Long-Term Impressions: Constantine's Upgraded Torque Tube Bearing System

#1

Rennlist Member

Thread Starter

A few weeks ago, I finished a large Drive Train Refurb Project that included a Torque Tube Rebuild with the upgraded bearing system that Constantine has been working on. Last I talked to him about them he was looking to have a volume order in the first couple months of 2009. The parts that I used for my rebuild were from a very short production run using the final production process. IIRC he mentioned further lightening the aluminum version of the part, but I don't have the details. Hopefully he will chime in.

From the very first moment I saw the pic of the part on this thread I was interested. In discussing the part with him I quickly realized that he had put a lot of thought into the design and tried to address every possible weakness in the original system. The second link above is my distillation of my understanding of the problems faced by would-be DIY rebuilders and the limitations of rebuilds carried out with used parts, as well as my take on what the replacement units offer. I admit I plagiarized Constantine on the first bullet point under "Replacement Bearings" but the rest is my own understanding of the various rebuild approaches available.

All of the gory details are on my website, and I do have a page there where I will post a summary of my experience with the new drivetrain parts and updates over the long haul but I wanted to start this thread as a further chronicle and a place where I can answer any questions about the process or the parts.

So, I'll get on to the 928 **** that you all were looking for when you clicked on the topic:

The rebuild process was very fast. 20 minutes to get the TT disassembled, Maybe 1/2 hour cleaning and drying, and 1/2 hour assembling(including taking pics).

I am very pleased with the result. Any new bearings in the TT would be smooth and quiet initially, but IMHO there is a great deal of satisfaction knowing that I have installed uprated parts in a component that can be troublesome.

What follows is mostly a rehash of what I have on the Long Term Results Page regarding the carriers. Enjoy!

The following three pictures illustrate the gauges used and the initial measurements. The actual measurements as absolute values are really meaningless since I am only checking for differences over time. The pics below are mostly to refresh my memory when checking periodically, and to show others who may be curious about my methods how I went about it.

Initially the torque tube bearings were almost completely silent. With a stethoscope I was able to detect that there were bearings in the tube, but they could not be heard without the stethoscope.

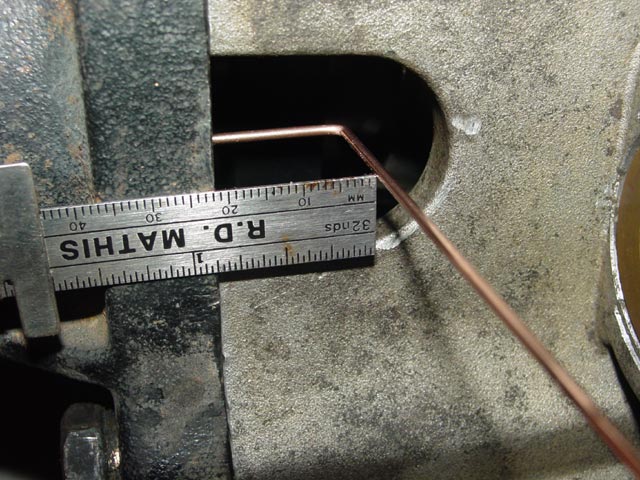

Before installing the front heat shield, I made a gauge out of welding rod to check the front carrier location. I made the gauge in such a way that this check could be performed with the heat shield and cat in place. Here is the initial measurement recorded for posterity.

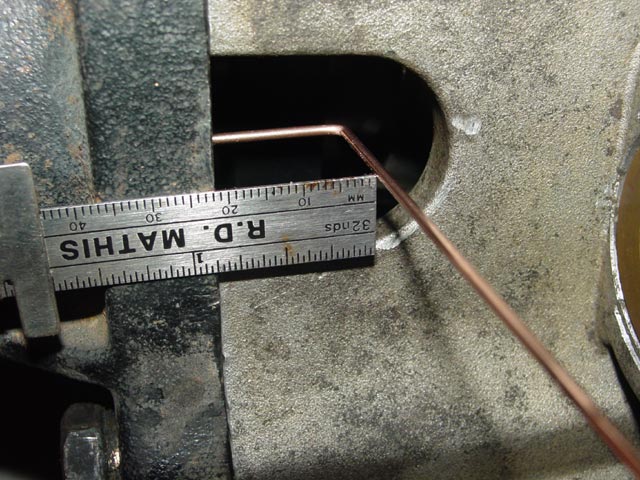

Here is a similar measurement of the rear carrier.

