AC belt replacement

#1

Is it in any way possible to replace the AC compressor belt without having to move the compressor? The manuals describe a procedure for removing the compressor itself (involving a lot of releasing of pressure and things which I'd rather not touch on the 20 year old, still working unit), but nothing about R&R of just the belt. Any BTDT?

#2

You "move" compressor without removing anything that has pressure. You just need to loosen the tension adjusting rod nuts and pivot bolts and swing the compressor in toward the block so you can replace the belt.

Since the AC belt is the innermost, you need to loosen the tension on the alternator, power steering and air pump belts and remove those belts first. Each of these accessories has tension adjusters and pivot bolts that need to be loosened. The power steering pump bracket has 3 bolts that lock it down. Study the tension adjusters for a minute and you will see that not only do you have to loosen the nuts on the threaded rods that make the adjustment, but each is locked down by a bolt and through the adjuster.

The only other trick is scoping out all the bolts that hold the compressor and the air pump in place that need to be loosened so that you can swing them in. Also, there are a couple of long brackets that go to both the compressor and the air pump that join at a bolt on the front of the block - that bolt has to be removed as these brackets trap the compressor belt.

Now, I need to qualify that since you have a Euro, there may be some variance from the above (e.g., no air pump), but I believe the general advice would apply.

Since the AC belt is the innermost, you need to loosen the tension on the alternator, power steering and air pump belts and remove those belts first. Each of these accessories has tension adjusters and pivot bolts that need to be loosened. The power steering pump bracket has 3 bolts that lock it down. Study the tension adjusters for a minute and you will see that not only do you have to loosen the nuts on the threaded rods that make the adjustment, but each is locked down by a bolt and through the adjuster.

The only other trick is scoping out all the bolts that hold the compressor and the air pump in place that need to be loosened so that you can swing them in. Also, there are a couple of long brackets that go to both the compressor and the air pump that join at a bolt on the front of the block - that bolt has to be removed as these brackets trap the compressor belt.

Now, I need to qualify that since you have a Euro, there may be some variance from the above (e.g., no air pump), but I believe the general advice would apply.

#3

Originally Posted by Bill Ball

Now, I need to qualify that since you have a Euro, there may be some variance from the above (e.g., no air pump), but I believe the general advice would apply.

#4

When Bill says " scope out the bolts", he really means it!  The AC has a locking bolt at the very top backside - as does the lower rear of the alt. Loosen all these first or you will 'pretzel' the adjuster bracket hardware. An '84 may not have an adjuster for the PS, in which case a pry bay is in order to retension the belt.

The AC has a locking bolt at the very top backside - as does the lower rear of the alt. Loosen all these first or you will 'pretzel' the adjuster bracket hardware. An '84 may not have an adjuster for the PS, in which case a pry bay is in order to retension the belt.

The AC has a locking bolt at the very top backside - as does the lower rear of the alt. Loosen all these first or you will 'pretzel' the adjuster bracket hardware. An '84 may not have an adjuster for the PS, in which case a pry bay is in order to retension the belt.

The AC has a locking bolt at the very top backside - as does the lower rear of the alt. Loosen all these first or you will 'pretzel' the adjuster bracket hardware. An '84 may not have an adjuster for the PS, in which case a pry bay is in order to retension the belt.

#6

You need to get the car on a lift or jackstands so you can remove the belly pan. Remove all the belts from below. The hardest belt to remove and reinstall is the power steering pump belt.

Since you'll have to remove every belt, you might consider replacing all of the belts at once. The cost is not that much extra.

Also, you might not have to loosen the two compressor swing bolts, as the compressor may swing enough to remove the belt from the pully. Let us know how it went.

Since you'll have to remove every belt, you might consider replacing all of the belts at once. The cost is not that much extra.

Also, you might not have to loosen the two compressor swing bolts, as the compressor may swing enough to remove the belt from the pully. Let us know how it went.

#7

Originally Posted by borland

You need to get the car on a lift or jackstands so you can remove the belly pan.

Yes....belly pan....where do I get one of those?

I think I know where the belts went.

But seriously, thanks all. I'm going to try and do this at the same time as the smog pump, but it may have to take back seat for a little while. I'm using the philosophy "first do no harm" on this car at the moment, so if you don't hear any results right away, that's why.

I have to say,

isn't all its cracked up to be!

isn't all its cracked up to be!

Trending Topics

#8

Devin

You are right about the manual and that's part of the reason Rernnlist is invaluable.

