S4 intake manifold facts and ideas

#46

Ken:

I recall the "bad" runners were 8-10 percent less flow, but the larger issue was what happens to flow velocity on the insides of the double tight bends.

Glad you find this interesting.

I recall the "bad" runners were 8-10 percent less flow, but the larger issue was what happens to flow velocity on the insides of the double tight bends.

Glad you find this interesting.

#47

Rennlist Member

Tuomo, the S3 only makes less power as stock compared to the S4 because of the extremely conservative ignition timing. You need to compare Ken's tuned version to a stock S4.

#48

Nordschleife Master

Thread Starter

Sure the greater margin of safety in the knock sensorless (is that even a word) S3 explains some of it, but it's still the case that S3 has bigger cams and if the S3 intake would be better at high rpms than the S4 intake then S3 should probably make more power in the top end than S4 given equally aggressive tune. It's my impression that it doesn't. Even Ken has seen the light and bought an S4! ;-)

#49

The S3 cams are also retarded 6 degrees by default. The timing must be set to very conservative to hide all the benefits compared to S4. At low lift it's the intake valve which defines the velocity, at high lift it should be the narrowest point of port, which is usually before valve guide in 4V heads. With smaller valves the S3 may also generate slightly better inertia effect, giving better throttle response at least.. Large valves and slow port velocity = low torque, bad throttle response, weak intertia effect, etc. The port velocity is pitful slow on both engines.

Things aren't still that easy, putting together all of the known pieces the real results may still be something else than expected..

If you look some of the WRC intake plenums, you'll find that the air input to plenum is below the bell mouth entry level. For some reason the air would like to flow inside to bellmouth laterally from the side of entry, rather than vertically from front of it. Therefore it's essential to make the diameter of bellmouth entry as little as possible. Also, the bellmouth edge should be smooth and it should allow the air to pass it while flowing from behind to front of bellmouth.

This will also give the best velocity profile for runner entry. You can see many CFD pictures about this in internet.

Not very well explained, hopefully you guys get the idea..

Just some random thoughts, related or not...

Things aren't still that easy, putting together all of the known pieces the real results may still be something else than expected..

If you look some of the WRC intake plenums, you'll find that the air input to plenum is below the bell mouth entry level. For some reason the air would like to flow inside to bellmouth laterally from the side of entry, rather than vertically from front of it. Therefore it's essential to make the diameter of bellmouth entry as little as possible. Also, the bellmouth edge should be smooth and it should allow the air to pass it while flowing from behind to front of bellmouth.

This will also give the best velocity profile for runner entry. You can see many CFD pictures about this in internet.

Not very well explained, hopefully you guys get the idea..

Just some random thoughts, related or not...

#51

Inventor

Rennlist Member

Rennlist Member

Center T to plenum ID: 73mm

Gasket opening ID: 46 x 52 (49)

Approx. length of runner, bellmouth to head: 400mm

IIRC, head to valve was said to be 95mm.

I would guess that the target was 500mm, bellmouth to intake valve?