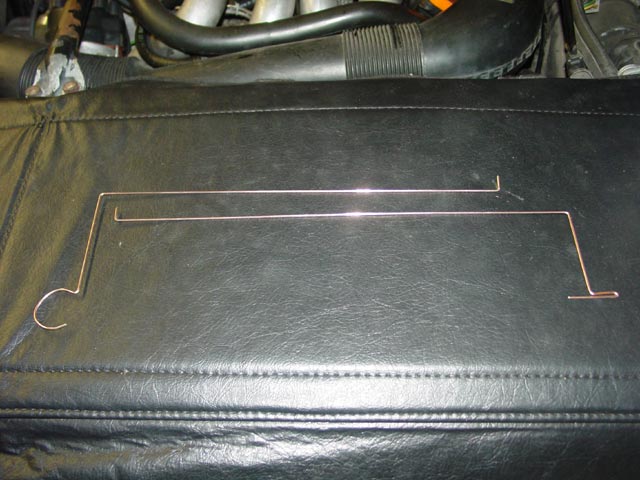

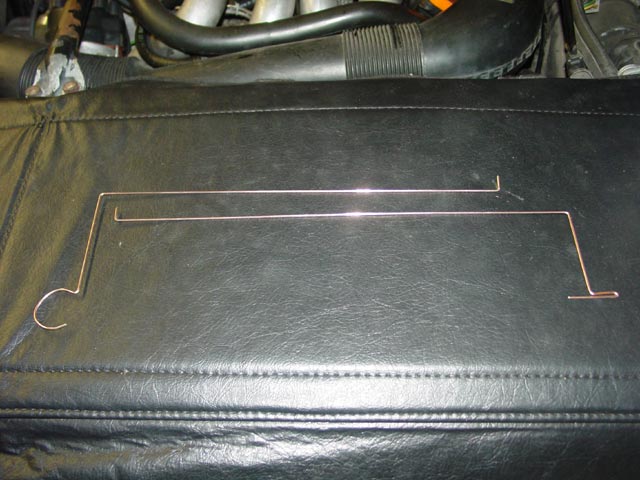

These are the gauges I made up for checking carrier position. The front one has a "C" formed in it to indicate "Clutch End" and the rear one has a "T" formed in it to indicate "Transaxle End". The gauges themselves and their exact dimensions would not be of use on any other car, but the concept may be of general interest. This is the method I will be using in the future to check the bearing carrier position over time.

Below are periodic observations that I have made to date, further observations will be in new replies to this post.

99,347 - 170 Miles: Re-checked for front and rear carrier walk using above method. No movement detected.

99,383 - 206 Miles: Still stiff shifting in the first 1/4-1/2 mile in the morning, Really smoothing out when warm with 2nd still pretty tight and 1st maybe 1/2 way broken in. Able to upshift and downshift to/from gears as appropriate for speed without grinding.

99,837 - 660 Miles: Checked while servicing Clutch Hydraulics. No movement of TT bearing carriers. Shifting is becoming much more manageable, with an occasional struggle to get into 1st when cold but otherwise working very well. Note that the fresh Clutch hydraulics have made the clutch noticeably smoother, more linear and predictable. I'm confident that the hose accounts for most of the improvement.

100,187 - 1,010 Miles: Checked toward end of Christmas break(Around Jan 4, 2009). No movement of TT bearing carriers, no new noises. Most of the miles I've put on since the last update have been highway miles.

to Constantine for a great product and I hope to get lots of

to Constantine for a great product and I hope to get lots of  and trouble-free service out of my upgraded TT.

and trouble-free service out of my upgraded TT.

From the very first moment I saw the pic of the part on this thread I was interested. In discussing the part with him I quickly realized that he had put a lot of thought into the design and tried to address every possible weakness in the original system. The second link above is my distillation of my understanding of the problems faced by would-be DIY rebuilders and the limitations of rebuilds carried out with used parts, as well as my take on what the replacement units offer. I admit I plagiarized Constantine on the first bullet point under "Replacement Bearings" but the rest is my own understanding of the various rebuild approaches available.

All of the gory details are on my website, and I do have a page there where I will post a summary of my experience with the new drivetrain parts and updates over the long haul but I wanted to start this thread as a further chronicle and a place where I can answer any questions about the process or the parts.

So, I'll get on to the 928 **** that you all were looking for when you clicked on the topic:

The rebuild process was very fast. 20 minutes to get the TT disassembled, Maybe 1/2 hour cleaning and drying, and 1/2 hour assembling(including taking pics).

