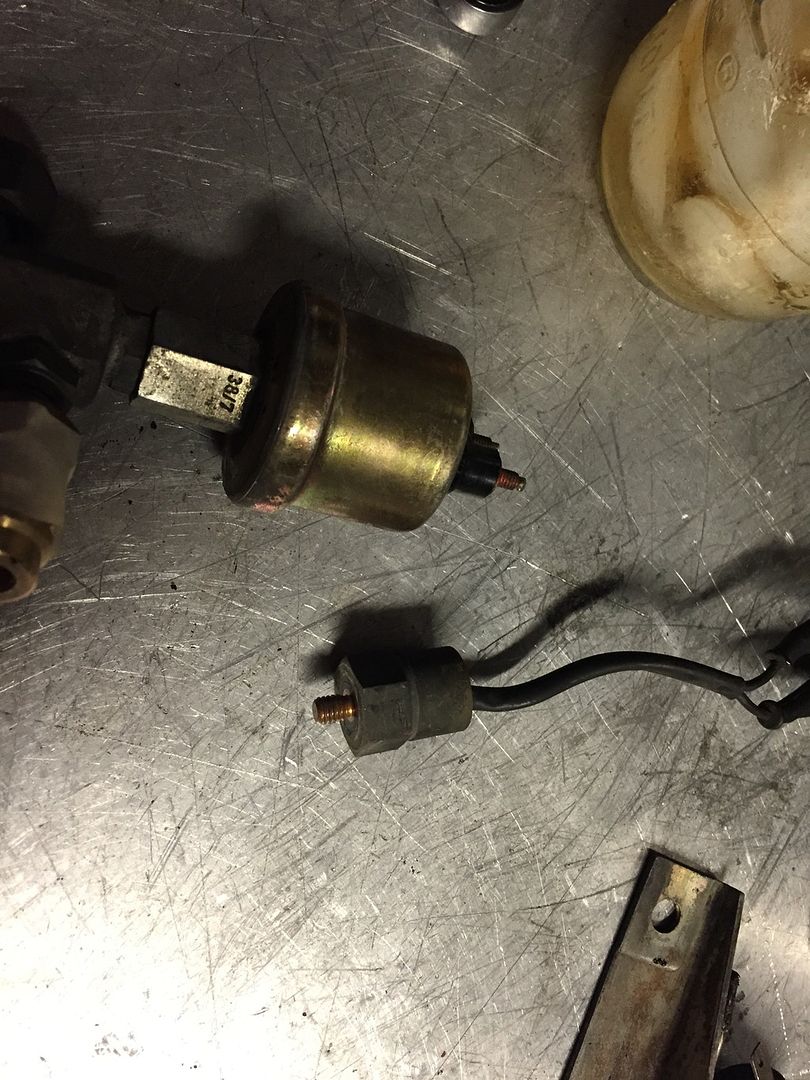

So I am adding a late model condenser and drier to my car for better flow (and the condenser was free and in fantastic shape), but, I noticed one issue that will be holding me up....

Early cars have the screw in temp sensor, and the late have the pressure transducer.. (Looks like a oil pressure sensor).

Both are two wire... Do the do the same function?

Early cars have the screw in temp sensor, and the late have the pressure transducer.. (Looks like a oil pressure sensor).

Both are two wire... Do the do the same function?

#2

I believe the ps had a pressure rating noted on them in either

bar or psi, that will give you a hint. For example if the says

25 psi, or 1.7 bar, that would be a low pressure cut out switch;

most low pressure cut out switches are designed below 40 psi.

If it says something greater than 225 psi (you can do the math yourself to convert to bar, 1 bar = 14.50377 psi) then its a high pressure cut out

switch.

Condenser wise, Bigger is not always better,,,, lol.

The early 928's used a serpentine condenser, smaller than the later models, then they moved over to tube and fin. If you have a later model with an auto trans the coil size is different to accommodate the oil cooler.

I owned three 928's, 78,84 and 89. All stock condensers, all systems converted to R134a. On the 78 with the smaller serpentine coil, I had no problems getting vent temps in the high 30's on mid 90 days, however the evaporator temp sensor would always shut down the system no matter how cold you want to get it.

Many aftermarket condenser mfg's are providing PF designed coils because they are easier to fabricate or that is the technology their production lines are tooled for.

Liquid flush that used condenser with something like Interdynamics Professional-Grade Aerosol Power Clean and Flush, pn CA1, or your favorite flavor. Replace all the orings in the system, install a new drier. Inspect the old oil in the compressor, if you find debris or contamination or jelled oil, liquid flush the whole system (you can't flush driers, compressors or TEV's).

http://griffiths.com/product-categor...tioning/928-2/

bar or psi, that will give you a hint. For example if the says

25 psi, or 1.7 bar, that would be a low pressure cut out switch;

most low pressure cut out switches are designed below 40 psi.