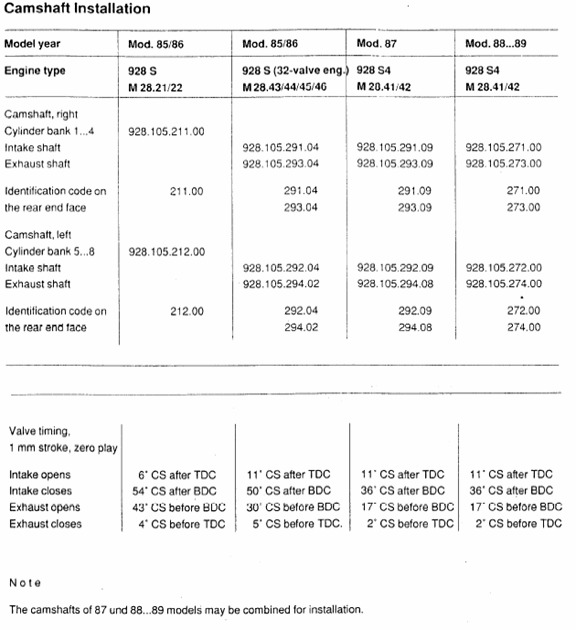

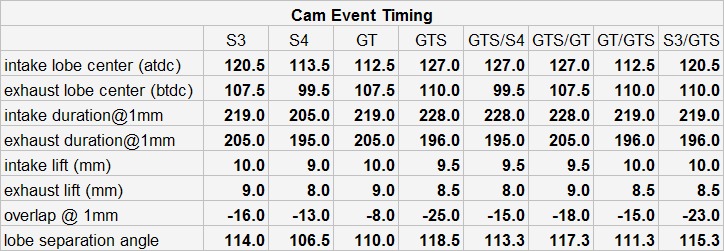

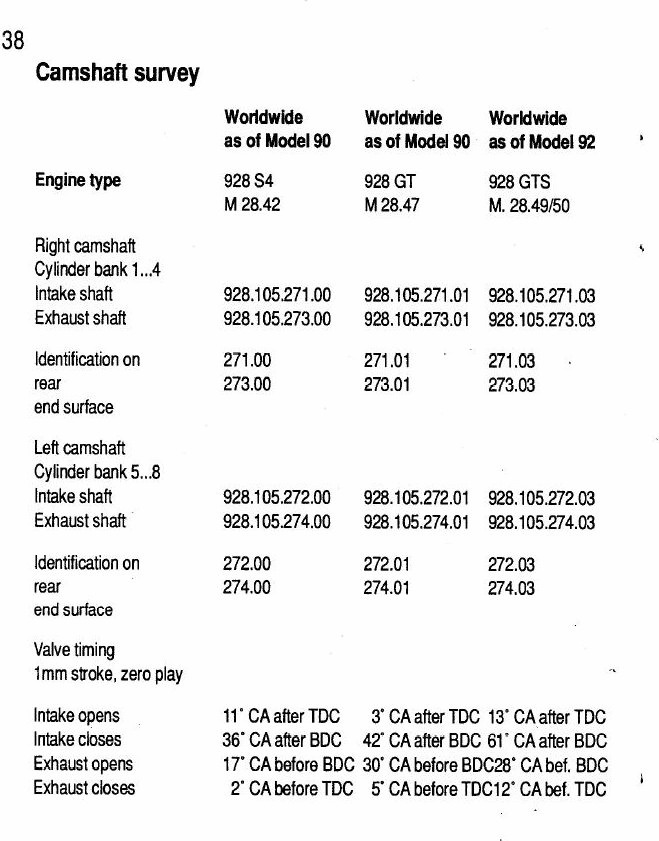

GT intake cams are advanced 8░ vs. S3.

AFAIK, the GT tighter 110 LSA makes them peakier than the S3 114.

S4 intake valves close 14░ before the S3, with a really tight 106 LSA.

From the (disappointing) results I'm getting trying to tune the S4 EZ, I think the S4 cams could be too advanced.

I'm going to try some retard to see if it will breathe a little better up top, and allow for more ignition advance down low.

Hopefully, the itty-bitty duration of the S4 cams will keep the dynamic compression high when retarded.

S3 cams don't like much if any retard - they lose power, everywhere.

Last edited by PorKen; 05-15-2013 at 06:12 PM.

#52

Inventor

Rennlist Member

Rennlist Member

As far as my limited understanding of cams goes, I would postulate that a narrower LSA was chosen for a sharp late torque peak at ~4200, using the variable intake manifold to make a new peak at ~3200.

On paper, a 106 LSA means a higher knock potential, and TQ will drop quickly after the peak vs. a wider LSA.