928 International produces an excellent replacement all-aluminium belly pan (engine undertray they call it) for about $280

Colin

You are right about the manual and that's part of the reason Rernnlist is invaluable.

928 International produces an excellent replacement all-aluminium belly pan (engine undertray they call it) for about $280

Colin

#9

Anyone know what size this bolt is?

I removed it and lost the bolt. Some stock bolts i try seem not to screw in and I'm hesitant to wrench a bolt on for fear of stripping the thread.

Also, there is mention of a Pivot / Locking bolt on the very back top of the cradle? Where is it approximately?

I'd like to avoid having to remove/drop the entire compressor.

Belly pan is removed.

#11

Thank you. I was trying an M8. I guess its good to go - I'll force it/socket it in.

Which number is the pivot/locking bolt on the top/back of the cradle?

I think I've got all the front pivot bolts loosened. But the compressor won't move toward the engine block as I'm trying to get the belt onto the pulley.

Which number is the pivot/locking bolt on the top/back of the cradle?

I think I've got all the front pivot bolts loosened. But the compressor won't move toward the engine block as I'm trying to get the belt onto the pulley.

#12

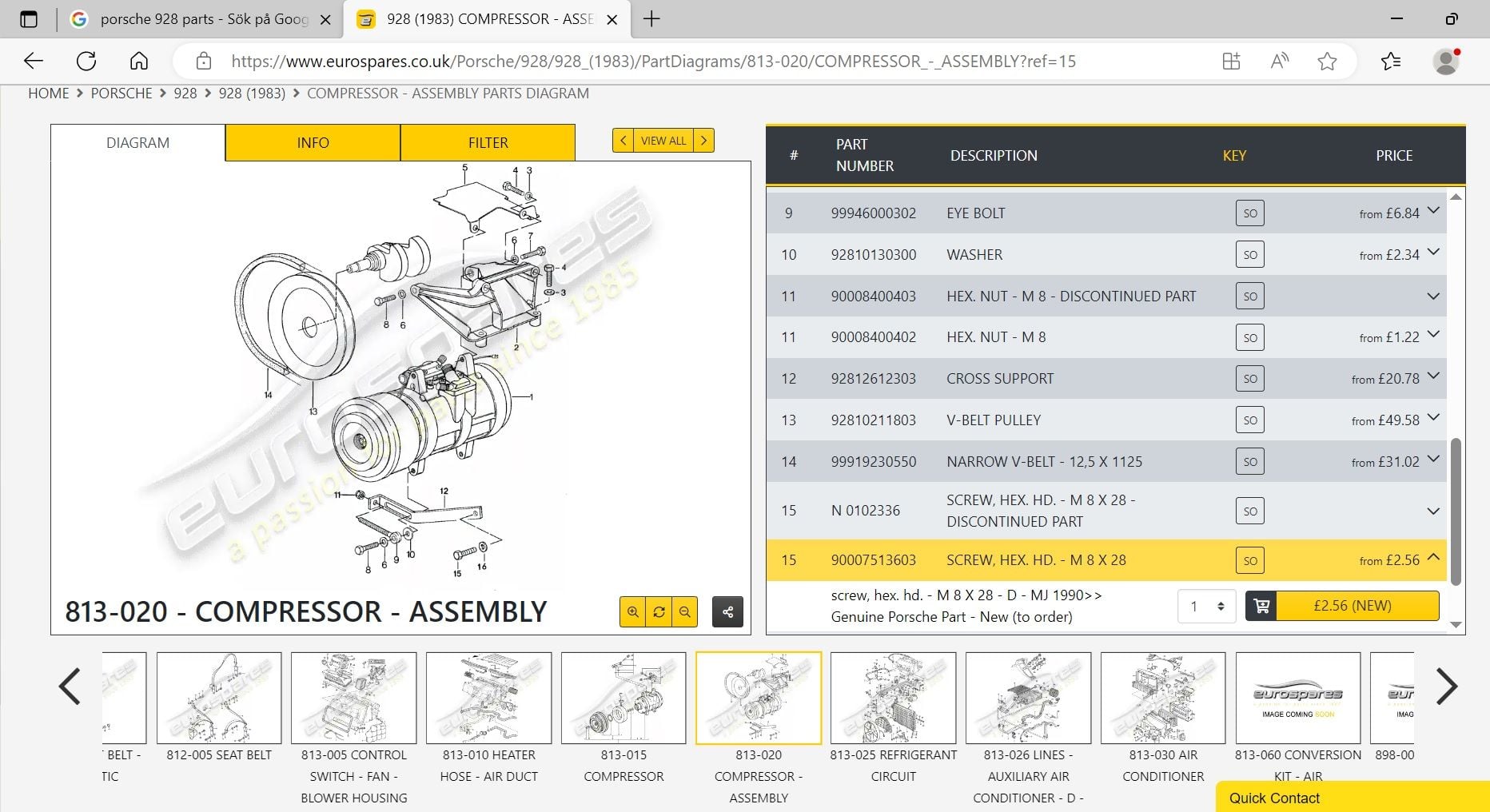

nr 7 and 8 in the picture. Make sure that the pivotbolts really are loose, and the tensionbracket with the tensionbolt also really are loose. The compressor won't move much towards the engine, you need to use some force to get the belt on. That's why the length on this belt is so crucial.

Last edited by WestInc; 06-03-2024 at 04:22 PM.

#13

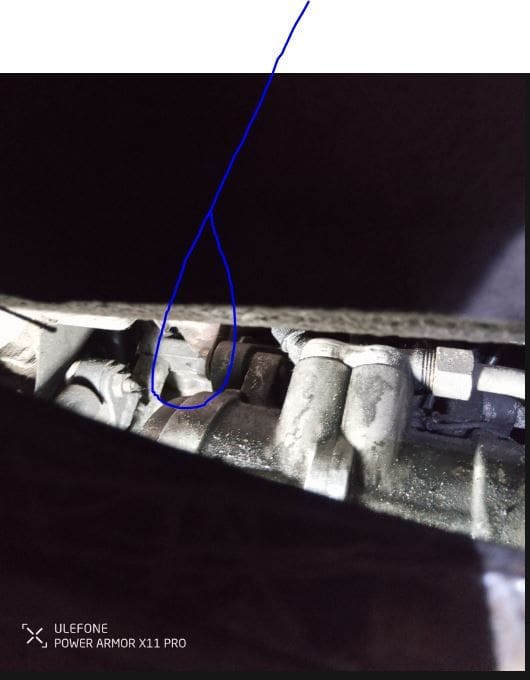

Is the blue circle the pivot screw in the top/back?

Can anyone help identify the pivot screw for the AC compressor that is located in the top/back?

I'm amidst replacing the belt on my 1980 (5 speed)

#14

In the last picture , thats it, the rear anchor /support / pivot bolt.

it is a 17 MM head bolt with a fine thread.

NOTE when you go to fit the anchor bolt, #15 from the previous diagram,

