My 928 Projects Master Thread

#46

Addict

Rennlist Member

Rennlist Member

Thread Starter

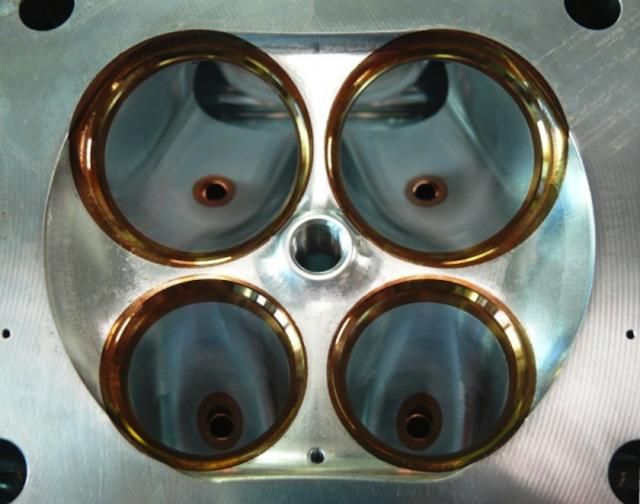

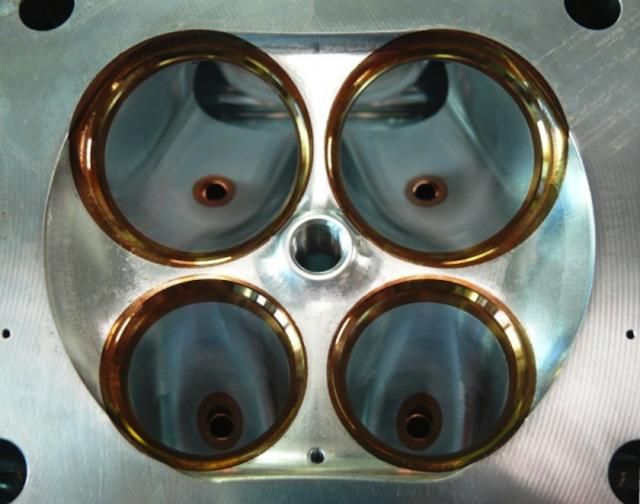

O.K some pics, oversized valves turned up yesterday and provided some interesting insights. The head gasket is 106 mm but the bore will be 108 mm when done. The exhaust valves you see are 37 mm and the intake are 41.91 mm. You will notice how close the intake and exhaust valves are to each other. Clearly this is no good.

However the neat thing about this conversion which is required to fit the convex tappets is the head needs to be drawn and plotting needs to be determined to keep the same valve spacing (Between the intake and exhaust banks) that was there originally. What will happen is the exhaust will move toward the quench area of the head. The valve seats will get very close to the flat surface of the head like the F1 head. There will be some shrouding at low lifts but we'll see how bad this is during development. From what I am seeing the exhaust will be in the 37 to 38 mm range. Ferrea make a 6 mm stem with 38 mm head valve but is out of stock at present. The intake I think will get further work to maximise its potential. I will aim for 0.75 to 1 mm gap between the intake valves. The valve spacing can be easily altered when we set the guide position. That said the absolute maximum would be 44 mm and the minimum 42.5 mm using stock valve spacing.

Below is the Toyota F1 combustion

What you should know about this chamber is the valves have effectively a double unshrouding courtesy of inward angled valves, so the intake valves move closer together as the lift progresses. That is the reason they start off further apart than my valves will. You can see how far they push the valves towards the cylinder wall. I worked out some time ago, so I am going by memory, this engine has around 36% of intake to bore area and I will be in the 33% range. You can see visually there is a big difference between the heads. So what I will have is about what many OEM race engines have but no where near what a dedicated, clean sheet design would have. I recently spoke to an engineer who I hope will design my cam specification and do the grinding, he was on the team that designed the cam for the above Toyota F1 engine.

However the neat thing about this conversion which is required to fit the convex tappets is the head needs to be drawn and plotting needs to be determined to keep the same valve spacing (Between the intake and exhaust banks) that was there originally. What will happen is the exhaust will move toward the quench area of the head. The valve seats will get very close to the flat surface of the head like the F1 head. There will be some shrouding at low lifts but we'll see how bad this is during development. From what I am seeing the exhaust will be in the 37 to 38 mm range. Ferrea make a 6 mm stem with 38 mm head valve but is out of stock at present. The intake I think will get further work to maximise its potential. I will aim for 0.75 to 1 mm gap between the intake valves. The valve spacing can be easily altered when we set the guide position. That said the absolute maximum would be 44 mm and the minimum 42.5 mm using stock valve spacing.

Below is the Toyota F1 combustion

What you should know about this chamber is the valves have effectively a double unshrouding courtesy of inward angled valves, so the intake valves move closer together as the lift progresses. That is the reason they start off further apart than my valves will. You can see how far they push the valves towards the cylinder wall. I worked out some time ago, so I am going by memory, this engine has around 36% of intake to bore area and I will be in the 33% range. You can see visually there is a big difference between the heads. So what I will have is about what many OEM race engines have but no where near what a dedicated, clean sheet design would have. I recently spoke to an engineer who I hope will design my cam specification and do the grinding, he was on the team that designed the cam for the above Toyota F1 engine.