I am very pleased with the result. Any new bearings in the TT would be smooth and quiet initially, but IMHO there is a great deal of satisfaction knowing that I have installed uprated parts in a component that can be troublesome.

What follows is mostly a rehash of what I have on the Long Term Results Page regarding the carriers. Enjoy!

The following three pictures illustrate the gauges used and the initial measurements. The actual measurements as absolute values are really meaningless since I am only checking for differences over time. The pics below are mostly to refresh my memory when checking periodically, and to show others who may be curious about my methods how I went about it.

Initially the torque tube bearings were almost completely silent. With a stethoscope I was able to detect that there were bearings in the tube, but they could not be heard without the stethoscope.

Before installing the front heat shield, I made a gauge out of welding rod to check the front carrier location. I made the gauge in such a way that this check could be performed with the heat shield and cat in place. Here is the initial measurement recorded for posterity.

Here is a similar measurement of the rear carrier.

These are the gauges I made up for checking carrier position. The front one has a "C" formed in it to indicate "Clutch End" and the rear one has a "T" formed in it to indicate "Transaxle End". The gauges themselves and their exact dimensions would not be of use on any other car, but the concept may be of general interest. This is the method I will be using in the future to check the bearing carrier position over time.

Below are periodic observations that I have made to date, further observations will be in new replies to this post.

99,347 - 170 Miles: Re-checked for front and rear carrier walk using above method. No movement detected.

99,383 - 206 Miles: Still stiff shifting in the first 1/4-1/2 mile in the morning, Really smoothing out when warm with 2nd still pretty tight and 1st maybe 1/2 way broken in. Able to upshift and downshift to/from gears as appropriate for speed without grinding.

99,837 - 660 Miles: Checked while servicing Clutch Hydraulics. No movement of TT bearing carriers. Shifting is becoming much more manageable, with an occasional struggle to get into 1st when cold but otherwise working very well. Note that the fresh Clutch hydraulics have made the clutch noticeably smoother, more linear and predictable. I'm confident that the hose accounts for most of the improvement.

100,187 - 1,010 Miles: Checked toward end of Christmas break(Around Jan 4, 2009). No movement of TT bearing carriers, no new noises. Most of the miles I've put on since the last update have been highway miles.

to Constantine for a great product and I hope to get lots of

to Constantine for a great product and I hope to get lots of  and trouble-free service out of my upgraded TT.

and trouble-free service out of my upgraded TT.

#2

Nordschleife Master

Dave,

Whats the total cost of this setup?

Is it the same for auto and 5 speed. (I believe the 5 speed has an additional bearing)

Looks good, rebuilding a torque tube in under an hour sounds great, the cost i assume is less then the typical $500 as well. If it just happens to be reengineered then hey its a win win!

Whats the total cost of this setup?

Is it the same for auto and 5 speed. (I believe the 5 speed has an additional bearing)

Looks good, rebuilding a torque tube in under an hour sounds great, the cost i assume is less then the typical $500 as well. If it just happens to be reengineered then hey its a win win!

#3

Rennlist Member

Thread Starter

Ryan, I'll let Constantine address the question of cost. I agreed not to divulge my cost for my set -- I believe it was one of two or three initial sets. Once Constantine has nailed down volume pricing he will make a public post with the info. It wouldn't be fair for me to speculate, but I can say that Constantine is aware of the cost of a used-carrier rebuild from 928I and he wanted the design to be manufacturable at a price point that would encourage those in need of rebuilt torque tubes to give this option fair consideration.

One point to ponder -- the cost of shipping these units was a pittance compared to shipping a rebuilt TT to you, then shipping the core back. At least, that would be the case if you lived far enough away to require shipping.

One point to ponder -- the cost of shipping these units was a pittance compared to shipping a rebuilt TT to you, then shipping the core back. At least, that would be the case if you lived far enough away to require shipping.

#4

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

1,100 miles is "long-term"? Good write up, Dave. I do like the design of the bearing holders. Be sure to come back and report at 100K miles!

#5

Rennlist Member

Thread Starter

I will be reporting each time I check the bearings, probably every few thousand miles from here on. This is a starting point, and is a place to report results to the community over the long term. It wouldn't be much use to wait until I had 100K on them before saying anything, now would it?

I will be reporting each time I check the bearings, probably every few thousand miles from here on. This is a starting point, and is a place to report results to the community over the long term. It wouldn't be much use to wait until I had 100K on them before saying anything, now would it?

