How to drill a 5L crank like a chevy?

#46

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Drilling like a Chevy just sounds like a too simple solution for me

I ran my hybrid track motor with a drilled crank from Taylor and an accusump. Only 360 grooved the #3 main. Motor never threw a rod and is currently being used in a street car.

Others have thrown rods with just an accusump and stock cranks.

So say what you will about the "band-aid solution". I for one believe it is the only proven modification at this time. Spending an extra $1K on a motor re-build for a drilled crank and accusump is good insurance money. Less than a set of new Hoosier tires

Joe Fan had a stroker crank (chevy oil paths) and an accusump and I have not read that he has thrown a rod. Seems like using the Chevy oil paths in the 928 motor works!

#47

Addict

Rennlist Member

Rennlist Member

Resurrecting this topic from the dead to provide an update on what exactly Taylor Engine does when they drill a 928 crank. Hopefully I can explain it clearly.

Let's start w/ a stock 928 crankshaft. For a stock 928 crankshaft the:

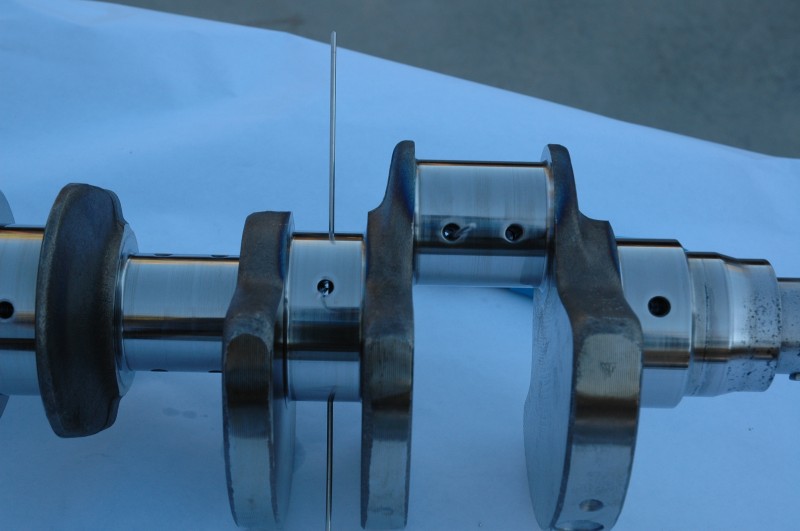

Pic that shows the new cross drills at the #2, #3 & #4 main journals:

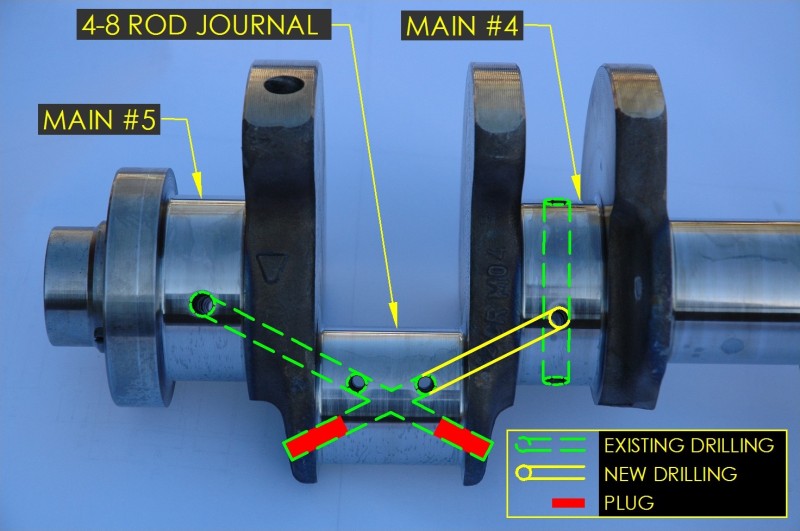

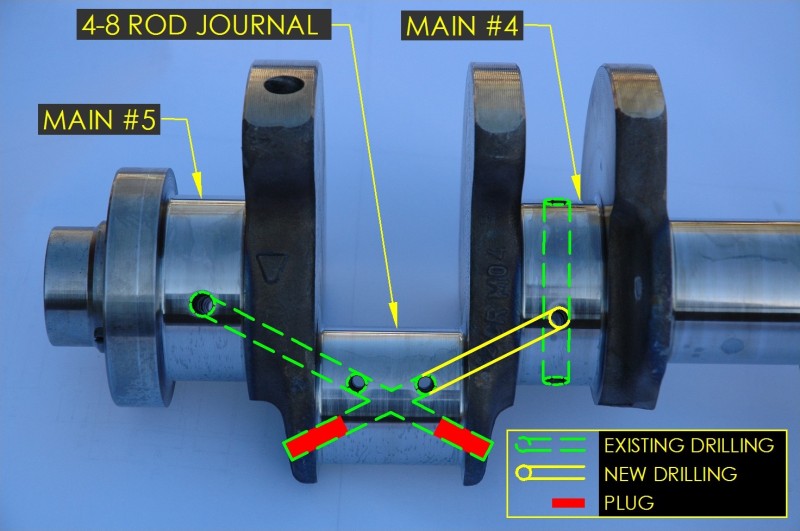

4-8 rod journal w/ new cross-drill @ #4 main:

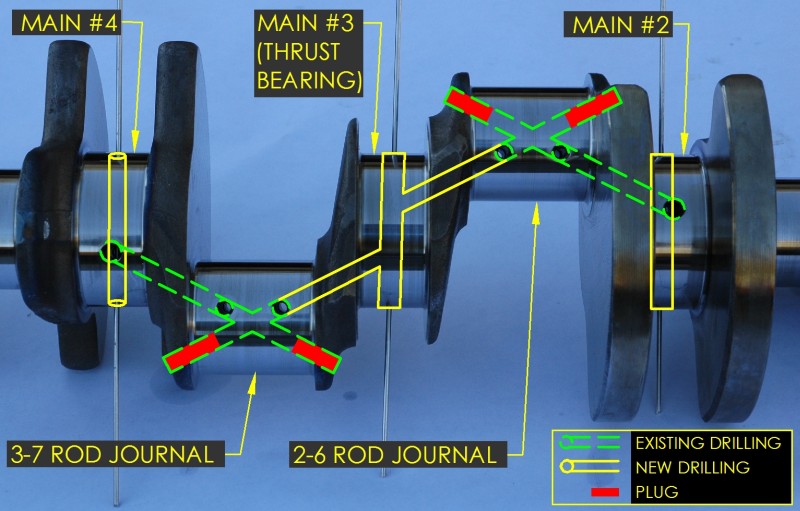

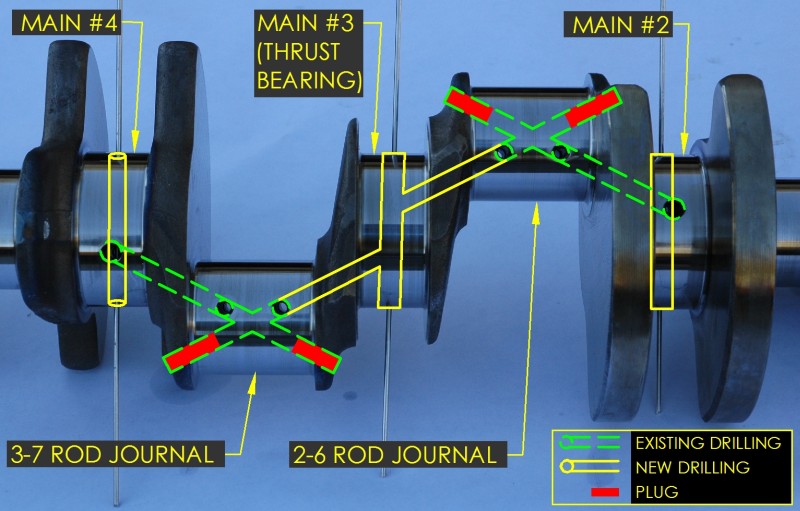

2-6 & 3-7 rod journals w/ new cross-drill @ #3 main (thrust bearing journal):