#47

Addict

Rennlist Member

Rennlist Member

Thread Starter

Below are the big valves, they are too big, they always were going to be cut down, you can only start big, you can't go the other way. Regardless Even when cut down they will really push up into the chamber. This is to preserve the gap between intake and exhaust valves to avoid clash at the time of overlap. Target flow is 400 cfm.

There is not the same level of problems with the larger exhausts but they will also be moved towards the quench area. Hopefully we will get close to our 300 cfm target.

There is not the same level of problems with the larger exhausts but they will also be moved towards the quench area. Hopefully we will get close to our 300 cfm target.

Last edited by slate blue; 03-22-2014 at 05:01 AM.

#48

Addict

Rennlist Member

Rennlist Member

Thread Starter

This is a Toyota F1 engine with what you can see is the same design throttle bodies. The question that has to be answered is how to do the carbon trumpets. The question being what width, that is stay oval or if the trumpets are crossed over they will need to be round at least. With the 122 mm bore spacing what to do???? Not so difficult or compromised if there is no crossover except the throttle body manufacturer says it is a big no no and it will weaken the pulse.

So here are the top injectors, unlike the F1 these will be situated in the upper part of the trumpets, not outside of them. I think I said before that there was 10 holes but there was in fact 12 holes, I can count, I just can't see!

As I have discussed before, the engine will turn high rpms, this creates a lot of heat, the springs need cooling. Here's the solution. One for each spring, we will build a spray bar and also target the tensioner pads mainly for cooling also.

So here are the top injectors, unlike the F1 these will be situated in the upper part of the trumpets, not outside of them. I think I said before that there was 10 holes but there was in fact 12 holes, I can count, I just can't see!

As I have discussed before, the engine will turn high rpms, this creates a lot of heat, the springs need cooling. Here's the solution. One for each spring, we will build a spray bar and also target the tensioner pads mainly for cooling also.

Last edited by slate blue; 03-22-2014 at 08:55 AM.

#50

Such an awesome project Greg, can't wait to see how it develops. On the tranny subject, why the desire for the 7 speed again? Is it the rev matching feature you're after or something else?

So we're looking at $7k-ish US for the ring and pinion, output shaft and Tremec to Porsche adapter? The only other requirement is a torque tube since the original cradle and axles are being used. I assume you're planning on using the 'vette tube since custom versions are relatively cheap even in carbon fiber. So figure another $1-2k here. Not insane numbers for such a custom conversion. There are people out there that would like a more modern transmission with a usable 6th or even 7th gear, but would like to retain as many Porsche parts as possible. Sort of a "sympathetic swap."

Those throttle bodies look really trick. How much does a set of those run? Do they make a manual version without the drive by wire setup by any chance? Do they sell any oval trumpets/air horns at all for a more typical ITB air box? A oval to round transitioned cross over in carbon fiber inside the air box would be a challenge, but wouldn't be out of line on such a uncompromising build.

The head work you're doing is really bleeding edge stuff, can't get enough of it! No one on this side of the Earth wants to get involved with re engineering the valve spacing/angles and lifter position. You must have one hell of a machinist down there.

I still say you don’t need variocam to tame the camshaft. Displacement tames big cams as well as compression and ITB intakes more than anything else really calms them down. But all of that with variocam will make that monster idle like a Cadillac.

Those sprayers will definitely keep the springs cool. Glad you're going with a dry sump. How many stages will be devoted to the heads?

So we're looking at $7k-ish US for the ring and pinion, output shaft and Tremec to Porsche adapter? The only other requirement is a torque tube since the original cradle and axles are being used. I assume you're planning on using the 'vette tube since custom versions are relatively cheap even in carbon fiber. So figure another $1-2k here. Not insane numbers for such a custom conversion. There are people out there that would like a more modern transmission with a usable 6th or even 7th gear, but would like to retain as many Porsche parts as possible. Sort of a "sympathetic swap."

Those throttle bodies look really trick. How much does a set of those run? Do they make a manual version without the drive by wire setup by any chance? Do they sell any oval trumpets/air horns at all for a more typical ITB air box? A oval to round transitioned cross over in carbon fiber inside the air box would be a challenge, but wouldn't be out of line on such a uncompromising build.

The head work you're doing is really bleeding edge stuff, can't get enough of it! No one on this side of the Earth wants to get involved with re engineering the valve spacing/angles and lifter position. You must have one hell of a machinist down there.

I still say you don’t need variocam to tame the camshaft. Displacement tames big cams as well as compression and ITB intakes more than anything else really calms them down. But all of that with variocam will make that monster idle like a Cadillac.

Those sprayers will definitely keep the springs cool. Glad you're going with a dry sump. How many stages will be devoted to the heads?

#51

Addict

Rennlist Member

Rennlist Member

Thread Starter

Such an awesome project Greg, can't wait to see how it develops. On the tranny subject, why the desire for the 7 speed again? Is it the rev matching feature you're after or something else?

So we're looking at $7k-ish US for the ring and pinion, output shaft and Tremec to Porsche adapter? The only other requirement is a torque tube since the original cradle and axles are being used. I assume you're planning on using the 'vette tube since custom versions are relatively cheap even in carbon fiber. So figure another $1-2k here. Not insane numbers for such a custom conversion. There are people out there that would like a more modern transmission with a usable 6th or even 7th gear, but would like to retain as many Porsche parts as possible. Sort of a "sympathetic swap."

