DIY Wheel Polishing. Help needed.

#1

Rennlist Member

Thread Starter

Can anyone give a method for DIY polishing original "manhole cover"

or D90 wheels.

I think these wheels are anodized. How do you remove that coating

before polishing?

or D90 wheels.

I think these wheels are anodized. How do you remove that coating

before polishing?

#2

Rennlist Member

The anodising process gives a very hard surface finish which resists mechanical polishing processes, but doesn't like acids which have been/are used in some wheel cleaners. That's why you see so many manhole covers which have ruined/dull anodised coatings. One acid which was common in mag wheel cleaners and is still used in some aluminium cleaners here in Australia is phosphoric acid. I've used a cleaner with phosphoric acid, available in marine outlets here, which is used for cleaning boats, and you might be able to get a similar product over there. I got a plastic storage bin with a lid large enough to hold a wheel, poured solution over it, and then kept turning, rolling and brushing over time until the anodised finish was gone. There is also another aluminium cleaner which has hydrofluoric acid and sulphuric acid in it which etches the aluminium a bit more, but the hydrofluoric component is nasty. I wasn't able to find many aluminium cleaners in automotive outlets, but all marine stores had lots of these types of acid cleaners which are used for alloy and stainless steel cleaning. WARNING: You're dealing with acids ... extreme safety first and read data sheets.

The photo shows all the baked on brake dust gone and just etched metal ready for polishing or re anodising.

The photo shows all the baked on brake dust gone and just etched metal ready for polishing or re anodising.

#3

Intermediate

To get rid of the anodizing you can do one of two things , ( self ) spray oven cleaner on them and use a gentle scourer to remove the coating , gloves and good ventilation is a must , ( other person ) take them to someone who does soda or glass bead blasting , second method will cost more clearly .

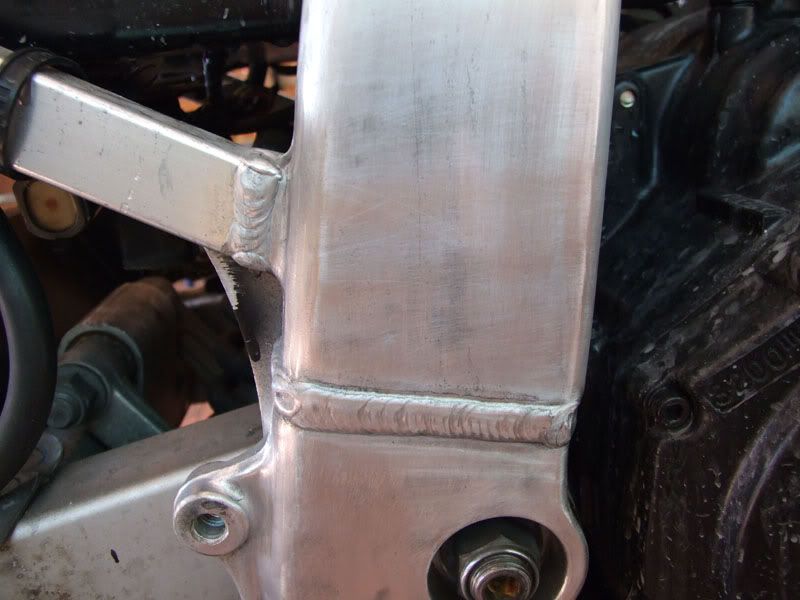

Hope this works its a how to i did for my bike on another forum but translates to what you want

