Should the Central Clutch Shaft be replaced when doing the clutch? Shaft Photos Added

#16

Rennlist Member

Jim just shipped me a replacement for my '78. There are several different models.... this is the 7 3/4 inch one. On the brand new one the diameter of the end that fits into the pilot bearing is 0.589 to 0.588 depending on where you measure. No idea about wear limits.

The grooves on the old one were quite worn...The symptom was that sometimes the clutch would fully disengage and sometimes it would not. I'm glad to have the part for the price, but I would not do it unless either you have had a problem, or you see a problem, or it is very hard or expensive for you to do the job over.

The grooves on the old one were quite worn...The symptom was that sometimes the clutch would fully disengage and sometimes it would not. I'm glad to have the part for the price, but I would not do it unless either you have had a problem, or you see a problem, or it is very hard or expensive for you to do the job over.

#17

Addict

Rennlist Member

Rennlist Member

Originally Posted by Jim bailey - 928 International

When Porsche stops making the clutch shaft .....THEN we are shafted  ....and $180 will seem like a bargain !

....and $180 will seem like a bargain !

....and $180 will seem like a bargain !

....and $180 will seem like a bargain !

#18

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

When the time comes we will probably have them made. We have had custom driveshafts made before this one is just much shorter !

#19

Racer

Thread Starter

Thanks Karl, Im getting the same here on my end 0.589 to 0.587

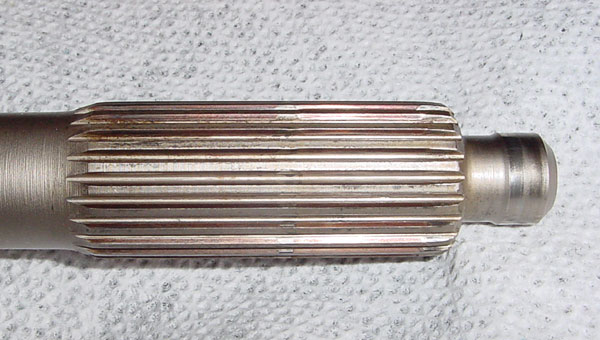

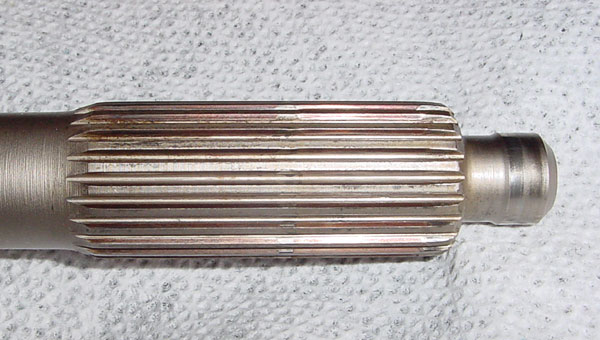

Jim is right, 140K on this one! perhaps just change it out - Here are some photos, maybe you all can spot something

Thanks for all the help...

Jim is right, 140K on this one! perhaps just change it out - Here are some photos, maybe you all can spot something

Thanks for all the help...

Last edited by edco; 02-07-2013 at 02:08 AM.

#22

Burning Brakes

Join Date: Jan 2002

Location: Springfield, MO

Posts: 842

Likes: 0

Received 0 Likes

on

0 Posts

Here is a pic of mine that I posted in another thread a few weeks ago. The end fits into the pilot bearing snuggly, but easily. I grease the splines, but I make sure that there is no grease on the part that goes into the pilot bearing. I did my clutch 2 1/2 years ago and experimented with a grease called "oil extreme". It seemed like another snake oil product, but when I took it apart again recently the shaft was still as slick as glass. The clutch pedal feels like it's not even doing anything.

Does anyone have a pic of a worn shaft? I would think that the splines would have to be pretty dished out to cause the disks to hang on the flywheel.

Does anyone have a pic of a worn shaft? I would think that the splines would have to be pretty dished out to cause the disks to hang on the flywheel.

#23

Under the Lift

Lifetime Rennlist

Member

Lifetime Rennlist

Member

John: On yours I can see a MINOR amount of wear close to the center of the splines - not enough to cause the clutch to catch. There's also some wear on the end of the splines.

Matt: If the end is in-spec, as it appears to be, I can't see why it should be replaced. As I recall, the splines were perfect.

Matt: If the end is in-spec, as it appears to be, I can't see why it should be replaced. As I recall, the splines were perfect.

#24

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

John,

That's more like what mine looks like. You can see where the clutch teeth sit, but there's no deformity or 'edge' to catch on or weaken it that I can see.

