Porting 2V heads and Custom Manifold Test

#1

Addict

Rennlist Member

Rennlist Member

Thread Starter

Guys this is a thread started by my cylinder head porter, the heads were already ported by another shop before I found peter, so for the sake of completeness I have included the standard flow numbers of these heads without any manifold on them, just the plasticine radius which all shops use. These numbers are also on page 2 of the below thread.

0.100"……...…54 cfm

0.200"…….…111 cfm

0.300"……...159 cfm

0.400"……...193 cfm

0.500"….... 212 cfm

0.600"…….…217 cfm

The exhaust

0.100"…………49 cfm

0.200"…….…107 cfm

0.300"……...135 cfm

0.400"……...162 cfm

0.500"……….173 cfm

0.600"…….…173 cfm

These heads are going on my 5.0 litre engine which may be sold later when the big engine is up and running or I may just keep it as a spare. The engine was always a pretty big performer for its development, I estimated between 385 and 395 flywheel hp based on what standard factory cars were doing on the dyno that my car was tested on and also when compared to other 928s.

The engine was never tuned properly and we bumped the comp and have increased the airflow. A modern EMS will be fitted and John Gill will tune this engine. It will use Motec'c new M150 ecu. On this engine I will just use the Bosch 4 spray hole injector and leave the Injector Dynamics injectors for the big engine. I am hoping for 400 HP+ from this engine with a very broad torque curve.

Have fun reading, there is lots of info and Peter is also in the process of doing the heads for my 104 mm 5.35 litre engine that is going in the wife's car. So that will also added to the same thread in the next two weeks. We are using 52 mm valves in that head which gives more scope to Peter as there is more material to shape and somebody hasn't already played with those heads.

http://www.aussiev8.com.au/holden-v8...928-heads.html

0.100"……...…54 cfm

0.200"…….…111 cfm

0.300"……...159 cfm

0.400"……...193 cfm

0.500"….... 212 cfm

0.600"…….…217 cfm

The exhaust

0.100"…………49 cfm

0.200"…….…107 cfm

0.300"……...135 cfm

0.400"……...162 cfm

0.500"……….173 cfm

0.600"…….…173 cfm

These heads are going on my 5.0 litre engine which may be sold later when the big engine is up and running or I may just keep it as a spare. The engine was always a pretty big performer for its development, I estimated between 385 and 395 flywheel hp based on what standard factory cars were doing on the dyno that my car was tested on and also when compared to other 928s.

The engine was never tuned properly and we bumped the comp and have increased the airflow. A modern EMS will be fitted and John Gill will tune this engine. It will use Motec'c new M150 ecu. On this engine I will just use the Bosch 4 spray hole injector and leave the Injector Dynamics injectors for the big engine. I am hoping for 400 HP+ from this engine with a very broad torque curve.

Have fun reading, there is lots of info and Peter is also in the process of doing the heads for my 104 mm 5.35 litre engine that is going in the wife's car. So that will also added to the same thread in the next two weeks. We are using 52 mm valves in that head which gives more scope to Peter as there is more material to shape and somebody hasn't already played with those heads.

http://www.aussiev8.com.au/holden-v8...928-heads.html

#2

Nordschleife Master

That's a lot of ambitious work. A real insight for someone unfamiliar with what can be done to guide and analyze head porting. The other thread is at 103 posts of data, discussion and some typical Internet trash type.

I've got a future race car on the driveway. As I'm a beginner, can you summarize what you're finding and what recommendations you would make? It's a '80 Euro S with the RoW heads.

I've got a future race car on the driveway. As I'm a beginner, can you summarize what you're finding and what recommendations you would make? It's a '80 Euro S with the RoW heads.

#3

Addict

Rennlist Member

Rennlist Member

Thread Starter

That's a lot of ambitious work. A real insight for someone unfamiliar with what can be done to guide and analyze head porting. The other thread is at 103 posts of data, discussion and some typical Internet trash type.

I've got a future race car on the driveway. As I'm a beginner, can you summarize what you're finding and what recommendations you would make? It's a '80 Euro S with the RoW heads.

I've got a future race car on the driveway. As I'm a beginner, can you summarize what you're finding and what recommendations you would make? It's a '80 Euro S with the RoW heads.

So basically these should be bench marks to aim for. I think that 250 cfm at 0.500" is the best you can hope for with a decent low lift profile if you do everything right. That will make really good power in a 5.0 litre. You will have very good velocity. Also you need to address the intake runners. Factory runners and plenum needs some work. The 944 flange plate mod is a pretty easy one. Wait till Peter gets back to me on sizing. The headers should be 1 3/4" and not the smaller headers. That may change if you have a 4.7 litre.

