FS: Moldex stroker crank

#16

Former Vendor

123', I think this Ti rods that fail in 24 hours claim is a myth.

Can you give me an example of a GM rod failing at all, ever? Not where the piston or something else broke but the rod itself. This sounds like someone once said something, it got passed down through a few thousand people over the internets who have no direct experience. In other words, I disagree

Greg, are you assuming I'm running these rods out of the box with no changes to put the pin end centered with the piston?

Here's what I do:

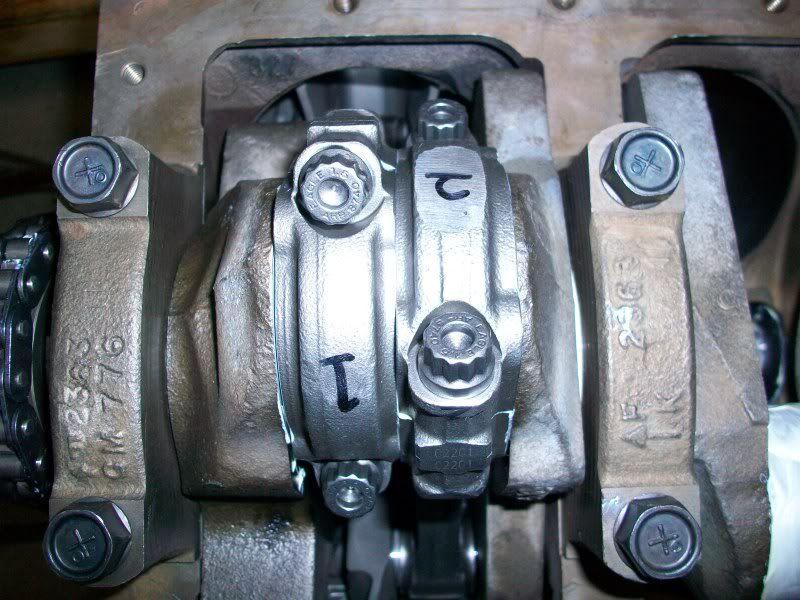

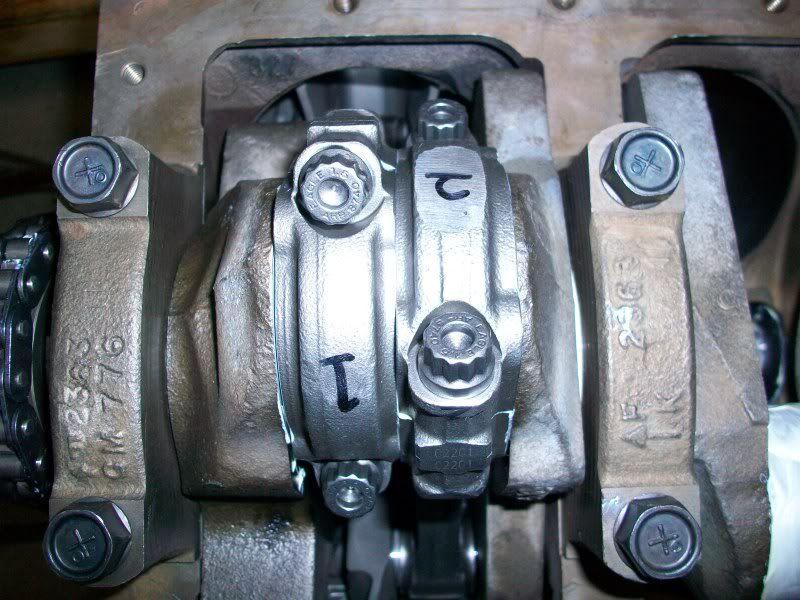

The stock pin bushing is removed.