make sure that you first use a thin tool to measure the approximate depth of the hole and test fit the screw.

NOTE that you have 2 brackets that this bolt captures,

so put them in the measurement computation.

use the longest bolt that wont bottom out,

or find that specific bolt.

or use a washer/s under the head of a longer bolt to take up the slack.

This is a uncommon bolt length, so pay attention to this detail.

NOTE loosen the brackets so they are not loaded ,

as it makes it easy to cross thread the anchor bolt.

Dont make that bolt too tight as its easy to strip the threads.

NOTE if you use a torque wrench,

go practice on other bolts first so you have some idea the amount of force you need to make the bolt tight.

This bolt anchor point is part of the engine girdle and is one of the more fragile points on this casting,

and thus can easily be damaged by a ham fisted wrench turner.

Extra skill and professionalism must be used to fasten this bolt.( #15)

it is a 17 MM head bolt with a fine thread.

NOTE when you go to fit the anchor bolt, #15 from the previous diagram,

make sure that you first use a thin tool to measure the approximate depth of the hole and test fit the screw.

NOTE that you have 2 brackets that this bolt captures,

so put them in the measurement computation.

use the longest bolt that wont bottom out,

or find that specific bolt.

or use a washer/s under the head of a longer bolt to take up the slack.

This is a uncommon bolt length, so pay attention to this detail.

NOTE loosen the brackets so they are not loaded ,

as it makes it easy to cross thread the anchor bolt.

Dont make that bolt too tight as its easy to strip the threads.

NOTE if you use a torque wrench,

go practice on other bolts first so you have some idea the amount of force you need to make the bolt tight.

This bolt anchor point is part of the engine girdle and is one of the more fragile points on this casting,

and thus can easily be damaged by a ham fisted wrench turner.

Extra skill and professionalism must be used to fasten this bolt.( #15)

The following users liked this post:

WestInc (06-04-2024)