Those throttle bodies look really trick. How much does a set of those run? Do they make a manual version without the drive by wire setup by any chance? Do they sell any oval trumpets/air horns at all for a more typical ITB air box? A oval to round transitioned cross over in carbon fiber inside the air box would be a challenge, but wouldn't be out of line on such a uncompromising build.

The head work you're doing is really bleeding edge stuff, can't get enough of it! No one on this side of the Earth wants to get involved with re engineering the valve spacing/angles and lifter position. You must have one hell of a machinist down there.

I still say you donĺt need variocam to tame the camshaft. Displacement tames big cams as well as compression and ITB intakes more than anything else really calms them down. But all of that with variocam will make that monster idle like a Cadillac.

Those sprayers will definitely keep the springs cool. Glad you're going with a dry sump. How many stages will be devoted to the heads?

So we're looking at $7k-ish US for the ring and pinion, output shaft and Tremec to Porsche adapter? The only other requirement is a torque tube since the original cradle and axles are being used. I assume you're planning on using the 'vette tube since custom versions are relatively cheap even in carbon fiber. So figure another $1-2k here. Not insane numbers for such a custom conversion. There are people out there that would like a more modern transmission with a usable 6th or even 7th gear, but would like to retain as many Porsche parts as possible. Sort of a "sympathetic swap."

Those throttle bodies look really trick. How much does a set of those run? Do they make a manual version without the drive by wire setup by any chance? Do they sell any oval trumpets/air horns at all for a more typical ITB air box? A oval to round transitioned cross over in carbon fiber inside the air box would be a challenge, but wouldn't be out of line on such a uncompromising build.

The head work you're doing is really bleeding edge stuff, can't get enough of it! No one on this side of the Earth wants to get involved with re engineering the valve spacing/angles and lifter position. You must have one hell of a machinist down there.

I still say you donĺt need variocam to tame the camshaft. Displacement tames big cams as well as compression and ITB intakes more than anything else really calms them down. But all of that with variocam will make that monster idle like a Cadillac.

Those sprayers will definitely keep the springs cool. Glad you're going with a dry sump. How many stages will be devoted to the heads?

You are right on the prices but these are estimates and I need to get them made and then firm prices will follow. I am just mentioning the prices just in case people are interested. So I am seeking expressions of interest not orders.

Yes Corvette tube and maybe some of the other guys doing conversions can supply the clutch, flywheel etc, I will be using my Tilton carbon clutch and carbon driveshaft. So I wont be making those parts available. You are right it is a sympathetic swap.

The throttles can be used manually or with the actuators, the cost is just for throttles and linkages is $4K, you still need to make adaptor plates which house the vacuum ports for the brakes and the fuel injectors. The ram tubes are not included as owners need to make a decision on whether they run the full length or the short length. They said with curved trumpets, you are better off with custom carbon ones. The quote I got was around $200 AUD each with the port for the upper injector. That price was the max it would be, might be cheaper but need to add the mold cost too. I am using factory injector rails as I see nothing wrong with them in my application. They wont be able to make fuel rails that have the 928 characteristics, I am using their rail for the upper injectors.

The machinist is keen, he makes billet engines for a living, seemed pretty relaxed about it all. He spent 20 years making parts for Supercars, so I guess it is just another project.

The variocam is their to ensure the easy drivability, I think the actual tensioner should cost around $2K. I propose to make it in alloy and sleeve the main chamber where the ports will be reversed. The cost of the cams will not be affected by the variocam. So it a relatively small price to pay.

The cams will be bigger than anything seen in a 928 engine, this could change the drivability because if you have heard a V8 Supercar idle it doesn't idle so well. As I mentioned the Porsche Cup cars with a non ITB setup idle between 1,600 and 2,000 rpm, so that is a big call to knock that down to 850 to 1,000 rpm where I would like it to be. With regards to duration we are probably looking at a cam with 270 degrees of duration at 0.050" on the intake and 260 degrees on the exhaust.

The dry sump will most likely have 4 vacuum stages and the one pressure stage. It will also have the oil separator. It is hard to fit that all in. I am battling against time to get all the parts to the machinist before I go away. There will be no direct head scavenging, it will have 4 bay scavenging, the oil in the heads will simply be sucked down to the vacuum ports but away from the rotating assembly.

#52

Anyone with a detailed mind has these big dreams, I know I do. It will be very cool to see how you assemble all of these sparkling pieces of aluminum, inconel, and stainless.

You have to respect the idea of doing all of thi$ instead of buying a new 100k car.

You have to respect the idea of doing all of thi$ instead of buying a new 100k car.

#53

Addict

Rennlist Member

Rennlist Member

Thread Starter

Lot's of things happening, I bought a new race and street wheel, this racing wheel is a beauty and I really think it suits the 928. It has the flat top that matches with the flat top of the pod. Also the flat bottom gives extra room at the bottom.

The other great thing about the Sparco is that the space available in the centre of the of the wheel perfectly suits the use of the Motec C125 mini dashboard and it will fit perfectly. The car btw is getting a black interior so that will change in time.