#7

Hi Dave,

Nice write up and we really appreciate your thoughts and kind words!

As a disclaimer to anyone reading this thread, the understanding between Dave and us was to let Dave give his real world impressions about the TT rebuild parts. If they were good, great, not so good, well then not so great for us. After initially discussing this whole venture with Dave , I quickly realized Dave is a thinking man's DIYer with a lot of technical background and he does get into the weeds about every aspect of a project. I also realized that Dave would not compromise himself and if the parts were not any good he would say so.

We were comfortable to allow someone to install the TT parts since we have been working on these for a few years. Every failure mode of the original bearing units has been reviewed and dialed out of these redesigned units. We have tested them and are very sure of their performance over the long haul.

We are comitted to developing products that are good upgrades for the 928 owners and DIYers who want to enhance their 928 enjoyment. As with the clamp, we designed these parts to be used as an upgrade to known problems. These new bearing units replace the aging TT innards and which are no longer available (NLA).

These new bearing units can be used in both the automatic (25mm drive shaft) and all 5 speed versions. Although we developed bearing inserts for the 28mm drive shafts, we will not sell rebuild kits for them due to the known problems of the 28mm drive shafts shearing. We will offer new 25mm drive shafts made from a much stronger material for those who have the 28mm drive shafts or 25mm drive shafts with problems, such as mangled splines. Of course used 25mm drive shafts can also be found in the used 928 parts market as well.

The cost is still being determined for the different kits one can make for their needs. When looking at standard costs of buying a rebuilt TT do not forget the shipping costs to you and then back of your own TT and the associated core charge. One should also consider for that money one is really only getting two to three new bearings, which are not the correct bearings Porsche specified in the first place, 2006 C5, but usually a C3 rated bearing which is not clearanced correctly for the job. This not a slam against anyone who rebuilds TTs, just a fact from the rebuilt TTs we dismantled in our R&D for these new products. The 2006 C5 clearanced bearings are NLA, at least from the many sources we initially contacted before deciding to radically change the bearing unit design and upgrade the bearing itself. Our bearing units use a 2008 C4 bearing which is physically bigger, dissipates heat better and the clearance range is nearly identical to the 2006 C5 bearing it replaces.

This is long enough and I'll end this here. As for the long term 100,000 mile report, we are very confident there will not really be any difference from when they were initially installed.

Cheers,

Constantine

Nice write up and we really appreciate your thoughts and kind words!

As a disclaimer to anyone reading this thread, the understanding between Dave and us was to let Dave give his real world impressions about the TT rebuild parts. If they were good, great, not so good, well then not so great for us. After initially discussing this whole venture with Dave , I quickly realized Dave is a thinking man's DIYer with a lot of technical background and he does get into the weeds about every aspect of a project. I also realized that Dave would not compromise himself and if the parts were not any good he would say so.

We were comfortable to allow someone to install the TT parts since we have been working on these for a few years. Every failure mode of the original bearing units has been reviewed and dialed out of these redesigned units. We have tested them and are very sure of their performance over the long haul.

We are comitted to developing products that are good upgrades for the 928 owners and DIYers who want to enhance their 928 enjoyment. As with the clamp, we designed these parts to be used as an upgrade to known problems. These new bearing units replace the aging TT innards and which are no longer available (NLA).

These new bearing units can be used in both the automatic (25mm drive shaft) and all 5 speed versions. Although we developed bearing inserts for the 28mm drive shafts, we will not sell rebuild kits for them due to the known problems of the 28mm drive shafts shearing. We will offer new 25mm drive shafts made from a much stronger material for those who have the 28mm drive shafts or 25mm drive shafts with problems, such as mangled splines. Of course used 25mm drive shafts can also be found in the used 928 parts market as well.

The cost is still being determined for the different kits one can make for their needs. When looking at standard costs of buying a rebuilt TT do not forget the shipping costs to you and then back of your own TT and the associated core charge. One should also consider for that money one is really only getting two to three new bearings, which are not the correct bearings Porsche specified in the first place, 2006 C5, but usually a C3 rated bearing which is not clearanced correctly for the job. This not a slam against anyone who rebuilds TTs, just a fact from the rebuilt TTs we dismantled in our R&D for these new products. The 2006 C5 clearanced bearings are NLA, at least from the many sources we initially contacted before deciding to radically change the bearing unit design and upgrade the bearing itself. Our bearing units use a 2008 C4 bearing which is physically bigger, dissipates heat better and the clearance range is nearly identical to the 2006 C5 bearing it replaces.