A new one is put in that is made from material that I've tested and know to have high strength and little friction. I tested this with simulated lab type stuff and by running them (over 24 hours) in a race engine and comparing. This bushing gets oil channels CNC machined and the whole rod and bushing is cut on a Wire EDM to final shape. This is when it is effectively moved .02" to be centered with the piston. While I'm at it the pin bore isn't just honed to size. No, it gets Wire EDMed to an oval shape to account for changes to the rod and pin under loading. Rods come out looking excellent after running that way. The material I use really is noticeably better than stock, they come looking nice with no lines on the pin.

Also noteworthy in this pic is that the pistons don't extend out of the cylinders at all. Another benefit of the sleeving that is surely subject to the same passed-on internet wisdom as Ti rods, 928s having flimsy timing belts and Chevy motors being 500 pounds lighter.

Anyone care to guess how much those pistons weigh?

Can you give me an example of a GM rod failing at all, ever? Not where the piston or something else broke but the rod itself. This sounds like someone once said something, it got passed down through a few thousand people over the internets who have no direct experience. In other words, I disagree

Greg, are you assuming I'm running these rods out of the box with no changes to put the pin end centered with the piston?

Here's what I do:

The stock pin bushing is removed.

A new one is put in that is made from material that I've tested and know to have high strength and little friction. I tested this with simulated lab type stuff and by running them (over 24 hours) in a race engine and comparing. This bushing gets oil channels CNC machined and the whole rod and bushing is cut on a Wire EDM to final shape. This is when it is effectively moved .02" to be centered with the piston. While I'm at it the pin bore isn't just honed to size. No, it gets Wire EDMed to an oval shape to account for changes to the rod and pin under loading. Rods come out looking excellent after running that way. The material I use really is noticeably better than stock, they come looking nice with no lines on the pin.

Also noteworthy in this pic is that the pistons don't extend out of the cylinders at all. Another benefit of the sleeving that is surely subject to the same passed-on internet wisdom as Ti rods, 928s having flimsy timing belts and Chevy motors being 500 pounds lighter.

Anyone care to guess how much those pistons weigh?

I had a Carrillo A-beam rod, with Chevy offset fail in a 928 application. Carrillo did all the failure analysis and discovered that the problem was the piston not pushing straight down on the centerline of the rod. The forces are very extreme.

They found that if the rod is offset by as little as .020" (relationship of center of piston to centerline of rod beam), the forces exerted on the rod are severe enough to make the rod fail. They claim that all offset issues need to be addressed on the big end of the rod.

Mike:

I'm not sure what you did to center that rod...nor which rod it is, to begin with...but it sure is pretty!

#17

Nordschleife Master

They found that if the rod is offset by as little as .020" (relationship of center of piston to centerline of rod beam), the forces exerted on the rod are severe enough to make the rod fail. They claim that all offset issues need to be addressed on the big end of the rod.

#18

Former Vendor

Tuomo:

I'm not the expert on this. I just know what the head engineer at Carrillo told me. (I also have a copy of the engineering modeling they did.) They did a computer model of the offset issue and found that the piston pushes down on the rod and unless the rod is on the exact centerline of the piston, there is a tremendous "twisting" motion transfered to the rod.

Apparently, they had never modeled this, since they always build rods with the correct offset and really never thought about this issue, before. They were very, very surprised at the force numbers and the resulting twisting forces.They were even more amazed when the force numbers became so large, even with very small offset amounts. The other thing that they looked into was how much force was transfered to the rod, even when the piston can't "rock" in the bore due to the piston to wall clearance holding it straight. They found that the same force was transfered to the rod, regardless if the piston could rock, or not.

If the rod is very stiff (which is not the case with their A-beam rod), the twisting motion is then transfered down the shaft and rocks the rod bearing, everytime the piston pushes down. If the bearing twists enough, it "punches" through the oil film on the edges of the twisting motion. This rang a big bell, for me. Every stroker I've ever taken apart, with Chevy rods, has uneven wear on the rod bearings...just like they were twisting....because they were! Also, the pistons always have wear on the skirts that show the twisting motion.

Pretty amazing study! Too bad we had to break something to learn this.

