928 Billet-Polyurethane Transaxle Mounts

#16

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The 928 drivetrain when bolted together is one solid unit with the torque tube (resists torsional force) just like 944 drivetrain. If anyone has measured the front engine twist to rear trans twist relationship under acceleration/load allowed by the TT, you may have a valid argument/hypothesis. I'm designing a polyurethane set for performance and quiet operation as compared to a noisy solid mount and the fact that Carl Faucett has stated many times that a solid trans mount could bust a Bellhousing due to the body flex relation to the drive train, especially when going over a curb or uneven drive path.

As far as a trans mount, be it solid, rubber, or stiffer polyurethane changing the length/relation of the outter drivetrain shell to driveshaft......that's a hard sell.

As far as a trans mount, be it solid, rubber, or stiffer polyurethane changing the length/relation of the outter drivetrain shell to driveshaft......that's a hard sell.

The transmission case is fixed to the torque tube. The engine bellhousing is fixed to the torque tube. These points are not going to change with relation to each other and presumably are not going to twist, flex or compress.

So you're saying that the crankshaft/flywheel->driveshaft->transmission input shaft are independent of the engine crankcase/block->torque tube->transmission case and that the forces that act on the internals will not be changed by the fact that the trans (or engine) are more tightly attached to the body rather than more cushioned as they are in the stock configuration.

I guess you're right and it comes down to the weakest link which has been shown to be the stock flex plate clamp. The housing of the trans being fixed to the body (or at least more fixed than stock) wouldn't affect the fact that the internal shafts will continue to act as they previously would.

Sorry for the detour, I'll delete this and the previous post if you like. Let me know.

#17

No, keep them up. I asked for opinions and input. I fought for your right to speak your mind, mine too. As far as the 928 auto drive train, it bewilders me why Porsche would use a clamp on the auto drive shaft, when the Manual driveshaft is a 2 piece and the clutch disc is free floating on the shaft just like the 944. There is a guy that has a chevy V8 in his automatic 944 that changed the large rubber disc with clamp to a free floating disc on the shaft and has had no problems. I have wondered if anyone has used a non-split clamp and just let it free float since the drive shaft is already locked at the coupler in the back? But that's a whole different story.

#18

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

No, keep them up. I asked for opinions and input. I fought for your right to speak your mind, mine too. As far as the 928 auto drive train, it bewilders me why Porsche would use a clamp on the auto drive shaft, when the Manual driveshaft is a 2 piece and the clutch disc is free floating on the shaft just like the 944. There is a guy that has a chevy V8 in his automatic 944 that changed the large rubber disc with clamp to a free floating disc on the shaft and has had no problems. I have wondered if anyone has used a non-split clamp and just let it free float since the drive shaft is already locked at the coupler in the back? But that's a whole different story.

Constantine researched this at great length before coming up with his 'SuperClamp' solution. He said there was just no way to get the splines to have enough play to slide without having so much that they beat the crap out of themselves and eventually spin or break. I'm paraphrasing of course but I think that's the gist of it.

You're right, that's another discussion for another thread.

I can see that there is a market for this product and obviously there are those for whom any play is too much so hopefully this will be the solution for them.

Good luck with it, new developments are always a good thing and the more choices we have the better.

#19

"""""He said there was just no way to get the splines to have enough play to slide without having so much that they beat the crap out of themselves and eventually spin or break""""

I think I see what you mean but don't quite understand what exact mechanism you are talking about in the phrase....

........so much?

As a side note, the factory 928 clamp and flex plate is being adapted to an LS engine as we speak.

I think I see what you mean but don't quite understand what exact mechanism you are talking about in the phrase....

........so much?

As a side note, the factory 928 clamp and flex plate is being adapted to an LS engine as we speak.

#20

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

"""""He said there was just no way to get the splines to have enough play to slide without having so much that they beat the crap out of themselves and eventually spin or break""""

I think I see what you mean but don't quite understand what exact mechanism you are talking about in the phrase....

........so much?

I think I see what you mean but don't quite understand what exact mechanism you are talking about in the phrase....

........so much?

He explored the idea of having some way for the flex plate to turn the driveshaft without having to be attached to it, but I think he said there would be too many additional or modified parts required to make it cost effective compared to stopping it from moving in the first place.

As a side note, the factory 928 clamp and flex plate is being adapted to an LS engine as we speak.

#21

The 5 speed drive shaft is pinned to the rear of the crankshaft which keeps everything nice and tidy as far as vibrations.

The auto drive shaft is shorter and needs to be clamped so it doesn't vibrate itself to death in an open free floating arrangement like a clutch system.

We experimented initially with a very beefy free floating design for the 928 automatics. Pitched it after a few revisions since the vibrations made it a very noisy affair. Plus it wouldn't last that long with that kind of vibration which would get worse with time.

Started to re-engineer the whole auto driveline before coming to the simple conclusion that it would be too expensive for just about anybody to buy.

Studied the initial design intent from Porsche about the automatic front flexplate clamp system and just made it better.

This is a well traveled road, have fun with it!

Cheers,

The auto drive shaft is shorter and needs to be clamped so it doesn't vibrate itself to death in an open free floating arrangement like a clutch system.