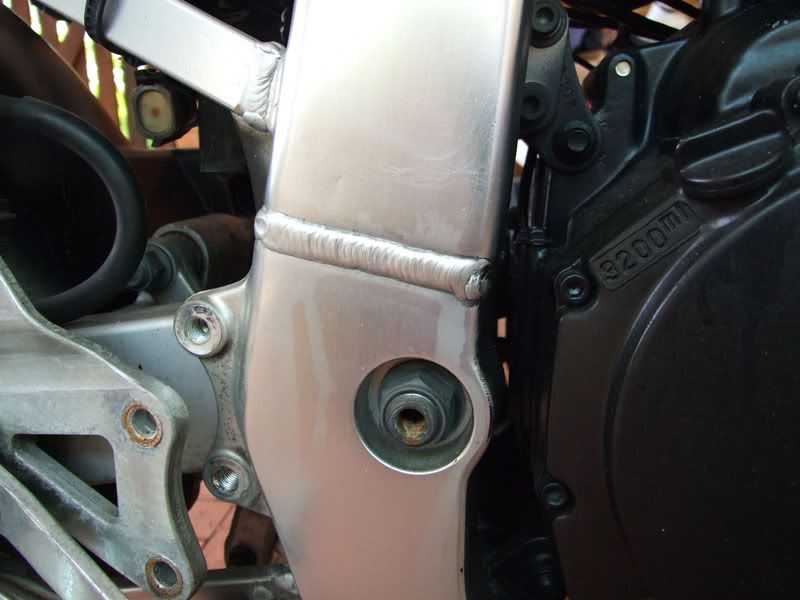

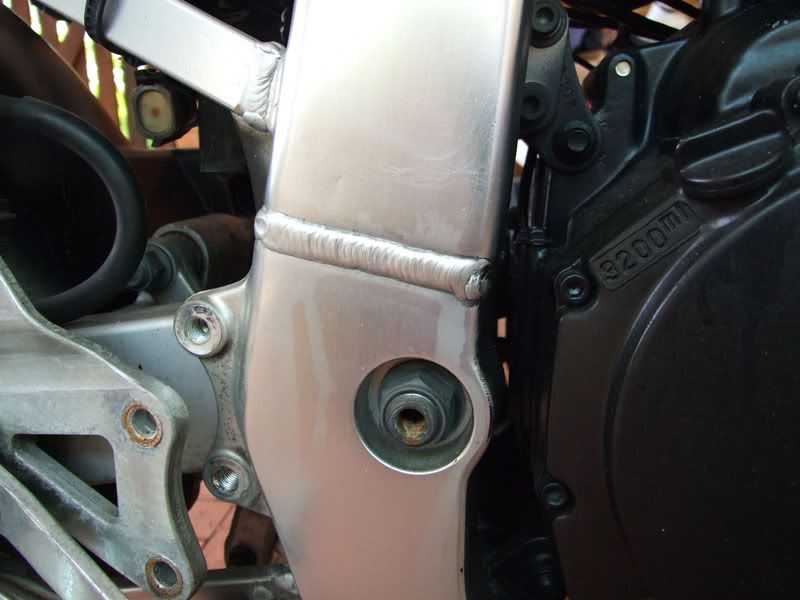

I started with this plastic striping wheel if you are doing something like your rims or if you have the bike completely stripped to the frame chemical stripper is the go, however I don’t want to rip my engine out anymore times than I need to (this will make more sense later on down the line think 7/11and NO I WONT FIGHTER IT! LOL).

Also never use a wire wheel on aluminium it “pits” the hell out of the metal and takes forever to polish out.

Stripping wheel

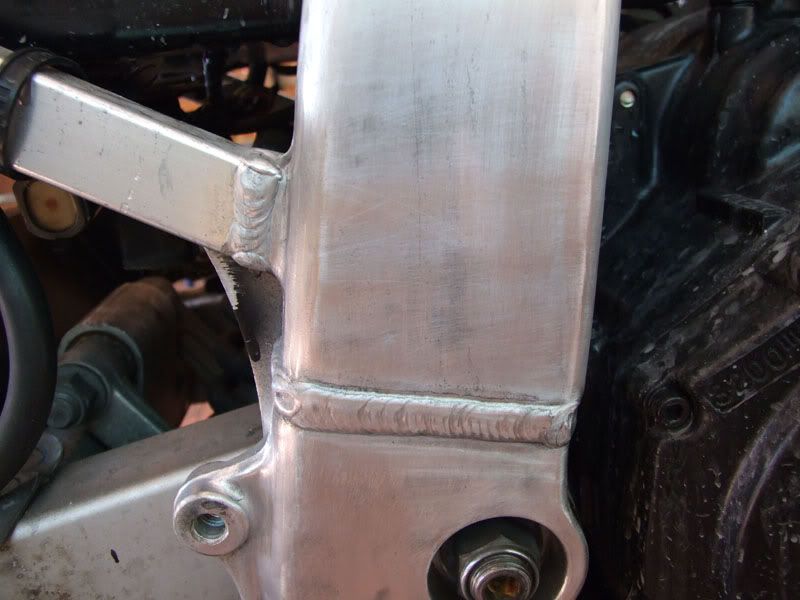

Now with a reasonablely lite amount of force run the strip wheel over the frame or whatever you are stripping don’t sit in one spot to long or you will scratch the metal to much and polishing it out will take awhile, I try to get about 90% of the paint off.