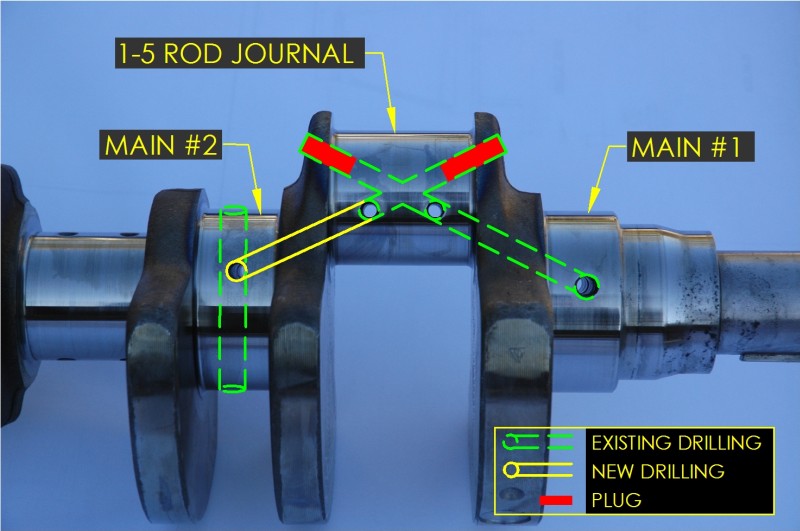

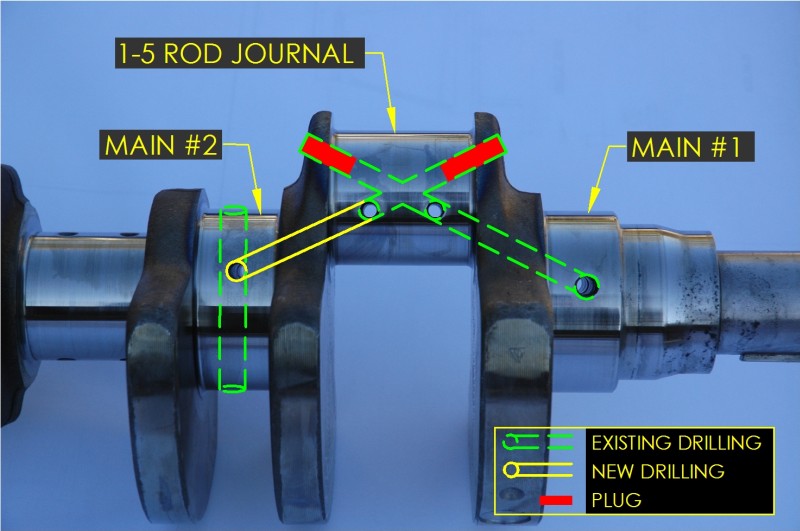

1-5 rod journal w/ new cross-drill @ #2 main:

Another pic of drilling at #2 main. The existing cross-drill and the new cross-drill are perpendicular and intersect each other:

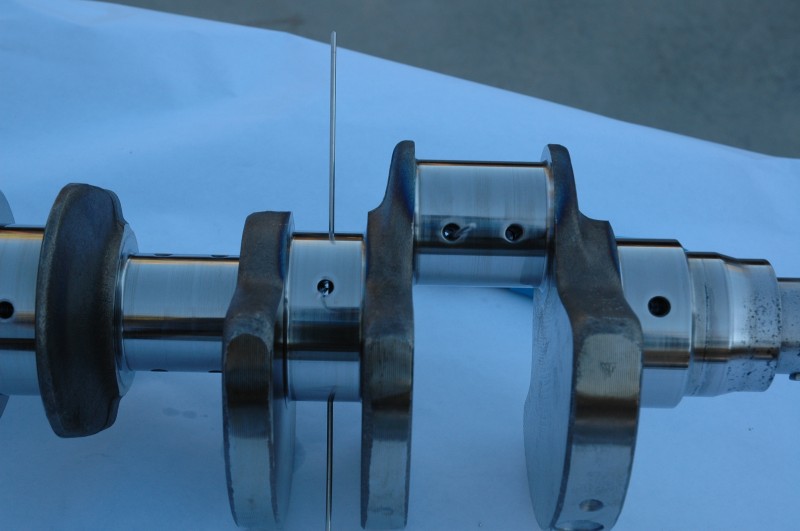

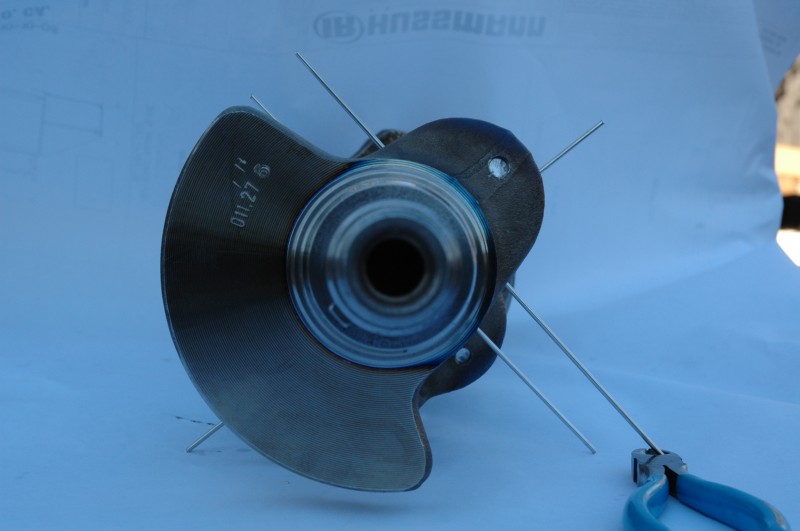

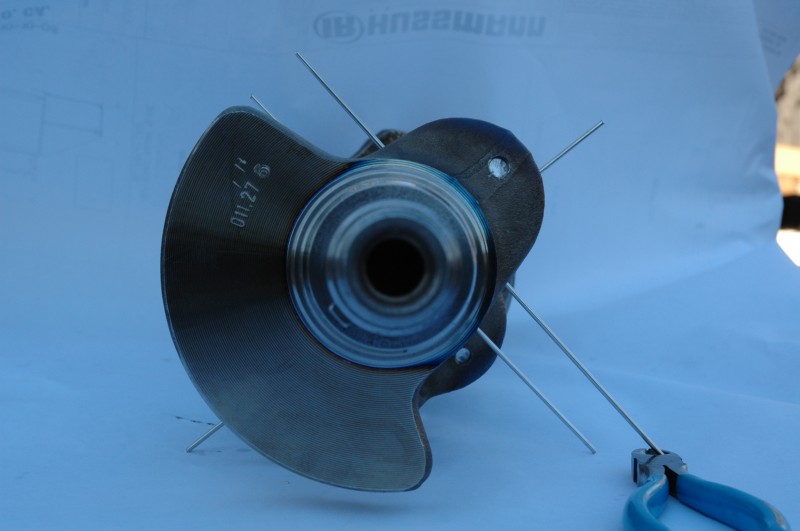

End-on pic from crank nose:

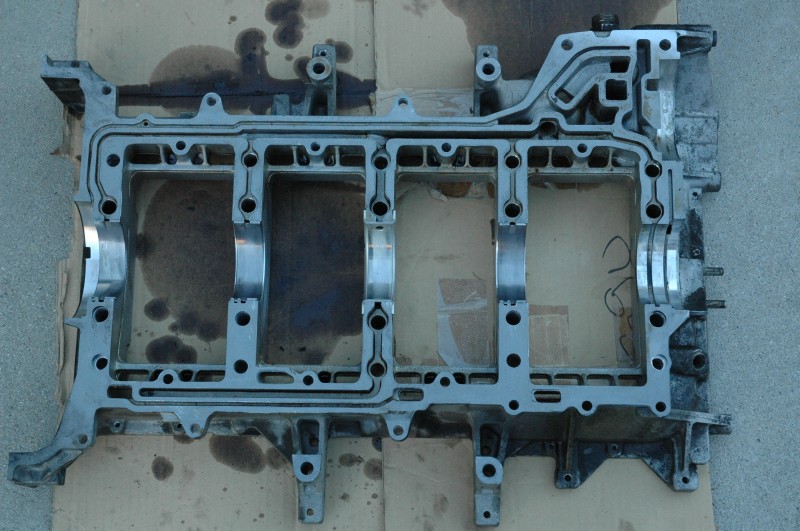

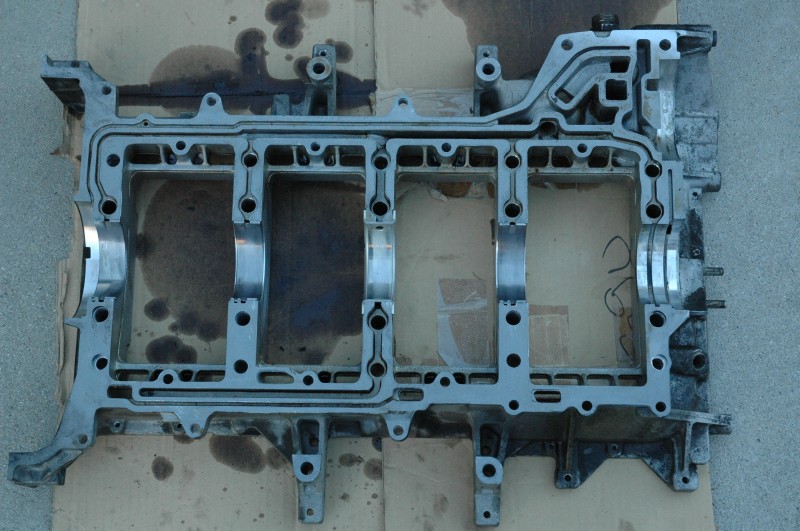

Stock girdle pic for referencing oiling path:

Hope this helps.

Let's start w/ a stock 928 crankshaft. For a stock 928 crankshaft the:

- 1-5 rod journal is connected to the #1 main cross-drill.

- 2-6 rod journal is connected to the #2 main cross-drill.

- 3-7 rod journal is connected to the #4 main cross-drill.

- 4-8 rod journal is connected to the #5 main cross-drill.

- The #3 main (center thrust bearing journal) has no cross -drill

- new cross-drills at #2, #3 and #4 mains

- connect 1-5 rod journal to #2 main

- connect 2-6 & 3-7 rod journals to #3 main

- connect 4-8 rod journal to #4 main

Pic that shows the new cross drills at the #2, #3 & #4 main journals:

4-8 rod journal w/ new cross-drill @ #4 main:

2-6 & 3-7 rod journals w/ new cross-drill @ #3 main (thrust bearing journal):

1-5 rod journal w/ new cross-drill @ #2 main:

Another pic of drilling at #2 main. The existing cross-drill and the new cross-drill are perpendicular and intersect each other:

End-on pic from crank nose:

Stock girdle pic for referencing oiling path:

Hope this helps.

Last edited by Dennis K; 02-27-2008 at 04:55 AM. Reason: typo

#48

Addict

Rennlist Member

Rennlist Member

Thank you very much Dennis. It would be interesting to know why exactly each drilling is done. Especially those extra cross drillings. Is it just to make oil available for extended stock drillings like I suspect or is there something else.

#49

From my very limited perspective:

Mark Anderson ran his 928 racer for 5+ years in heavy racing and it never had a rod bearing failure. His engine runs a drilled crank and a drysump. Before the drilled crank the drysump system alone did not save his race engine(s).

John Veninger had a drilled crank and an accusump in his older 928 race motor and never had a rod bearing failure. I believe his current stroker has one too.

Joe Fan has a drilled crank and accusump in his 928 racer and no rod bearing failures.

If I ever have an engine built up it will have a drilled crank, just makes sense to do.