Below is the new line of Motec ECUs and they are a big step forward. The reason I didn't go motec on the other car and used the OBR EFI ECU was because it was simply out of date. The new Motec M series ECUs allows you to write the firmware, this will be very useful in this car due to the strategies that will be employed.

The other great thing about the Sparco is that the space available in the centre of the of the wheel perfectly suits the use of the Motec C125 mini dashboard and it will fit perfectly. The car btw is getting a black interior so that will change in time.

Below is the new line of Motec ECUs and they are a big step forward. The reason I didn't go motec on the other car and used the OBR EFI ECU was because it was simply out of date. The new Motec M series ECUs allows you to write the firmware, this will be very useful in this car due to the strategies that will be employed.

#54

Addict

Rennlist Member

Rennlist Member

Thread Starter

Nothing but flat out over this part of the world, however some major dramas in the details. The first problem which effects the whole project is that the trans supplier has advised me in no uncertain terms that the TR 6060 or 6070 for that matter will not change gear at high RPMs. The fellow who I was dealing with went on holidays and his partner asked about the project. The short of the long is that he said don't do it!

I did advise that the clutch is carbon and so is the driveshaft, he said the Honda's using the T56 gearbox have trouble with high RPMs. He said you need to convert the Vette box to the PPG gearsets. PPG is made here but costs between 10 to 16K depending on H or sequential pattern. In all honesty I can't drive a dog box on the street, that would be a chore and ruin the experience.

The PPG gearsets are btw helical so they are not noisy and then I thought well if I go with that, there is no noise but you really then need paddle shift so you don't need to bang through the gears. However that is another $15K and how will it drive around town? So that gearbox conversion is now running at $60K, to me that is just absurd. Doesn't matter how much you have that is just throwing it away and getting a very little in return.

So fortunately the crank has not been ordered, the only option I can see unless one of you guys has an idea is to increase the stroke of the crank and decrease the RPMs and change the diff ratio again not ordered yet. Something I didn't want to do but we all live with compromises. I am looking into whether the guys that are having trouble do or don't have lightened drivelines and whether they have the ability to run "flatshift" options in their engine management systems. There is a number a options when it comes to flat shifting, such as strain gauges, micro switches in the gear selector, even basic open loop ignition cuts. I am going to look into the extent of the problem with the T56 style boxes, I think the problem comes with the fact that the engineers have increased the width of the gears for torque at the expense of the syncro rings.

So shorter rod but not as advanced in design as the later rods and I don't want to cough up the $1,000 bucks a rod for the later design, however it does have the big piston pin (22 mm) that the piston maker wanted.

The shorter rod has more material in it as it weighs the same as the longer 6.2" rod, so I suppose that is a positive for longevity and the 6" rod has DLC on the piston guided area of the wrist pin eye and has bearing 48 mm in diameter and a length of 20.116 mm with EDM hole.

So the increased stroke increases the loadings on the bottom end, something I didn't want to do, the engine will still be able to go to 8,200 on occasions but generally 500 rpms below that, no need to go to the limit all the time, I really wanted to limit the mass forces but these are light parts. The thing with less rpms, it means less duration on the cam and less duration on the cam can mean less ability to run the max lift I was aiming at. However less duration will increase the streetability of the engine, I suppose that is looking on the bright side. A fair bit of money has been somewhat wasted on the convex tappet conversion giving the RPMs have to be bought back. I say somewhat wasted because the ultra light weight parts are not absolutely needed now. I will still get the advantage of the convex tappets due to fast acceleration ability of the tappets.

A fair bit of money has been somewhat wasted on the convex tappet conversion giving the RPMs have to be bought back. I say somewhat wasted because the ultra light weight parts are not absolutely needed now. I will still get the advantage of the convex tappets due to fast acceleration ability of the tappets.

So peak power will most likely be down due to the cam and the fact that higher VEs are possible with higher RPMs. Remember F1 engines used to do around 145% VE. I am aiming at 115% obviously at a much lower RPM. That wont be easy with a reduction 750 to 1,000 rpm. The other factor you need to consider is that I have more cubic inches to fill with the same valve area.

All the exhaust material has been ordered, the sizing is correct, for the record the headers are 2 1/8" 0.9 mm thick then stepping to 2 1/4" 0.7mm thick going into the secondaries it is 2 1/2" again 0.7 mm and then duel 3 1/2" all the way through. The debate has been over what thickness to run the next section of the exhaust, I am not using inconel any further than the headers, the rest is 321 and the mufflers are 304 from Burns Stainless. You can't buy lightweight mufflers in 321. I have selected 0.7 mm for the rear section of the exhaust, the H pipe material hasn't been ordered but I am thinking 0.9 mm 321. The car will run at least 6 mufflers maybe seven in street mode depending on how noisy it is.

For those who are wondering what the big deal is with the thickness is, I estimated that if you didn't try to save weight and just built a 3 1/2" system in standard thickness stainless you would end up with a weight around 65 to 70 kgs. I am hoping we will be in the 25 to 30 kgs range and given the size of these pipes that is pretty good.

