Torque tube rebuild pictures and tools

#62

Addict

Rennlist Member

Rennlist Member

Hi Bill,

I took the shaft out today and it seems ok, I think the mid bearing is shot.

The front had walked two inches rearwards but looks ok, the rear seems to be seated where it should be and also looks ok.

Still in the tube though, will remove the bearings tomorrow.

Plan is to leave the vibration damper alone since it seems ok.

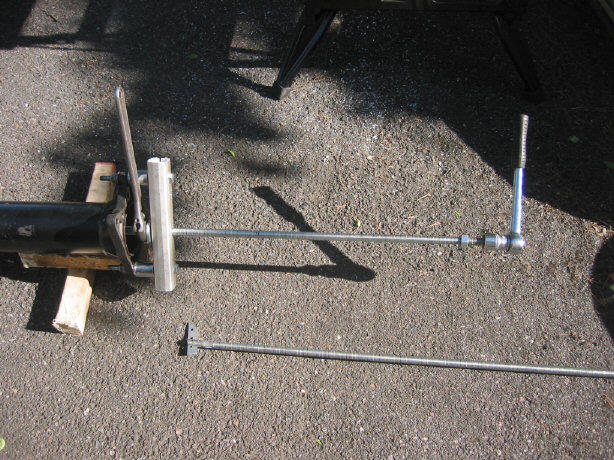

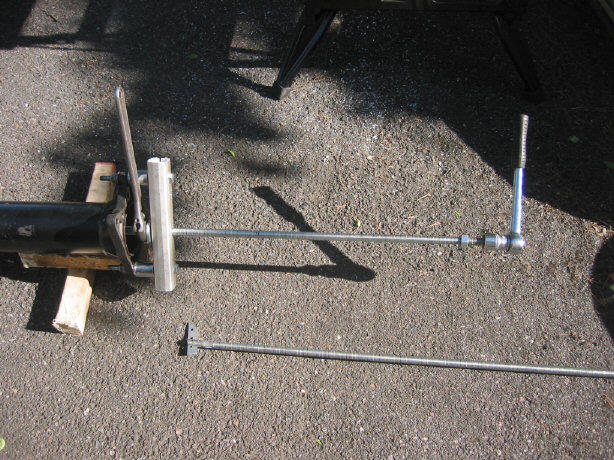

Enclosed a picture of my tooling to remove the center shaft.

(in the end i got tired of using the ratchet and switched to my electric bolt machine, got the shaft out in a flash )

)

/Peter

I took the shaft out today and it seems ok, I think the mid bearing is shot.

The front had walked two inches rearwards but looks ok, the rear seems to be seated where it should be and also looks ok.

Still in the tube though, will remove the bearings tomorrow.

Plan is to leave the vibration damper alone since it seems ok.

Enclosed a picture of my tooling to remove the center shaft.

(in the end i got tired of using the ratchet and switched to my electric bolt machine, got the shaft out in a flash

)

)

/Peter

#64

Vilhuer

I am in the process of putting my tt back together. I noticed that you seem to have installed the nylon inserts in the bearing backwards.

If you look at frame 22 in this thread , it shows the relationship of the insert when you pulled the part out of the tube. In frame 50 it shows the insert installed backwards.

I could'nt remember myself so I refered to your thread. I'm now a little confused but I think I will go with the frame 22 orientation.

I am in the process of putting my tt back together. I noticed that you seem to have installed the nylon inserts in the bearing backwards.

If you look at frame 22 in this thread , it shows the relationship of the insert when you pulled the part out of the tube. In frame 50 it shows the insert installed backwards.

I could'nt remember myself so I refered to your thread. I'm now a little confused but I think I will go with the frame 22 orientation.

#65

Addict

Rennlist Member

Rennlist Member

Steen

I can't remember which way around is the way it came from the factory. But the picture in frame 50 is the orientation that Eric in NZ and I used when we reassembled the TT for his 85. With the insert the other way around (our first attempt) it is very easy (guaranteed) for the insert to slide back out of the bearing when the assembly is inserted back into the TT with the shaft already in position.

I can't think of any reason why the sleeve should be a specific way around once it is installed (same goes for the bearing carrier) maybe someone can enlighten me. I reckon it's all to do with getting it all assembled with all the pieces still together.

I can't remember which way around is the way it came from the factory. But the picture in frame 50 is the orientation that Eric in NZ and I used when we reassembled the TT for his 85. With the insert the other way around (our first attempt) it is very easy (guaranteed) for the insert to slide back out of the bearing when the assembly is inserted back into the TT with the shaft already in position.

I can't think of any reason why the sleeve should be a specific way around once it is installed (same goes for the bearing carrier) maybe someone can enlighten me. I reckon it's all to do with getting it all assembled with all the pieces still together.

#66

jon928se

Yes , it makes more sense to install it as you did for the reasons you stated. It seemed obvious to me but that picture of it coming apart threw me for a loop.

If you did it as in frame 50 with no problems afterward that's the way I'll do it.

Yes , it makes more sense to install it as you did for the reasons you stated. It seemed obvious to me but that picture of it coming apart threw me for a loop.

If you did it as in frame 50 with no problems afterward that's the way I'll do it.

#67

Addict

Rennlist Member

Rennlist Member

Steen

The only other thing I would do next time if on my own cars would be to omit the vibration damper weight on reassembly. (Thats if there is one in the SE) I can't really see how much good if anything it does, but thats a personal choice. Heard too many tales of them separating from their rubber mounts and going walkabout down the tube and moving the bearings all to one end.