If it says something greater than 225 psi (you can do the math yourself to convert to bar, 1 bar = 14.50377 psi) then its a high pressure cut out

switch.

Condenser wise, Bigger is not always better,,,, lol.

The early 928's used a serpentine condenser, smaller than the later models, then they moved over to tube and fin. If you have a later model with an auto trans the coil size is different to accommodate the oil cooler.

I owned three 928's, 78,84 and 89. All stock condensers, all systems converted to R134a. On the 78 with the smaller serpentine coil, I had no problems getting vent temps in the high 30's on mid 90 days, however the evaporator temp sensor would always shut down the system no matter how cold you want to get it.

Many aftermarket condenser mfg's are providing PF designed coils because they are easier to fabricate or that is the technology their production lines are tooled for.

Liquid flush that used condenser with something like Interdynamics Professional-Grade Aerosol Power Clean and Flush, pn CA1, or your favorite flavor. Replace all the orings in the system, install a new drier. Inspect the old oil in the compressor, if you find debris or contamination or jelled oil, liquid flush the whole system (you can't flush driers, compressors or TEV's).

http://griffiths.com/product-categor...tioning/928-2/

#3

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

They are not the same. The later car has a current-loop

transducer for pressure. It corresponds with temperature amazingly, so it's less sensitive to local under hood conditions. The late cars have a fan speed controller that adjusts based on the pressure. The sensors all fit on to Schaeder-equipped fittings, at least the later ones.

transducer for pressure. It corresponds with temperature amazingly, so it's less sensitive to local under hood conditions. The late cars have a fan speed controller that adjusts based on the pressure. The sensors all fit on to Schaeder-equipped fittings, at least the later ones.

#5

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Beginning with '87 models. There's a pressure transducer for the AC high side, top of the drier. Has two thumb-nut terminals on top, with the pressure safety switch at the bottom, and the high-side test port there together on the tubing manifold. The transducer talks to a controller under the cover next to the passenger's seat. That controller also receives input from the temperature transducer at the bottom front of the radiator, plus the intake temp switch, and the auto trans overheat switch if the car is an automatic. Commands from tha controller in the cabin go forward to the "final stages" module on the apron at the front right corner under the hood. Those in turn meter power to the fans.

#6

Thread Starter

so the little pressure switch on the bottom of the piping is for the low pressure cut off switch?

now i do that that temp send in the bottom of the radiator.... how was it involved with the stock (81) temp switch?

now i do that that temp send in the bottom of the radiator.... how was it involved with the stock (81) temp switch?

#7

Thread Starter

ok, had my coffee and did some diagram checking. so that temp switch is in line with the radiator temp switch for the fan, so which ever decides the fans need to come on, on it goes. low pressure switch is the same on both systems.

SO

the big question is, if i hook up that newer pressure transducer in place of the refrigerant temp sensor of old, will it kick on the fan when it needs to?

OR

do i make up an adapter to screw on the temp sensor in place of the newer pressure transducer.

SO

the big question is, if i hook up that newer pressure transducer in place of the refrigerant temp sensor of old, will it kick on the fan when it needs to?

OR

do i make up an adapter to screw on the temp sensor in place of the newer pressure transducer.