The other issue I have been grappling with is the Hi/Lo injector set up, again not so important now, again........

however V8 Supercars run High injectors with their 7,500 limit so I suppose their is still some benefit, my machinist who worked for years in this field said regarding the valley tray which will support the throttle actuators and the Hi injectors, it is better done in alloy and then do the top cover in carbon. This will save some money as the quote in carbon with the trumpets is $10K. Doing the lower section in alloy costs around $2K so that is cheaper and probably more durable i.e ability to support loads.

however V8 Supercars run High injectors with their 7,500 limit so I suppose their is still some benefit, my machinist who worked for years in this field said regarding the valley tray which will support the throttle actuators and the Hi injectors, it is better done in alloy and then do the top cover in carbon. This will save some money as the quote in carbon with the trumpets is $10K. Doing the lower section in alloy costs around $2K so that is cheaper and probably more durable i.e ability to support loads.

The advice the machinist gave me and he makes a lot of highly strung engines, was to use these injectors, he says they really help idle quality and are generally better everywhere else too, this is the cheapest I can find them, you need to double the list price as that is for 4.

http://www.ebay.com/itm/380856481200...84.m1423.l2649

Saving money is important as there is many areas that are popping up, the guards have been welded up, that was a challenge but they have lots of curves, the bonnet is basically flat and will distort when seem welded. You could spot weld with epoxy but if I can afford it I will use that spot welded with epoxy bonnet as the mould or buck for a carbon version. That way I don't have to worry about a crack developing due to vibration and heat.

Same goes for the roof panel, which will be a carbon kevlar composite, I hope to integrate a roll cage into various cavities of the 928, exposed cages apparently aren't allowed in street driven cars here.

So back to the fundamental change to make this project work, the reduction of the revs and the lengthening of the stroke. The stroke I am thinking about is 96 mm. The crank would be made by Winberg's but they will only make 3 at a time.

http://winbergcrankshafts.com/

http://winbergcrankshafts.com/index.php/technology/

http://winbergcrankshafts.com/index....-micro-polish/

The price would be approx $5K without superfinish add another $750 for that, well worth it for the reduction of friction. The crank they would make is basically a pro-stock big block crankshaft. While my crank will be specced with smaller mains to use different main bearings, others don't have to follow this route and my other crank would just be standard bearing crankshaft. The crank will be what I believe to be the first stroker crank with standard Porsche rod journal widths. The Porsche width journals will help to reduce weight, you can see how the cranks in the links have their weight pared. If anybody is interested in one of these cranks I think you would need to allow $6K to be safe.

I did advise that the clutch is carbon and so is the driveshaft, he said the Honda's using the T56 gearbox have trouble with high RPMs. He said you need to convert the Vette box to the PPG gearsets. PPG is made here but costs between 10 to 16K depending on H or sequential pattern. In all honesty I can't drive a dog box on the street, that would be a chore and ruin the experience.

The PPG gearsets are btw helical so they are not noisy and then I thought well if I go with that, there is no noise but you really then need paddle shift so you don't need to bang through the gears. However that is another $15K and how will it drive around town? So that gearbox conversion is now running at $60K, to me that is just absurd. Doesn't matter how much you have that is just throwing it away and getting a very little in return.

So fortunately the crank has not been ordered, the only option I can see unless one of you guys has an idea is to increase the stroke of the crank and decrease the RPMs and change the diff ratio again not ordered yet. Something I didn't want to do but we all live with compromises. I am looking into whether the guys that are having trouble do or don't have lightened drivelines and whether they have the ability to run "flatshift" options in their engine management systems. There is a number a options when it comes to flat shifting, such as strain gauges, micro switches in the gear selector, even basic open loop ignition cuts. I am going to look into the extent of the problem with the T56 style boxes, I think the problem comes with the fact that the engineers have increased the width of the gears for torque at the expense of the syncro rings.

So shorter rod but not as advanced in design as the later rods and I don't want to cough up the $1,000 bucks a rod for the later design, however it does have the big piston pin (22 mm) that the piston maker wanted.

The shorter rod has more material in it as it weighs the same as the longer 6.2" rod, so I suppose that is a positive for longevity and the 6" rod has DLC on the piston guided area of the wrist pin eye and has bearing 48 mm in diameter and a length of 20.116 mm with EDM hole.

So the increased stroke increases the loadings on the bottom end, something I didn't want to do, the engine will still be able to go to 8,200 on occasions but generally 500 rpms below that, no need to go to the limit all the time, I really wanted to limit the mass forces but these are light parts. The thing with less rpms, it means less duration on the cam and less duration on the cam can mean less ability to run the max lift I was aiming at. However less duration will increase the streetability of the engine, I suppose that is looking on the bright side.

A fair bit of money has been somewhat wasted on the convex tappet conversion giving the RPMs have to be bought back. I say somewhat wasted because the ultra light weight parts are not absolutely needed now. I will still get the advantage of the convex tappets due to fast acceleration ability of the tappets.

A fair bit of money has been somewhat wasted on the convex tappet conversion giving the RPMs have to be bought back. I say somewhat wasted because the ultra light weight parts are not absolutely needed now. I will still get the advantage of the convex tappets due to fast acceleration ability of the tappets.So peak power will most likely be down due to the cam and the fact that higher VEs are possible with higher RPMs. Remember F1 engines used to do around 145% VE. I am aiming at 115% obviously at a much lower RPM. That wont be easy with a reduction 750 to 1,000 rpm. The other factor you need to consider is that I have more cubic inches to fill with the same valve area.

