Piston wrist pin offset

#31

Nordschleife Master

I just read some more about this and maybe Porsche isn't crazy after all. The most important benefits may come from the pin being slightly offset in _either_ direction. More to follow, once I got time to report.

#34

Nordschleife Master

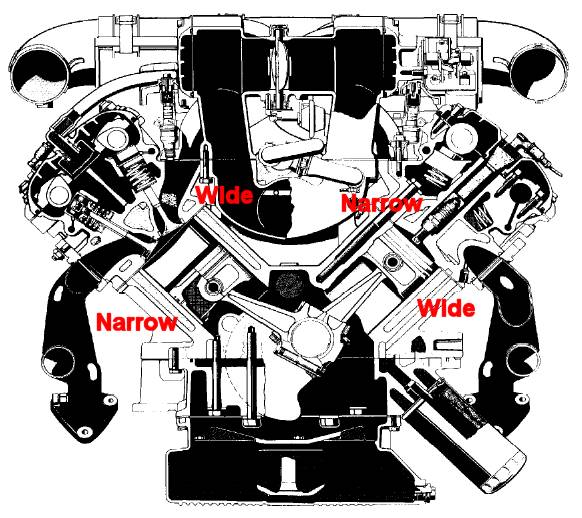

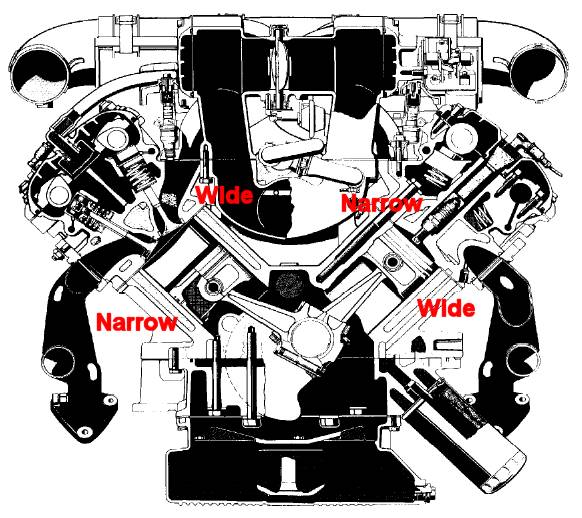

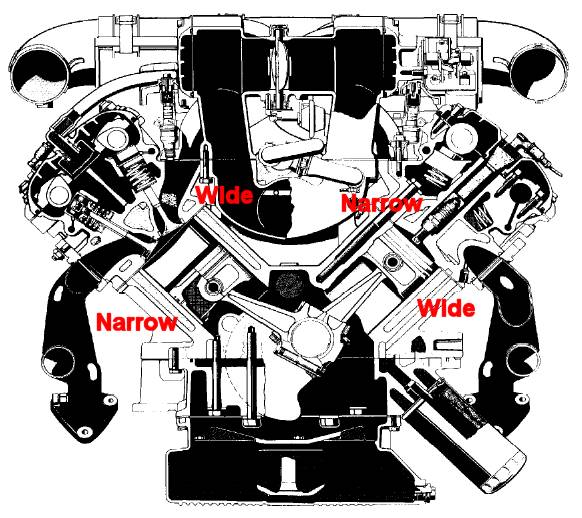

Look at the picture. It shows you how to install the offset piston for maximum power:

http://picasaweb.google.com/lh/photo...eat=directlink

For the dyno proof, see the rest of the pages.

http://picasaweb.google.com/lh/photo...eat=directlink

For the dyno proof, see the rest of the pages.

#35

Rennlist

Basic Site Sponsor

Basic Site Sponsor

But do they install one side one way and the other side the opposite way?

As far as the 911 engines are concerned, it took Porsche until the very latest "cup" race engines to make 3 left and 3 right pistons. Not bad...43 years to fix a simple design problem.

Never have been able to figure out why the Germans lost 2 World Wars......

