Dry Sump Question

#1

Rennlist Member

Thread Starter

Hello all,

I have made some considerable progress on the pan and its manufacture. In fact my welder and aluminium fabricator assured me that I should have it within a week. This brings me to the next stage - a suitable scavenge pump. I am using the existing oil pump on the pressure side, and I will scavenge the sump, from both sides of the cross member. I have also sourced two 8ltr tanks to store the oil

Can any one help with regards to scavenge pump capacity. That will be really appreciated, because I can almost see the end of the project in sight and a really fast lap of the Ring coming...

I have made some considerable progress on the pan and its manufacture. In fact my welder and aluminium fabricator assured me that I should have it within a week. This brings me to the next stage - a suitable scavenge pump. I am using the existing oil pump on the pressure side, and I will scavenge the sump, from both sides of the cross member. I have also sourced two 8ltr tanks to store the oil

Can any one help with regards to scavenge pump capacity. That will be really appreciated, because I can almost see the end of the project in sight and a really fast lap of the Ring coming...

#2

Rennlist Member

Originally Posted by Cheburator

Hello all,

I have made some considerable progress on the pan and its manufacture. In fact my welder and aluminium fabricator assured me that I should have it within a week. This brings me to the next stage - a suitable scavenge pump. I am using the existing oil pump on the pressure side, and I will scavenge the sump, from both sides of the cross member. I have also sourced two 8ltr tanks to store the oil

Can any one help with regards to scavenge pump capacity. That will be really appreciated, because I can almost see the end of the project in sight and a really fast lap of the Ring coming...

I have made some considerable progress on the pan and its manufacture. In fact my welder and aluminium fabricator assured me that I should have it within a week. This brings me to the next stage - a suitable scavenge pump. I am using the existing oil pump on the pressure side, and I will scavenge the sump, from both sides of the cross member. I have also sourced two 8ltr tanks to store the oil

Can any one help with regards to scavenge pump capacity. That will be really appreciated, because I can almost see the end of the project in sight and a really fast lap of the Ring coming...

http://www.racelinepumps.com/catalog.htm

At this point I plan on using a Raceline too since Mark apparently has had no problems with his.

How much is your pan going to cost you? How did you determine it's external dimensions? How are you going to hook-up the external oil-supply to the oil-pump feed?

It appears that the toughest part will be the pulleys and their subsequent alignment which means that one must have the pump first in order to do a mock-up.

Right now I'm thinking that the best place to mount the crank-pulley is right at the end, ahead of the alternator. But that means the dry-sump pump must be spaced-outwards towards the radiator from it's air-pump location.

#3

Rennlist Member

Thread Starter

Originally Posted by SwayBar

Mark Anderson is using a Raceline two-stage scavenging pump:

http://www.racelinepumps.com/catalog.htm

At this point I plan on using a Raceline too since Mark apparently has had no problems with his.

How much is your pan going to cost you? How did you determine it's external dimensions? How are you going to hook-up the external oil-supply to the oil-pump feed?

It appears that the toughest part will be the pulleys and their subsequent alignment which means that one must have the pump first in order to do a mock-up.

Right now I'm thinking that the best place to mount the crank-pulley is right at the end, ahead of the alternator. But that means the dry-sump pump must be spaced-outwards towards the radiator from it's air-pump location.

http://www.racelinepumps.com/catalog.htm

At this point I plan on using a Raceline too since Mark apparently has had no problems with his.

How much is your pan going to cost you? How did you determine it's external dimensions? How are you going to hook-up the external oil-supply to the oil-pump feed?

It appears that the toughest part will be the pulleys and their subsequent alignment which means that one must have the pump first in order to do a mock-up.

Right now I'm thinking that the best place to mount the crank-pulley is right at the end, ahead of the alternator. But that means the dry-sump pump must be spaced-outwards towards the radiator from it's air-pump location.

The pressure side - the original oil pump pick up has been modified to take a short armoured flexible hose which screws into a fitting welded into the pan, which in turns has another flexi hose connection to the two oil storage / de-aeration tanks...

I am mounting the scavenge pump where the air pump is. Thus I plan to have two pulleys made to take a tootthed belt. I will also modify the factory pulleys, so that the alternator and power steering pump continue to be driven by the factory belts...

#4

Rennlist Member

Originally Posted by Cheburator

I am using the existing pan as a base and then I have welded sections to assist scavenging on both sides of the cross member. I will provide pics once I have the pan back...

I just talked to my pan-guy, and he'll have a mock-up to me in about two weeks.

The pressure side - the original oil pump pick up has been modified to take a short armoured flexible hose which screws into a fitting welded into the pan, which in turns has another flexi hose connection to the two oil storage / de-aeration tanks...

I am mounting the scavenge pump where the air pump is. Thus I plan to have two pulleys made to take a tootthed belt. I will also modify the factory pulleys, so that the alternator and power steering pump continue to be driven by the factory belts...

Thanks for sharing!

#6

Drifting

alex, i hope the welding guy dosent develop 928itis and get sick of welding those pans... we need at least two

as for the crank pulley, you could mount it in place of the aircon pulley, it can be wider than the aircon pulley - extending over the first unused part of the crank pulley.

as for the crank pulley, you could mount it in place of the aircon pulley, it can be wider than the aircon pulley - extending over the first unused part of the crank pulley.