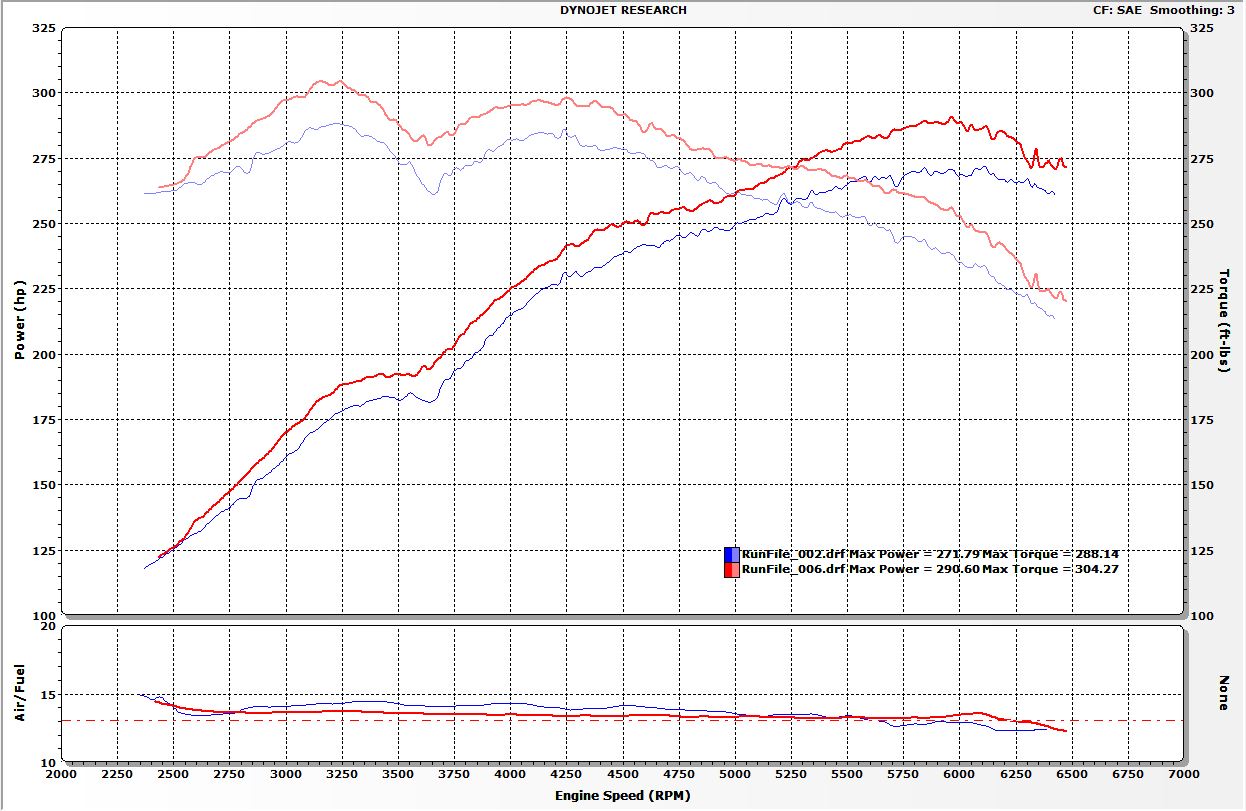

I'm having a difficult time staying knock free, even with ideal fueling, and the early 88's lower static compression, and I can't seem to get much over 290 whp.

On paper, a 106 LSA means a higher knock potential, and TQ will drop quickly after the peak vs. a wider LSA.

I'm having a difficult time staying knock free, even with ideal fueling, and the early 88's lower static compression, and I can't seem to get much over 290 whp.

#53

Louie Ott also found some 8-10 HP by reshaping the bottom of the stock air filter box, to more of a bellmouth shape like the earlier cars. the 90 degree air turn on the bottom of the S4 and later air filter boxes are especially damaging to clean air flow. This may be why some of the 928'sRUS AIS systme flows so much better than stock....

#54

Rennlist Member

If that were true, then the S4 cams (106 LSA) would be "peakier" than GT (LSA=110), but that's not the case. And Devek B2 and S4 cams are both LSA=106, and they are poles apart.

I don't think it is possible to make sense of LSA without also considering duration. Beyond that, I am mostly clueless.

Something's not right. It's a 5-speed, right?

Our '88s4 (early, 5-speed) was 295 rwhp (SAE) with stock maps, cams at zero. The only mods were a Motorsports/SLC x-pipe, hi-flow cats, Constantine rear muffler-- everything else is stock.

I don't think it is possible to make sense of LSA without also considering duration. Beyond that, I am mostly clueless.

Our '88s4 (early, 5-speed) was 295 rwhp (SAE) with stock maps, cams at zero. The only mods were a Motorsports/SLC x-pipe, hi-flow cats, Constantine rear muffler-- everything else is stock.

#55

Inventor

Rennlist Member

Rennlist Member

I just can't seem to smooth out the fueling between 5600-6100. MAF voltages get bumpier and bumpier with temp.

The problem may be that I've stubbornly been trying to use 89-octane. Might not be possible with the knock sensor loop.

#56

Inventor

Rennlist Member

Rennlist Member

#57

Rennlist Member

Join Date: Oct 2009

Location: Michigan... Grand Rapids

Posts: 758

Likes: 0

Received 2 Likes

on

1 Post

A couple months ago I switched to 60lb injectors in my supercharged car to help Jeff figure out his lean waves issues. He was thinking it may be a combination of the large injectors and the dead ended fuel rails. The injectors came with a data sheet showing 2.5 & 5 ms outputs, which varied from 92 to 100. I originally placed the largest injectors farthest from the fuel inlet. But After moving them around a few times to get the best tune, I figured out that there is definately a difference in air flow between the cylinders affecting tune as much or more than the small amount of fuel pressure difference. I now get zero knocks on my car under heavy boost and running close to stock timing advance

#58

Racer

Join Date: Jan 2009

Location: Adelaide South Australia'79 5spd twin turbo

Posts: 326

Likes: 0

Received 1 Like

on

1 Post

Now, let me get this straight, from all that I've read on here, I come to the conclusion that the stock S4 manifold is excellent on a stock S4 engine.