I am running a 236 degree @ 0.050" cam on the intake, smaller on the exhaust. The compression is at least 11 to 1 and on the 5.35 litre it will be around 11.3 to 1. If you want any other info let me know.

#4

Burning Brakes

I had a set of US heads done by a very experienced engine builder 3500.00 in porting alone . Using 944 valves with the sodium cooled exhaust valve . At .500 lift the intakes flows 280 cfm . Racing valve spring with titanium retainers .Cams are .515 lift on the intake ( billet cams from Porsche -devek ) 110 lobe centers .Headers / stand alone engine management system . With a 4.5 L bottom end I was getting just over 300 HP at the rear wheels . With a stroked 5.8 L bottom end I was getting 300 HP at 4000 RPM and well over 425 HP in the 6000 RPM range .Good luck with your project . If I ever get a 85-86 bottom end I might put this motor back together .

#5

Nordschleife Master

My next engine build will be for US PCA racing in a stock class. Very few engine mods allowed but starting with an RoW car is permitted. There's always room for subtle mods, like porting. I'd be running with the stock cams, heads intake, etc. Exhaust is "free." "Maintenance" machine work is allowed like decking the head and block.

I'll be following along and looking for more info later. Just blew the racing budget on this: Tow rig

What is the "944 flange plate mod?"

I'll be following along and looking for more info later. Just blew the racing budget on this: Tow rig

What is the "944 flange plate mod?"

#7

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,232

Received 464 Likes

on

249 Posts

I had a set of US heads done by a very experienced engine builder 3500.00 in porting alone . Using 944 valves with the sodium cooled exhaust valve . At .500 lift the intakes flows 280 cfm . Racing valve spring with titanium retainers .Cams are .515 lift on the intake ( billet cams from Porsche -devek ) 110 lobe centers .Headers / stand alone engine management system . With a 4.5 L bottom end I was getting just over 300 HP at the rear wheels . With a stroked 5.8 L bottom end I was getting 300 HP at 4000 RPM and well over 425 HP in the 6000 RPM range .Good luck with your project . If I ever get a 85-86 bottom end I might put this motor back together .

Åke

Trending Topics

#8

Addict

Rennlist Member

Rennlist Member

Thread Starter

So the 928s engine only has 46.4% and we are slightly increasing this but no where near the maximum, however the bigger the valve the drivability normally declines in such an application. Maybe that is what Porsche was looking for?

I am taking bit of a risk with my big engine and going for 51.3% as that is outside the parameters we have gotten to work however when you move the valve guides and in the case of that big engine maybe move the head 1 mm also to further unshroud the valves.

I hope to post more later but the more I post the less actual work can be done.

#9

Addict

Rennlist Member

Rennlist Member

Thread Starter

1, use the 944 flange plate and then use the S runners instead of the S2 runners which are horrible.

2, use the 944 flange plate and then use custom tubing like I did in the aussiev8 thread. or see below. In my case on one of my engines I used the S runners and converted them to the S2 style injector. This was a long time ago but it did work and those runners were fully ported along with the plenum. Which again is required. You will get a decent increase in airflow doing this. Lots of aluminium will end up on the floor!

https://rennlist.com/forums/928-foru...-2-valver.html

#10

Addict

Rennlist Member

Rennlist Member

Thread Starter

45mm intake valve, 97mm bore (4.5L), 280 CFM @ 28" at .500" lift sound too good to be true for me. The intake flow of an Euro unmodified head is about 214 CFM at .500" lift (100mm bore) according to my flow testing. A well modified head I did once, having larger 48mm intake valves, flow 246 CFM at the same lift over the same bore. The very same head flow 280 CFM at a very high lift of .670" which is far above any useful camshaft. In order to achieve 280 CFM at .500" lift I reckon a 50mm intake valve very much unshrouded (at least a 104mm bore) is needed.

Åke

Åke

#11

Former Sponsor

Great reading.

Beautiful port work with a logical realistic approach. He's an artist!

Beautiful port work with a logical realistic approach. He's an artist!