All the exhaust material has been ordered, the sizing is correct, for the record the headers are 2 1/8" 0.9 mm thick then stepping to 2 1/4" 0.7mm thick going into the secondaries it is 2 1/2" again 0.7 mm and then duel 3 1/2" all the way through. The debate has been over what thickness to run the next section of the exhaust, I am not using inconel any further than the headers, the rest is 321 and the mufflers are 304 from Burns Stainless. You can't buy lightweight mufflers in 321. I have selected 0.7 mm for the rear section of the exhaust, the H pipe material hasn't been ordered but I am thinking 0.9 mm 321. The car will run at least 6 mufflers maybe seven in street mode depending on how noisy it is.

For those who are wondering what the big deal is with the thickness is, I estimated that if you didn't try to save weight and just built a 3 1/2" system in standard thickness stainless you would end up with a weight around 65 to 70 kgs. I am hoping we will be in the 25 to 30 kgs range and given the size of these pipes that is pretty good.

The other issue I have been grappling with is the Hi/Lo injector set up, again not so important now, again........

however V8 Supercars run High injectors with their 7,500 limit so I suppose their is still some benefit, my machinist who worked for years in this field said regarding the valley tray which will support the throttle actuators and the Hi injectors, it is better done in alloy and then do the top cover in carbon. This will save some money as the quote in carbon with the trumpets is $10K. Doing the lower section in alloy costs around $2K so that is cheaper and probably more durable i.e ability to support loads.

however V8 Supercars run High injectors with their 7,500 limit so I suppose their is still some benefit, my machinist who worked for years in this field said regarding the valley tray which will support the throttle actuators and the Hi injectors, it is better done in alloy and then do the top cover in carbon. This will save some money as the quote in carbon with the trumpets is $10K. Doing the lower section in alloy costs around $2K so that is cheaper and probably more durable i.e ability to support loads. The advice the machinist gave me and he makes a lot of highly strung engines, was to use these injectors, he says they really help idle quality and are generally better everywhere else too, this is the cheapest I can find them, you need to double the list price as that is for 4.

http://www.ebay.com/itm/380856481200...84.m1423.l2649

Saving money is important as there is many areas that are popping up, the guards have been welded up, that was a challenge but they have lots of curves, the bonnet is basically flat and will distort when seem welded. You could spot weld with epoxy but if I can afford it I will use that spot welded with epoxy bonnet as the mould or buck for a carbon version. That way I don't have to worry about a crack developing due to vibration and heat.

Same goes for the roof panel, which will be a carbon kevlar composite, I hope to integrate a roll cage into various cavities of the 928, exposed cages apparently aren't allowed in street driven cars here.

So back to the fundamental change to make this project work, the reduction of the revs and the lengthening of the stroke. The stroke I am thinking about is 96 mm. The crank would be made by Winberg's but they will only make 3 at a time.

http://winbergcrankshafts.com/

http://winbergcrankshafts.com/index.php/technology/

http://winbergcrankshafts.com/index....-micro-polish/

The price would be approx $5K without superfinish add another $750 for that, well worth it for the reduction of friction. The crank they would make is basically a pro-stock big block crankshaft. While my crank will be specced with smaller mains to use different main bearings, others don't have to follow this route and my other crank would just be standard bearing crankshaft. The crank will be what I believe to be the first stroker crank with standard Porsche rod journal widths. The Porsche width journals will help to reduce weight, you can see how the cranks in the links have their weight pared. If anybody is interested in one of these cranks I think you would need to allow $6K to be safe.

#55

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,235

Received 467 Likes

on

250 Posts

Greg, with the valves you have 43,75/37mm, bore 108mm, stroke 96mm, the engine probably will have it┤s peak at 8000 rpm. I would design the valve train for a safe 8500 rpm redline. Remember Mike Simard┤s engine did peak at 7500 rpm having much smaller 40mm intake valves. Mike┤s cams had a lift of 12,7mm and a duration of about 250 degrees at .050". For your radiused lifters I think you can increase the lift up to about 14mm with the same or slightly more duration.

┼ke

┼ke

#56

All of the Tremec transmissions have a hard time shifting above 7k rpms with the extra mass of a torque tube setup. These trannys were designed to handle the torque of Vipers, ZR1's, GT500's etc, none of which exceed 7k. I have heard of high rpm, destroked LS7 setups shifting at 8k+ utilizing a carbon clutch and carbon fiber torque tube and triple synchros with good results. But, these were drag cars not road race but it's what I'm going to try. Carbon fiber torque tube and synchros are very cheap when compared to custom gear sets.

I might have went in with you on the crank shaft but Moldex finished my 94mm crank a little over a week ago. We're moving forward with 109mm Nikasil coated aluminum wet sleeves and 6.098" Ti rods, CP pistons with roughly 13.5:1 compression, S2 heads with 41/34mm Ferrea valves. Camshafts will be very similar to Mike's original build.

I'm wide open on injectors, the only thing set is I plan on using only 8, which ones are you considering? The link above went to the crank builder.