BEFORE

AFTER

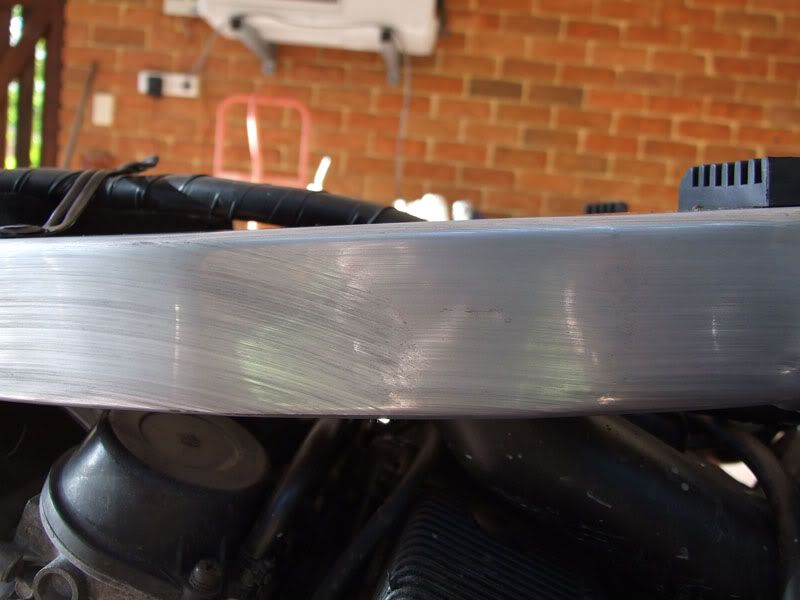

Once you’re happy that enough paint is off time to grab a seat and some water.

I start with 200 – 300 grit wet and dry try to get any deep scratches out and any paint left over but don’t panic if you don’t get every last bit off.

Once you’ve gone over everything start again but with a finer grade.

I used 400 grit because I still had some small spots of paint in a few places

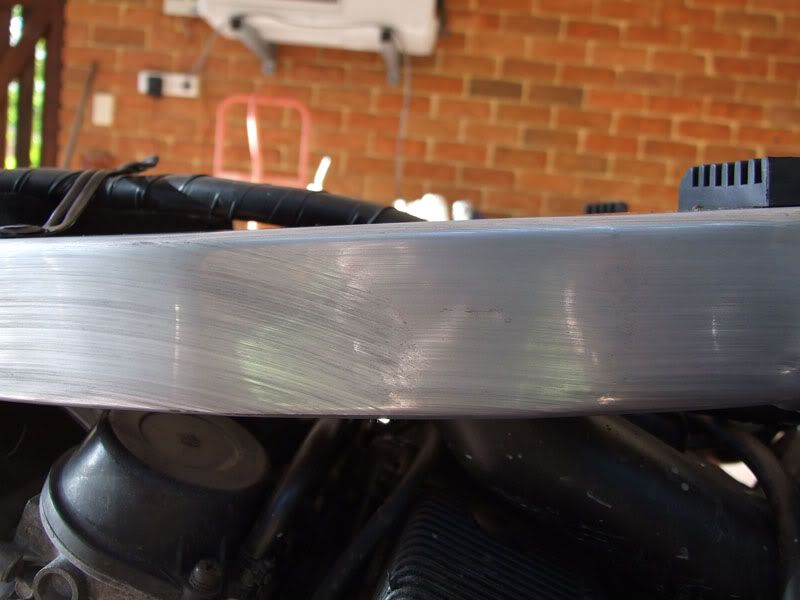

Once you have that done go again with a very fine grade about 600 or higher to get it all as smooth as before you hit it with the polish. If you are super **** you can keep going out to say 1000 – 1500 grit.

200 grit

400 grit

600 grit

Now once she’s all neat and you have any deepish scratches out, time to grab the buffing gear. Below is a picture of what you will need, all these things are readily available from your local Bunnings or whatever store the hard buff wheel will cost you about $15 the loose flap wheels about $10 and the wax I use the white block as it is the one specifically designed for aluminium there about $15 .

If that’s to rich for you or you only want to polish a small amount you can buy a kit with 2 wheels about 3 inches in diameter and 2 wax compounds about 4 inches long for about $25 dollars.

Into it, firstly I like to ruff up the hard buff before using it, just give it a quick spin on the pavers or bricks to furry up the outside.

