Cam tower removal

#1

Rennlist Member

Thread Starter

Join Date: May 2009

Location: Woodstock Ga.

Posts: 1,482

Likes: 0

Received 0 Likes

on

0 Posts

I was wondering if anyone had helpful hints in regards to cam tower removal. I did a search and learned about the tool that 928 motorsports has. I don't have time to order one. I am leaving Fl for Ga on Sat so I am under the gun!

Having a hard time getting to the bolts, my mechanic mentioned it was a allen, just cant seem to get to it.

Any secrets or help would be awesome.

Stephen

Having a hard time getting to the bolts, my mechanic mentioned it was a allen, just cant seem to get to it.

Any secrets or help would be awesome.

Stephen

#4

Make sure you're careful not to let the top bolts fall back into the tower when you're trying to remove them. It can make removing the cam difficult and could also damage a lob as you're trying to pull the cam past the lose bolt. I've removed about 18 cam towers from 16v cars and losing a bolt back into the tower is what I try and avoid. Also, spray down the lower bolts because they are exposed to the elements and can sometime bind in the head and break on the way out... or worse you break off the threaded section of the head which I have also done... regretably.

#5

Nordschleife Master

You can make your own tool by cutting an Allen wrench into a atraight piece and putting the matching socket on the end. I'm thinking it's a 6mm wrench.

If you're in a hurry then postpone something. I rate this was the most frustrating job I've ever done on a 928. The bolts were hard to get and and mostly frozen. I reached a point of being happy when I could break them because at least I could then get the head off and have a machine shop fix it. Beware!

If you're in a hurry then postpone something. I rate this was the most frustrating job I've ever done on a 928. The bolts were hard to get and and mostly frozen. I reached a point of being happy when I could break them because at least I could then get the head off and have a machine shop fix it. Beware!

#7

Rennlist Member

not to mention if the gaskets are baked on the heads. that alone was a 8 hour job in the car. back breaking. keep in mind, i can get this engine on an engine stand in 3.5 hours. with the engine out of the car, everything is only minutes to do. in the car, its a pain! but, Ive done it before and its possible.

I would see if you can crack all the bolts first and get them out, if you cant, just stop and pull the engine.

I would see if you can crack all the bolts first and get them out, if you cant, just stop and pull the engine.

Trending Topics

#8

Rennlist Member

Thread Starter

Join Date: May 2009

Location: Woodstock Ga.

Posts: 1,482

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for all of the info.

We will see what happens, he just might have to pull it.

GlenL Thanks for the tip, he is going to try it!

Looks like there were some delays here in regards to moving so it looks like I will be moving anywhere between Mon and Wed. So that gives us some more time!

Stephen

We will see what happens, he just might have to pull it.

GlenL Thanks for the tip, he is going to try it!

Looks like there were some delays here in regards to moving so it looks like I will be moving anywhere between Mon and Wed. So that gives us some more time!

Stephen

#9

not to mention if the gaskets are baked on the heads. that alone was a 8 hour job in the car. back breaking. keep in mind, i can get this engine on an engine stand in 3.5 hours. with the engine out of the car, everything is only minutes to do. in the car, its a pain! but, Ive done it before and its possible.

#10

Instructor

This is a pretty time consuming and tedious job. Probably easier to pull the engine. I removed both cam towers on my engine. One still had the original gasket, which peeled right off. The other side had been replaced with some sort of fiber-reinforced gasket that someone had glued on. If you have to scrape off something like that, it is next to impossible to keep debris from falling into the engine. A major advantage to pulling the engine, is that you can rotate this surface to face down for scraping, and gravity will prevent debris from falling in. Having said all that, here is how I did it in-car:

