MAF and fuel pressure problems

#16

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Tuomo--

No matter whether you continue with stock boot or silicone, stock clamps or other, dump the screwdriver and use a long-shaft nutdriver or even a 1/4" drive with the flexi extension mentioned above. With the clamp in the right position, screw on top and facing the right (pass) side of the car, the driver will go on with the rail cover in place. Using a socket on the end means you don't have to have fingers in there to keep the tool centered as they get trashed.

The 1/4" drive tool adds the ability to use a torque wrench or torque-limiting screwdriver on the clamp. That will give you some basis for determining that the torque needed for correct clamping under boost and heat is more than the original clamp can muster.

No matter whether you continue with stock boot or silicone, stock clamps or other, dump the screwdriver and use a long-shaft nutdriver or even a 1/4" drive with the flexi extension mentioned above. With the clamp in the right position, screw on top and facing the right (pass) side of the car, the driver will go on with the rail cover in place. Using a socket on the end means you don't have to have fingers in there to keep the tool centered as they get trashed.

The 1/4" drive tool adds the ability to use a torque wrench or torque-limiting screwdriver on the clamp. That will give you some basis for determining that the torque needed for correct clamping under boost and heat is more than the original clamp can muster.

#17

Nordschleife Master

Thread Starter

Second, it seems that I am repeating your problems! First, I boiled the fuel like you did and now I popped the MAF boot! Please give me a heads up what was your next problem so I can prepare? ;-)

Third, I am looking at your two failed MAF boots, and both failures seem to have started from one of the clamps. In the first failure, it's as if the small hose clamp has bitten into the rubber and the crack has started from there. In the second failure, it looks like the big clamp has bitten into the boot and started another failure.

Would it be fair to say that if you don't overtighten the stock clamps, the MAF sensor housing pops out of the boot and if you do overtighten the clamp, the clamp cuts the boot and the boot breaks? Damned if you do and damned if you don't.

#18

Burning Brakes

Join Date: Oct 2008

Location: Palo Alto, CA

Posts: 972

Likes: 0

Received 0 Likes

on

0 Posts

Tuomo, you should consider tack welding some studs onto the side of the throttle body and see if you can get some steel turnbuckle fittings worked out extending to a ring that goes all the way around the MAF (the stock MAF has a nice lip that I bet you could use...). Then you just tighten the piece together and it shouldn't blow off, and your hose clamps just need to provide an airtight seal, not actively hold the boot in place...maybe someone else has tried this and failed horribly, but to my (possibly addled) mind, it seems like it ought to work...

#21

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Tuomo: One of George's current problems is maintaining fuel pressure despite a 100 GPH Aeromotive in-tank pump, AN10 fuel lines, and an Aeromotive rising rate FPR. On repeated dyno runs the fuel pressure begins to fall at high RPM, duty cycle max's out (despite 54 lb injectors) and the mixture gets leaner, knocks increase and power drops. Instead of increasing with boost as it is supposed to, the fuel pressure rises with boost up to about 4000 RPM, then levels off, and as we repeat runs, it falls off above 4000 RPM to below idle baseline. We replaced the FPR, increased the size of the fuel lines, checked the current to the fuel pump, etc. And despite doubling the fuel return lines and adding a pump controller to reduce fuel recirculation heating, the fuel is still getting hot (reaches 100F+ just driving on a 70F day, 118F+ during dyno runs). Frustrating. In theory, we should be able to use a stock FPR and use Sharktuner to take care of fuel requirements, but we are max'd out despite the big injectors. So, we either need to get the fuel pressure back up or figure out why this thing is eating so much fuel - maybe Vortex superchargers are a folly for this application (open road racing). I hope you don't repeat all his problems.