As far as the 911 engines are concerned, it took Porsche until the very latest "cup" race engines to make 3 left and 3 right pistons. Not bad...43 years to fix a simple design problem.

Never have been able to figure out why the Germans lost 2 World Wars......

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

#36

Nordschleife Master

But do they install one side one way and the other side the opposite way? As far as the 911 engines are concerned, it took Porsche until the very latest "cup" race engines to make 3 left and 3 right pistons. Not bad...43 years to fix a simple design problem. Never have been able to figure out why the Germans lost 2 World Wars......

The reason why I think Porsche isn't doing something stupid here is that the majority of the benefits from piston offset is realized as long as the piston is offset in *either direction.* There's a small difference between wear vs. power vs. ability to take detonation depending on which way yhey are installed, but that's small compared to having the offset in any direction vs. having the pin centered.

Smokey focused on which way to offset the pistons. Yes, by offsetting the piston in a way that is described in the diagram of my earlier link produces more power. But that's a small benefit compared to the reduction of maximum inertial force on the piston-rod combination caused by offset in either direction. See a description from the web below:

http://www.motorcycleproject.com/mot...ws-offset.html

The piston and its half of the connecting rod stops twice per crankshaft revolution, even though the crankshaft continues to turn. This means the piston and top of the rod also start back up twice. This stopping and starting imposes stresses on all three of the parts, stresses that increase with crankshaft rpm. To reduce these loads, the piston is mounted to the connecting rod slightly offset. This causes the piston to reach top dead center at a different time than the connecting rod, effectively spreading the shock loading over a greater number of crankshaft degrees. In short, the real reason for piston pin offset is that it softens reciprocal loading, permitting lighter more power-efficient parts to be used, and the engines to be capable of higher rpm.

However, there is another phenomenon at work also, a kind of side benefit. Because the connecting rod spends most of its time in the engine at an angle, the piston engine has what is called minor and major thrust. Major thrust refers to the downward-stroking piston's force against the cylinder wall during combustion, due to the rod being angled in that direction. Minor thrust is the piston's thrust against the opposite cylinder wall during compression, because the rod's angle is opposite also. These thrust forces push the piston firmly against the cylinder wall. The important thing is that at TDC, they flip-flop. Major thrust turns into minor thrust, and visa-versa. In older engines, this flip-flop caused the piston smack the cylinder, resulting in a noise. Fortunately, the piston pin offset in today's engines, besides reducing inertia stresses, does two things that reduce this noise. First, because the piston is mounted off center, the transition from major to minor thrust is less sudden. There is less impact. Second, instead of a sudden lateral shift, the piston actually rolls from major to minor thrust. That is, the piston shifts first at the skirt, then gradually the rest of the piston makes contact, instead of all of the piston at once.

To summarize, piston pin offset is the manufacturer's way of reducing stress on reciprocating parts. It permits these parts to be lighter, which results in more efficient manufacture and less power loss in the engine, as well as higher rpm. A complementary result of piston pin offset is reduced piston slap due to the more gradual shift from major to minor thrust.

However, there is another phenomenon at work also, a kind of side benefit. Because the connecting rod spends most of its time in the engine at an angle, the piston engine has what is called minor and major thrust. Major thrust refers to the downward-stroking piston's force against the cylinder wall during combustion, due to the rod being angled in that direction. Minor thrust is the piston's thrust against the opposite cylinder wall during compression, because the rod's angle is opposite also. These thrust forces push the piston firmly against the cylinder wall. The important thing is that at TDC, they flip-flop. Major thrust turns into minor thrust, and visa-versa. In older engines, this flip-flop caused the piston smack the cylinder, resulting in a noise. Fortunately, the piston pin offset in today's engines, besides reducing inertia stresses, does two things that reduce this noise. First, because the piston is mounted off center, the transition from major to minor thrust is less sudden. There is less impact. Second, instead of a sudden lateral shift, the piston actually rolls from major to minor thrust. That is, the piston shifts first at the skirt, then gradually the rest of the piston makes contact, instead of all of the piston at once.