We experimented initially with a very beefy free floating design for the 928 automatics. Pitched it after a few revisions since the vibrations made it a very noisy affair. Plus it wouldn't last that long with that kind of vibration which would get worse with time.

Started to re-engineer the whole auto driveline before coming to the simple conclusion that it would be too expensive for just about anybody to buy.

Studied the initial design intent from Porsche about the automatic front flexplate clamp system and just made it better.

This is a well traveled road, have fun with it!

Cheers,

#22

Hey Const, thanks for chiming in. What if the auto driveshaft were elongated to insert into a pilot bearing like the manual TT shaft? Would be a good reason to go 300M. And you are right, your upgraded clamp is the best alternative/$ solution to the driveshaft walk however the mechanism.

I guess I need to start another thread on the Manual TT shaft dimensions with the 2-piece coupler. I have never seen good pics or posted dims of the 2-piece shaft and coupler in relation to the 928 TT flange on the 5 speed. I'm rethinking the 928 box and TT for my 948 swap. I love the idea of not have to remove the tranny to do a clutch change, especially since I've got a 2 piece bellhousing now.

I guess I need to start another thread on the Manual TT shaft dimensions with the 2-piece coupler. I have never seen good pics or posted dims of the 2-piece shaft and coupler in relation to the 928 TT flange on the 5 speed. I'm rethinking the 928 box and TT for my 948 swap. I love the idea of not have to remove the tranny to do a clutch change, especially since I've got a 2 piece bellhousing now.

#25

I have the materials and poly inserts and will make a set soon now that I have a 928 in my garage. Originally I got a spare set from Rob Edwards and I poly-filled them with Window urethane after getting all the dimensions from them for the billet parts. They are running around OKC somewhere on a 928 that I have built a few parts for.

#26

I'm interested in a replacement for the stock trans mounts for the Auto if you come up with something.

#27

Nordschleife Master

Another talented person contributing to our luscious cars. Bravo xschop!

#28

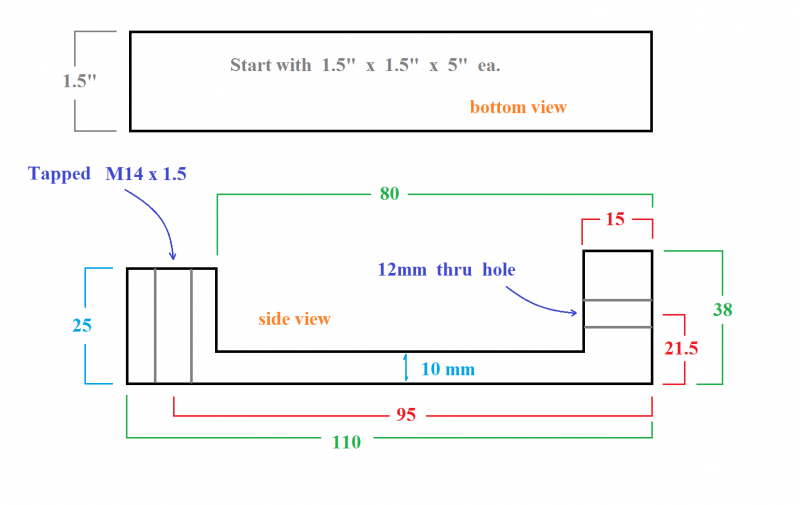

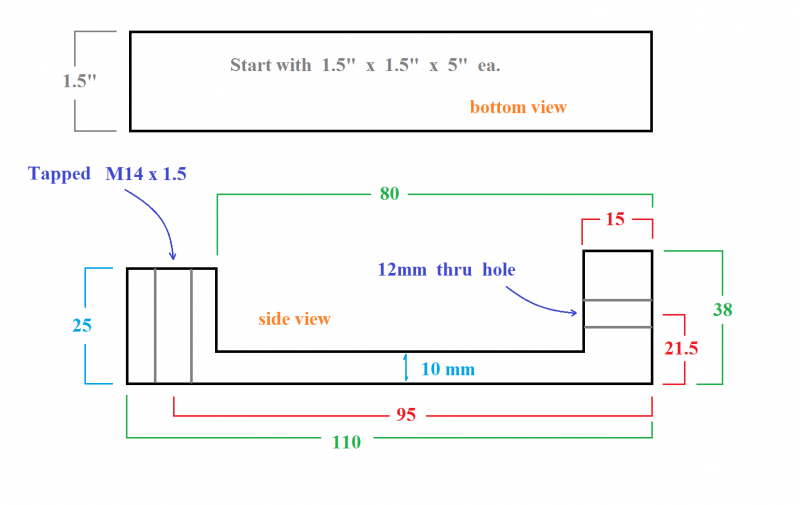

I found the sketch of the rough rebuild jig I made over a year ago. I transfered it to a paint drawing for you guys. I just don't see it worth my time to build billet-poly mounts when the 928 mount can be modded with liquid poly easily. I'll be doing a set soon since I'll be using the factory trans dimensions with my LS swap....

#29

Where is the discussion of the poly?