Convert early fuse board to blade sockets

#91

Rennlist Member

Thread Starter

Good to see! Thats 3 of us now down this path, need to convert a few more people/cars. No issues with mine so far, but dont have much mileage yet, with the lockdown we are under now. At least our infection growth rate is trending well down.

jp 83 Euro S AT 57k

jp 83 Euro S AT 57k

#92

Rennlist Member

heater fan keeps on running at max...

Also are the older round fuses not that easy to get here in Europe.

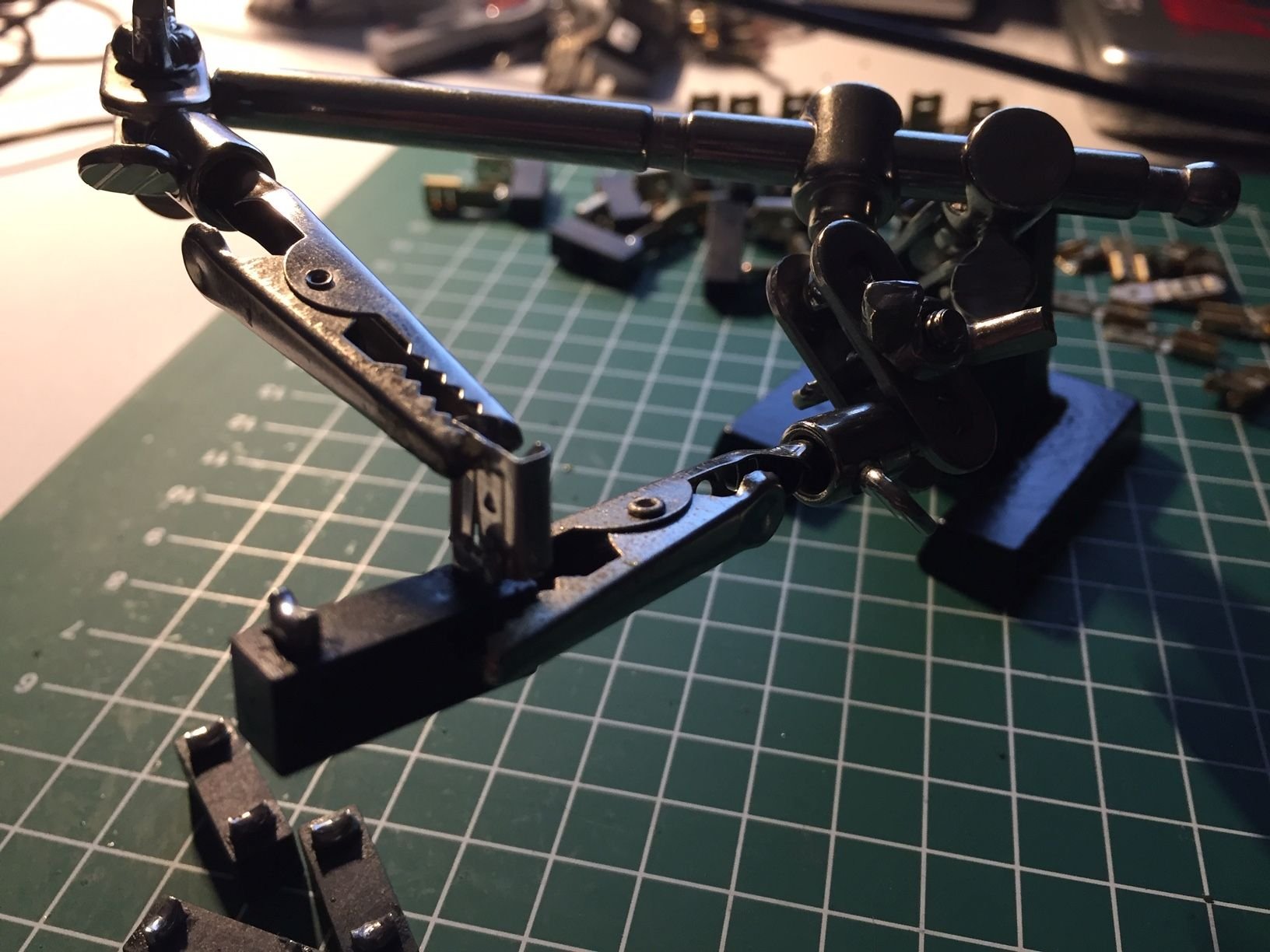

Here some more photos about the soldering : you really need to have crocodile claws to put the pieces correctly placed before soldering

The following users liked this post:

cgraner (01-16-2023)

#94

Rennlist Member

Thread Starter

Now for a bit more fun...recently moved into a 70s English car, which uses 3AG glass fuses. The fuses are OK, but the clips they seat into are a bit odd - the two sides of each clip are NOT mechanically or electrically connected except by the fuse end cap. On top of this the headlights on high beam total 250W (2 x 50W + 2 x 75W), and despite the left and right beams being on separate fuses the poor plastic of the fuse block is infamous for softening and distorting. So, in the same spirit as the above, I am moving this car into blade fuses.