#12

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,232

Received 464 Likes

on

249 Posts

928 2-valve porting by Pete. Three pages of pictures.

http://s1106.photobucket.com/user/pm...?sort=3&page=1

http://s1106.photobucket.com/user/pm...?sort=3&page=1

#13

Addict

Rennlist Member

Rennlist Member

Thread Starter

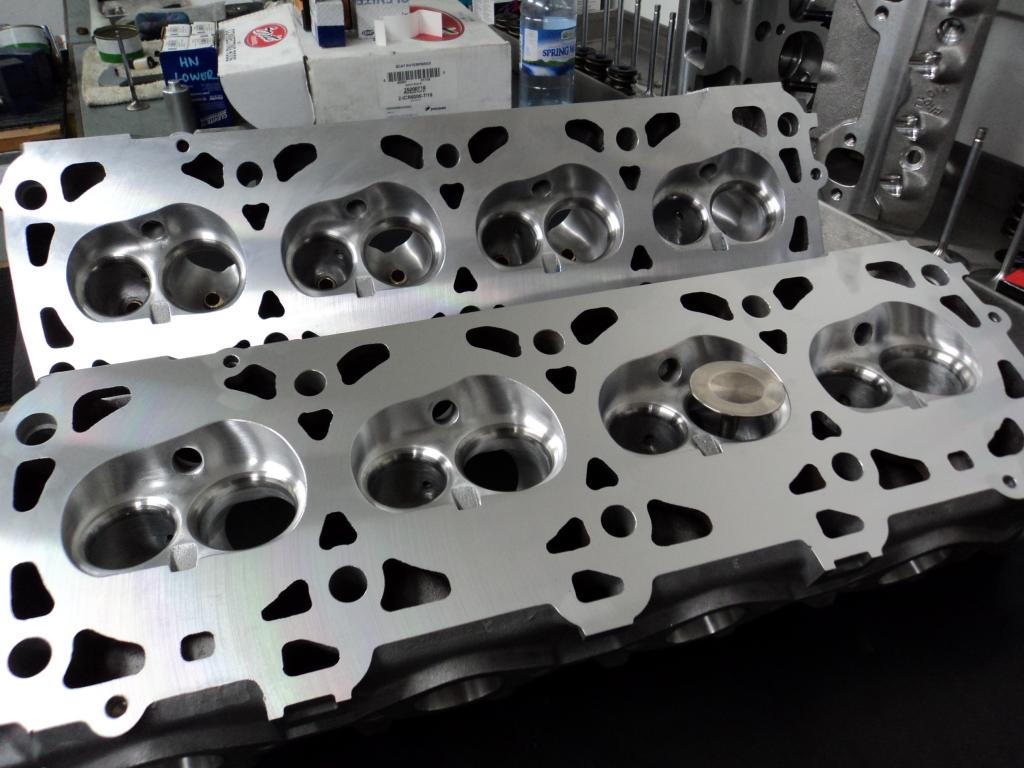

Well, progress has been slow thanks to all concerned having a full workload but we are getting there, so soon two 2V engines will go together. Here is some details, I don't have all the facts yet as this came through late at night.

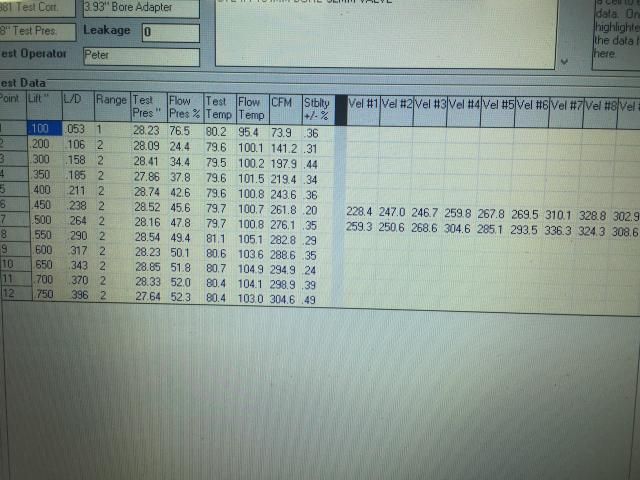

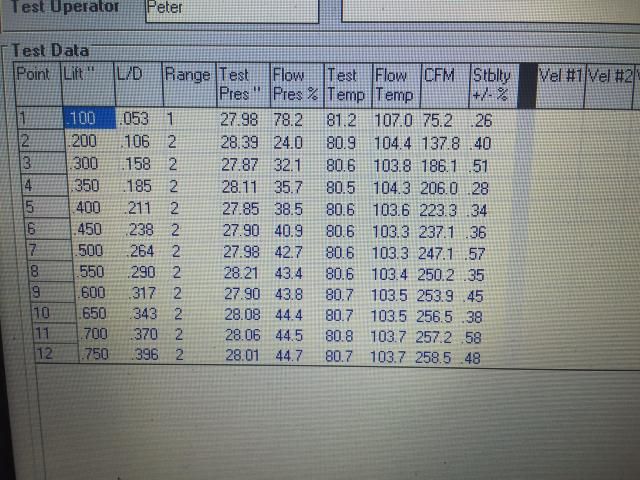

These tests relate to the 104 mm bore engine.

