Windshield washer pump replacement and why it failed...

#1

Rennlist Member

Thread Starter

Haven't used my windshield washer pump for quite some time, due to the summer like winter in TX. When I tried to use it 3 weeks ago...nothing!

Checked the wiring and everything is good. Ordered a new pump and replaced it. Getting to the tank is easy and taking it out too. Yes, there are easy jobs on a 928 . I flushed the tank a couple of time and found the usual crud at the bottom. At least I take the stuff out that made the pump fail....

. I flushed the tank a couple of time and found the usual crud at the bottom. At least I take the stuff out that made the pump fail....

WRONG! I couldn't believe my eyes when I saw the rust at the filler neck of the tank!!! The factory inserts a metal sleeve into the neck to prevent deforming of the plastic from the rubber hose clamp. That thing was in very bad shape .

.

Tank inside passenger side front fender:

Tank filler with old sleeve:

Old sleeve removed with rust left inside filler:

New sleeve 3/4' socket for 1/2' drive (who needs SAE anyhow ):

):

After cleaning with the new "sleeve"installed:

The same disaster with the filler neck:

Filler neck after cleaning with new "sleeve":

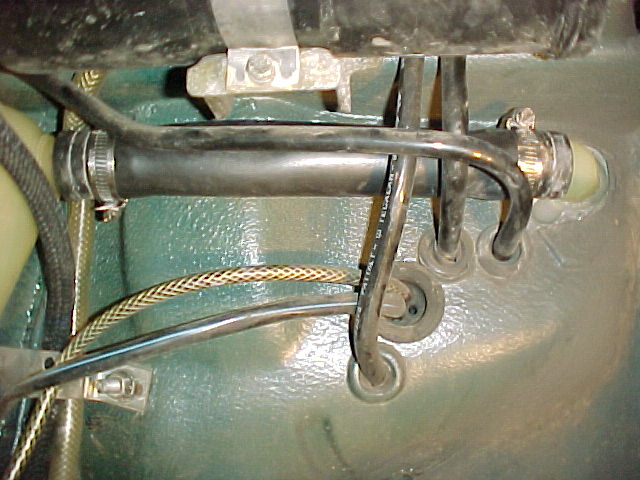

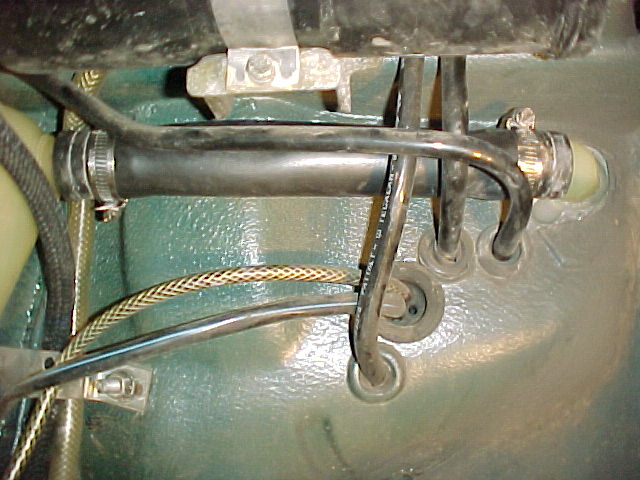

Everything back in place with new stainless steel clamps on the filler to tank rubber hose:

New filler cap:

Checked the wiring and everything is good. Ordered a new pump and replaced it. Getting to the tank is easy and taking it out too. Yes, there are easy jobs on a 928

. I flushed the tank a couple of time and found the usual crud at the bottom. At least I take the stuff out that made the pump fail....

. I flushed the tank a couple of time and found the usual crud at the bottom. At least I take the stuff out that made the pump fail....WRONG! I couldn't believe my eyes when I saw the rust at the filler neck of the tank!!! The factory inserts a metal sleeve into the neck to prevent deforming of the plastic from the rubber hose clamp. That thing was in very bad shape

.

.Tank inside passenger side front fender:

Tank filler with old sleeve:

Old sleeve removed with rust left inside filler:

New sleeve 3/4' socket for 1/2' drive (who needs SAE anyhow

):

):

After cleaning with the new "sleeve"installed:

The same disaster with the filler neck:

Filler neck after cleaning with new "sleeve":

Everything back in place with new stainless steel clamps on the filler to tank rubber hose:

New filler cap:

Last edited by Schocki; 03-31-2006 at 05:56 PM.

#7

Team Owner

I would suggest that you remove the socket, nothing is better than most anything you could put in there except for a piece of stainless,

still its not really needed as your not securing as pressure line its just a gravity transfer line.

here is a link to another like thread

https://rennlist.com/forums/928-foru...-question.html

still its not really needed as your not securing as pressure line its just a gravity transfer line.

here is a link to another like thread

https://rennlist.com/forums/928-foru...-question.html

Trending Topics

#8

Instructor

Join Date: Sep 2007

Location: NE PA aka-the endless mountains

Posts: 184

Likes: 0

Received 0 Likes

on

0 Posts

i had the same problem, nice job diagnosing and solving. rust debris certainly will clog all those little tubes and pump parts.

i however was too cheap to buy a new pump and thus dissembled the electric motor driven little gear-type pump. it was gunked up with old, dried washer fluid, etc. a little scrub brush cleaning of the gears and shaft to remove anything that would bind it up, cleaned ports, and viola! it worked great. if you still have your old pump, take it apart and see if it could be salvaged as a spare.

i however was too cheap to buy a new pump and thus dissembled the electric motor driven little gear-type pump. it was gunked up with old, dried washer fluid, etc. a little scrub brush cleaning of the gears and shaft to remove anything that would bind it up, cleaned ports, and viola! it worked great. if you still have your old pump, take it apart and see if it could be salvaged as a spare.

#10

Rennlist Member

Thread Starter

I would suggest that you remove the socket, nothing is better than most anything you could put in there except for a piece of stainless,

still its not really needed as your not securing as pressure line its just a gravity transfer line.

here is a link to another like thread

https://rennlist.com/forums/928-foru...-question.html

still its not really needed as your not securing as pressure line its just a gravity transfer line.

here is a link to another like thread

https://rennlist.com/forums/928-foru...-question.html

#11

Team Owner

Schocki I didnt say your fix wouldnt work i just suggested that its not needed and should be removed, eventually the sockets will corrode and they will also trap washer fluid be tween the tank the fill port, and since you now know the diameter of the tube if you feel that you must have another piece of metal in the line you could follow Gregs instructins to get a piece of stainless made to replace the sockets.

Still i believe that NOTHING in the tubes is a satisfactory solution YMMV

Still i believe that NOTHING in the tubes is a satisfactory solution YMMV

#12

Rennlist Member

Thread Starter

The original design uses clamps that apply permanent pressure to the hose and plastic tube. That´s why they used this design.

If another WYAIT situation arises inside the right fender, I will look into it again.

So far so good

I was just surprised that the threat showed up again after 3 years.

If another WYAIT situation arises inside the right fender, I will look into it again.

So far so good

I was just surprised that the threat showed up again after 3 years.

#13

Addict

Rennlist Member

Rennlist Member