#22

Nordschleife Master

Thread Starter

Tuomo: One of George's current problems is maintaining fuel pressure despite a 100 GPH Aeromotive in-tank pump, AN10 fuel lines, and an Aeromotive rising rate FPR. On repeated dyno runs the fuel pressure begins to fall at high RPM, duty cycle max's out (despite 54 lb injectors) and the mixture gets leaner, knocks increase and power drops. Instead of increasing with boost as it is supposed to, the fuel pressure rises with boost up to about 4000 RPM, then levels off, and as we repeat runs, it falls off above 4000 RPM to below idle baseline. We replaced the FPR, increased the size of the fuel lines, checked the current to the fuel pump, etc. And despite doubling the fuel return lines and adding a pump controller to reduce fuel recirculation heating, the fuel is still getting hot (reaches 100F+ just driving on a 70F day, 118F+ during dyno runs). Frustrating. In theory, we should be able to use a stock FPR and use Sharktuner to take care of fuel requirements, but we are max'd out despite the big injectors. So, we either need to get the fuel pressure back up or figure out why this thing is eating so much fuel - maybe Vortex superchargers are a folly for this application (open road racing). I hope you don't repeat all his problems.

I think it's that Aeromotive pump. Those Aeromotive pumps have a reputation of moving a lot of GPH against a low pressure but then running out of steam when they see larger pressures. John Kuhn told me that he looked into them, and found out that even Bosch 044 pumps more after certain pressure hurdle.

Too small of a return line would cause the rial pressure to spike, so it's not that. Too hot fuel would cause the density to drop, but the pressure should be high. If the FPR is working, then it has to be the pump, thinking about it logically.

You could borrow another Aeromotive pump and hook it up in line externally. If my theory is correct and it's the pump having trouble pumping against pressure, then two pumps in line will overcome that problem. I think.

Although I don't think fuel temperature is the cause of the problem, I think it's good to reduce the variation in fuel temperature. I have the stock fuel cooler still installed which drives off the A/C. If you've ditched the A/C, maybe run a heat-sink fuel cooler?

What I have now seems to work ok, with my 60 lbh injectors still having significant headroom. I am running that Fuelab 42401 pump at reduced constant speed, still. It's fed with -10AN and pressure line is also -10AN. I've got the stock return line and stock fuel cooler. There were many problems with my first iteration, including stock tank pickup. This second iteration seems to be working pretty well, I've got maybe 1500 miles on it now.

#23

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Tuomo: Thanks for the input. We were reluctant to blame the pump. I think George already tried a Fuel Lab.

Oh, and George blew the MAF boot off again today, but not on the dyno. Instead it came off on the way home when he juiced it a bit to pass a car. Probably worked itself most of the way off during the dyno sessions today. We took a bit more care to position the clamp once he got home. Who knows how long it will hold. The main advanatage of the silicone boot is that it is essentially indestructible.

When the boot pops off, the car becomes undrivably rich due to the huge rush of air the MAF is metering that never makes it to the motor (the MAF value max's out). Pulling the MAF plug makes the car (barely) drivable in limp mode.

Oh, and George blew the MAF boot off again today, but not on the dyno. Instead it came off on the way home when he juiced it a bit to pass a car. Probably worked itself most of the way off during the dyno sessions today. We took a bit more care to position the clamp once he got home. Who knows how long it will hold. The main advanatage of the silicone boot is that it is essentially indestructible.

When the boot pops off, the car becomes undrivably rich due to the huge rush of air the MAF is metering that never makes it to the motor (the MAF value max's out). Pulling the MAF plug makes the car (barely) drivable in limp mode.

#24

Nordschleife Master

Thread Starter

For example, 41403 pumps a huge volume against low pressure but doesn't seem to be able to do much against high pressure.