Constantine

Mark Anderson ran his 928 racer for 5+ years in heavy racing and it never had a rod bearing failure. His engine runs a drilled crank and a drysump. Before the drilled crank the drysump system alone did not save his race engine(s).

John Veninger had a drilled crank and an accusump in his older 928 race motor and never had a rod bearing failure. I believe his current stroker has one too.

Joe Fan has a drilled crank and accusump in his 928 racer and no rod bearing failures.

If I ever have an engine built up it will have a drilled crank, just makes sense to do.

Constantine

#50

Addict

Rennlist Member

Rennlist Member

Erkka -

Yes the new cross-drills at the mains are to provide extra supply to the rod journals. Based on a backyard experiment on a stock crank, we were able to see that there is less pressure available at the rod bearings furthest away from the feeds from the mains. #5 rod had less pressure available than #1, #6 less than #2, #3 less than 7 and #4 less than #8. This convinced me to have the crank drilling done. With the new feeds, the pressure should be equalized at all rods bearings. At least this what I believe what will happen.

-Dennis

Yes the new cross-drills at the mains are to provide extra supply to the rod journals. Based on a backyard experiment on a stock crank, we were able to see that there is less pressure available at the rod bearings furthest away from the feeds from the mains. #5 rod had less pressure available than #1, #6 less than #2, #3 less than 7 and #4 less than #8. This convinced me to have the crank drilling done. With the new feeds, the pressure should be equalized at all rods bearings. At least this what I believe what will happen.

-Dennis

#52

Rennlist Member

3 weeks +/- a day or two.

The crank WOULD have arrived at the shop last Friday had they shipped it to where I requested. They made an error and shipped it to my home in Georgia. They made good on their mistake and I am now sending it on their $$$$$ to the shop. The week of time we lost hurts, however we should be ok with having 3 weeks before the 22nd..

FYI~ crated weight is 67lbs

The crank WOULD have arrived at the shop last Friday had they shipped it to where I requested. They made an error and shipped it to my home in Georgia. They made good on their mistake and I am now sending it on their $$$$$ to the shop. The week of time we lost hurts, however we should be ok with having 3 weeks before the 22nd..

FYI~ crated weight is 67lbs

#53

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

When we packaged Dennis's crank we used a sturdy cardboard box, but we encased the crank in expanding foam. They used to sell this stuff in aerosol cans at the hardware store that REALLY expanded when it shot out, but all I could find recently was spray foam that only modestly expanded - not good enough. However, Jim Morton had this stuff that although not aerosol, expanded HUGELY when activated. So we wrapped the crank and filled the box with that. Anyway, I think a cardboard box is fine as long as the crank is packed on all sides with foam or some other packing that cannot shift.

When I got a crank from Adam Birnbaum, it came in a cardboard box with several expanded foam sections fit around it that conformed to the shape of the crank. The foam sections were each in plastic bags. If you can locate some expanding foam and some trash bags, you could do it that way.

When I got a crank from Adam Birnbaum, it came in a cardboard box with several expanded foam sections fit around it that conformed to the shape of the crank. The foam sections were each in plastic bags. If you can locate some expanding foam and some trash bags, you could do it that way.

#59

Rennlist Member

I have seen this drill pattern a few times and there is something that bothers me. I'm afraid it might be a dumb question so I haven't asked, but what the hell.

According to the yellow and green coding all cross drilling appears to be previously half done. For example, the cross drill from Journal 1/5 to Main #2 shows predrilled to the vertical oiler in 1/5 and then new drilled the rest of the way to Main #2' vertical oiler.

That makes no sense to me, So I assume I have it wrong.

According to the yellow and green coding all cross drilling appears to be previously half done. For example, the cross drill from Journal 1/5 to Main #2 shows predrilled to the vertical oiler in 1/5 and then new drilled the rest of the way to Main #2' vertical oiler.

That makes no sense to me, So I assume I have it wrong.

#60

Nordschleife Master

nope you have it correct Charley,

Porsche just only drilled so far. they are just continuing the drill hole to get it to meet with the next main journal.

Porsche just only drilled so far. they are just continuing the drill hole to get it to meet with the next main journal.