I might have went in with you on the crank shaft but Moldex finished my 94mm crank a little over a week ago. We're moving forward with 109mm Nikasil coated aluminum wet sleeves and 6.098" Ti rods, CP pistons with roughly 13.5:1 compression, S2 heads with 41/34mm Ferrea valves. Camshafts will be very similar to Mike's original build.

I'm wide open on injectors, the only thing set is I plan on using only 8, which ones are you considering? The link above went to the crank builder.

#57

Addict

Rennlist Member

Rennlist Member

Thread Starter

Greg, with the valves you have 43,75/37mm, bore 108mm, stroke 96mm, the engine probably will have it┤s peak at 8000 rpm. I would design the valve train for a safe 8500 rpm redline. Remember Mike Simard┤s engine did peak at 7500 rpm having much smaller 40mm intake valves. Mike┤s cams had a lift of 12,7mm and a duration of about 250 degrees at .050". For your radiused lifters I think you can increase the lift up to about 14mm with the same or slightly more duration.

┼ke

┼ke

In the end this change may end up doing me a favour, not the way I am looking at it at present but if the change meant the cam was 260 degrees at 0.050" and we know that Mike's engine purrs like a kitten and has good low speed behaviour, mine with the bigger cam and Variocam should come back to be about the same in terms of low speed behaviour which is important on the street.

#58

Addict

Rennlist Member

Rennlist Member

Thread Starter

All of the Tremec transmissions have a hard time shifting above 7k rpms with the extra mass of a torque tube setup. These trannys were designed to handle the torque of Vipers, ZR1's, GT500's etc, none of which exceed 7k. I have heard of high rpm, destroked LS7 setups shifting at 8k+ utilizing a carbon clutch and carbon fiber torque tube and triple synchros with good results. But, these were drag cars not road race but it's what I'm going to try. Carbon fiber torque tube and synchros are very cheap when compared to custom gear sets.

I might have went in with you on the crank shaft but Moldex finished my 94mm crank a little over a week ago. We're moving forward with 109mm Nikasil coated aluminum wet sleeves and 6.098" Ti rods, CP pistons with roughly 13.5:1 compression, S2 heads with 41/34mm Ferrea valves. Camshafts will be very similar to Mike's original build.

I'm wide open on injectors, the only thing set is I plan on using only 8, which ones are you considering? The link above went to the crank builder.

I might have went in with you on the crank shaft but Moldex finished my 94mm crank a little over a week ago. We're moving forward with 109mm Nikasil coated aluminum wet sleeves and 6.098" Ti rods, CP pistons with roughly 13.5:1 compression, S2 heads with 41/34mm Ferrea valves. Camshafts will be very similar to Mike's original build.

I'm wide open on injectors, the only thing set is I plan on using only 8, which ones are you considering? The link above went to the crank builder.

Hey Texas Dude, have a look at my post again, you will find the ebay link there and then look up injector dynamics for a good read.

I agree with you about having a go with the carbon tube and lightweight clutch, I think if you employed a flat shift ECU strategy it may also help. I will be looking at that closely. I am waiting on some measurements from the trans place regarding tube lengths etc as I don't know at this point whether the 7 speed is in or out due to length issues. Now that I must shift lower I must wait for the higher torque version coming out in the Z06 or use the TR 6060. Incidentally as the TR 6060 doesn't have a speed sensor on the output shaft like the TR 6070 for gear matching, we could use the speedo sensor in the back diff housing as the output speed with an allowance for the ratio. That would seem an easy way to achieve that.

Yes regarding the crank I may start a thread for anybody interested in purchasing such a crank to make up the volume required or I will go with Moldex myself. Now that the crank wont spin so fast again the weight reduction is not so important although it will be spinning further from its axis. My cranks as you know are specced to the Honda journals or 48 mm vs the Porsche at 52 mm. You would be able to use piston guided rods or custom crank guided rods. Winberg's make an awesome crank. Incidentally I am looking at the Mercedes SLS main bearings as candidates for use. That engine I believe red lines at 8,000 which is not far from where I will be.

The other area I am pissed about now is the valves, while I haven't forked out for the Ti valves yet I have bought the valves seats, they were obscenely expensive and anybody who knows me knows that I hate tearing up money, so I will probably stick with the Ti valves on the intakes and I suppose try to get a benefit from valve acceleration and low friction due to low spring pressures.

Regarding your sleeves love to see some pics, mine will be actually 4.25" as there is plenty of rings to choose from, are you using Total Seal? If so are you using their gapless rings? That is what I am going with. What is your actual bore size? Is it 109 mm or like mine really an imperial size that is very close? Mike warned me about ring selection on these larger bore motors. I would rather use 109 mm myself and go down in the stroke and have about the same as you. I suppose it is all about compromises!

You will certainly have a lot of comp, are you running on a race fuel or is the cam super big? I thought I would go with 13 to 1 when we had the high rpm limit but the smaller cam will probably cause a reduction, maybe 12.7 or something like that.

#59

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,235

Received 467 Likes

on

250 Posts

Greg, Mike Simard always said his car "drives like a lamb", meaning very good street behaviour. Do not think increasing the camshaft duration to 260 degrees @ .050" will make much of a difference so expect good streetability if the tuning is properly done.