Then run it on the wax you wont get much on there to start with till its been run a few times on the metal so don’t go mental just yet or you’ll have wax everywhere except where you want it.

Try not to do to large an area at a time the best way I find is to focus on about 6 inches or so that way you can get a decent amount of heat in the metal ( heat is good heat helps), keep putting wax on the buff as often as is needed once the wheel is worn in and lean on it put a decent amount of pressure on the buff.

Once the metal is warn enough you can just rub the wax straight on rather than putting it on the buff wheel.

Or if you want to speed things up get a small blow torch and heat it up just don’t go over board.

When you are happy that she is all nice and shiny and you have all the scratches out it should look near mirror finish just a little dirty from the polish left on the metal don’t go to mental just yet trying to get every last lump of wax of that comes later.

Now grab the loose flap wheel and go over it all again.

You don’t need to put **** loads of polish on this buff wheel just enough to move the wax still on the metal and to shine it up all nice, again don’t panic trying to get all the wax off the metal but try to get most of it with this pass.

Now for a final clean off you can give it a wipe down with thinners first if you like to remove any wax left.

I next grab the wadding polish this stuff I have only found in Coventry’s stores can’t remember the cost but its great stuff it’s like a lump of wool and has an oil through it.

It will shiny up most metals, aluminium, stainless steel and titanium.

Go over everything until it all goes foggy looking and rub a bit harder if you have any lumps of wax left on this will move it no drama’s.

Hmph, I missed a bit on that weld will have to go a bit more anyway, grab a “cheese cloth” type rag or what have you and rub it all off

Once you have finished cleaning everything off she should come up all pretty and shiny. From time to time when you detail your bike you can just give the polished bits a quick rub down again with the cotton wadding polish and they will keep shining!

Hope this works its a how to i did for my bike on another forum but translates to what you want

I started with this plastic striping wheel if you are doing something like your rims or if you have the bike completely stripped to the frame chemical stripper is the go, however I don’t want to rip my engine out anymore times than I need to (this will make more sense later on down the line think 7/11and NO I WONT FIGHTER IT! LOL).

Also never use a wire wheel on aluminium it “pits” the hell out of the metal and takes forever to polish out.

Stripping wheel

Now with a reasonablely lite amount of force run the strip wheel over the frame or whatever you are stripping don’t sit in one spot to long or you will scratch the metal to much and polishing it out will take awhile, I try to get about 90% of the paint off.

BEFORE

AFTER

Once you’re happy that enough paint is off time to grab a seat and some water.

I start with 200 – 300 grit wet and dry try to get any deep scratches out and any paint left over but don’t panic if you don’t get every last bit off.

Once you’ve gone over everything start again but with a finer grade.

I used 400 grit because I still had some small spots of paint in a few places

Once you have that done go again with a very fine grade about 600 or higher to get it all as smooth as before you hit it with the polish. If you are super **** you can keep going out to say 1000 – 1500 grit.

200 grit

400 grit

600 grit

Now once she’s all neat and you have any deepish scratches out, time to grab the buffing gear. Below is a picture of what you will need, all these things are readily available from your local Bunnings or whatever store the hard buff wheel will cost you about $15 the loose flap wheels about $10 and the wax I use the white block as it is the one specifically designed for aluminium there about $15 .

If that’s to rich for you or you only want to polish a small amount you can buy a kit with 2 wheels about 3 inches in diameter and 2 wax compounds about 4 inches long for about $25 dollars.

Into it, firstly I like to ruff up the hard buff before using it, just give it a quick spin on the pavers or bricks to furry up the outside.

Then run it on the wax you wont get much on there to start with till its been run a few times on the metal so don’t go mental just yet or you’ll have wax everywhere except where you want it.

Try not to do to large an area at a time the best way I find is to focus on about 6 inches or so that way you can get a decent amount of heat in the metal ( heat is good heat helps), keep putting wax on the buff as often as is needed once the wheel is worn in and lean on it put a decent amount of pressure on the buff.

Once the metal is warn enough you can just rub the wax straight on rather than putting it on the buff wheel.

Or if you want to speed things up get a small blow torch and heat it up just don’t go over board.

When you are happy that she is all nice and shiny and you have all the scratches out it should look near mirror finish just a little dirty from the polish left on the metal don’t go to mental just yet trying to get every last lump of wax of that comes later.

Now grab the loose flap wheel and go over it all again.