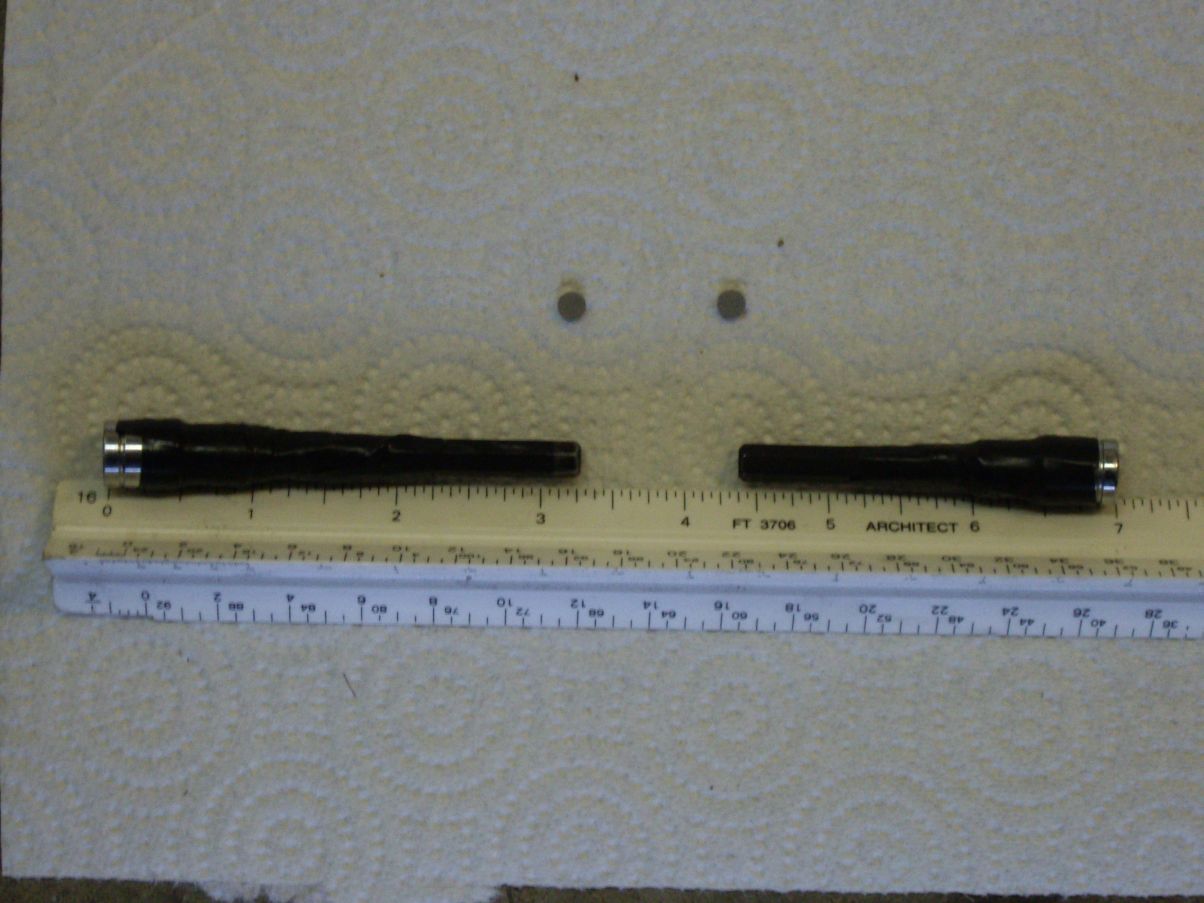

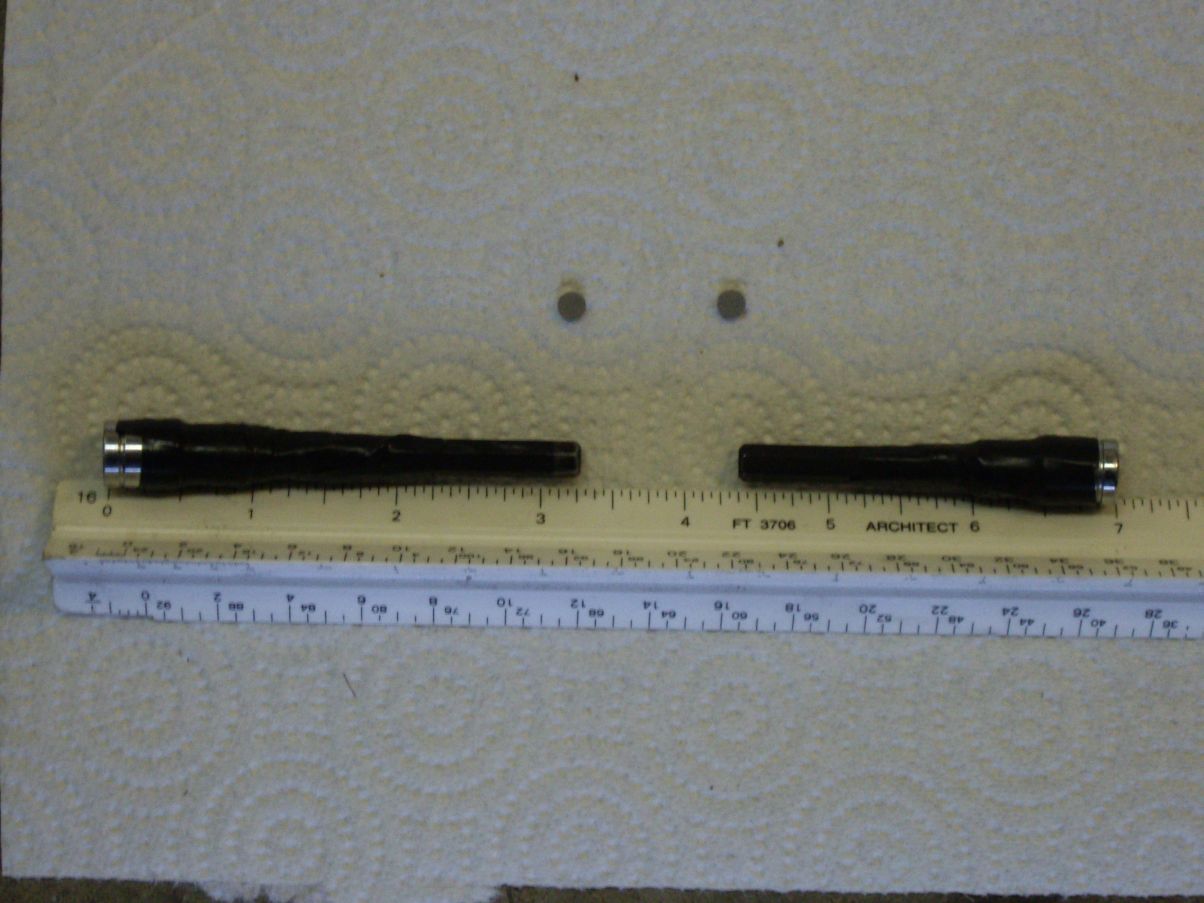

Buy a set of long internal hex sockets from Harbor Freight, remove the hex portion from the socket adapter, and cut the hex portion into two halves that are different lengths. You will then permanently or semi-permanently attach each of them to 6mm 1/4"-drive sockets, like so:

I found that I needed both of these lengths to do the job. There is not much room for error. I used a non-functional HF torque wrench as both a breaker bar and a ratchet drive. A regular 1/4" breaker bar did not give enough leverage to break the lower bolts loose.

For re-installation, I would recommend making a second set of the hex keys, only with small rare-earth magnets epoxied to the ends. These will be handy for re-installing the internal bolts, but cannot be used to torque the bolts down.

As previously stated, do not pull the cam out of the housing with any loose metal inside, as you can easily scratch a cam bearing surface, which may require replacement of the cam tower.

Also on 78-79 cars, the access holes for the top bolts are covered by rubber plugs. Don't expect to get these out in one piece. Your goal should be remove them without scratching the sealing surfaces in the cam tower. I found it easiest to break them and shove the remains into the cam tower. You can retrieve the pieces later.

It would have been nice if Porsche had located the heads for the top bolts outside of the cam tower. Having them inside makes the job about 2x more difficult.

Buy a set of long internal hex sockets from Harbor Freight, remove the hex portion from the socket adapter, and cut the hex portion into two halves that are different lengths. You will then permanently or semi-permanently attach each of them to 6mm 1/4"-drive sockets, like so:

I found that I needed both of these lengths to do the job. There is not much room for error. I used a non-functional HF torque wrench as both a breaker bar and a ratchet drive. A regular 1/4" breaker bar did not give enough leverage to break the lower bolts loose.

For re-installation, I would recommend making a second set of the hex keys, only with small rare-earth magnets epoxied to the ends. These will be handy for re-installing the internal bolts, but cannot be used to torque the bolts down.

As previously stated, do not pull the cam out of the housing with any loose metal inside, as you can easily scratch a cam bearing surface, which may require replacement of the cam tower.

Also on 78-79 cars, the access holes for the top bolts are covered by rubber plugs. Don't expect to get these out in one piece. Your goal should be remove them without scratching the sealing surfaces in the cam tower. I found it easiest to break them and shove the remains into the cam tower. You can retrieve the pieces later.

