Re-ring question for the guru's

#1

Racer

Thread Starter

I want to install fresh rings in my 28 M 11 engine while the heads are off.

I understand the 928 engine is not "Honed" in a conventional manner.

If my bores look good, not scored. are new rings just installed?

If honing is required to aid in the seating of a fresh set of rings what method is used?

If honing is required for new rings do I need to remove my crank?

TIA

I understand the 928 engine is not "Honed" in a conventional manner.

If my bores look good, not scored. are new rings just installed?

If honing is required to aid in the seating of a fresh set of rings what method is used?

If honing is required for new rings do I need to remove my crank?

TIA

#2

Rennlist Member

if the bores look good, just put it back together. pulling the pistons out is not a simple job and may not be worth the effort. do you have the pan off? re-ringing is probably not nessesary unless you have some sign of a ring issue. buring oil, low compression , etc.

Mk

Mk

Originally Posted by 918-S

I want to install fresh rings in my 28 M 11 engine while the heads are off.

I understand the 928 engine is not "Honed" in a conventional manner.

If my bores look good, not scored. are new rings just installed?

If honing is required to aid in the seating of a fresh set of rings what method is used?

If honing is required for new rings do I need to remove my crank?

TIA

I understand the 928 engine is not "Honed" in a conventional manner.

If my bores look good, not scored. are new rings just installed?

If honing is required to aid in the seating of a fresh set of rings what method is used?

If honing is required for new rings do I need to remove my crank?

TIA

#5

Addict

Rennlist Member

Rennlist Member

Only honing allowed in these blocks is lapping done as last phase in drilling to oversize. It can also be done to used stock size cylinder.

I would be more worried about main and conrod bearing condition than rings as long as bores look ok.

I would be more worried about main and conrod bearing condition than rings as long as bores look ok.

#6

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Why I cannot find this at the moment is beyond me. Is the 28 M 11 engine a 4.5 liter or 4.7?

Reson why I ask is the cost of rings is about 4x's higher for the 4.5 liter vs. 4.7. Might be cheaper to source out a 4.7 for a rebuild and toss the 4.5 aside. At least that is the game plan for my 81.

Reson why I ask is the cost of rings is about 4x's higher for the 4.5 liter vs. 4.7. Might be cheaper to source out a 4.7 for a rebuild and toss the 4.5 aside. At least that is the game plan for my 81.

#7

Racer

Thread Starter

Originally Posted by Vilhuer

Only honing allowed in these blocks is lapping done as last phase in drilling to oversize. It can also be done to used stock size cylinder.

I would be more worried about main and conrod bearing condition than rings as long as bores look ok.

I would be more worried about main and conrod bearing condition than rings as long as bores look ok.

The manual in not very discriptive. The discription of the 616 honing is intended for a machinist.

I have the pan off. I planned on checking rod bearing while changing the rings.

I seem to recall reading something a long time ago about a crank oiling problem. I thought this was on the early engines.

Q.) Can someone jog my memory in the oiling subject?

Q.) Did this continue on into the 1980 euro spec "S" models?

BTW: My motor came from a salvage yard. I was told it had around 80,000 miles when I purchased it. I would guess I put less than 10,000 on it. During that time I discovered I had a broke valve spring. Hence the need for tear down.

Trending Topics

#9

Racer

Thread Starter

Originally Posted by Hacker-Pschorr

Why I cannot find this at the moment is beyond me. Is the 28 M 11 engine a 4.5 liter or 4.7?

Reson why I ask is the cost of rings is about 4x's higher for the 4.5 liter vs. 4.7. Might be cheaper to source out a 4.7 for a rebuild and toss the 4.5 aside. At least that is the game plan for my 81.

Reson why I ask is the cost of rings is about 4x's higher for the 4.5 liter vs. 4.7. Might be cheaper to source out a 4.7 for a rebuild and toss the 4.5 aside. At least that is the game plan for my 81.

97 mm bore. I have the rings.

#10

Addict

Rennlist Member

Rennlist Member

Originally Posted by 918-S

Q.) Can you explain the lapping process?

The manual in not very discriptive. The discription of the 616 honing is intended for a machinist.