We tested the port with the manifold and plenum attached, more on that later in this post.

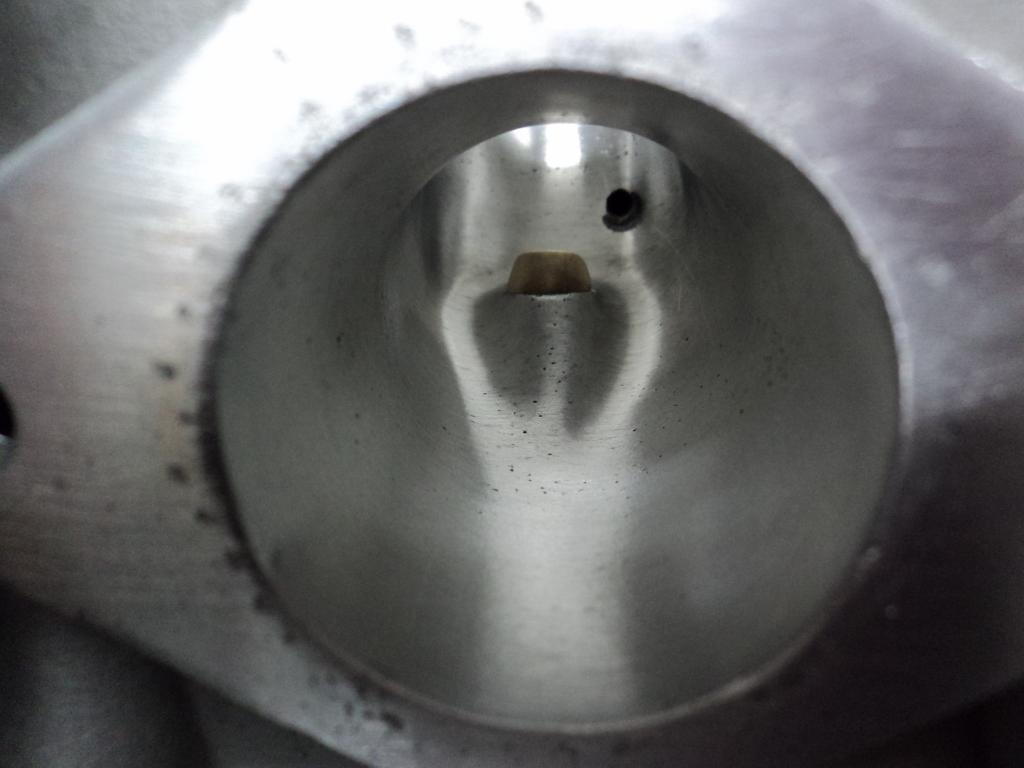

This is the finished intake port, we'll get more pics later,

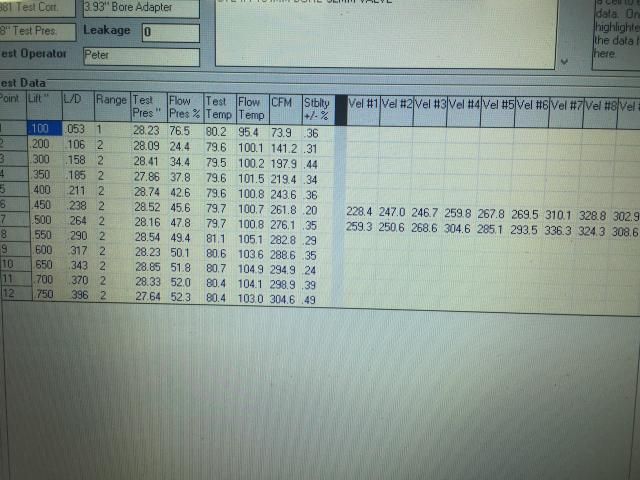

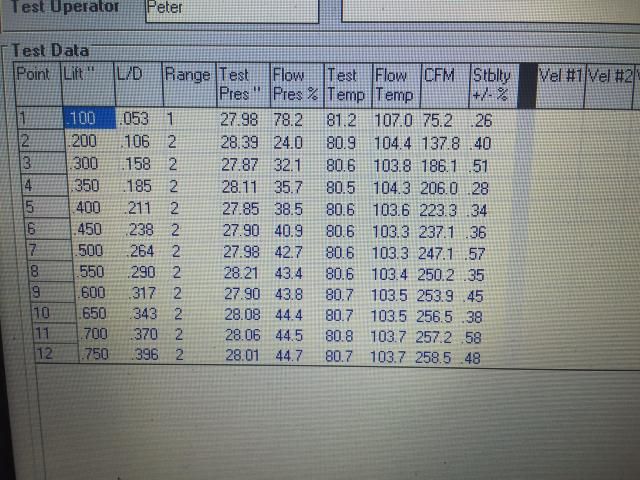

These are the flow numbers without the manifold or plenum, that is with a plasticine bell mouth directly on the head. These aren't too bad and are close to the test ports numbers.

These numbers are with the manifold and plenum attached, they drop off quite a lot.

So I need to enquire if we have a test with the manifold attached and no plenum that will determine where the problem is. Previously as stated in this thread the manifold preformed quite well on the smaller and lower flowing head. That testing didn't include the plenum, so we now need to find out what effect the plenum has. Either way I will use the stock/ported factory plenum on the 5.0 litre engine.

I should add the cam lift details and then this can be related back to the flow figures, the smaller 5.0 litre engine has 0.470"/0.440" and the bigger 104 mm bore engine has 0.500"/0.470" lift.

I think a custom plenum with larger runners at the 90 degree turn will probably be beneficial. So the plan would be something like using 2" or 50 mm O.D pipe at the plenum and then transition to the 47.6 mm pipe or some variation of this. I would also include in the larger plenum a set of proper bell mouths. This will require the plenum becoming longer which will require some tight packaging.

These tests relate to the 104 mm bore engine.

We tested the port with the manifold and plenum attached, more on that later in this post.

This is the finished intake port, we'll get more pics later,

These are the flow numbers without the manifold or plenum, that is with a plasticine bell mouth directly on the head. These aren't too bad and are close to the test ports numbers.

These numbers are with the manifold and plenum attached, they drop off quite a lot.

So I need to enquire if we have a test with the manifold attached and no plenum that will determine where the problem is. Previously as stated in this thread the manifold preformed quite well on the smaller and lower flowing head. That testing didn't include the plenum, so we now need to find out what effect the plenum has. Either way I will use the stock/ported factory plenum on the 5.0 litre engine.