and a fuse - 2 short pieces of 1/4" brass tube with a blade holder soldered on. VERY firmfit in the fuse clips, works a treat!

jp 83 Euro S AT 57k

74 Rover P6b V8 4mt

[i[img]https://i.imgur.com/cQ1CRwT.jpgmg]https://i.imgur.com/cQ1CRwT.jpg

and a fuse - 2 short pieces of 1/4" brass tube with a blade holder soldered on. VERY firmfit in the fuse clips, works a treat!

jp 83 Euro S AT 57k

74 Rover P6b V8 4mt

[i[img]https://i.imgur.com/cQ1CRwT.jpgmg]https://i.imgur.com/cQ1CRwT.jpg

Last edited by jpitman2; 05-02-2022 at 09:02 AM.

#95

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Rotating blade fuses Batman! Or are you going to solder the brass ends to the fuse holders in the car? I think I would for 2 less connections to worry about.

Rover V8?

Alan

Rover V8?

Alan

#96

Rennlist Member

Thread Starter

Alan,

Soldering them in had occurred to me, but the fuse board body softens very easily when near any heat, and to do 24 connections might be too much for it. Fitting these units takes a VERY firm push, so the contact is good.

jp 83 Euro S AT 57k

Soldering them in had occurred to me, but the fuse board body softens very easily when near any heat, and to do 24 connections might be too much for it. Fitting these units takes a VERY firm push, so the contact is good.

jp 83 Euro S AT 57k

#97

I had been dreaming of this solution for a while. What is the parts list to put this together and about how much material cost is there? Someone needs to sell a complete conversion kit ready to swap. LOL

#99

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

For a Rover? or for an early 928?

There are details above in this thread (by Ducman82) where the top fuse section of an '85 or later car's CE panel was epoxied in place of the sawn off fuse section from an early car. Then the fuses were rewired to the new fuse panel. This is what I would do for best robustness and long term reliability. You do need to invert the sense of the fuses inputs at the top on new fuse panels (vs on the bottom on the old ones) this means you should have some extra wire lengths to works with... Note you don't want to map directly 1:1 since you have some premade connections to the new panel (and IN the new fuse-holders) for battery power and ignition (15) and (X) accessory connections. Take advantage of those. See the other thread on this by Ducman82

Alan

There are details above in this thread (by Ducman82) where the top fuse section of an '85 or later car's CE panel was epoxied in place of the sawn off fuse section from an early car. Then the fuses were rewired to the new fuse panel. This is what I would do for best robustness and long term reliability. You do need to invert the sense of the fuses inputs at the top on new fuse panels (vs on the bottom on the old ones) this means you should have some extra wire lengths to works with... Note you don't want to map directly 1:1 since you have some premade connections to the new panel (and IN the new fuse-holders) for battery power and ignition (15) and (X) accessory connections. Take advantage of those. See the other thread on this by Ducman82

Alan

#101

Former Vendor

18 years later since the first post,

and I still don't understand converting from the early style fuses to the blade style.

I have far worse issues with the copper pieces which hold the blade style fuses getting loose, oxidizing, and making poor contact than I've ever had with the early style fuses.

Plus that, on the early style fuses, I can see connection problems and heat issues, whereas on the blade style, I can't see the loose/oxidized copper parts unless I remove those plastic covers.(Which is a real pain.)

The connection problems, on the blade style fuses, is so severe that I'm constantly buying relay boards to get the proper copper pieces and the correctly numbered plastic pieces, once the originals have overheated and melted the plastic.

Conversely, with the early fuses, I can count on one hand how many fuse holders that were so damaged that I needed to bypass the fuse with a separate fuse holder.

and I still don't understand converting from the early style fuses to the blade style.

I have far worse issues with the copper pieces which hold the blade style fuses getting loose, oxidizing, and making poor contact than I've ever had with the early style fuses.

Plus that, on the early style fuses, I can see connection problems and heat issues, whereas on the blade style, I can't see the loose/oxidized copper parts unless I remove those plastic covers.(Which is a real pain.)

The connection problems, on the blade style fuses, is so severe that I'm constantly buying relay boards to get the proper copper pieces and the correctly numbered plastic pieces, once the originals have overheated and melted the plastic.

Conversely, with the early fuses, I can count on one hand how many fuse holders that were so damaged that I needed to bypass the fuse with a separate fuse holder.

Last edited by GregBBRD; 01-18-2023 at 10:08 PM.

The following users liked this post:

cgraner (01-18-2023)

#102

Drifting

Hi Greg, I have an old style fuse holder that can't hold the fuse tight enough.... on the fuel pump fuse. What do you recommend? The grip is just "perfect" to hold it well enough to work most of the time, while occassionally arcing to the degree that the plastic pin melts away. Sometimes, the car doesn't start; I just have to twirl the fuse in it's holder and it connects and works.