#25

Addict

Rennlist Member

Rennlist Member

Tuomo,

So far I've tried 2 Bosch 044, 1 Fuelab 41402, and 2 Aeromotive A1000 pumps, and still can't

seem to keep the fuel pressure up at high RPM. Also have tried a low pressure pump feed to a fuel

sump, two low pressure pumps feeding the 044, then the Fuelab, and a Aeromotive, then just

the Aeromotive mounted externally at the base level of the fuel cell, and now the Aeromotive

mounted inside the fuel cell. Have tried 3 different fuel pressure regulators, increased the feed

line, doubled the return line, increased the injector size to 52 lb-hr (and lowered the base fuel

pressure), cleaned up the feed to the fuel rails, cleaned up the in-tank plumbing, added a fuel

cooler on the return line (decreased the fuel temp by 3 degrees incoming verses outgoing),

changed the pick-ups in the tank from the ATL -8AN duckfoot (1 then 2) to the ATL -10AN in-tank

sump and added a fuel pump controller. Still not able to maintain fuel pressure at high RPM and

engine load when the fuel and engine heats up. We hope that what we've done will at least enable

us to make the drive out to Ely, Nv and then complete the 90 mile Silver State run this weekend.

So far I've tried 2 Bosch 044, 1 Fuelab 41402, and 2 Aeromotive A1000 pumps, and still can't

seem to keep the fuel pressure up at high RPM. Also have tried a low pressure pump feed to a fuel

sump, two low pressure pumps feeding the 044, then the Fuelab, and a Aeromotive, then just

the Aeromotive mounted externally at the base level of the fuel cell, and now the Aeromotive

mounted inside the fuel cell. Have tried 3 different fuel pressure regulators, increased the feed

line, doubled the return line, increased the injector size to 52 lb-hr (and lowered the base fuel

pressure), cleaned up the feed to the fuel rails, cleaned up the in-tank plumbing, added a fuel

cooler on the return line (decreased the fuel temp by 3 degrees incoming verses outgoing),

changed the pick-ups in the tank from the ATL -8AN duckfoot (1 then 2) to the ATL -10AN in-tank

sump and added a fuel pump controller. Still not able to maintain fuel pressure at high RPM and

engine load when the fuel and engine heats up. We hope that what we've done will at least enable

us to make the drive out to Ely, Nv and then complete the 90 mile Silver State run this weekend.

#26

Nordschleife Master

Thread Starter

Tuomo,

So far I've tried 2 Bosch 044, 1 Fuelab 41402, and 2 Aeromotive A1000 pumps, and still can't seem to keep the fuel pressure up at high RPM. Also have tried a low pressure pump feed to a fuel sump, two low pressure pumps feeding the 044, then the Fuelab, and a Aeromotive, then just the Aeromotive mounted externally at the base level of the fuel cell, and now the Aeromotive mounted inside the fuel cell. Have tried 3 different fuel pressure regulators, increased the feed line, doubled the return line, increased the injector size to 52 lb-hr (and lowered the base fuel pressure), cleaned up the feed to the fuel rails, cleaned up the in-tank plumbing, added a fuel cooler on the return line (decreased the fuel temp by 3 degrees incoming verses outgoing), changed the pick-ups in the tank from the ATL -8AN duckfoot (1 then 2) to the ATL -10AN in-tank sump and added a fuel pump controller. Still not able to maintain fuel pressure at high RPM and engine load when the fuel and engine heats up. We hope that what we've done will at least enable us to make the drive out to Ely, Nv and then complete the 90 mile Silver State run this weekend.

So far I've tried 2 Bosch 044, 1 Fuelab 41402, and 2 Aeromotive A1000 pumps, and still can't seem to keep the fuel pressure up at high RPM. Also have tried a low pressure pump feed to a fuel sump, two low pressure pumps feeding the 044, then the Fuelab, and a Aeromotive, then just the Aeromotive mounted externally at the base level of the fuel cell, and now the Aeromotive mounted inside the fuel cell. Have tried 3 different fuel pressure regulators, increased the feed line, doubled the return line, increased the injector size to 52 lb-hr (and lowered the base fuel pressure), cleaned up the feed to the fuel rails, cleaned up the in-tank plumbing, added a fuel cooler on the return line (decreased the fuel temp by 3 degrees incoming verses outgoing), changed the pick-ups in the tank from the ATL -8AN duckfoot (1 then 2) to the ATL -10AN in-tank sump and added a fuel pump controller. Still not able to maintain fuel pressure at high RPM and engine load when the fuel and engine heats up. We hope that what we've done will at least enable us to make the drive out to Ely, Nv and then complete the 90 mile Silver State run this weekend.