It also makes a fair fist of the job on a stock S4 engine with healthy boost supplied by Kuhn Turbos to the tune of 700 rwhp.

So why would we imagine it should be capable of doing anything more than that ! It already does what it was designed to do, nigh on perfectly.

Increasing engine capacity or asking it to flow more than twice the designed volume, moves it outside it's design parameters and not a bad word should be said if it fails to deliver on expectations.

The expectations are poor not the manifold.

It also makes a fair fist of the job on a stock S4 engine with healthy boost supplied by Kuhn Turbos to the tune of 700 rwhp.

So why would we imagine it should be capable of doing anything more than that ! It already does what it was designed to do, nigh on perfectly.

Increasing engine capacity or asking it to flow more than twice the designed volume, moves it outside it's design parameters and not a bad word should be said if it fails to deliver on expectations.

The expectations are poor not the manifold.

#59

Nordschleife Master

Thread Starter

If they had instead engineered some more taper into these runners by making them larger upstream, then the resonance points would be broader and the shrinking cross section would make it less likely that the flow separates.

I can't think of a practical way to add enough taper to the runners of the S3 or S4 manifold. You can grind in some for the last couple of inches with S4, but that's it.

Louie Ott also found some 8-10 HP by reshaping the bottom of the stock air filter box, to more of a bellmouth shape like the earlier cars. the 90 degree air turn on the bottom of the S4 and later air filter boxes are especially damaging to clean air flow. This may be why some of the 928'sRUS AIS systme flows so much better than stock....

For the higher powered cars with the air filter in the stock air box, my instinct would be to focus more on the air entry into the airbox on the sides than air exit from the bottom. Air is actually pretty good at going thru a shrinking hole efficiently, but has real problems going out of an expanding hole without major losses. That's why all those restrictor nozzles have a very short and steep entry and a very long exit (diffuser). My intuition says that it's the same in the S4 air box, that one will get more mileage at higher air flow demands by working on making the air box entries better. Just my opinion, and everyone should consider the source.

Now, let me get this straight, from all that I've read on here, I come to the conclusion that the stock S4 manifold is excellent on a stock S4 engine. It also makes a fair fist of the job on a stock S4 engine with healthy boost supplied by Kuhn Turbos to the tune of 700 rwhp. So why would we imagine it should be capable of doing anything more than that ! It already does what it was designed to do, nigh on perfectly. Increasing engine capacity or asking it to flow more than twice the designed volume, moves it outside it's design parameters and not a bad word should be said if it fails to deliver on expectations. The expectations are poor not the manifold.

Specifically on my application: Whether a modified S4 manifold is the final solution depends on the size of the turbos we can fit in close to the exhaust ports. If we could fit very large turbos then I'd say let's live with the manifold that does a great job spooling the turbos and then boost the living daylight out of the engine at high rpm. Alas, we can't fit huge turbos close to the exhaust ports and therefore the S4 manifold may have to go in the 3rd iteration engine.

#60

Rennlist Member

Join Date: Oct 2009

Location: Michigan... Grand Rapids

Posts: 758

Likes: 0

Received 2 Likes

on

1 Post

What I would really really like to obtain from this thread, or if someone could point me to the correct thread, is the actual flow numbers at each cylinder. Without "actual" data, I am using trial & error and basic logic as to which cylinder should get the highest flowing injector. This makes a huge difference on tune and best HP output.

When I think about all the time Ken is putting creating a better chip for these s4 cars, I think he is shooting himself in the foot a little bit. He is basically trying to obtain maximum HP with timing and fuel ratios... But if the air flow is different at each cylinder and the injectors are also a variable, then he will never obtain optimum fuel ratio, and hence never get to optimum timing

When I think about all the time Ken is putting creating a better chip for these s4 cars, I think he is shooting himself in the foot a little bit. He is basically trying to obtain maximum HP with timing and fuel ratios... But if the air flow is different at each cylinder and the injectors are also a variable, then he will never obtain optimum fuel ratio, and hence never get to optimum timing