Mike┤s own words: This engine is too good for a race car and deserves a nice 928 chassis that can be enjoyed on roads, in traffic or track days. The 427 cu in displacement, ITBs and 32 valves make for a rare treat of nice street manners but the ability to make huge power and not be stressed.

It will be happy in traffic on a hot day and on 93 octane.

Because of the lightweight reciprocating mass and flywheel, it can free rev at 18,000 rpm/sec.

I have faith in it going cross country right now. It has never run hot, even on hot August days racing with a stock radiator.

┼ke

Mike┤s own words: This engine is too good for a race car and deserves a nice 928 chassis that can be enjoyed on roads, in traffic or track days. The 427 cu in displacement, ITBs and 32 valves make for a rare treat of nice street manners but the ability to make huge power and not be stressed.

It will be happy in traffic on a hot day and on 93 octane.

Because of the lightweight reciprocating mass and flywheel, it can free rev at 18,000 rpm/sec.

I have faith in it going cross country right now. It has never run hot, even on hot August days racing with a stock radiator.

┼ke

#60

Addict

Rennlist Member

Rennlist Member

Thread Starter

Interestingly Ake I was speaking to the machinist today and telling him about the high RPM shifting issues and how I would have to go to a dog box or reduce the RPMs. he said straight away, don't go down the dog box route, he said you will never drive the car if you do that. He said he had driven a number of V8 style racing sedans from very winning teams btw and he said "they drive so bad at low speed you would think something is wrong or broken" He said you are now just dealing with reality. John Gill who will do the tuning, said, well you are pioneering this approach expect these set backs, it is a slippery slope. Yep I can't say I ever thought it was going to be easy and again while in conversation with the machinist, "you are doing the right thing regarding the changes" i.e the intake plenum and reduction in RPMs. "On a project like this you need to save where you can because on a project like this, there is going to be areas where you have trouble and haven't budgeted for." He did again reinforce the use of the injector dynamics injectors.

I can't say I ever thought it was going to be easy and again while in conversation with the machinist, "you are doing the right thing regarding the changes" i.e the intake plenum and reduction in RPMs. "On a project like this you need to save where you can because on a project like this, there is going to be areas where you have trouble and haven't budgeted for." He did again reinforce the use of the injector dynamics injectors.

I did some further investigation via Pipemax, to achieve a 115% volumetric efficiency at 8,000 we need a flow with the manifold, intake system connected of between 378 to 400 cfm. I think that is the maximum possible. The machinist backed up what David Vizard had said about K&N air filters, that they have low restriction and I think you also said two of these 928 filters would be adequate to support the engine.

To get to 110% you need nett 357 to 378 cfm, that 5% drop in efficiency makes a 50 hp difference. However 110% VE still delivers an impressive HP. I still think that the redline of 8250 is the absolute max and a RPM of 8,500 exceeds pistons speeds in Nascar. At 8250 it is equivalent to the loads placed on a Nascar engine at 9750 RPM assuming the piston weight is about the same. It hopefully wont be quite as heavy, Mike stated his pistons were 369 grams bare. Nascar has a min weight of 400 grams. So I don't know where mine will end up but somewhere in that range.

I did some further investigation via Pipemax, to achieve a 115% volumetric efficiency at 8,000 we need a flow with the manifold, intake system connected of between 378 to 400 cfm. I think that is the maximum possible. The machinist backed up what David Vizard had said about K&N air filters, that they have low restriction and I think you also said two of these 928 filters would be adequate to support the engine.

To get to 110% you need nett 357 to 378 cfm, that 5% drop in efficiency makes a 50 hp difference. However 110% VE still delivers an impressive HP. I still think that the redline of 8250 is the absolute max and a RPM of 8,500 exceeds pistons speeds in Nascar. At 8250 it is equivalent to the loads placed on a Nascar engine at 9750 RPM assuming the piston weight is about the same. It hopefully wont be quite as heavy, Mike stated his pistons were 369 grams bare. Nascar has a min weight of 400 grams. So I don't know where mine will end up but somewhere in that range.

Greg, Mike Simard always said his car "drives like a lamb", meaning very good street behaviour. Do not think increasing the camshaft duration to 260 degrees @ .050" will make much of a difference so expect good streetability if the tuning is properly done.

Mike┤s own words: This engine is too good for a race car and deserves a nice 928 chassis that can be enjoyed on roads, in traffic or track days. The 427 cu in displacement, ITBs and 32 valves make for a rare treat of nice street manners but the ability to make huge power and not be stressed.

It will be happy in traffic on a hot day and on 93 octane.

Because of the lightweight reciprocating mass and flywheel, it can free rev at 18,000 rpm/sec.

I have faith in it going cross country right now. It has never run hot, even on hot August days racing with a stock radiator.

┼ke

Mike┤s own words: This engine is too good for a race car and deserves a nice 928 chassis that can be enjoyed on roads, in traffic or track days. The 427 cu in displacement, ITBs and 32 valves make for a rare treat of nice street manners but the ability to make huge power and not be stressed.

It will be happy in traffic on a hot day and on 93 octane.

Because of the lightweight reciprocating mass and flywheel, it can free rev at 18,000 rpm/sec.

I have faith in it going cross country right now. It has never run hot, even on hot August days racing with a stock radiator.

┼ke