You don’t need to put **** loads of polish on this buff wheel just enough to move the wax still on the metal and to shine it up all nice, again don’t panic trying to get all the wax off the metal but try to get most of it with this pass.

Now for a final clean off you can give it a wipe down with thinners first if you like to remove any wax left.

I next grab the wadding polish this stuff I have only found in Coventry’s stores can’t remember the cost but its great stuff it’s like a lump of wool and has an oil through it.

It will shiny up most metals, aluminium, stainless steel and titanium.

Go over everything until it all goes foggy looking and rub a bit harder if you have any lumps of wax left on this will move it no drama’s.

Hmph, I missed a bit on that weld will have to go a bit more anyway, grab a “cheese cloth” type rag or what have you and rub it all off

Once you have finished cleaning everything off she should come up all pretty and shiny. From time to time when you detail your bike you can just give the polished bits a quick rub down again with the cotton wadding polish and they will keep shining!

#4

Captain Obvious

Super User

Super User

Self cleaning oven sprays supposed to be good too. I've tried on a small spot on a spare wheel and it looked like it took off the coating.

#5

Intermediate

Sorry forgot to edit out the stripper wheel aspect of the write up , i use oven cleaner now that write up was done a while ago

#6

Captain Obvious

Super User

Super User

You and I posted at the same time and I didn't see yours unitll mine came up. Seems like the oven cleaner is the simplest to use. Nice write up by the way.

#7

Rennlist Member

I tried the two acid cleaners I've already mentioned and also strong alkalis like oven cleaners, and found the acid cleaners worked a bit better on removing the anodised coating, but also worked best on baked on brake dust, with a bit of scrubbing. Nice write up on the polishing raven928  .

.

.

.

Trending Topics

#8

Rennlist Member

Thanks for this, I've got a set that need attention this week pre-tires.

If annodized and weathered, a spritz of WD 40 makes them appear nicer than they really are. For a week or so.

If annodized and weathered, a spritz of WD 40 makes them appear nicer than they really are. For a week or so.

#9

Rennlist Member

Thread Starter

Wow Raven 928, that's what I call an answer!

Fabulous detailed write up and the pictures make it all so clear.

Thank you and all the other responders so much.

This forum is just the best.

Searching on the web I found this website with loads

of information on polishing.

www.englishcustompolishing.com

Fabulous detailed write up and the pictures make it all so clear.

Thank you and all the other responders so much.

This forum is just the best.

Searching on the web I found this website with loads

of information on polishing.

www.englishcustompolishing.com

#10

Household Lye (Drano in the US.) mixed with water will strip the anodization in minutes. It will leave a powdery black residue which will wash off with soapy water. DO be extremely careful as splashed lye will burn. I've used it on wheels by mixing the lye solution in a flat vessel large enough to allow the wheel to soak one face at a time. If you leave it in too long it will pit the aluminum.

#12

Intermediate

No probs mate that is just a small snippet from a long and lengthy build/tidy/restore thread for my bike but it all translates !

Im not very CDO ( OCD but in correct alphabetical order LMAO )

Im not very CDO ( OCD but in correct alphabetical order LMAO )

#13

Not the sharpest tool in the shed

Rennlist Member

Rennlist Member

Rod - is the lye solution diluted at all or do you use the drain clearing product full strength? How long did you let each side of the wheel sit in the solution?

Household Lye (Drano in the US.) mixed with water will strip the anodization in minutes. It will leave a powdery black residue which will wash off with soapy water. DO be extremely careful as splashed lye will burn. I've used it on wheels by mixing the lye solution in a flat vessel large enough to allow the wheel to soak one face at a time. If you leave it in too long it will pit the aluminum.

#14

The lye is mixed full strength - if you splash it on yourself it combines with the fat in the skin and makes soap. The time required for de-anodizing is variable; 10 to 30-45 minutes and inconsistent, some areas will take longer and may require sandpaper to remove completely. In my area polishers which cater to big trucks use a rotary polishing machine which spins the wheel. The cost for car wheels is around $50/wheel.

#15

Not the sharpest tool in the shed

Rennlist Member

Rennlist Member

The lye is mixed full strength - if you splash it on yourself it combines with the fat in the skin and makes soap. The time required for de-anodizing is variable; 10 to 30-45 minutes and inconsistent, some areas will take longer and may require sandpaper to remove completely. In my area polishers which cater to big trucks use a rotary polishing machine which spins the wheel. The cost for car wheels is around $50/wheel.