Drilled Crank Thoughts...

#166

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2001

Location: Wilbraham, MA

Posts: 2,758

Likes: 0

Received 0 Likes

on

0 Posts

I am done.

#167

Addict

Rennlist Member

Rennlist Member

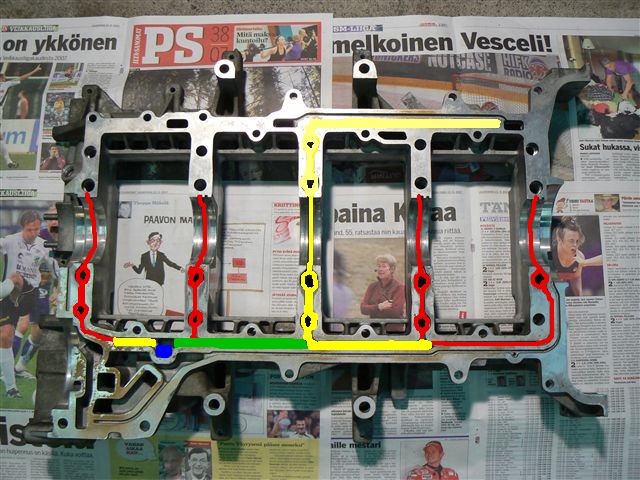

Despite the fact that I buy milk from shops and do not care about the cows too much lets continue discussion about those oil channels. Took these measurements over the weekend while doing other stuff in garage.

Blue = 15mm wide round feed pipe from oil filter = 177mm^2

Green = 8.5mm wide x 16mm deep = 136mm^2

Yellow = 8.5mm wide x 10mm deep = 85mm^2

Light yellow = 7.5mm wide x 11 deep = 83mm^2

Red = 5mm wide x 5 mm deep = 25mm^2

Yellow means both short straight thing from blue feed to #1 main bearing and from green to end of #3 main bearing and towards #4 and #5. Light yellow is from #3 main to input to upper half of block for right head.

Left head takes its oil from green area IIRR or maybe more likely from forward yellow. Anyone remember exact position for it? How close it is to red input of #2 main?

4x25mm^2 + 85mm^2 = 185mm^2. Should total area for 5 main bearings be larger or smaller than feed from filter? Does it make any difference in to this relationship that feed is round while channels are rectangle? Obviously feed to left head needs to be added also. So total area for all channels is significantly larger than feed.

Should light yellow feed to head be smaller or larger in size when using stroker crank where #3 is feeding two rods too?

Could and should feeds to both head be made slightly smaller or larger in order to leave more oil for main and rod bearings?

Last edited by Vilhuer; 10-08-2007 at 03:54 PM.

#168

How do F1 Engines operate at 2G side load, and 20,000 rpm? Is there a way to find that out?

I think it has been socially proven, that with proper oil scraping, making the pan lower, and some sort of accusump, *And a drilled crank*

If we want to spend 3k to insure a 10-15k engine, we can then put on a dry sump.

Do any of us have enough time or engineering ability to determine if the oil journals in the girdle need to be changed by 1mm up or down?

I think it has been socially proven, that with proper oil scraping, making the pan lower, and some sort of accusump, *And a drilled crank*

If we want to spend 3k to insure a 10-15k engine, we can then put on a dry sump.

Do any of us have enough time or engineering ability to determine if the oil journals in the girdle need to be changed by 1mm up or down?

Last edited by BC; 10-08-2007 at 05:00 PM. Reason: "My crank" needs drilling.

#169

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2001

Location: Wilbraham, MA

Posts: 2,758

Likes: 0

Received 0 Likes

on

0 Posts

I think scrapers have been in 928s for perhaps a couple of years and my recollection is that there were failures initially (Glen L. jumps to mind). Presumably they have been improved since then. Nevertheless, how has it been proven that a drilled crank is not needed? I don't think you are going to find a 928 that has been tracked for any substantial period of time without a drilled crank and with a scraper. So how can this be proven "socially"?

