928 Billet-Polyurethane Transaxle Mounts

#1

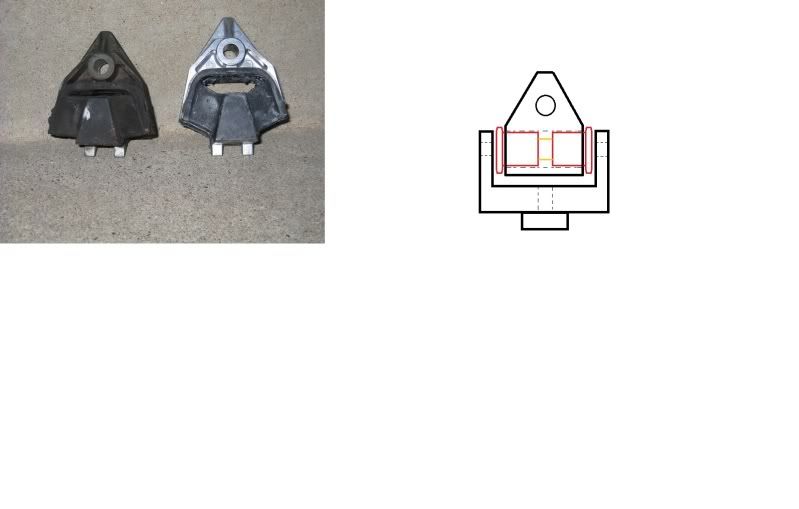

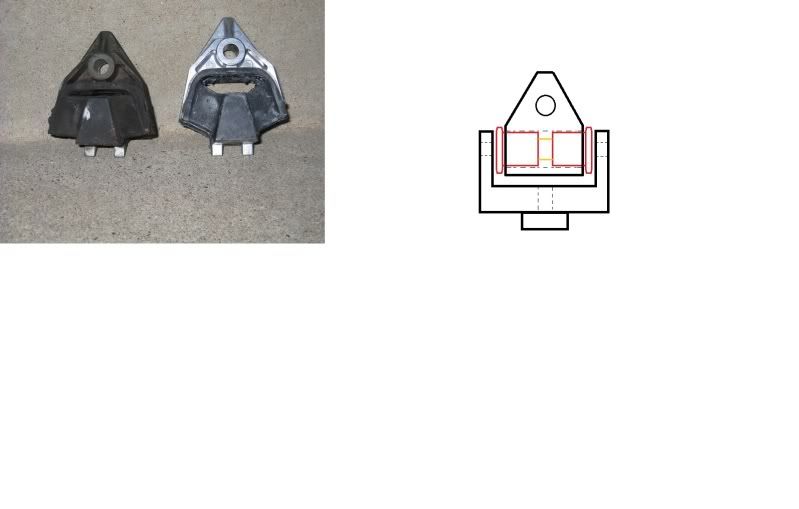

Thanks to Rob edwards for sending a set of 928 trans mounts. I will be working on the first set of Billet-Polyurethane 928 trans mounts in the next few weeks once the urethane isolators show in the mail. I'm pondering 2 different designs, this one and one that would mimic the Early 944 trans mount design which would be less expensive to make. I will get that diagram up later to get some opinions..... either way they would come with inexpensive replaceable polyurethane inserts and be Billet T6061-T6