Matt, I'm inclined to think yours has been replaced at some point. At 140k I would think you'd have some wear showing, but yours looks brand new.

Matt and John, thanks for the awesome pics.

That's more like what mine looks like. You can see where the clutch teeth sit, but there's no deformity or 'edge' to catch on or weaken it that I can see.

Matt, I'm inclined to think yours has been replaced at some point. At 140k I would think you'd have some wear showing, but yours looks brand new.

Matt and John, thanks for the awesome pics.

#25

Archive Gatekeeper

Rennlist Member

Rennlist Member

Assuming one is replacing everything between the flywheel and the torque tube on a clutch job on a '90 (I have a new intermediate shaft but won't use it if the old one looks good), Is this the complete list of lubed bits?

This list is from a few previous threads btw Dave C and Peter F:

1. Splines on the intermediate shaft - Optimoly longtime EP

2. Ball cup bushing on arm - lithium grease

3. Contact surfaces of PP ( I assume this means the fingers contacting the throwout bearing?) , Optimoly longtime EP (?)

4. Contact point between throwout bearing and arm

5. Intermediate shaft sliding surfaces where the clutch disc sits.

6. Rear splined end of the intermediate shaft - the part that slides into the clamp sleave to the torque tube.

7. Front end that goes into the pilot bearing.

8. And a little dab on the end of slave clutch cylinder piston. Basically any parts with metal to metal contact that a) need to come apart again or b) slide, slip or pivot.

Do not lube the inside of the throwout bearing or the outside of the later guide tube, unlike original guide tube, which is NLA (per Peter F, 9/06

This list is from a few previous threads btw Dave C and Peter F:

1. Splines on the intermediate shaft - Optimoly longtime EP

2. Ball cup bushing on arm - lithium grease

3. Contact surfaces of PP ( I assume this means the fingers contacting the throwout bearing?) , Optimoly longtime EP (?)

4. Contact point between throwout bearing and arm

5. Intermediate shaft sliding surfaces where the clutch disc sits.

6. Rear splined end of the intermediate shaft - the part that slides into the clamp sleave to the torque tube.

7. Front end that goes into the pilot bearing.

8. And a little dab on the end of slave clutch cylinder piston. Basically any parts with metal to metal contact that a) need to come apart again or b) slide, slip or pivot.

Do not lube the inside of the throwout bearing or the outside of the later guide tube, unlike original guide tube, which is NLA (per Peter F, 9/06

#26

Addict

Rennlist Member

Rennlist Member

Assuming one is replacing everything between the flywheel and the torque tube on a clutch job on a '90 (I have a new intermediate shaft but won't use it if the old one looks good), Is this the complete list of lubed bits?

This list is from a few previous threads btw Dave C and Peter F:

1. Splines on the intermediate shaft - Optimoly longtime EP

2. Ball cup bushing on arm - lithium grease

3. Contact surfaces of PP ( I assume this means the fingers contacting the throwout bearing?) , Optimoly longtime EP (?)

4. Contact point between throwout bearing and arm

5. Intermediate shaft sliding surfaces where the clutch disc sits.

6. Rear splined end of the intermediate shaft - the part that slides into the clamp sleave to the torque tube.

7. Front end that goes into the pilot bearing.

8. And a little dab on the end of slave clutch cylinder piston. Basically any parts with metal to metal contact that a) need to come apart again or b) slide, slip or pivot.

Do not lube the inside of the throwout bearing or the outside of the later guide tube, unlike original guide tube, which is NLA (per Peter F, 9/06

This list is from a few previous threads btw Dave C and Peter F:

1. Splines on the intermediate shaft - Optimoly longtime EP

2. Ball cup bushing on arm - lithium grease

3. Contact surfaces of PP ( I assume this means the fingers contacting the throwout bearing?) , Optimoly longtime EP (?)

4. Contact point between throwout bearing and arm

5. Intermediate shaft sliding surfaces where the clutch disc sits.

6. Rear splined end of the intermediate shaft - the part that slides into the clamp sleave to the torque tube.

7. Front end that goes into the pilot bearing.

8. And a little dab on the end of slave clutch cylinder piston. Basically any parts with metal to metal contact that a) need to come apart again or b) slide, slip or pivot.

Do not lube the inside of the throwout bearing or the outside of the later guide tube, unlike original guide tube, which is NLA (per Peter F, 9/06

Wouldn't think fingers to throwout bearing should be greased - would make fingers slip relative to bearing making the bearing redundant when the bearing is there to make rotation possible between fingers and release arm.

#27

Burning Brakes

Join Date: Jan 2002

Location: Springfield, MO

Posts: 842

Likes: 0

Received 0 Likes

on

0 Posts