Trending Topics

#8

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

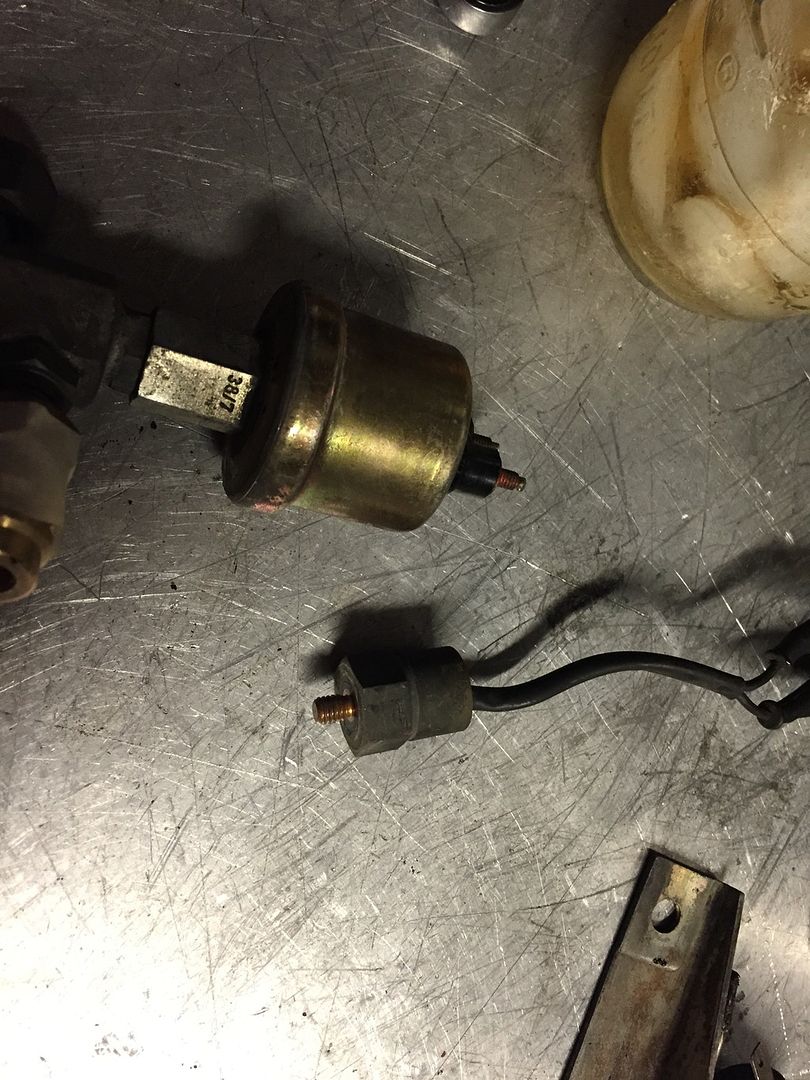

The functions are not interchangeable. You'll want to find an adapter from the drier connection to the temp switch originally fitted to your '81. FWIW, I've adapted freon bottles to NPT fittings using pieces from Home Depot. Same fitting you have on the new new-style drier. Use a smear of 574 or maybe Hylomar on the fitting to guarantee the seal. The original fittings have O-rings, while the H-D brass adapter is metal on metal. You might be able to fit an O-ring there but the H-D part isn't grooved to hold one. It would likely squish out.

#11

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Looks, umm, less than ideal that way. The straight threads will bleed even with sealant at 300+ psi potential high-side pressures.

Were it mine, I would plug that fitting, and use the compressor trigger to actuate a relay for the fan. Reality, especially in Los Angeles, is that you need the fan running whenever the compressor is running. No serious risk of it over-cooling the condenser in that climate. Plugging or capping the existing fitting means no chance of that switch breaking off, leaking, whatever. My too sense.

Were it mine, I would plug that fitting, and use the compressor trigger to actuate a relay for the fan. Reality, especially in Los Angeles, is that you need the fan running whenever the compressor is running. No serious risk of it over-cooling the condenser in that climate. Plugging or capping the existing fitting means no chance of that switch breaking off, leaking, whatever. My too sense.

#13

Thread Starter

#14

Rennlist Member

Join Date: Sep 2006

Location: carthage,mo

Posts: 674

Likes: 0

Received 0 Likes

on

0 Posts

On the 78 with the smaller serpentine coil, I had no problems getting vent temps in the high 30's on mid 90 days, however the evaporator temp sensor would always shut down the system no matter how cold you want to get it.

[/QUOTE]

So, what was the cure for this issue?

[/QUOTE]

So, what was the cure for this issue?

#15

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Late model cars run the fans continuously whenever the AC is on, early cars controlled the fans based on refrigerant temp. You are probably better going with the late model concept.

Since you have an aftermarket variable speed fan controller, make sure AC triggers at least a mid speed (not the lowest speed level) - this is esp. important if you convert to R134a. In that case you may want to get the GTS:R134a pressure switch - it has 3 functions. Low pressure compressor clutch disable, mid-pressure fan high command and over pressure compressor clutch disable.

If the fan flow on the condenser is insufficient for an R134a system - system pressure mounts very fast - the stock GTS R134a high pressure cutoff is off at 32 bar - 32 bar is 464psi... When 1 cooling fan failed during a Phoenix summer my compressor cycled at 464 bar - the load on the engine is huge! - certainly enough to make the compressor belt howl (and stink) the only option was to turn the AC off - which is a rather painful thing to do in the summer here...

Alan

Since you have an aftermarket variable speed fan controller, make sure AC triggers at least a mid speed (not the lowest speed level) - this is esp. important if you convert to R134a. In that case you may want to get the GTS:R134a pressure switch - it has 3 functions. Low pressure compressor clutch disable, mid-pressure fan high command and over pressure compressor clutch disable.

If the fan flow on the condenser is insufficient for an R134a system - system pressure mounts very fast - the stock GTS R134a high pressure cutoff is off at 32 bar - 32 bar is 464psi... When 1 cooling fan failed during a Phoenix summer my compressor cycled at 464 bar - the load on the engine is huge! - certainly enough to make the compressor belt howl (and stink) the only option was to turn the AC off - which is a rather painful thing to do in the summer here...

Alan