If I've understood this correctly, it's that you can't get the fuel pressure to 43.5 psi + the manifold pressure, even when the engine and fuel are cold. Is this true? Since there's no fuel leak, it has to be either the fuel pressure regulator or the pump. That's it.

41402 may not pump enough against pressure at the reduced speed setting. My 42401 seem to be able to handle it, at least so far.

When you say you tried Aeromotive pumps, did you try two of them? If you did, did you (a) try them one at the time, (b) in series, or (c) in parallel? My guess is if it's the Aeromotive pump being weak against pressure, two in series would work.

One test you might want to run is the following. The FPR has a manifold pressure reference line. Hook up a presure gauge to that line close to the FPR. Does it match the boost pressure you see from other sensors? That line might have some sort of a blockage upstream and then a leak downstream, or something.

#27

George,

Are you sure that your tank is venting sufficiently so that you aren't creating a vacuum in the tank during those periods of high fuel usage where you're seeing the fuel pressure drops?

Are you sure that your tank is venting sufficiently so that you aren't creating a vacuum in the tank during those periods of high fuel usage where you're seeing the fuel pressure drops?

#28

Addict

Rennlist Member

Rennlist Member

Yes, I checked the fuel cell vent, also did some dyno runs with the gas cap

off, no difference.

#29

Addict

Rennlist Member

Rennlist Member

Sounds like a royal pain in the *** debugging effort! Sorry to hear that, I am knocking on wood that I don't end up in the same situation. Although all indications are that I might, if the historical correlation between our problems is any guide.

If I've understood this correctly, it's that you can't get the fuel pressure to 43.5 psi + the manifold pressure, even when the engine and fuel are cold. Is this true? Since there's no fuel leak, it has to be either the fuel pressure regulator or the pump. That's it.

41402 may not pump enough against pressure at the reduced speed setting. My 42401 seem to be able to handle it, at least so far.

When you say you tried Aeromotive pumps, did you try two of them? If you did, did you (a) try them one at the time, (b) in series, or (c) in parallel? My guess is if it's the Aeromotive pump being weak against pressure, two in series would work.

One test you might want to run is the following. The FPR has a manifold pressure reference line. Hook up a presure gauge to that line close to the FPR. Does it match the boost pressure you see from other sensors? That line might have some sort of a blockage upstream and then a leak downstream, or something.

If I've understood this correctly, it's that you can't get the fuel pressure to 43.5 psi + the manifold pressure, even when the engine and fuel are cold. Is this true? Since there's no fuel leak, it has to be either the fuel pressure regulator or the pump. That's it.

41402 may not pump enough against pressure at the reduced speed setting. My 42401 seem to be able to handle it, at least so far.

When you say you tried Aeromotive pumps, did you try two of them? If you did, did you (a) try them one at the time, (b) in series, or (c) in parallel? My guess is if it's the Aeromotive pump being weak against pressure, two in series would work.

One test you might want to run is the following. The FPR has a manifold pressure reference line. Hook up a presure gauge to that line close to the FPR. Does it match the boost pressure you see from other sensors? That line might have some sort of a blockage upstream and then a leak downstream, or something.

time. The vacuum line that "feeds" the fuel pressure regulator is the same one

that feeds my in dash boost gauge and LMA-3. There is a Tee just in front of

the fuel pressure regulator, then another one inside the cabin.

The electronic fuel pressure sensor is on the passenger side fuel rail with a

guage in the cabin and a mechanical gauge is mounted on the fuel pressure

regulator. They are usually with one psi of each other while taking readings.