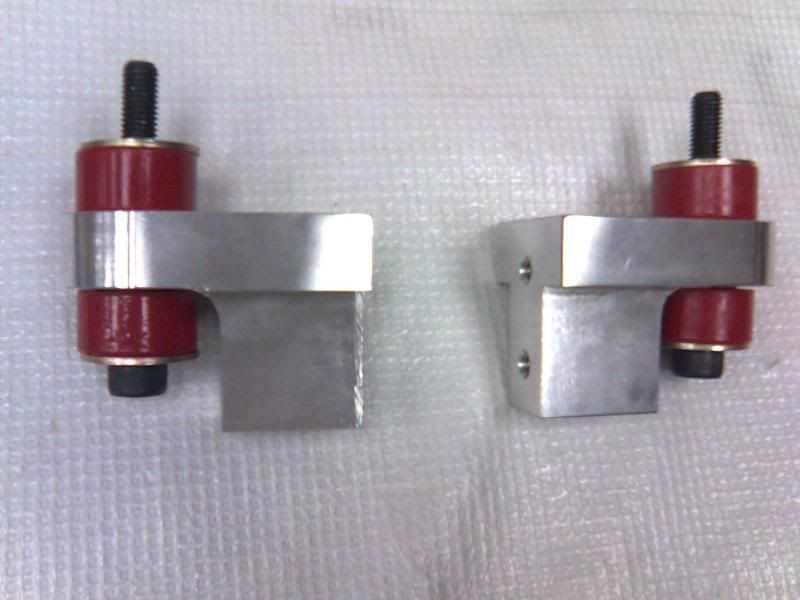

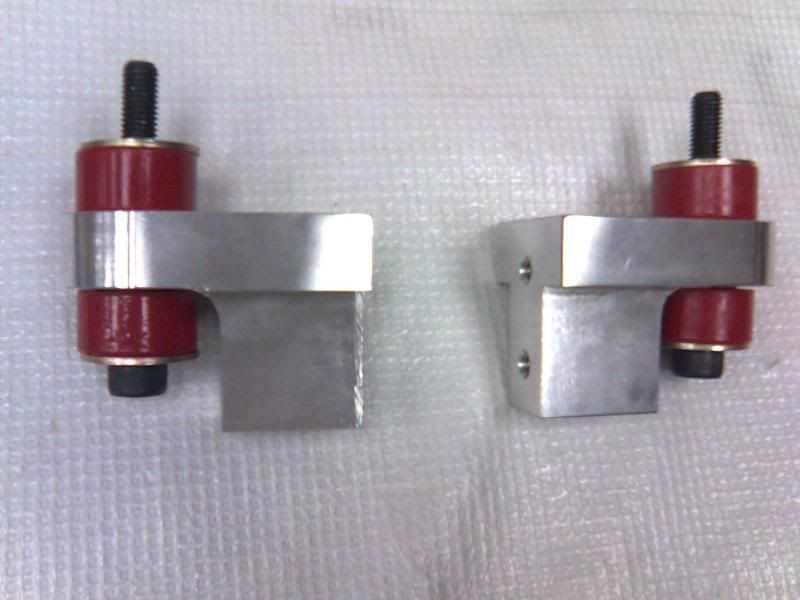

Here is a set of the early 944 mounts that I can expand on the design and machine the 928 trans interface dimensions. My question on this style is would it be necessary to incorporate a failure mode like the 2 piece 928 trans mount where metal to metal contact occurs?

Here is a set of the early 944 mounts that I can expand on the design and machine the 928 trans interface dimensions. My question on this style is would it be necessary to incorporate a failure mode like the 2 piece 928 trans mount where metal to metal contact occurs?

Last edited by xschop; 11-04-2010 at 07:47 AM.

#4

Yes, on a 3-axis in my shop. I have my own Bridgeport and lathe as well and can change design on the fly.

From the diagrams I only see a square shim/washer on the bottom of the cross member under the bolt head. Either way washers can be used in various thicknesses.

From the diagrams I only see a square shim/washer on the bottom of the cross member under the bolt head. Either way washers can be used in various thicknesses.

#5

I feel the transmission move around alot. I think that a non-solid but much more stringent control of the transmission and rear-TT-area weight is a good thing.

The fact that the engine and transmission and TT are all one piece and are isolated from the body and suspended by just four pieces of rubber has always been an interesting piece of trivia for the 928. Many modern cars have a similar situation, though the two ends are usually on multi-point subframes.

The fact that the engine and transmission and TT are all one piece and are isolated from the body and suspended by just four pieces of rubber has always been an interesting piece of trivia for the 928. Many modern cars have a similar situation, though the two ends are usually on multi-point subframes.

#6

Enough 948 swappers have realized that the rubber trans mounts are letting the trans slap towards the driver's side under the torque of the V8 and destroying CV joints. These 928 mounts look like they have been smacked around because of the crappy rubber design as well and there are metal to metal failure contacts that are worn on them. The Polyurethane eliminates any play and still doesn't allow vibrations into the chassis on the 948 transaxles.

If I can get a good design out of the 2 piece set, it will be under $225 all hardware and shipping. The 1st diagram would be 4-pieces of billet and cost more obviously.

If I can get a good design out of the 2 piece set, it will be under $225 all hardware and shipping. The 1st diagram would be 4-pieces of billet and cost more obviously.

#7

Archive Gatekeeper

Rennlist Member

Rennlist Member

These 928 mounts look like they have been smacked around because of the crappy rubber design as well and there are metal to metal failure contacts that are worn on them.

Those were from my GTS, which had been tracked an awful lot in the last 25,000 miles. But the mounts on my GT had collapsed to the exact same degree (from 117 mm to 112mm), which I would guess is the point where the metal-to-metal contact happens (?)

Trending Topics

#8

Former Sponsor

Enough 948 swappers have realized that the rubber trans mounts are letting the trans slap towards the driver's side under the torque of the V8 and destroying CV joints. These 928 mounts look like they have been smacked around because of the crappy rubber design as well and there are metal to metal failure contacts that are worn on them. The Polyurethane eliminates any play and still doesn't allow vibrations into the chassis on the 948 transaxles.

If I can get a good design out of the 2 piece set, it will be under $225 all hardware and shipping. The 1st diagram would be 4-pieces of billet and cost more obviously.

If I can get a good design out of the 2 piece set, it will be under $225 all hardware and shipping. The 1st diagram would be 4-pieces of billet and cost more obviously.

Therefore, the transmission in a 928 can't move far enough sideways to get even close to destroying an axle...something else is causing that.