Other than that it's just a case of figuring out in what order you are going to reassemble and how and then orientating the bearing carriers and sleeves so that they won't come apart during re-assembly

The only other thing I would do next time if on my own cars would be to omit the vibration damper weight on reassembly. (Thats if there is one in the SE) I can't really see how much good if anything it does, but thats a personal choice. Heard too many tales of them separating from their rubber mounts and going walkabout down the tube and moving the bearings all to one end.

Other than that it's just a case of figuring out in what order you are going to reassemble and how and then orientating the bearing carriers and sleeves so that they won't come apart during re-assembly

#68

Addict

Rennlist Member

Rennlist Member

Thread Starter

What Jon says is exact reason why we put carrier and insert together way we did. Resistance when inserting center shaft back was so great that there is real possibility for plastic portion of insert to be pushed out of the bearing or bearing to be pushed out of the carrier. I coundn't figure out any reason either why they should be installed in any specific way.

#69

Vilhuer

Thanks for that. Looks like the way to go.

Did anyone else out there secure the brg carriers in the tube in any way? I'm thinking of drilling holes through the tube and carrier in 3 equally spaced places around the circumference and using some sort of metal screw to hold them in place during reassembly and to prevent them from moving around in the future.

Thanks for that. Looks like the way to go.

Did anyone else out there secure the brg carriers in the tube in any way? I'm thinking of drilling holes through the tube and carrier in 3 equally spaced places around the circumference and using some sort of metal screw to hold them in place during reassembly and to prevent them from moving around in the future.

#70

Addict

Rennlist Member

Rennlist Member

Thread Starter

As mentioned before. I know one case where this was done. It didn't cause any problems during short while screws were in. Personally I'mm willing to spend extra effort to make pipes as I believe it might be beneficial to allow carriers to be on their own inside the tube instead of locking them solid into wall. Probably doesn't make any real difference but will do it hard way just to be on safe side.

#71

One thing to think about is the bearings in the bearing carrier are not secured within them very well, only by friction fit. The bearing carriers get a bit worn and do not hold the bearings in them as well when new, especially when re-used. What might happen is the forces that move the bearing carrier up and down the tube might also work on the bearing if the carrier is held in place with screws. This could have the effect of the bearing coming out of the carrier under operation.

Just something to consider,

Constantine

Just something to consider,

Constantine

Originally Posted by Steen Jensen

Vilhuer

Thanks for that. Looks like the way to go.

Did anyone else out there secure the brg carriers in the tube in any way? I'm thinking of drilling holes through the tube and carrier in 3 equally spaced places around the circumference and using some sort of metal screw to hold them in place during reassembly and to prevent them from moving around in the future.

Thanks for that. Looks like the way to go.

Did anyone else out there secure the brg carriers in the tube in any way? I'm thinking of drilling holes through the tube and carrier in 3 equally spaced places around the circumference and using some sort of metal screw to hold them in place during reassembly and to prevent them from moving around in the future.

#72

Addict

Rennlist Member

Rennlist Member

Thread Starter

Few comparison pictures of '90 S4 automatic and '92 GTS manual tube and gearbox. Pictures do not show very well that rear end of automatic differential housing is some 3cm +/- few mm further back than manual gearbox rear end when TT front ends are at same plane. This comes from same '80 MY change where manual gearbox was moved 30mm forward. To do this TT was shortened and rear subframe changed. When automatic gearbox was changed from 3sp to 4sp in '83 MY in US and '84 in ROW TT was shortened but rear subframe stayed same. Thus there is difference in total lenght of the drivetrain package and subframe between automatic and manual gearbox cars all the way to '95 MY. '87 MY torque converter enlargement was done without change to total lenght of the gearbox and thus TT could be left same as earlier 4sp use. Measurements and pictures of automatic tube dismantling once job progresses.

That automatic box is huge compared to manual. No wonder its some 30kg heavier too.

No wonder its some 30kg heavier too.

PS. Automatic box is for sale for 500 euros. Without differential, torque converter is included. From front end damage '90 S4 in Germany. I believe its 140-150k kilometers driven. Shipping into US is likely too much but maybe someone in Sweden needs it.

That automatic box is huge compared to manual.

No wonder its some 30kg heavier too.

No wonder its some 30kg heavier too.PS. Automatic box is for sale for 500 euros. Without differential, torque converter is included. From front end damage '90 S4 in Germany. I believe its 140-150k kilometers driven. Shipping into US is likely too much but maybe someone in Sweden needs it.

#74

They are very similar H. The Torque converter bearings convey the noise to the front of the car.

The only think I can think of to describe tube bearings is that the sound is more multi-toned. Its like its in stereo, since each bearing would sound slightly different.

The only think I can think of to describe tube bearings is that the sound is more multi-toned. Its like its in stereo, since each bearing would sound slightly different.

#75

Rennlist Member

On my 84; I have a 'Whiiiring" noise that sounds like it is just behind the engine from the outside and right under the shifter inside the car. Along with this I have a vibration whenever the engine is running.

I think this is a torque tube problem; however, I am not sure.

Also does it damage the TT, torque converter etc to drive the car under these conditions?

Any help would be appreciated.

I think this is a torque tube problem; however, I am not sure.

Also does it damage the TT, torque converter etc to drive the car under these conditions?

Any help would be appreciated.