I am afraid to continue trying to bend the connectors together to increase the pressure, for fear of breaking it and causing a more significant problem.

I am afraid to continue trying to bend the connectors together to increase the pressure, for fear of breaking it and causing a more significant problem.

#103

Rennlist Member

Thread Starter

My experience with fuses (admittedly not many examples compared to Greg's) is that I have NEVER had a problem with a blade fuse installation in any car. With 3AG glass fuses as used in British cars I probably did have some issues back in the day (60s to 80s), but there is a lot more contact between the fuse and the socket with these, compared to barely more than a line contact with the 928's fuses, and tension is critical. When I had my second pump relay fail (hot to the touch) and literally saw a spark at the fuse holder when I jumpered the relay socket, blade fuses became a certainty for me. Pulling, Cleaning and re-tensioning the top fuse socket on our boards is a much bigger PITA than an R&R of a blade fuse ,where that action does all the cleaning needed, although a wipe with Deoxit is a good idea.

I have an early fuse board I used for my prototypes, but have no knowledge of how the 928's blade fuse holders are mounted - is there something there that makes for issues?

Bronto - if your fuse body is melting/softening (plastic pin = fuse body?) that would suggest there is too much current going through. My single pump pulls 7A - if yours pulls more there is something wrong.

jp 83 Euro S AT 57k

I have an early fuse board I used for my prototypes, but have no knowledge of how the 928's blade fuse holders are mounted - is there something there that makes for issues?

Bronto - if your fuse body is melting/softening (plastic pin = fuse body?) that would suggest there is too much current going through. My single pump pulls 7A - if yours pulls more there is something wrong.

jp 83 Euro S AT 57k

#104

Pro

I've had four different vehicles now that use these GBC fuses, and all three of the ones I drove for any significant time had corrosion issues with the tiny contact surface that this design has.

80s VW, I fought with it until I replaced the whole panel with a new one.

Two 80s MB s class cars, numerous issues, but at least MB realized that the GBC fuses aren't suited for high current loads and issued a few recalls to modify the fuse box, moving the larger circuits out and to strip fuses.

Even then, the current production, plastic body fuses are not well regarded in the MB owner forums due to allowing the fuses to deform if there is any heat, sometimes causing short circuits with adjacent sockets, or ejecting the fuse entirely. The older ceramic fuses don't suffer this, leading some to replacing the fuse strip on an older fuse with a copper step pulled from a new production plastic fuse.

The aluminum fuses are probably the biggest issue in the GBC fuse lineup, as they seem to corrode quickly with the slightest bit of environmental moisture. Using dielectric paste or the like helps, but avoiding the issue and only using the copper fuses helped more.

That all said, only having the little ring of contact at either end of the fuse in many fuse holders isn't a particularly great design, and the industry as a whole moving away from these after the 80s seems to reflect it.

I'm not going to claim that all versions of bladed fuse holders are perfect, especially not the earliest versions, but I've had less issues with them.

80s VW, I fought with it until I replaced the whole panel with a new one.

Two 80s MB s class cars, numerous issues, but at least MB realized that the GBC fuses aren't suited for high current loads and issued a few recalls to modify the fuse box, moving the larger circuits out and to strip fuses.

Even then, the current production, plastic body fuses are not well regarded in the MB owner forums due to allowing the fuses to deform if there is any heat, sometimes causing short circuits with adjacent sockets, or ejecting the fuse entirely. The older ceramic fuses don't suffer this, leading some to replacing the fuse strip on an older fuse with a copper step pulled from a new production plastic fuse.

The aluminum fuses are probably the biggest issue in the GBC fuse lineup, as they seem to corrode quickly with the slightest bit of environmental moisture. Using dielectric paste or the like helps, but avoiding the issue and only using the copper fuses helped more.

That all said, only having the little ring of contact at either end of the fuse in many fuse holders isn't a particularly great design, and the industry as a whole moving away from these after the 80s seems to reflect it.

I'm not going to claim that all versions of bladed fuse holders are perfect, especially not the earliest versions, but I've had less issues with them.

#105

Former Vendor

Hi Greg, I have an old style fuse holder that can't hold the fuse tight enough.... on the fuel pump fuse. What do you recommend? The grip is just "perfect" to hold it well enough to work most of the time, while occassionally arcing to the degree that the plastic pin melts away. Sometimes, the car doesn't start; I just have to twirl the fuse in it's holder and it connects and works.

I am afraid to continue trying to bend the connectors together to increase the pressure, for fear of breaking it and causing a more significant problem.

I am afraid to continue trying to bend the connectors together to increase the pressure, for fear of breaking it and causing a more significant problem.

Buy a remove fuse holder (either for the blade style or the bullet style.)

Disconnect the battery. Pull the relay board forward and take the two wires that attach to the fuel pump fuse and hook them to the remote fuse wires.

Re-assemble with the appropriate amp fuse.

The following 2 users liked this post by GregBBRD:

cgraner (01-19-2023),

Cymadesign (01-20-2023)