You are going to have to do your homework to improve on the stock 928 mount.

Last edited by GregBBRD; 11-03-2010 at 09:28 PM.

#9

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

#10

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

And speculation about why a 944 CV joint lets go with V-8 torque ......... pretty silly. Also worth noting that with the engine bolted to the torque tube bolted to the transaxle the forces and vectors are much different than it first seems.

pretty silly. Also worth noting that with the engine bolted to the torque tube bolted to the transaxle the forces and vectors are much different than it first seems.

pretty silly. Also worth noting that with the engine bolted to the torque tube bolted to the transaxle the forces and vectors are much different than it first seems.

pretty silly. Also worth noting that with the engine bolted to the torque tube bolted to the transaxle the forces and vectors are much different than it first seems.

#11

There's no speculation, it usually is the inner driver's side CV joint that takes the beatdown, busted cages on the 944 High HP Turbo cars and just about every V8 unless a solid trans mount was installed. There is a good write-up here on Rennlist about a trans to chassis brace for a 944 that fixed the problem but transfered alot of noise into the cabin, same problem with the solid trans mounts. The reason I designed this for my 85.5 car.....Even a new factory mount has too much side-to-side oscillation for my comfort....

#12

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

So is this for track use or street use?

I've seen lots of people coming up with 'solid' or nearly solid alternatives to the plastic and rubber bushings and mounts like steering rack mounts and different bushings. I get that you want things to be stiffer and more responsive on the track. You can exchange some of the 'insulation' you get from the parts designed to make a luxury touring car more quiet and comfortable for speed and road feel. You can also expect to change things out on a set schedule and check for wear much more often in a racing environment.

Isn't this design going to exacerbate the causes of TBF in an auto trans though?

The cause of TBF as I understand it is the shortening (due to twisting during rapid, even violent acceleration) of the driveshaft and the fact that the stock clamp is too weak to prevent the driveshaft from pulling out slightly during hard acceleration but is strong enough to prevent it from creeping back to its normal position afterward. The wear on the rear of the thrust bearings is caused by the constant pressure of the (now effectively longer) driveshaft on the bearing.

This happens now, even though in stock configuration the engine has rubber mounts to allow for some slight cushioning of the engine's initial rotation, and the transmission is cushioned with relation to the rest of the car by the rubber trans mounts.

Under heavy initial load with flexible stock motor and trans mounts the engine rotates one way and the trans the other way and the driveshaft still manages to twist enough to cause TBF. If you replace the trans mounts with something stiffer, as it seems is the proposed design, won't that just put even more strain on the driveshaft and the flex plate clamping?

I've seen lots of people coming up with 'solid' or nearly solid alternatives to the plastic and rubber bushings and mounts like steering rack mounts and different bushings. I get that you want things to be stiffer and more responsive on the track. You can exchange some of the 'insulation' you get from the parts designed to make a luxury touring car more quiet and comfortable for speed and road feel. You can also expect to change things out on a set schedule and check for wear much more often in a racing environment.

Isn't this design going to exacerbate the causes of TBF in an auto trans though?

The cause of TBF as I understand it is the shortening (due to twisting during rapid, even violent acceleration) of the driveshaft and the fact that the stock clamp is too weak to prevent the driveshaft from pulling out slightly during hard acceleration but is strong enough to prevent it from creeping back to its normal position afterward. The wear on the rear of the thrust bearings is caused by the constant pressure of the (now effectively longer) driveshaft on the bearing.

This happens now, even though in stock configuration the engine has rubber mounts to allow for some slight cushioning of the engine's initial rotation, and the transmission is cushioned with relation to the rest of the car by the rubber trans mounts.

Under heavy initial load with flexible stock motor and trans mounts the engine rotates one way and the trans the other way and the driveshaft still manages to twist enough to cause TBF. If you replace the trans mounts with something stiffer, as it seems is the proposed design, won't that just put even more strain on the driveshaft and the flex plate clamping?

#13

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Damn it....I stay away from the 944 forums to avoid seeing parts like this so I stop spending money on it.

Add this to the list.......

Add this to the list.......

#14

The 928 drivetrain when bolted together is one solid unit with the torque tube (resists torsional force) just like 944 drivetrain. If anyone has measured the front engine twist to rear trans twist relationship under acceleration/load allowed by the TT, you may have a valid argument/hypothesis. I'm designing a polyurethane set for performance and quiet operation as compared to a noisy solid mount and the fact that Carl Faucett has stated many times that a solid trans mount could bust a Bellhousing due to the body flex relation to the drive train, especially when going over a curb or uneven drive path.

As far as a trans mount, be it solid, rubber, or stiffer polyurethane changing the length/relation of the outter drivetrain shell to driveshaft......that's a hard sell.

As far as a trans mount, be it solid, rubber, or stiffer polyurethane changing the length/relation of the outter drivetrain shell to driveshaft......that's a hard sell.