I don't claim to have proven anything, but for those standing on the sidelines considering tracking a 928, the smartest course would seem to be the most proven at this point. I rely on Mark A's experience as the standard of what has been proven.

#170

Interesting, "socially" huh?

I think scrapers have been in 928s for perhaps a couple of years and my recollection is that there were failures initially (Glen L. jumps to mind). Presumably they have been improved since then. Nevertheless, how has it been proven that a drilled crank is not needed? I don't think you are going to find a 928 that has been tracked for any substantial period of time without a drilled crank and with a scraper. So how can this be proven "socially"?

I think scrapers have been in 928s for perhaps a couple of years and my recollection is that there were failures initially (Glen L. jumps to mind). Presumably they have been improved since then. Nevertheless, how has it been proven that a drilled crank is not needed? I don't think you are going to find a 928 that has been tracked for any substantial period of time without a drilled crank and with a scraper. So how can this be proven "socially"?

#171

1) Equiped with a mix of what you mentioned, including the drilled crank, pan changes, accusump, etc or,

2) Kiborts Super-Duper Special never been opened, factory tweeked alien-abducted and rephasered down to earth block.

Anything else soon becomes a 600 pound hand grenade somewhere around the switch to R compounds, and them hitting the red run groups.

#172

In Your Face, Ace

Rennlist Member

Rennlist Member

Accusumps have variable pressure activation valves available now. Something to look into -- Canton can explain them. Great idea and improvement. I know when I bought my Accusump about 17 years ago they were not available.

This is different than just the electric valve.

This is different than just the electric valve.

Also, you do not need an entirely new valve set up if you already have the ECV. You can simply buy the retrofit kit.

#174

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

One of Anderson's early engines based on 16 value Euro with Big valves muho porting heavy valve springs big cams he used to spin that one up pretty high BUT as soon as you go stroker engine with a 95.25 MM stroke it makes sense to hold the RPM down because the piston speeds get pretty high.

#176

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2001

Location: Wilbraham, MA

Posts: 2,758

Likes: 0

Received 0 Likes

on

0 Posts

I meant "And a drilled crank" By Socially, I mean that its not scientifically tested, and there is no way we really can. Its all bandaids (that I hope work, since I have spent alot of money on the engine, the scraper, the drilled crank, etc) for an engine that was never really meant or designed to be in a car pulling 1G or more under cornering and braking repeatedly.

#177

Nope. The Drilled Crank, and the grooved bearings were the first thing I budgeted for on this motor build. I am now working on the lowered pan (already have the tiny starter)

#178

Addict

Rennlist Member

Rennlist Member

Thread Starter

Join Date: May 2001

Location: Wilbraham, MA

Posts: 2,758

Likes: 0

Received 0 Likes

on

0 Posts

Kind of funny, since you imply we are all asking the same questions over and over. When in fact the consensus in the 928 world is that a drilled crank with drysump is reliable solution. Scrapers may provide an improvement or even replacement of one or both, but I am not going to be on the bleeding edge to find out. Mark A. has had a reliable motor in the past with drilled stroked crank and drysump. That is good enough for me.

If you go back to the first post in this thread, you will not find me asking a question of whether a drilled crank is desirable or needed.

#180

Addict

Rennlist Member

Rennlist Member

Stop the aeration, save the engine. Cross drilling cranks doesn't stop aeration. Modifying the passages will shift the failure to another area -- the net result is the same, i.e. engine failure. There are known, scientifically proven, ways to suppress oil aeration.

Another thing is if its possible to make all bearings fail at same time instead of only killing cylinder 2 and 6 rods regardless of what type crank drilling is used. I think making all bearings fail at same time will buy some time on how long it takes before first failure occurs. To me this would be worth some minor block mods regardless of what other oiling system mods are done like scrapers or dry sump.