I'm not the expert on this. I just know what the head engineer at Carrillo told me. (I also have a copy of the engineering modeling they did.) They did a computer model of the offset issue and found that the piston pushes down on the rod and unless the rod is on the exact centerline of the piston, there is a tremendous "twisting" motion transfered to the rod.

Apparently, they had never modeled this, since they always build rods with the correct offset and really never thought about this issue, before. They were very, very surprised at the force numbers and the resulting twisting forces.They were even more amazed when the force numbers became so large, even with very small offset amounts. The other thing that they looked into was how much force was transfered to the rod, even when the piston can't "rock" in the bore due to the piston to wall clearance holding it straight. They found that the same force was transfered to the rod, regardless if the piston could rock, or not.

If the rod is very stiff (which is not the case with their A-beam rod), the twisting motion is then transfered down the shaft and rocks the rod bearing, everytime the piston pushes down. If the bearing twists enough, it "punches" through the oil film on the edges of the twisting motion. This rang a big bell, for me. Every stroker I've ever taken apart, with Chevy rods, has uneven wear on the rod bearings...just like they were twisting....because they were! Also, the pistons always have wear on the skirts that show the twisting motion.

Pretty amazing study! Too bad we had to break something to learn this.

#20

Three Wheelin'

Thread Starter

#21

Nordschleife Master

Then I am guessing those are the LS7 production rods, part number 12586258.

EDIT: I found your earlier post that says "LS7 Titanium rod, they weigh 480 grams and are forged."

Those are not hugely expensive rods, they are very light, and they are hard to break. The Corvette forum boys say:

I am curious, how wide is the big end of those rods? Also, is the big end symmetric?

EDIT: I found your earlier post that says "The big end is the normal 2.1 x .94, pin is .926"

The reason why I am asking is that I am wondering if the rod is narrow enough that it's possible to center the beam relative to the piston in the stock bore location. Assuming that the bore spacing is stock, will the rod fit centered on the Moldex crank or will it hit the fillets or the other rod on the same pin?

If it fits, I think one could in principle run the rod, as is, piston guided. Are you doing just that?

EDIT: I am looking at the photo in http://forums.pelicanparts.com/uploa...1249043418.jpg, and I noticed some differences. First, your new pistons are x-forgings while the old one look like they had the old-style forging. What's apparent in that picture as well is that the ls7 rod used to sit off center. Can't see from your new iteration of the engine whether those rods are now right smack in the middle of not.

EDIT 2: I obviously wasn't paying attention. You said that the LS7 rod has .940" big end width. You also said that the bores are .985" apart. For comparison, the stock 928 rods are 1.063" wide. So the LS7 rods should fit in the middle just fine, as long as the crank pin width is .985" + .940" + 2*.020"= 1.965" or more. There would be a .045" gap between the rods, though, so I think this would need to be piston guided.

I think (but do not know) the "standard" stroker crank has a big end journal width of 1.900" so the 2*.940" rod + 3*.020" clearances fit but don't fit centered relative to the piston. This combination seems to require rods with big end width offset relative to beam, much the same way as the stock 928 rods except the wide part on the inside instead of the outside.

EDIT: I found your earlier post that says "LS7 Titanium rod, they weigh 480 grams and are forged."

Those are not hugely expensive rods, they are very light, and they are hard to break. The Corvette forum boys say:

Also, on the Ti rods.... if you want to search around, you will see that you will NOT find A SINGLE ls7 failure that is due to a Ti rod failure. A piston will go, or a liner and potentially hurt a rod but the rods are incredibly strong for their weight.

EDIT: I found your earlier post that says "The big end is the normal 2.1 x .94, pin is .926"

The reason why I am asking is that I am wondering if the rod is narrow enough that it's possible to center the beam relative to the piston in the stock bore location. Assuming that the bore spacing is stock, will the rod fit centered on the Moldex crank or will it hit the fillets or the other rod on the same pin?