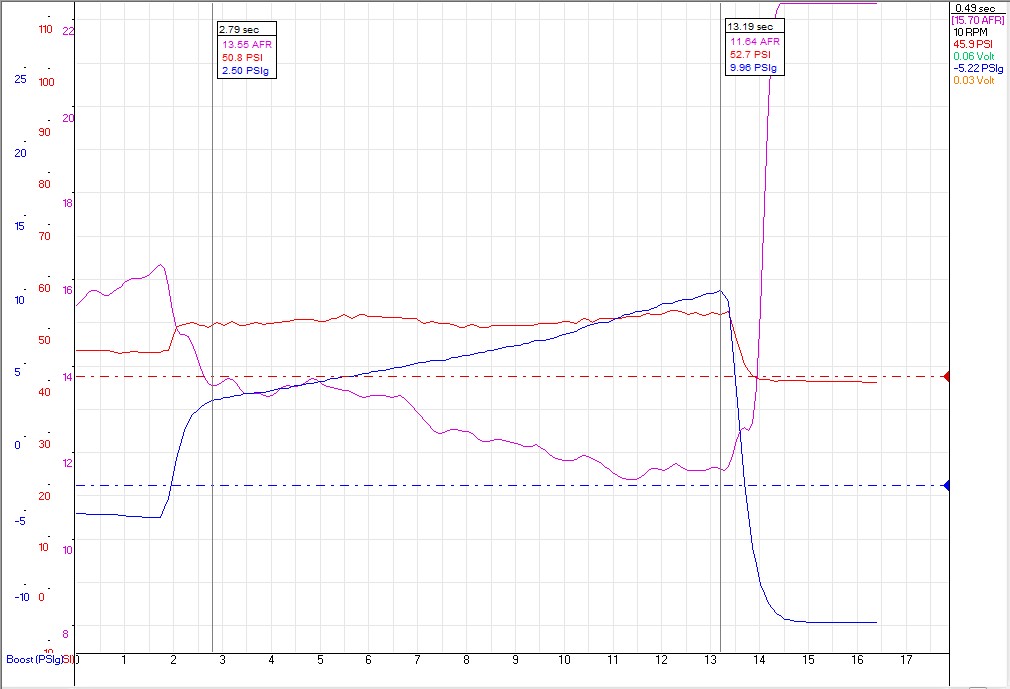

Here is a image of the LM-1 graph data from an early run (9/3/2010):

Sorry not tach signal, the wire had come loose. I fixed it for the next dyno

session.

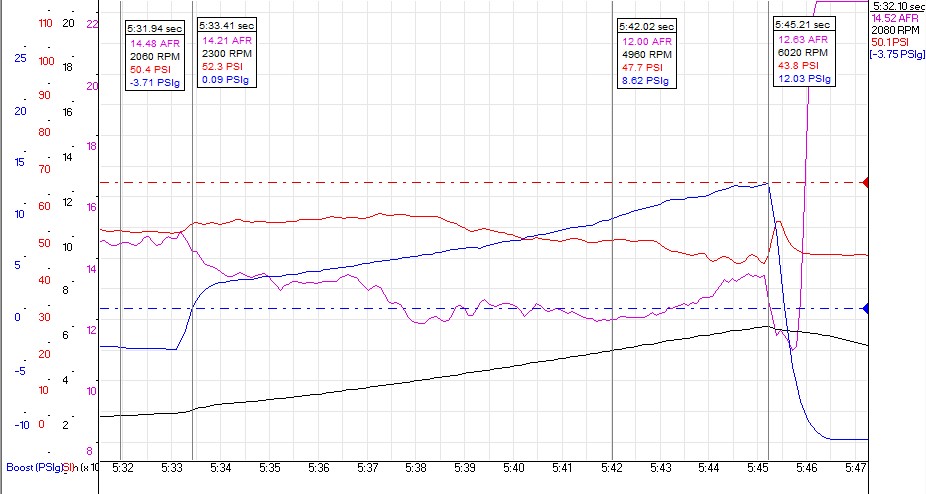

Here is an image of a later run from yesterday. We had increased the base

fuel pressure to see if that would help, but it still dropped (more dramatically)

when it heated up:

#30

Nordschleife Master

Thread Starter

I don't know what I am talking about, but that's rarely stopped me from speculating. ;-)

Based on boost, I am guessing that the first dyno run went up to about 5500. It looks to me that there's already a problem in the first dyno pull. The fuel pressure starts at 50.8 and ends at 52.7, a difference of 1.9 psi. At the same time, the boost grows from 2.5 psi to 10 psi, a difference of 7.5 psi. The fuel pressure should have increased to 58.3 psi, not to 52.7 psi. Either the FPR is not doing its job or the fuel pump is not doing its job.