I should add the cam lift details and then this can be related back to the flow figures, the smaller 5.0 litre engine has 0.470"/0.440" and the bigger 104 mm bore engine has 0.500"/0.470" lift.

I think a custom plenum with larger runners at the 90 degree turn will probably be beneficial. So the plan would be something like using 2" or 50 mm O.D pipe at the plenum and then transition to the 47.6 mm pipe or some variation of this. I would also include in the larger plenum a set of proper bell mouths. This will require the plenum becoming longer which will require some tight packaging.

#14

Addict

Rennlist Member

Rennlist Member

Thread Starter

Ok so the word is that the current manifold is well suited to the 5.0 litre engine. The runners are 45 mm I.D and taper to 41 mm. The plenum is ported to 45 mm with the best bell mouth I could carve out of the factory casting.

I am thinking that the new manifold should be in the 49 to 50 mm I.D it then takes the 90 degree turn and I will taper some 45 mm I.D pipe to join this, it will then meet the 944 flange and this will taper to around 42 mm.

I will attempt to widen and lengthen the plenum so that I can use proper bell mouths inside the plenum. I won't be able to do a lot in this respect while retaining the stock throttle body but I will just do what is possible. Four hundred and fifty horsepower is the goal as it stands and the porter said he was able to increase exhaust flow over what he had done in the previous heads as nobody had been there before him. So this will help the overlap period as the cams have a pretty wide LSA as they were designed for a auto.

I am thinking that the new manifold should be in the 49 to 50 mm I.D it then takes the 90 degree turn and I will taper some 45 mm I.D pipe to join this, it will then meet the 944 flange and this will taper to around 42 mm.

I will attempt to widen and lengthen the plenum so that I can use proper bell mouths inside the plenum. I won't be able to do a lot in this respect while retaining the stock throttle body but I will just do what is possible. Four hundred and fifty horsepower is the goal as it stands and the porter said he was able to increase exhaust flow over what he had done in the previous heads as nobody had been there before him. So this will help the overlap period as the cams have a pretty wide LSA as they were designed for a auto.