If it fits, I think one could in principle run the rod, as is, piston guided. Are you doing just that?

EDIT: I am looking at the photo in http://forums.pelicanparts.com/uploa...1249043418.jpg, and I noticed some differences. First, your new pistons are x-forgings while the old one look like they had the old-style forging. What's apparent in that picture as well is that the ls7 rod used to sit off center. Can't see from your new iteration of the engine whether those rods are now right smack in the middle of not.

EDIT 2: I obviously wasn't paying attention. You said that the LS7 rod has .940" big end width. You also said that the bores are .985" apart. For comparison, the stock 928 rods are 1.063" wide. So the LS7 rods should fit in the middle just fine, as long as the crank pin width is .985" + .940" + 2*.020"= 1.965" or more. There would be a .045" gap between the rods, though, so I think this would need to be piston guided.

I think (but do not know) the "standard" stroker crank has a big end journal width of 1.900" so the 2*.940" rod + 3*.020" clearances fit but don't fit centered relative to the piston. This combination seems to require rods with big end width offset relative to beam, much the same way as the stock 928 rods except the wide part on the inside instead of the outside.

Last edited by ptuomov; 03-25-2010 at 11:25 PM. Reason: bad memory, late recall, general stupidity

#22

What I am doing with Chevy rods is turning them around and machining a relief on the cheek of the rods that the crank radius would contact without the machining, i.e cause binding. It gets very close to what is required. Not perfect, my calculations estimate 0.15 mm offset, that should be o.k as there is more than that in side clearance.

Greg

Greg

#23

Nordschleife Master

GG --

I reading all this with great interest.

Without knowing much about the Chevy rods, I think that the LS* engines have on-center rods and the older SBC engines have off-center rods. If you are using SBC rods, I think you can flip the SBC rods and hit the piston center almost exactly, and still use the 1.900" crank pin journal width stroker crank. That's theory. Since you've done this, it must also work in practice.

Photos of the old-school small block rods, crank, and block:

The 928 has wider bore spacing than SBC, and thus flipping the SBC rods will take the beams further apart and therefore they'll hit the piston almost right smack in the middle.

If one wants to use the superhero titanium ls7 rods, then flipping them around is not going to help. They are symmetric. Also, since the ls7 titanium rod is coated with some sort of fancy coating that prevents galling, it would be a total bitch to machine a relief in them and then somehow replace the double-secret coating. If one is really *insisting* on getting the ls7 rod beam in the center, one would need a crank with wider crank pin journal and then make the rod piston guided. I don't know if there are any issues caused by the wider gap between rods, can't think of any.

I think dealing with the offset in the big end is the best, but it must still cause some imbalance as the oil film in the bearing transmits the load evently. There's going to be some tilting force no matter how, unless the rod is symmetric on-center and right smack in the middle of the bore. Piston-guided on-center symmetric rods in the exact center of the bore seem to be the ideal solution.

With the usual caveat that I have no idea what I am talking about, just googling at my cubicle...

Best, Tuomo

I reading all this with great interest.

Without knowing much about the Chevy rods, I think that the LS* engines have on-center rods and the older SBC engines have off-center rods. If you are using SBC rods, I think you can flip the SBC rods and hit the piston center almost exactly, and still use the 1.900" crank pin journal width stroker crank. That's theory. Since you've done this, it must also work in practice.

Photos of the old-school small block rods, crank, and block:

The 928 has wider bore spacing than SBC, and thus flipping the SBC rods will take the beams further apart and therefore they'll hit the piston almost right smack in the middle.

If one wants to use the superhero titanium ls7 rods, then flipping them around is not going to help. They are symmetric. Also, since the ls7 titanium rod is coated with some sort of fancy coating that prevents galling, it would be a total bitch to machine a relief in them and then somehow replace the double-secret coating. If one is really *insisting* on getting the ls7 rod beam in the center, one would need a crank with wider crank pin journal and then make the rod piston guided. I don't know if there are any issues caused by the wider gap between rods, can't think of any.