Trending Topics

#8

Rennlist Member

Thread Starter

Originally Posted by drnick

oh yeah, whats the scoop on the pace pump - is it suitable?

#9

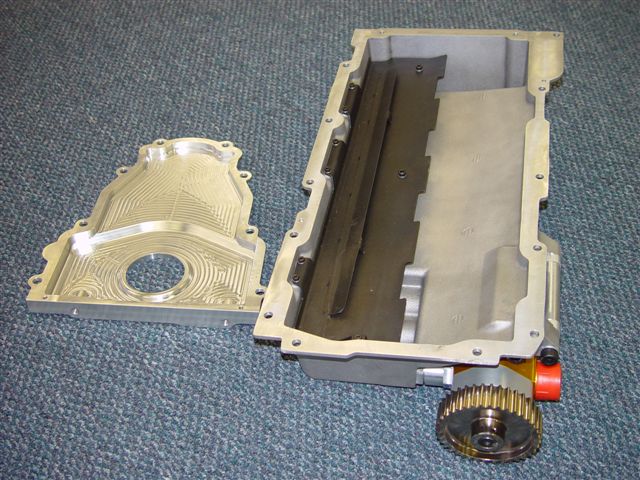

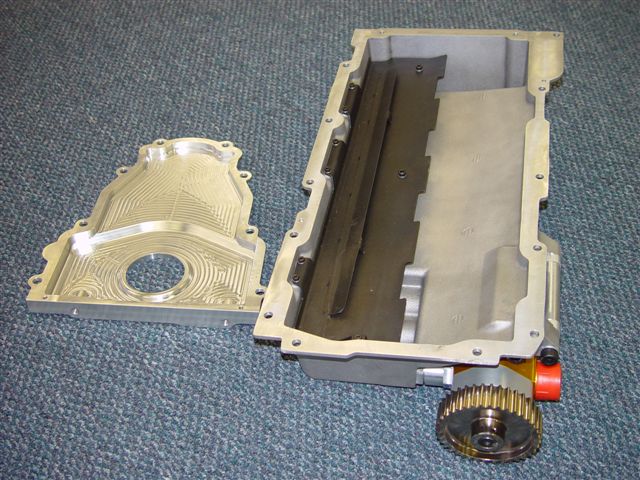

Buy one second hand on Ebay but be fussy. I bought a Nascar pump which can be reduced in stages, it has 6 stages but I will use only 4. We pulled it apart and it was perfect. It cost $440 and the brand is Barnes, I could have used a local pump but many more dollars and they are dollars I just don't have at the moment. Here is a pic of what I plan to do early next year, what I have found it that every design has it positives and negatives.

I will add compartmants to this design and a windage tray. My block has squirters so I'm not concerned about lack of lubrication of the walls.

Here's the pump

I will put the tank where the big washer bottle is, 20 an hose back to the factory pump. Capacity between 8 to 10 litres. 4 scavenge stages I also bought the super strong lightweight hoses off Ebay too, they are XRP and they freaked me out a bit when I picked them up, they are made from some type of plastic reinforced with stainless steel kevlar and have a rubber outer. They can handle oil or coolant. The fittings are made to be ultra reliable and light.

By the time I cut out the sump I hope that the nett difference in weight is only around 5 kgs.

Greg

I will add compartmants to this design and a windage tray. My block has squirters so I'm not concerned about lack of lubrication of the walls.

Here's the pump

I will put the tank where the big washer bottle is, 20 an hose back to the factory pump. Capacity between 8 to 10 litres. 4 scavenge stages I also bought the super strong lightweight hoses off Ebay too, they are XRP and they freaked me out a bit when I picked them up, they are made from some type of plastic reinforced with stainless steel kevlar and have a rubber outer. They can handle oil or coolant. The fittings are made to be ultra reliable and light.

By the time I cut out the sump I hope that the nett difference in weight is only around 5 kgs.

Greg

#10

Addict

Rennlist Member

Rennlist Member

How does oil returning from heads get to dry sump tank? Is it allowed to drain back to crank chamber like in stock engine? I think it would be good to have it diverted directly to tank or scavenge pump as this would take out large part of unnecessary windage.

#11

Rennlist Member

Thread Starter

Originally Posted by Vilhuer

How does oil returning from heads get to dry sump tank? Is it allowed to drain back to crank chamber like in stock engine? I think it would be good to have it diverted directly to tank or scavenge pump as this would take out large part of unnecessary windage.

#12

Rennlist Member

Originally Posted by drnick

as for the crank pulley, you could mount it in place of the aircon pulley, it can be wider than the aircon pulley - extending over the first unused part of the crank pulley.

#13

Rennlist Member

Originally Posted by Cheburator

I know what you mean, but I am trying to keep it simple - the return channels from the heads are good enough and I plan to eliminate windage by installing crank scrapers anyway...

#14

Three Wheelin'

The heads do have really good drain provisions, much better than most engines. The head drain channels come out on each side of the block at crankshaft level. Would a W shaped pan with scavenge pickups on each side be a good way to go? Maybe one scavenge per side with a pan tilting toward the front? I wonder if the drain passages from the heads that exit in the crankshaft area would like to be sheilded from windage or are they not affected? One side drops out below the crankshaft but one side is exposed to the area around the crankshaft, that oil isn't going to touch the crank, it's just a matter of whether it gets frothed or not.