It would have been nice if Porsche had located the heads for the top bolts outside of the cam tower. Having them inside makes the job about 2x more difficult.

#11

Instructor

One more thing - if your engine is a 78-79 engine, the cam tower gasket is NLA. You must use a later model gasket and trim it using the old gasket as a template. I used Victor Reinz gaskets, installed dry, and have not had any leaks so far.

#12

Rennlist Member

Good tips here....keepr!

#14

Shameful Thread Killer

Rennlist Member

Rennlist Member

These Allen tools are very useful for the recessed bolts. I've found that once broke loose, it's a good idea to have a strong parts/pen magnet handy. Put the magnet on the end of the Allen tool and extract the bolt by magnetizing the bolt/tool assembly.

During assembly, watch the position of the gasket carefully. You can use the pen magnet again to insert some of the tough to reach bolts and get them started. Some WD-40 on the bolt threads will help then start in the cam housing. Once the bolt thread is started, it can be driven down with the Allen drivers above.

It is a long, time consuming, and bitchy job to do in the car. I also advocate loosening the motor mounts and jacking the engine left or right as needed for clearance to access some bolts.

During assembly, watch the position of the gasket carefully. You can use the pen magnet again to insert some of the tough to reach bolts and get them started. Some WD-40 on the bolt threads will help then start in the cam housing. Once the bolt thread is started, it can be driven down with the Allen drivers above.

It is a long, time consuming, and bitchy job to do in the car. I also advocate loosening the motor mounts and jacking the engine left or right as needed for clearance to access some bolts.

#15

Rennlist Member

Thread Starter

Join Date: May 2009

Location: Woodstock Ga.

Posts: 1,482

Likes: 0

Received 0 Likes

on

0 Posts

Well I went over and saw the car being worked on. A lot of pieces have broken. Hoses, bolts etc. Old parts that were hanging on for dear life. They are being replaced along with anything else that needs to be. Not sure they are having fun but they said they weren't giving up and laughed!

More money, more money, but I look forward to seeing the work finished, seiing what gains are to be had, but more importantly knowing that all the maintenance will be up to date. I just hope they don't find to much! LOL

Stephen

More money, more money, but I look forward to seeing the work finished, seiing what gains are to be had, but more importantly knowing that all the maintenance will be up to date. I just hope they don't find to much! LOL

Stephen