I think dealing with the offset in the big end is the best, but it must still cause some imbalance as the oil film in the bearing transmits the load evently. There's going to be some tilting force no matter how, unless the rod is symmetric on-center and right smack in the middle of the bore. Piston-guided on-center symmetric rods in the exact center of the bore seem to be the ideal solution.

With the usual caveat that I have no idea what I am talking about, just googling at my cubicle...

Best, Tuomo

What I am doing with Chevy rods is turning them around and machining a relief on the cheek of the rods that the crank radius would contact without the machining, i.e cause binding. It gets very close to what is required. Not perfect, my calculations estimate 0.15 mm offset, that should be o.k as there is more than that in side clearance.

#24

Nordschleife Master

A quick question to Greg Brown:

Suppose that one uses an asymmetric rod big end such that the rod bearing surface is offset relative to the rod beam and piston midpoint. (This is for example the case with the 928 stock rods.) Since the oil in the bearing will distribute force about evenly across the ebaring surface, doesn't this also cause a tilting force to the rod? Did the Carrillo report compute how large this effect is?

Suppose that one uses an asymmetric rod big end such that the rod bearing surface is offset relative to the rod beam and piston midpoint. (This is for example the case with the 928 stock rods.) Since the oil in the bearing will distribute force about evenly across the ebaring surface, doesn't this also cause a tilting force to the rod? Did the Carrillo report compute how large this effect is?

#25

Three Wheelin'

Thread Starter

Tuomo, the 928 rod beam and bearing are probably centered. I shouldn't have said they they are "offset". The big end does protrude on one side but that's just to allow for the corner radius while keeping the bearing centered. For practical purposes everything important is centered.

For fun you can contemplate the centeredness of bearings on various rods but IMHO it's not important. Modern Chevy rods are all symetrical but the bearings are offset within the rod by .024" to clear the radius.

I still don't feel that a rod being offset by .020 in the piston will cause failure and I would have had a furrowed brow if a rod company told me that. The beam being warped or pin bushing not honed parallel would be of more concern for an otherwise surprise failure.

There is always some offset just from the tolerances of bore to crank spacing, especially if you bore relative to the cast block towers instead of the crankshaft. If that offset were a problem than why don't we see more mystery rod failures in all engines?

I just dug up the 2 sets of rod bearings I've replaced in my engine along with rod bushings after running with an offset rod and I can't see any signs of uneven wear at all. Not that I'd rather have everything ideally lined up like GB, it's just not that important to me. I have bigger worries like my engine exploding at 24 hours and the usual stuff like broken valves etc.

For fun you can contemplate the centeredness of bearings on various rods but IMHO it's not important. Modern Chevy rods are all symetrical but the bearings are offset within the rod by .024" to clear the radius.

I still don't feel that a rod being offset by .020 in the piston will cause failure and I would have had a furrowed brow if a rod company told me that. The beam being warped or pin bushing not honed parallel would be of more concern for an otherwise surprise failure.

There is always some offset just from the tolerances of bore to crank spacing, especially if you bore relative to the cast block towers instead of the crankshaft. If that offset were a problem than why don't we see more mystery rod failures in all engines?

I just dug up the 2 sets of rod bearings I've replaced in my engine along with rod bushings after running with an offset rod and I can't see any signs of uneven wear at all. Not that I'd rather have everything ideally lined up like GB, it's just not that important to me. I have bigger worries like my engine exploding at 24 hours and the usual stuff like broken valves etc.

#26

Nordschleife Master

Tuomo, the 928 rod beam and bearing are probably centered. I shouldn't have said they they are "offset". The big end does protrude on one side but that's just to allow for the corner radius while keeping the bearing centered. For practical purposes everything important is centered.

It makes sense that the ideal set-up has the bearing centered relative to the piston and the beam.

For me, this is just a way to waste time on the internet so I am definitely doing this contemplation purely for fun.