To summarize, piston pin offset is the manufacturer's way of reducing stress on reciprocating parts. It permits these parts to be lighter, which results in more efficient manufacture and less power loss in the engine, as well as higher rpm. A complementary result of piston pin offset is reduced piston slap due to the more gradual shift from major to minor thrust.

#38

Rennlist Member

I read it, my head hurts. So, which way to you mount the piston so the offset gives all the benefits of less wear and more HP?

on a side note, didnt porsche figure this out on the S4, with asymetrical pistons that could be reversed side to side to keep the offset correct? (for asymetrical valve relief requirements)

on a side note, didnt porsche figure this out on the S4, with asymetrical pistons that could be reversed side to side to keep the offset correct? (for asymetrical valve relief requirements)

#39

Addict

Rennlist Member

Rennlist Member

Thread Starter

All I want to know is which way to put pistons

1. for best power

2. for least wear and noise

How to put narrow and wide side for 1. and 2.?

#40

Rennlist Member

No, and correct me if im wrong, but it would NOT have them in different positions, it would have the forces the same on both sides. on both sides the rod would be closer to the left side of the piston, pushing down on the crank as the rod journal moves toward the right as it goes down. this looks like it adds to the forces to the side of the cylinder walls (to the left) but better leverage on the crank. (more power). correct??

So, you want the narrow side of the piston toward the passenger side on BOTH sides of the engine.

in contrast, the 2 valvers and early 4 valve engines had piston arrows that pointed to the exhaust valve side (down). that meant both sides were different. we corrected this by flipping the pistons on the one side and cutting the valve reliefs in opposite configuration . now, there is left and right side pistons in those engines (5 liter part euro 2 valver)

mk

So, you want the narrow side of the piston toward the passenger side on BOTH sides of the engine.

in contrast, the 2 valvers and early 4 valve engines had piston arrows that pointed to the exhaust valve side (down). that meant both sides were different. we corrected this by flipping the pistons on the one side and cutting the valve reliefs in opposite configuration . now, there is left and right side pistons in those engines (5 liter part euro 2 valver)

mk

Yes and no. S4 pistons can be reversed IIRR but Porsche in their infinite wisdom put arrow into them and said install them arrow pointing forward. This results one side to be one way and other other way.

All I want to know is which way to put pistons

1. for best power

2. for least wear and noise

How to put narrow and wide side for 1. and 2.?

All I want to know is which way to put pistons

1. for best power

2. for least wear and noise

How to put narrow and wide side for 1. and 2.?

#41

Three Wheelin'

so on the passenger side (1,2,3,4) pistons arrow should point to the front belts and on the driver side (5,6,7,8) pistons arrow should point to the flywheel.

basically the narrow side of the piston pin offset should be on the exhaust valve side pointing to the ground.

basically the narrow side of the piston pin offset should be on the exhaust valve side pointing to the ground.

#43

Three Wheelin'

I know but from reading, their saying the manufacturer did this to reduce noise. some engine builders turn the pistons on the driver side so the narrow part be on the exhaust side like the passenger side. The engine is a 90 GT short block so the valve pockets are the same. I want to know if any one has assembled their engine with the arrows on the driver side pointing to the flywheel.

Edit: Okay I think I got it wrong about only swapping one side.

Edit: Okay I think I got it wrong about only swapping one side.

Last edited by namasgt; 12-04-2009 at 02:04 AM.

#45

Three Wheelin'

I already read that,

I found this thread explaining it with drawing

http://www.onecamonly.com/general-te...in-offset.html

and then on this thread someone is saying that the trust side on the cylinder wall is on the exhaust side of the passenger side and on the intake side on the drivers side, According to this Porsche did it right to reduce noise,

http://www.realoldspower.com/phpBB2/...f4bfbf05e4d7fb

Last edited by namasgt; 12-04-2009 at 02:16 AM.