This is long enough and I'll end this here. As for the long term 100,000 mile report, we are very confident there will not really be any difference from when they were initially installed.

Cheers,

Constantine

Last edited by Black Sea RD; 02-04-2009 at 09:23 AM. Reason: currect spilling

Trending Topics

#8

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Ive got a core/shaft sitting in the attic from when i basically took my car apart last summer. I was eventually going to return it but if these bearings/carriers are available now i'd defintiely be interested in a set up for my 4 spd auto. Good test bed for running around at 440ftlbs of Tq.

Not that i want to drop everyhting out of the bottom again but i do have a small small seep from the converter seal i replaced that needs to be redone eventually. ..leaves about a dime size stain after a few nights.

Glad to see you got them up and running Constantine....they look great!

The way the tube makes contact with the bearing is different....no plastic bushing in there anymore?

Not that i want to drop everyhting out of the bottom again but i do have a small small seep from the converter seal i replaced that needs to be redone eventually. ..leaves about a dime size stain after a few nights.

Glad to see you got them up and running Constantine....they look great!

The way the tube makes contact with the bearing is different....no plastic bushing in there anymore?

#9

Rennlist Member

Thread Starter

#10

Nordschleife Master

is there a ballpark price?

Shipping isnt a concern for me as i live in So Cal. Ive also heard of guys buying $50-$100 worth of bearings and rebuilding them themselves. I am a 5 speed guy and am not sure TT replacement is that much of an issue on those cars. So i may not be the ideal customer for a number of reasons.

I think i recalled seeing $1500 floated around? As a business man myself i would think you would need to be under $500 to have any luck at selling more then a half dozen of these things.

I am curious to just get a ballpark if thats even possible?

Cool idea, it looks really nicely made but im just curious what it costs? If you cant give me a ballpark, do you have an idea of when you will have solid pricing?

Cheers

Shipping isnt a concern for me as i live in So Cal. Ive also heard of guys buying $50-$100 worth of bearings and rebuilding them themselves. I am a 5 speed guy and am not sure TT replacement is that much of an issue on those cars. So i may not be the ideal customer for a number of reasons.

I think i recalled seeing $1500 floated around? As a business man myself i would think you would need to be under $500 to have any luck at selling more then a half dozen of these things.

I am curious to just get a ballpark if thats even possible?

Cool idea, it looks really nicely made but im just curious what it costs? If you cant give me a ballpark, do you have an idea of when you will have solid pricing?

Cheers

#11

Rennlist Member

Thread Starter

Ryan, If you think I have mentioned any price at all for these parts I need to go back and correct it. I think a new TT from Porsche might be that much, but IMHO Constantine would be ill advised to pursue a solution anywhere near that price point. I think there is enough info above that you can make a reasonable guess.

I agreed not to divulge my cost because it would not be representative of what volume pricing would reflect. Having said that though, if you are looking for a $50-$100 solution and are willing to live with the shortcomings of that approach then these are probably not for you.

I agreed not to divulge my cost because it would not be representative of what volume pricing would reflect. Having said that though, if you are looking for a $50-$100 solution and are willing to live with the shortcomings of that approach then these are probably not for you.

#12

Nordschleife Master

Ryan, If you think I have mentioned any price at all for these parts I need to go back and correct it. I think a new TT from Porsche might be that much, but IMHO Constantine would be ill advised to pursue a solution anywhere near that price point. I think there is enough info above that you can make a reasonable guess.

I agreed not to divulge my cost because it would not be representative of what volume pricing would reflect. Having said that though, if you are looking for a $50-$100 solution and are willing to live with the shortcomings of that approach then these are probably not for you.

I agreed not to divulge my cost because it would not be representative of what volume pricing would reflect. Having said that though, if you are looking for a $50-$100 solution and are willing to live with the shortcomings of that approach then these are probably not for you.

Please dont take this the wrong way, i am simply looking for an idea on price. I dont hold anyone to it as its totally speculative. But Constantine produced that fact the TT's were $1500-$1800 and if thats the market he is after then so be it, i will bow out now.

As i said above, if its the $500 rebuilt TT market then i think its the way i would go because i see it as a serious upgrade. If it happens to cost $750, well thats probably too much for me too but i dont know, because i have ZERO idea of what the thing could, or should cost.

#13

Rennlist Member

I guess that's pretty clear, but just to make sure, if someone wants to order the bearing kit and they have a 28mm driveshaft, that order will not be filled?

#14

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member