If you lower the base fuel pressure to 43.5 psi, does the FPR then increase fuel pressure 1 for 1 with boost? If so, your desired fuel pressure may be exceeding the FPRs range or the pump may be running out of steam.

If you idle the car and apply different test pressures to the FPR's manifold pressure reference line, does the fuel pressure rise 1 for 1 with the test pressure? In particular, if you apply 20 psi of test pressure, does the fuel pressure rise to 68.3 psi? If it does, then it's not the FPR and it has to be the pump.

Here's another test you can run. Unhook the return line near the fuel pressure regulator and direct it to fuel container. Then run the dyno test. Does the flow out of the return line stop at some point during your run? If it does, it has to be the pump.

If it's the pump, it's either that the pump runs out of steam (asked to pump too much flow against a too high pressure) or there's a restriction upstream of the pump. Since your pump is in tank and I assume the fuel tank is more than half full when you test, it's probably not just the elevation. So this leaves at least the following three potential explanations:

(1) If the pre-filter is restrictive, it may cause cavitation in the pump. What straining filter are you using upstream of the pump? You may try temporarily removing it for a test, I don't know how risky that would be.

(2) If there's a hose upstream of the pump, is it possible that the hose is collapsing? If it is, you can put a coil spring inside the hose and retry.

(3) Maybe the pump can't pump enough flow against your requested high pressure. If you add another Aeromotive pump in series outside the tank, that should reveal a problem caused by a weak pump. Or you could try replacing the Aeromotive pump with a Fuelab 42401 pump or with some higher capacity Aeromotive pump.

I am shooting in the dark here, and maybe you've tried the above already.

Based on boost, I am guessing that the first dyno run went up to about 5500. It looks to me that there's already a problem in the first dyno pull. The fuel pressure starts at 50.8 and ends at 52.7, a difference of 1.9 psi. At the same time, the boost grows from 2.5 psi to 10 psi, a difference of 7.5 psi. The fuel pressure should have increased to 58.3 psi, not to 52.7 psi. Either the FPR is not doing its job or the fuel pump is not doing its job.

If you lower the base fuel pressure to 43.5 psi, does the FPR then increase fuel pressure 1 for 1 with boost? If so, your desired fuel pressure may be exceeding the FPRs range or the pump may be running out of steam.

If you idle the car and apply different test pressures to the FPR's manifold pressure reference line, does the fuel pressure rise 1 for 1 with the test pressure? In particular, if you apply 20 psi of test pressure, does the fuel pressure rise to 68.3 psi? If it does, then it's not the FPR and it has to be the pump.

Here's another test you can run. Unhook the return line near the fuel pressure regulator and direct it to fuel container. Then run the dyno test. Does the flow out of the return line stop at some point during your run? If it does, it has to be the pump.

If it's the pump, it's either that the pump runs out of steam (asked to pump too much flow against a too high pressure) or there's a restriction upstream of the pump. Since your pump is in tank and I assume the fuel tank is more than half full when you test, it's probably not just the elevation. So this leaves at least the following three potential explanations:

(1) If the pre-filter is restrictive, it may cause cavitation in the pump. What straining filter are you using upstream of the pump? You may try temporarily removing it for a test, I don't know how risky that would be.

(2) If there's a hose upstream of the pump, is it possible that the hose is collapsing? If it is, you can put a coil spring inside the hose and retry.

(3) Maybe the pump can't pump enough flow against your requested high pressure. If you add another Aeromotive pump in series outside the tank, that should reveal a problem caused by a weak pump. Or you could try replacing the Aeromotive pump with a Fuelab 42401 pump or with some higher capacity Aeromotive pump.

I am shooting in the dark here, and maybe you've tried the above already.