The manual in not very discriptive. The discription of the 616 honing is intended for a machinist.

Q.) Can someone jog my memory in the oiling subject?

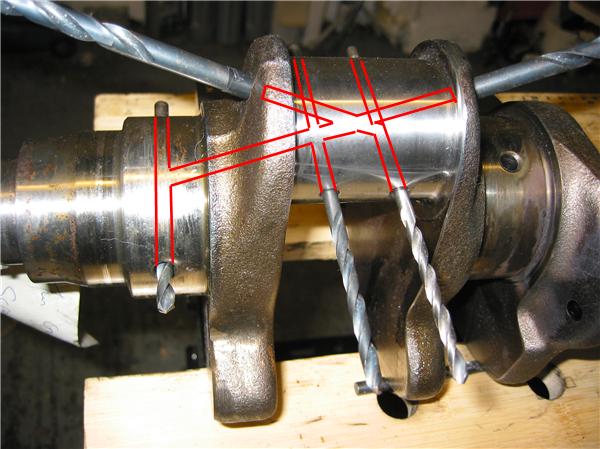

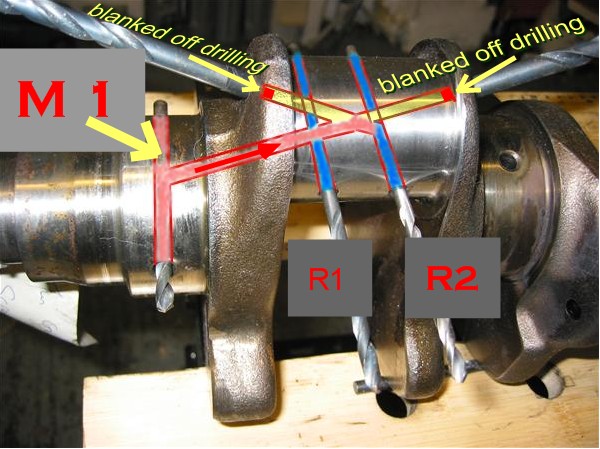

When crank is rotating oil is fed in from upper half of main bearings. One of two ends is always on upper 180 while other is at lower bearing half. At high revs oil gets out from lower side as its "pushed" there by centrifucal force. This leaves conrod bearings too dry. Usually first ones to fail are #2 or/and #6. Other contributing factor is that much of the oil is whiped around crank because oilpan is too shallow. Combine fast cornering and oil pickup will suck air.

Real fix is dry sump system. Having crank drilled like Chevy does help too. Each rod bearing gets its own direct feed from main bearing. This means also lower half of mains need to be grooved for oil feed.

Even easier option is to plug one of two ends of mains holes and use 360 grooved bearings. This will help somewhat I think.

Q.) Did this continue on into the 1980 euro spec "S" models?

#11

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Originally Posted by 918-S

97 mm bore. I have the rings.

#12

Racer

Thread Starter

Vilhuer,

Nice link! thanks, My wireless connection is wigging out so I couldn't get it all to load but I will study the pages then I'm sure I will have more questions.

Rick

Nice link! thanks, My wireless connection is wigging out so I couldn't get it all to load but I will study the pages then I'm sure I will have more questions.

Rick

#13

Rennlist Member

The block is impregnated with silicon crystals. The cylinder gets bored first. Then they are lapped with a compound which removes some of the aluminum between the crystals leaving the crystals exposed. The piston/ring assembly rides on the silicon crystals which is why they last so long. That's the process.

Hammer

Hammer

#14

Originally Posted by Hacker-Pschorr

Reson why I ask is the cost of rings is about 4x's higher for the 4.5 liter vs. 4.7. Might be cheaper to source out a 4.7 for a rebuild and toss the 4.5 aside. At least that is the game plan for my 81.

4.7 are not cheap either.

Maybe its cheaper to just buy your pistons through your "JE distributor" and you get pistons, pins, rings and clips, and coat them with Swain on the side to work with the alusil. It works.

#15

918 - Why don't you find a 5.0L block? It is the same dimensions as that 4.7l, or even bore it to 5.0L and get some 5L pistons from an 86 flycut?

That would move your 914 real well.

That would move your 914 real well.